Pull-joint type double-steel-plate composite shear wall

A combined shear wall and double steel plate technology, applied in the direction of walls, buildings, building components, etc., can solve the problems that the mechanical performance is controlled by the welding performance, the welding temperature of the steel plate is affected, and the wall surface is not flat, so as to achieve excellent seismic performance, The effect of welding seam quality is small, and the effect of meeting the requirements of the wall width-thickness ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

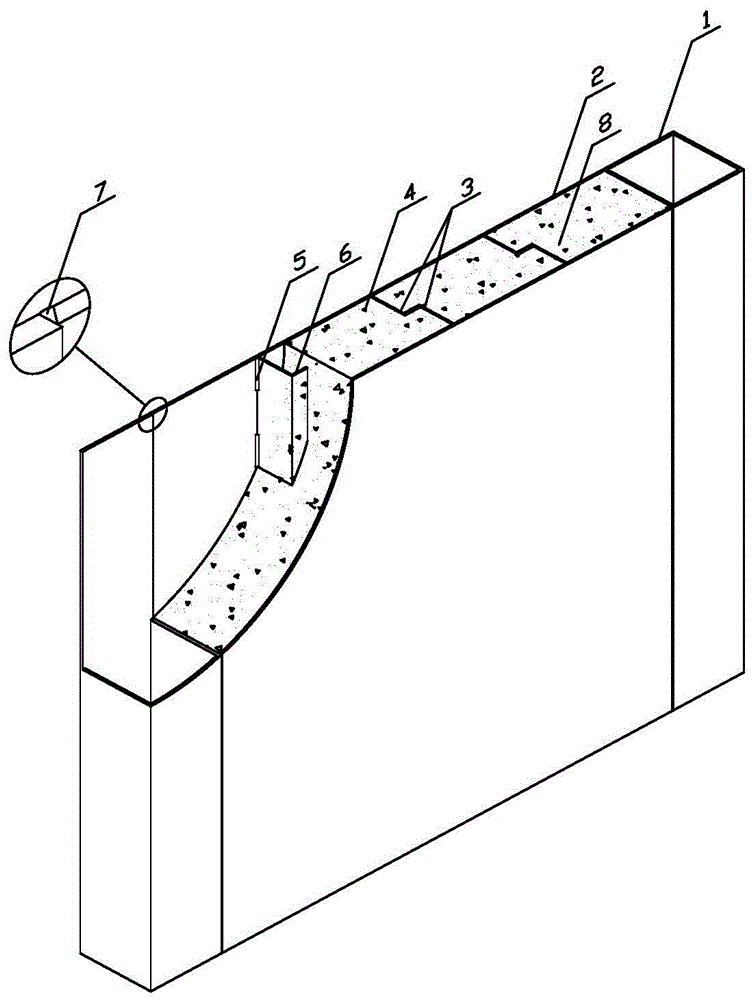

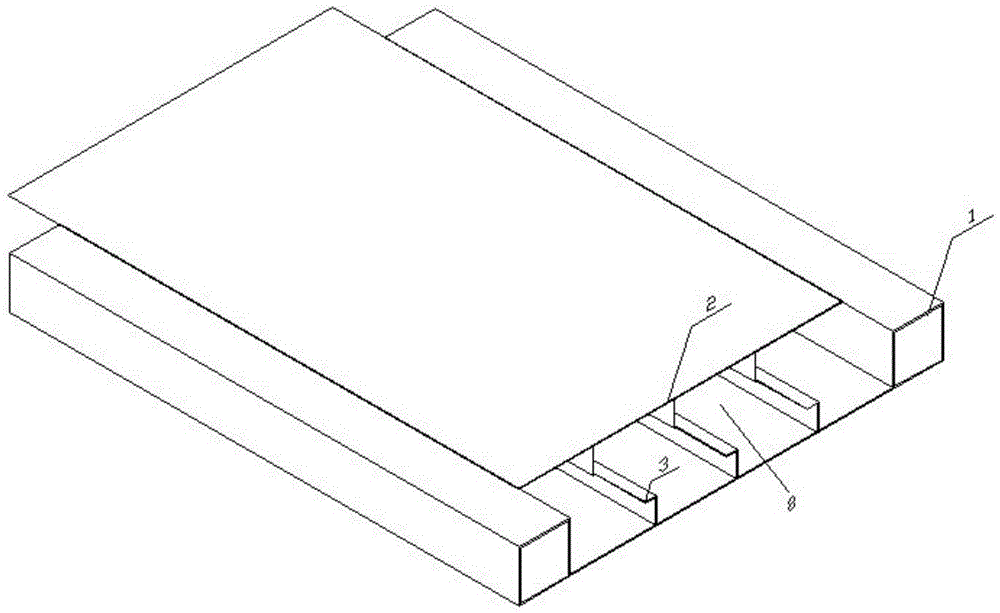

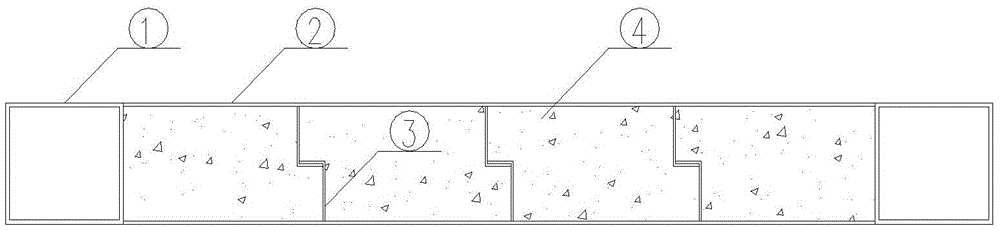

[0033] Please refer to Figure 1-6 , the present invention provides a tie-type double-steel composite shear wall, which includes a steel pipe column 1 located at both ends, a pair of steel plates 2 and at least one tie-type connector 3, and the two steel plates 2 pass through the tie-type connector 3 The knots form a whole. The tie-type connector 3 divides the cavity between the two steel plates 2 into at least two tubular cavities 8. Concrete 4 is poured in the tubular cavities 8, and concrete is poured between the double steel plate wall panels. The end steel pipe columns are poured or not concreted according to the needs; compared with the traditional concrete shear wall, the tie-type double-steel plate composite shear wall has high bearing capacity, good ductility, strong energy dissipation capacity, excellent seismic performance, and does not require support. Compared with other double-steel plate composite shear walls, the tie-type connectors are firstly welded and conne...

Embodiment 2

[0044] Please refer to Figure 5 , preferably, the rest of the structure and manufacturing method are the same as in Embodiment 1, the cross section of the branch connector 6 is a hook type, and the angle between the bent part and the straight rod part of the hook-shaped branch connector 6 is 0°, which is It is easy to assemble, and the bending radius is not less than twice the thickness of the connector. The draw-knot position of every pair of crotch-type branch connectors 6 is located in the middle or edge of the combined wall thickness.

Embodiment 3

[0046] Please refer to Figure 6 , Preferably, the rest of the structure and manufacturing method are the same as in Embodiment 1, and the cross section of the branch connector 6 is sickle-hook type. Please refer to figure 1 , preferably, the angle between the bent portion and the straight rod portion of the hook-shaped branch connector 6 is not greater than 60°. The knot position of each pair of sickle-hook type branch connectors 6 is located in the middle or edge of the combined wall thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com