Steel screen restricted column plastic hinge region concrete structure and making method thereof

A technology of concrete structure and steel mesh, which is applied in the direction of structural elements, columns, pier columns, etc., can solve the problems of low ductility of reinforced concrete columns, and achieve the effects of convenient and fast construction, improved ductility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

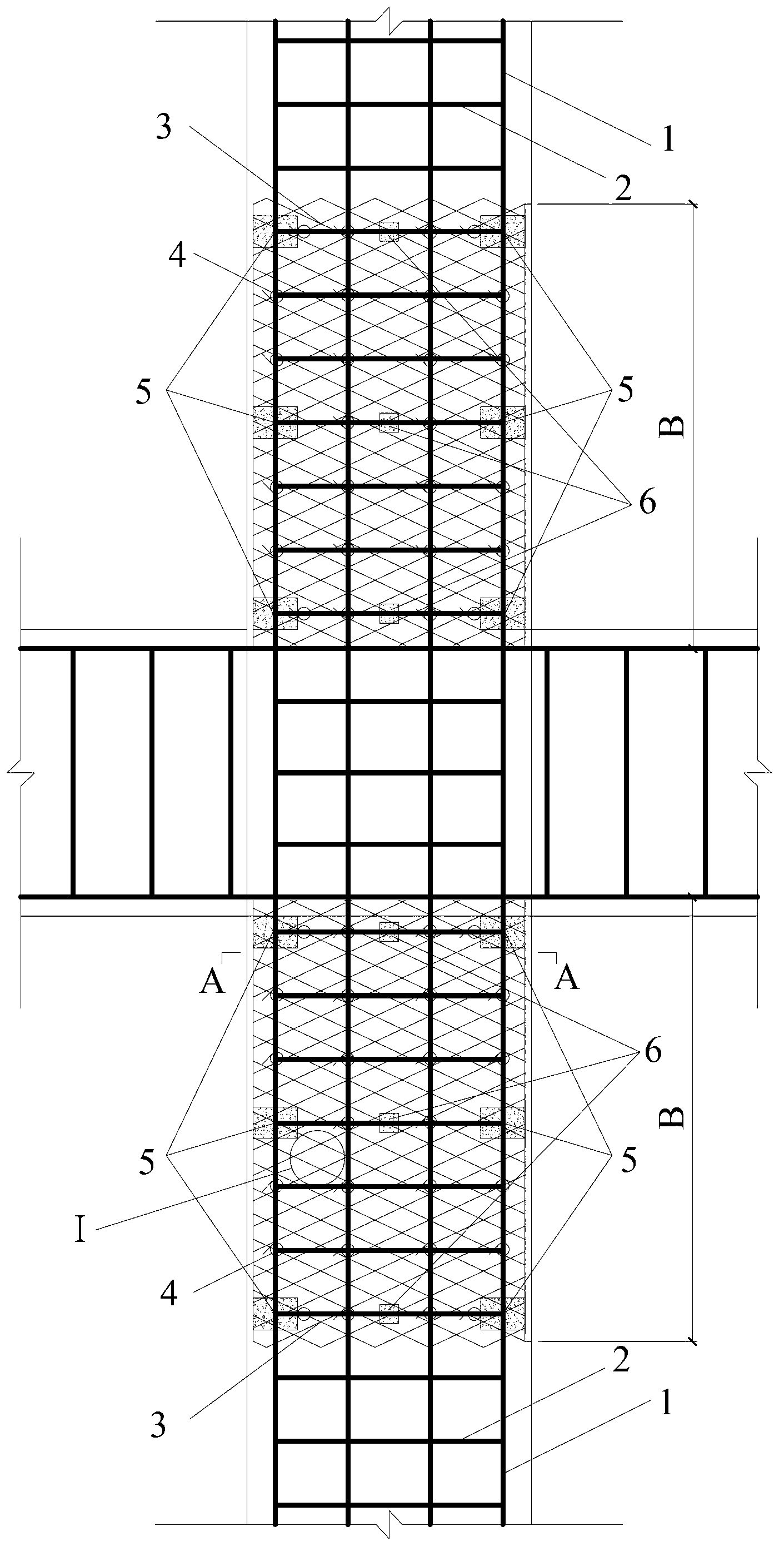

[0025] 1. Binding of steel cage

[0026] The binding of the reinforcement cage must be carried out in strict accordance with the relevant specifications and drawings.

[0027] 2. Cutting of steel mesh

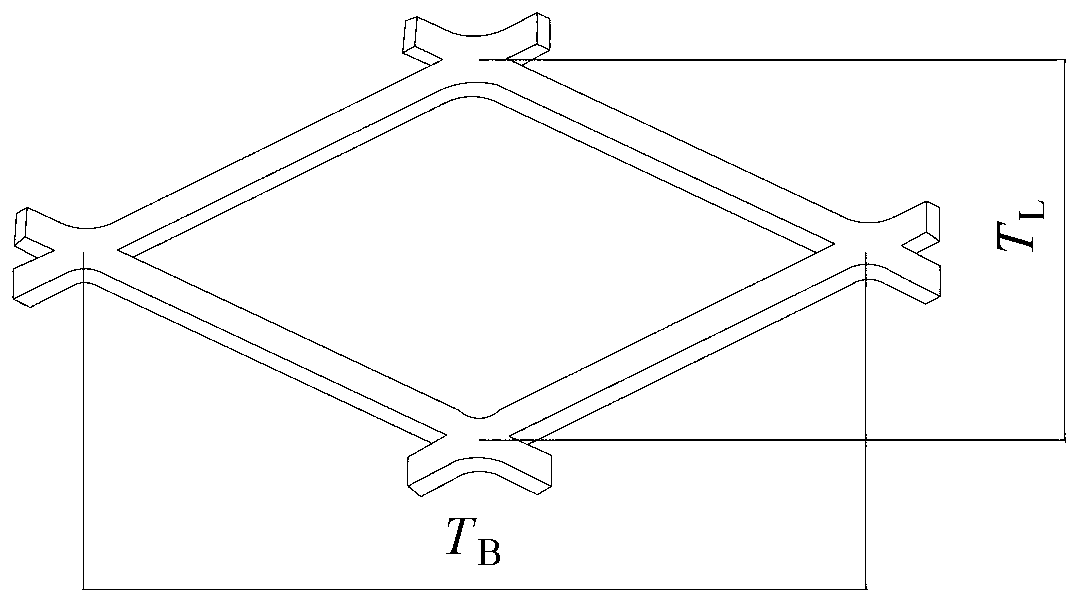

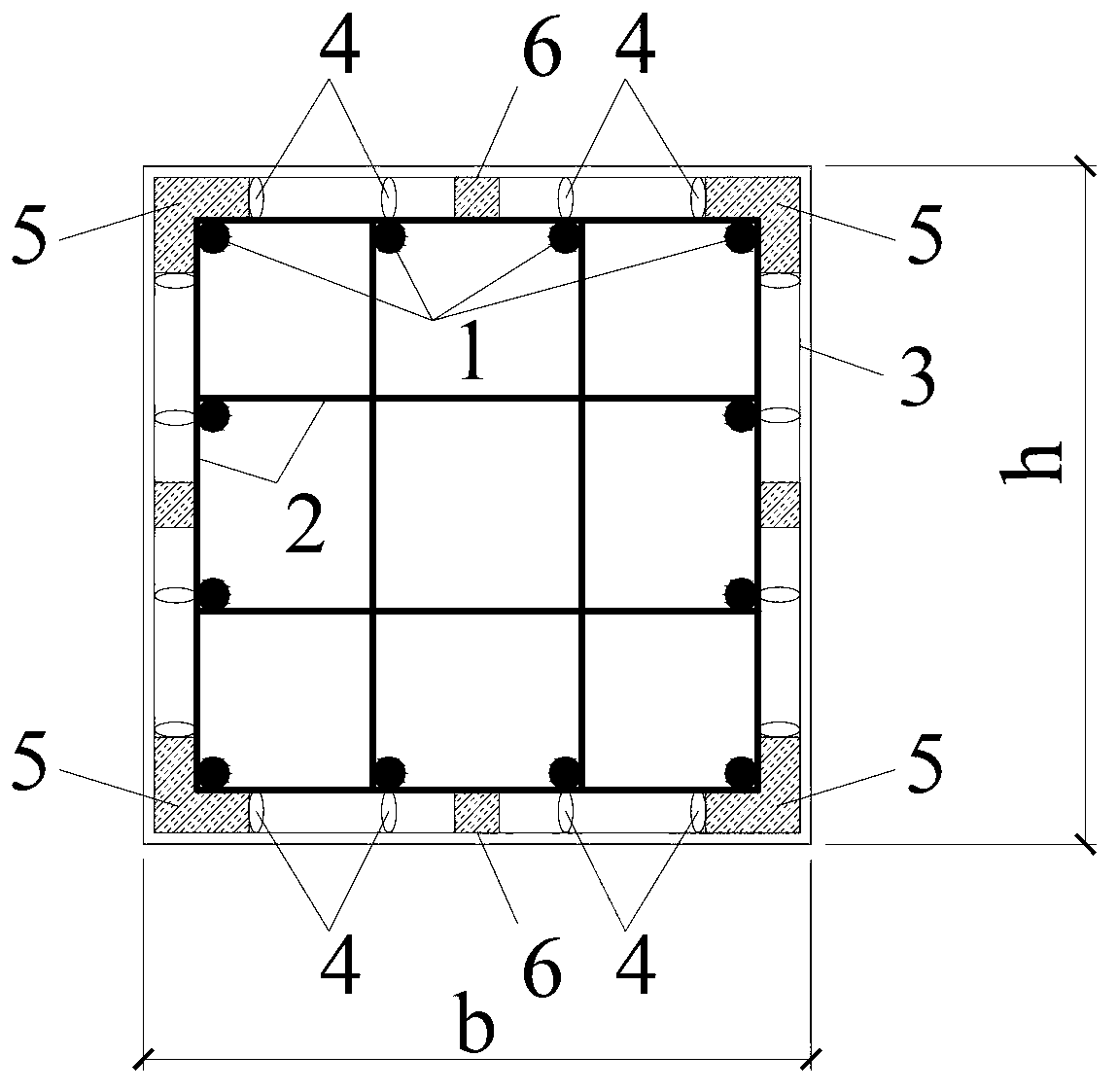

[0028] The width B of the steel mesh is taken as 1.5 times the maximum value of the column cross-section b or h, and the length of the overlapped part is 2 (b / 2+h / 2+2×5mm), where b and h are the sides of the column cross-section long.

[0029] 3. Bending of steel mesh

[0030] Take the edge of the steel mesh in the length direction as the reference line, first measure half b / 2 of the section width with a tape measure, then subtract the steel mesh protective layer, that is, 5mm, as the first bending line; then take the first bending line as the reference line, Measure the height of the entire column section and subtract two steel mesh protective layers, that is, 10mm as the second bending line; further take the second bending line as the baseline, measure the entire column se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grid size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com