Shot blasting machine with V-shaped blades

A shot blasting machine and blade technology, which is applied in the direction of rotor blades, impellers, grinding/polishing equipment, etc., can solve the problems of different support force, non-replacement, vibration, etc., and achieve the goal of improving service life, good restraint effect, and reducing vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

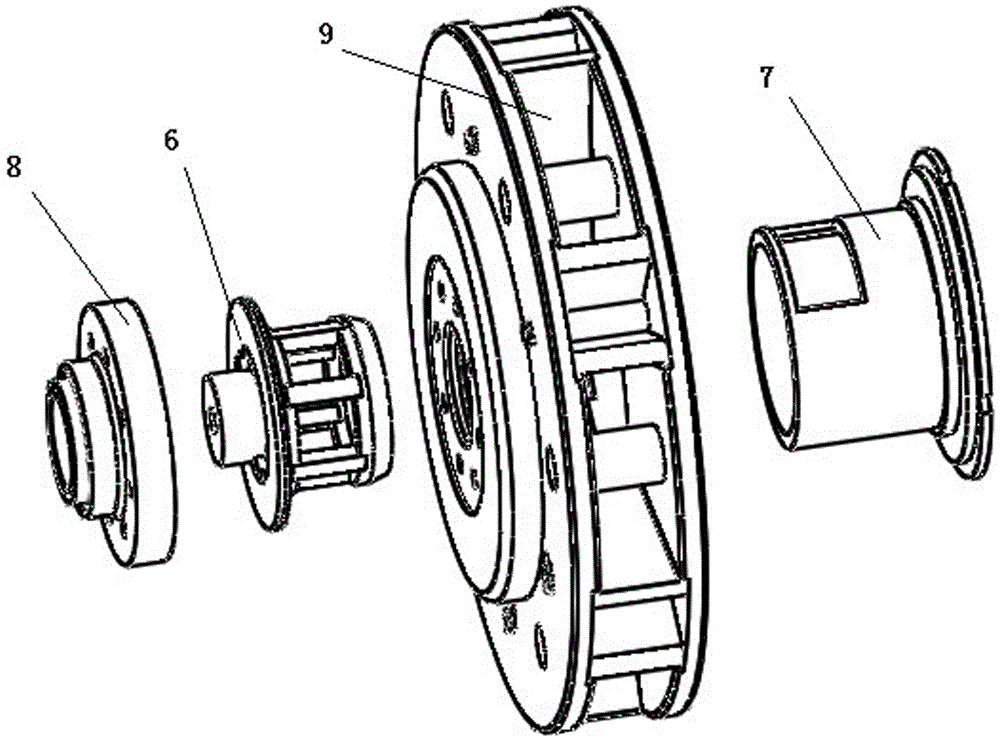

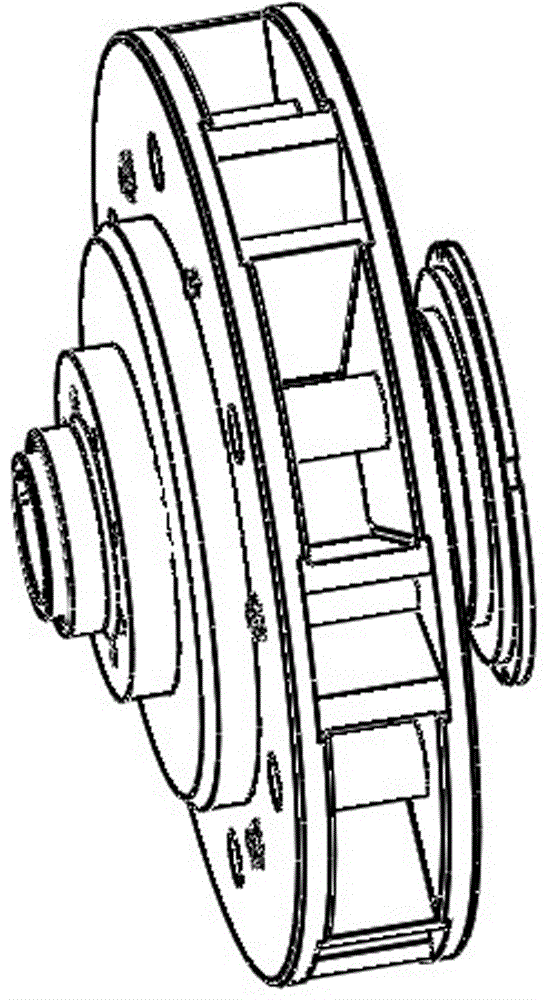

[0035] Refer to the attached figure 2 , The V-blade shot blaster is a typical wheeled part, and its whole is similar to a cylinder, or equivalent to a cylinder, so its end face is essentially its axial end face. The so-called radial direction refers to the radial direction under the condition of the wheel axis structure of the blade shot blasting machine as a whole.

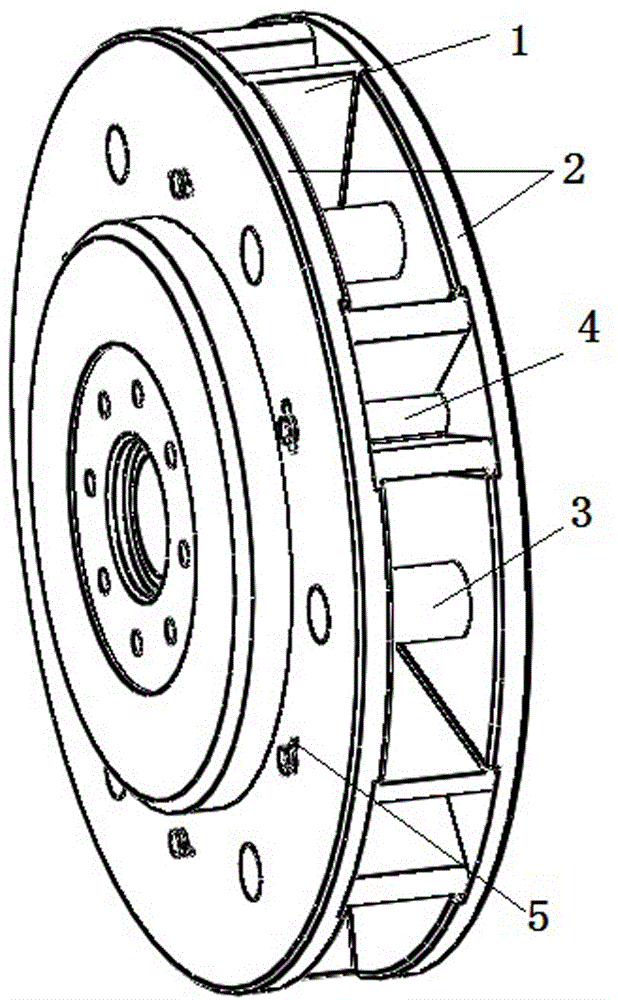

[0036] For the V-shaped blade 1, its whole is a V-shaped block, based on the wheel structure, for Image 6 In the structure shown in , the base 1-2 constitutes the end panel part of the V-shaped block, and the sheet body 1-3 shown in the figure is the working surface and has a front side and a back side based on the direction of rotation. At the same time, since the V-shaped blade shot blasting device can be turned forward and backward, the front side is also the rear side. Overall, the fact that the working surface is the front and back of the V-shaped block does not affect the correct understanding of it by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com