Preparation method of high-transparency potassium sodium niobate-barium strontium titanate transparent ceramic

A technology of potassium sodium niobate and barium strontium titanate, applied in the field of lead-free piezoelectric materials, can solve problems such as unfriendly environment and human health, and achieve the effects of easy operation, simple process steps and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

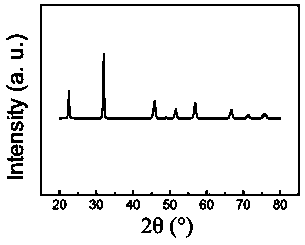

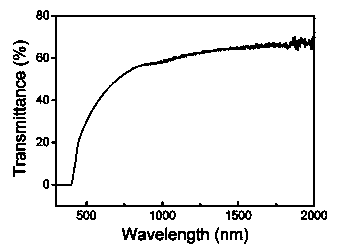

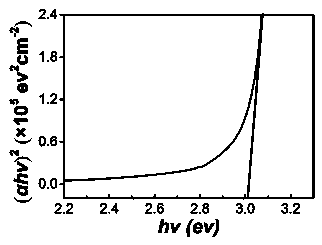

Image

Examples

Embodiment 1

[0033] (1) Ingredients: Weigh the raw material Na according to the mass ratio 2 CO 3 : K 2 CO 3 : Nb 2 o5 : BaCO 3 : SrCO 3 : TiO 2 = 0.399 : 0.52 : 1 : 0.059 : 0.044 : 0.024, then mix to obtain the mixture;

[0034] (2) Ball milling: add the mixture into the ball milling medium, put it into a ball mill tank and carry out ball milling for 8 h at a milling speed of 250 r / min. After the ball milling, the mixture is dried in an oven at 80°C, and then Then the mixture is put into a mortar for grinding, the grinding medium is ethanol, and the weight ratio of the mixture to ethanol is 1:2;

[0035] (3) Pre-burning: Add the above-mentioned ground mixture into the crucible, compact it, put it in a muffle furnace, raise the temperature to 800 °C at a heating rate of 3 °C / min and keep it warm for 2 h for pre-burning, and then Then take out the crucible after naturally cooling to room temperature;

[0036] (4) Secondary ball milling: After adding ball milling medium to the...

Embodiment 2

[0044] (1) Ingredients: Weigh the raw material Na according to the mass ratio 2 CO 3 : K 2 CO 3 : Nb 2 o 5 : BaCO 3 : SrCO 3 : TiO 2 = 0.399 : 0.52 : 1 : 0.067 : 0.05 : 0.027, then mix to obtain the mixture;

[0045] (2) Ball milling: Add the mixture to the ball milling medium, put it into a ball mill tank and mill for 12 h at a milling speed of 200 r / min. After the ball milling, put the mixture in an oven for drying at 85°C, and Then the mixture is put into a mortar for grinding, the grinding medium is ethanol, and the weight ratio of the mixture to ethanol is 1:2.5;

[0046] (3) Pre-burning: Add the above-mentioned ground mixture into the crucible, after compaction, put it in a muffle furnace, raise the temperature to 850°C at a heating rate of 4°C / min and keep it warm for 4 hours for pre-burning , and then take out the crucible after naturally cooling to room temperature;

[0047] (4) Secondary ball milling: After adding ball milling media to the above-menti...

Embodiment 3

[0056] (1) Ingredients: Weigh the raw material Na according to the mass ratio 2 CO 3 : K 2 CO 3 : Nb 2 o 5 : BaCO 3 : SrCO 3 : TiO 2 = 0.399 :0.52 : 1 : 0.074: 0.056 : 0.03, then mix to obtain the mixture;

[0057] (2) Ball milling: Add the mixture into the ball milling medium, put it into a ball mill tank and mill it for 10 h at a milling speed of 250 r / min. After the ball milling, dry the mixture in an oven at 80°C, and then Then the mixture is put into a mortar for grinding, the grinding medium is ethanol, and the weight ratio of the mixture to ethanol is 1:2.5;

[0058] (3) Pre-burning: Add the above-mentioned ground mixture into the crucible, after compaction, put it in a muffle furnace, raise the temperature to 800 °C at a heating rate of 5 °C / min and keep it warm for 3 h for pre-burning. Then take out the crucible after naturally cooling to room temperature;

[0059] (4) Secondary ball milling: After adding ball milling media to the above-mentioned pre-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com