A ferrite material with high magnetic permeance

A ferrite material and high magnetic permeability technology, applied in the field of magnetic core materials, can solve the problems of unsatisfactory comprehensive performance of ferrite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

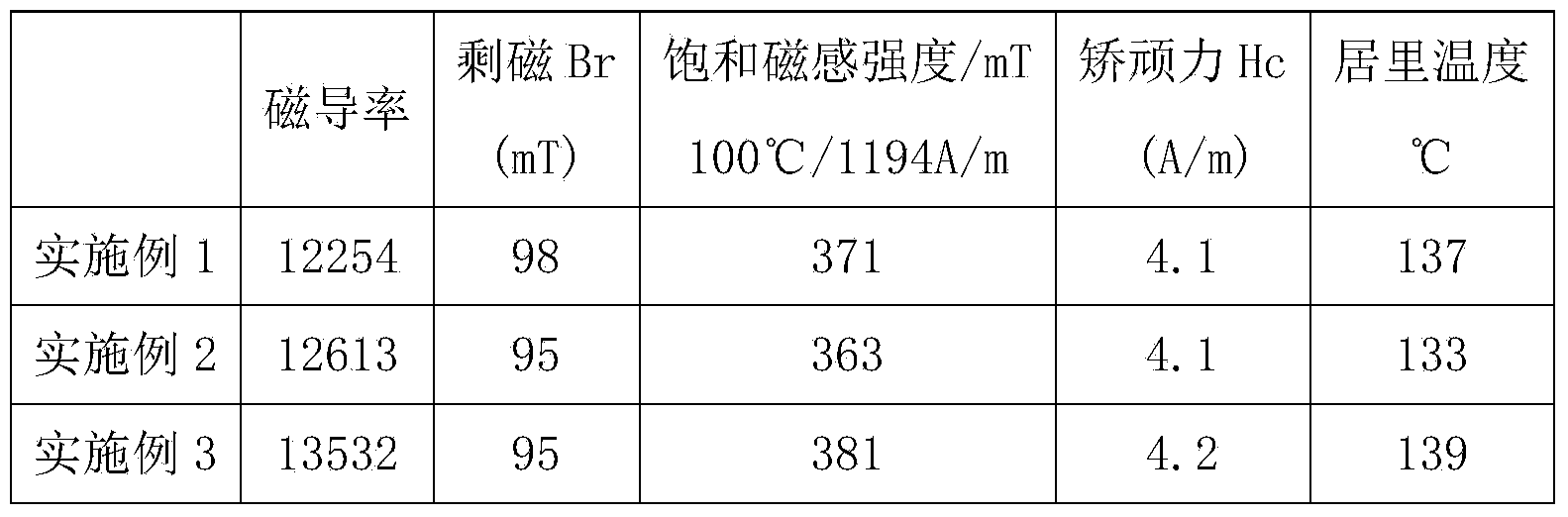

Embodiment 1

[0017] A high magnetic permeability ferrite material, its raw materials include: Fe 2 o 3 , MnO, ZnO, sodium dodecylbenzenesulfonate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 , where Fe 2 o 3 :MnO:ZnO molar ratio is 53.5:23.5:23, with Fe 2 o 3 , MnO, ZnO three quality and as the basis, sodium dodecylbenzenesulfonate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 The mass fractions are 0.9%, 0.026%, 0.0028%, 0.018%, 0.013%, 0.026%, 0.022%, respectively;

[0018] According to above-mentioned raw material proportioning, prepare according to the following steps:

[0019] S1: Weigh each raw material and measure Fe 2 o 3 , MnO, ZnO, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 Each powder is subjected to ball milling, pre-calcination, and secondary ball milling for use, wherein, during the secondary ball milling process, sodium dodecylbenzenesulfonate is added as a dispersant;

[0020] S2: Granulation: mix the polyethylene solvent with a ma...

Embodiment 2

[0024] A high magnetic permeability ferrite material, its raw materials include: Fe 2 o 3 , MnO, ZnO, sodium dodecylbenzenesulfonate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 , where Fe 2 o 3 : The molar ratio of MnO: ZnO is 53:24:23.5, with Fe 2 o 3 , MnO, ZnO three quality and as the basis, sodium dodecylbenzenesulfonate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 The mass fractions are 1.3%, 0.029%, 0.0039%, 0.022%, 0.017%, 0.022%, 0.029%, respectively;

[0025] According to above-mentioned raw material proportioning, prepare according to the following steps:

[0026] S1: Weigh each raw material and measure Fe 2 o 3 , MnO, ZnO, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 Each powder is subjected to ball milling, pre-calcination, and secondary ball milling for use, wherein, during the secondary ball milling process, sodium dodecylbenzenesulfonate is added as a dispersant;

[0027] S2: Granulation: mix the polyethylene solvent with...

Embodiment 3

[0031] A high magnetic permeability ferrite material, its raw materials include: Fe 2 o 3 , MnO, ZnO, sodium dodecylbenzenesulfonate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 , where Fe 2 o 3 :MnO:ZnO molar ratio is 54:22.5:23.5, with Fe 2 o 3 , MnO, ZnO three quality and as the basis, sodium dodecylbenzenesulfonate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 The mass fractions are 1.5%, 0.0045%, 0.023%, 0.022%, 0.019%, 0.025%, 0.022%, respectively;

[0032] According to above-mentioned raw material proportioning, prepare according to the following steps:

[0033] S1: Weigh each raw material and measure Fe 2 o 3 , MnO, ZnO, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 Each powder is subjected to ball milling, pre-calcination, and secondary ball milling for use, wherein, during the secondary ball milling process, sodium dodecylbenzenesulfonate is added as a dispersant;

[0034] S2: Granulation: mix the polyethylene solvent with a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com