Patents

Literature

36results about How to "Good repeatability of the preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of multilayer semitransparent zirconia full-porcelain dental repair material

InactiveCN103121840AHigh molding densitySmall sintering shrinkageChemical compositionRepair material

The invention belongs to the field of porcelain materials and preparation thereof, and in particular relates to a multilayer semitransparent zirconia full-porcelain dental repair material and a preparation method thereof. The material comprises the chemical ingredients such as magnesium oxide and part stable square-phase zirconia, wherein the molecular contents of the magnesium oxide and the zirconia are respectively 2-10% and 90-98%; the part stable square-phase zirconia is added with a modifying agent to be modified, wherein the molar ratio of the modifying agent and the part stable square-phase zirconia is 1: (0.01-0.1); and a coloring agent is added into the modified zirconia repair material, and the coloring agent and the modified zirconia repair material respectively account for 0.1-1% and 99-99.9%. The method comprises the following steps of power preparing, mixing and granulating, two-step forming, plastic discharging and sintering. Compared with the prior art, the material has the advantages of good producing technology repeatability, stable quality, reliable performance and convenience in production.

Owner:ZXTGY BEIJING TECH

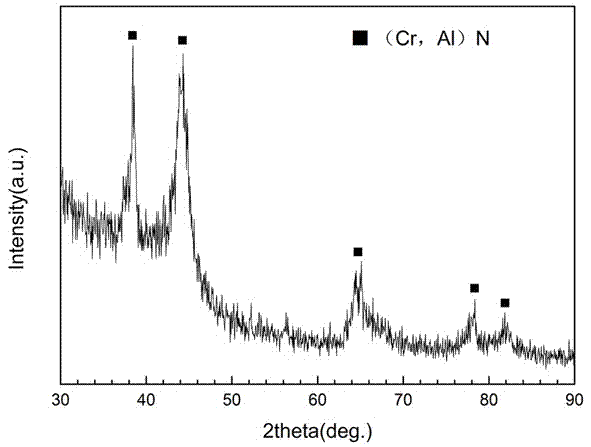

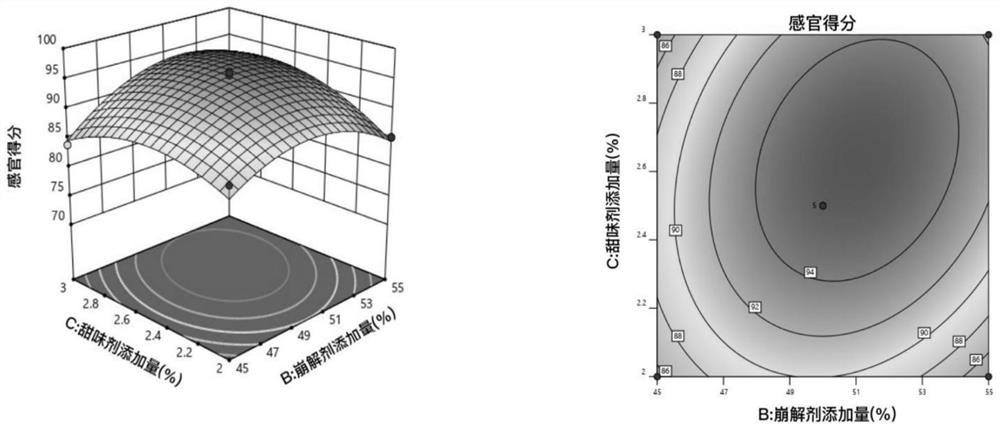

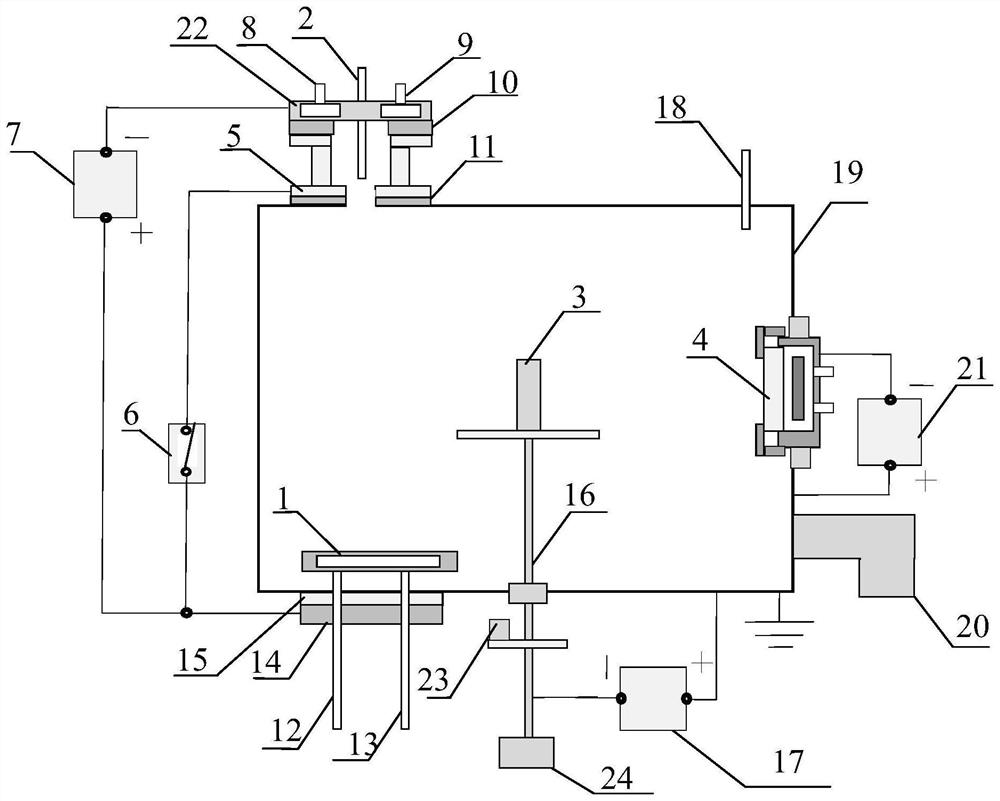

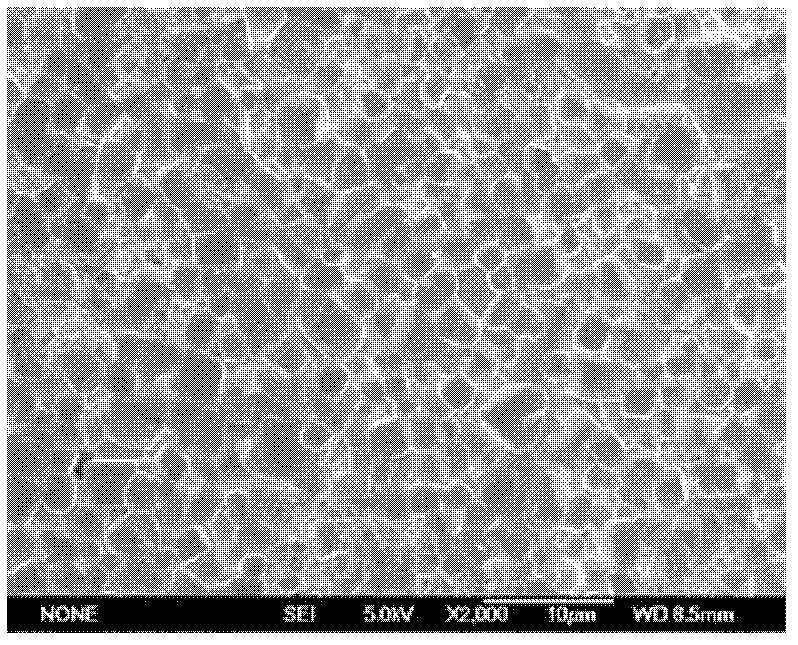

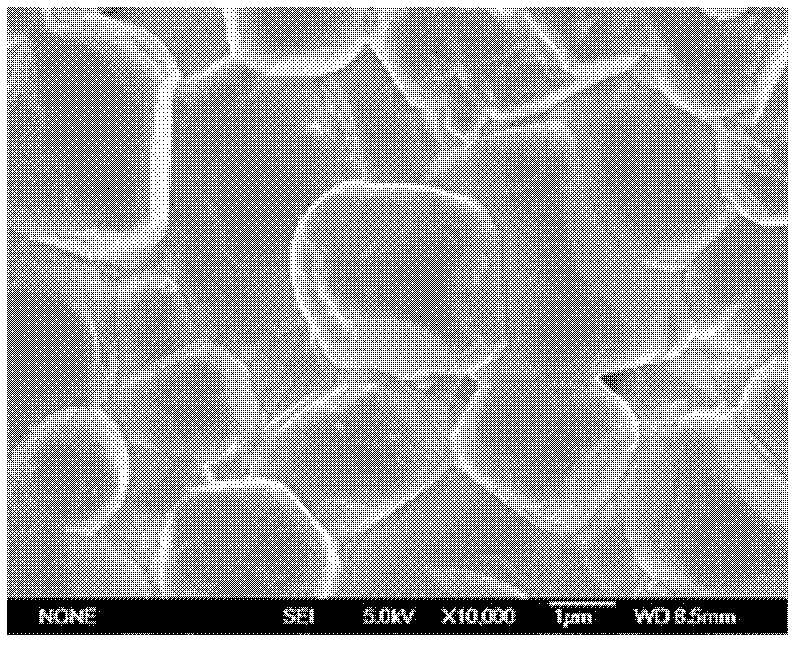

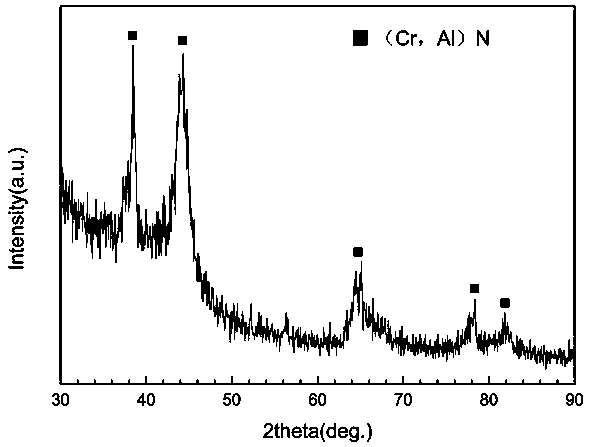

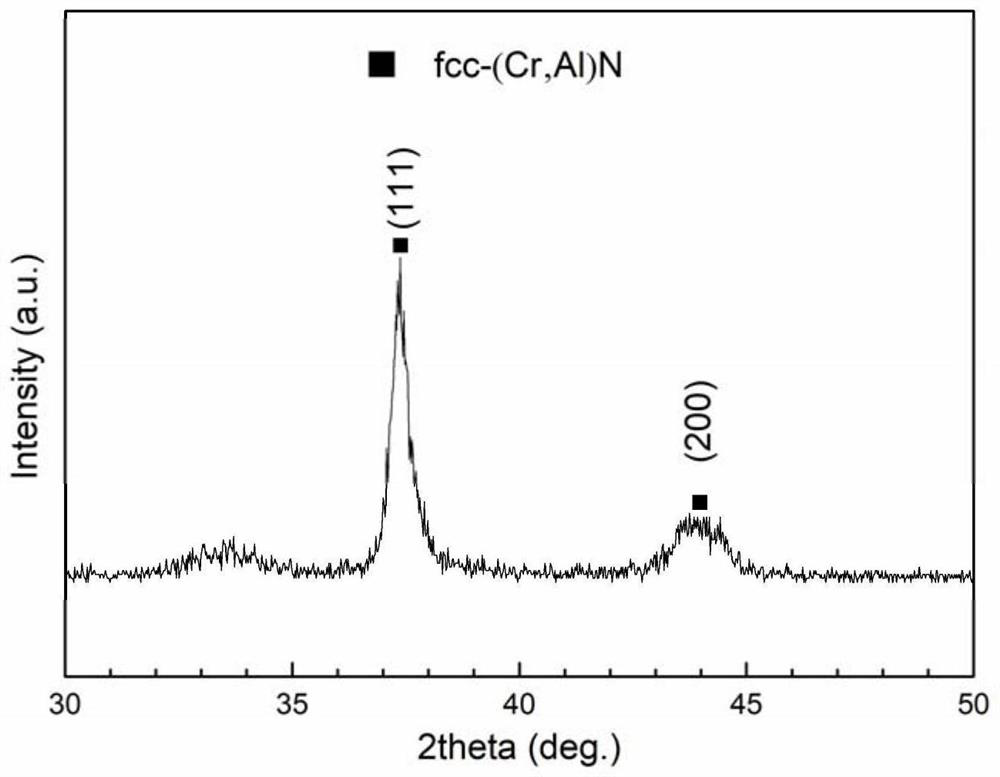

High-hardness AlCrN nanocomposite coating and preparation process thereof

ActiveCN106893986AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingNanocomposite coatingHardness

The invention relates to a nanocomposite coating and a preparation technology of the nanocomposite coating, in particular to a preparation process for a high-Al-content AlCrN nanocomposite coating. The AlCrN nanocomposite coating is prepared on a metal or cemented carbide substrate by the adoption of an electric arc ion plating technology. Pure metal Al and Cr are used as targets, and the content of Al and Cr in the coating is adjusted and controlled by controlling the current of the Al targets and the Cr targets. The four pure Cr targets and the four pure Al targets are evenly distributed on the inner wall of a furnace body at intervals. Ar gas is introduced firstly before film plating, the bias pressure of 600-1,000 V is adopted, glow cleaning is conducted on the substrate for 10-20 min, then the Cr targets are opened, bombardment cleaning is conducted on the substrate, the bias pressure is gradually lowered to 30-100 V, and the metal Cr layer is deposited. The preparation process of the AlCrN nanocomposite coating is simple, and industrial production is facilitated; and the prepared AlCrN coating has the high hardness and strength and good high-temperature and oxidation resistance and corrosion resistance.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

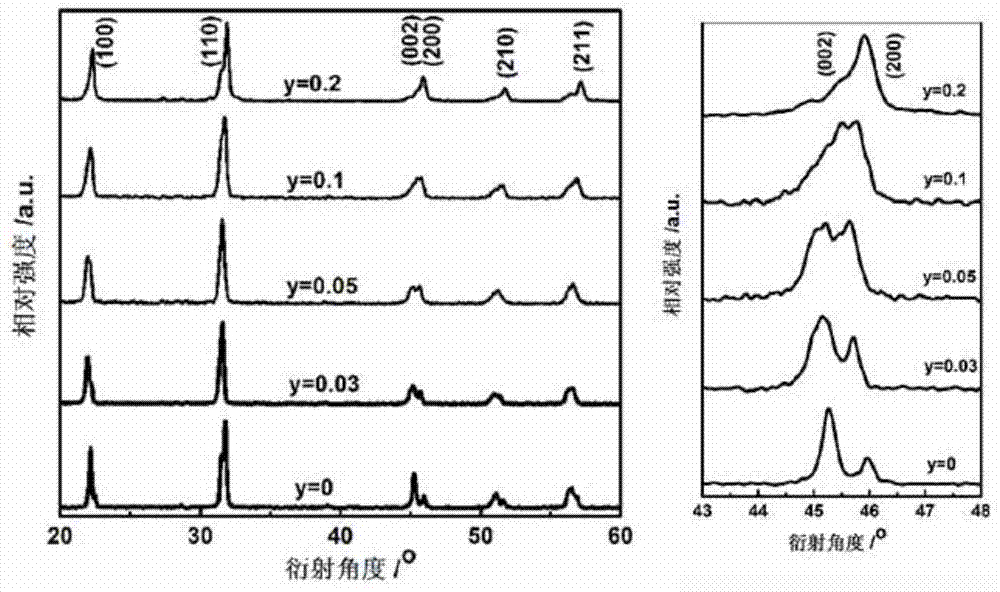

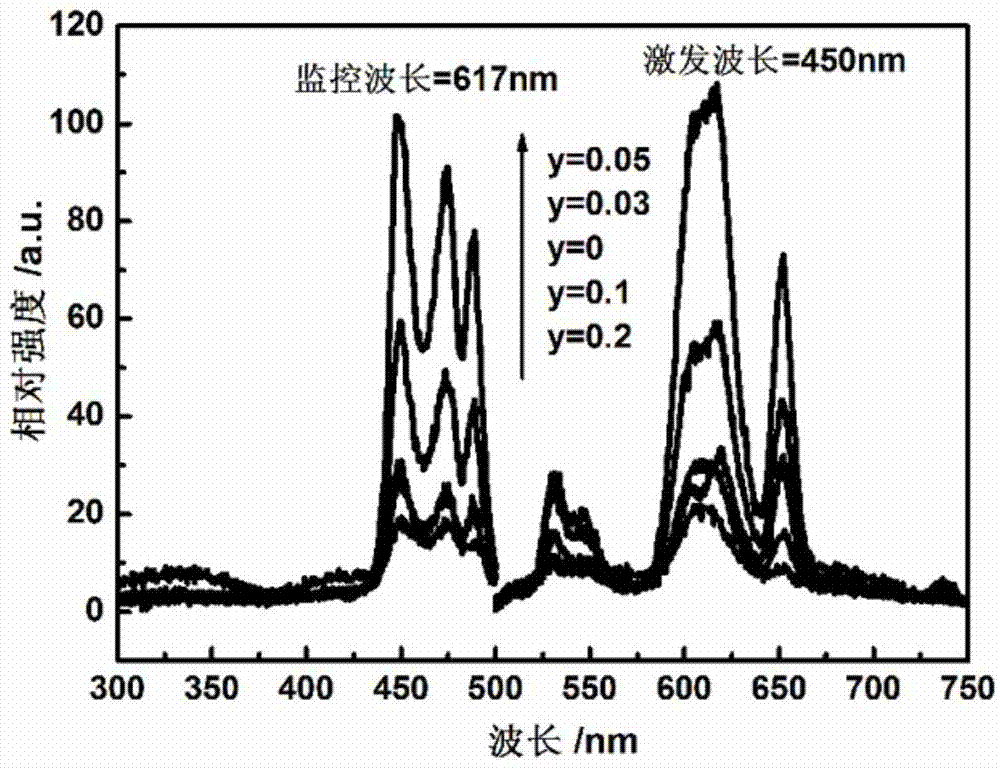

Lead-free piezoelectric potassium sodium niobate optoelectronic multifunctional material and preparation method thereof

InactiveCN103787658AExcellent piezoelectric ferroelectric propertiesExcellent luminous propertiesRare-earth elementFluorescence

The invention relates to a lead-free piezoelectric potassium sodium niobate optoelectronic multifunctional material and a preparation method thereof and belongs to the technical field of luminescent materials. According to the invention, the fluorescence property and the piezoelectric property of a lead-free piezoelectric potassium sodium niobate material are remarkably increased by utilizing the synergistic combination effect between rare earth ion and metal ion. The multifunctional material disclosed by the invention comprises the following components in percentage by mass: (K0.5Na0.5) (1-y-x) MyLnxNb (1-y) TiyO3, wherein the Ln is selected from at least one of Sm, Pr and Eu; M is one or more than one ion in metal elements Ca, Sr and Ba; x is greater than 0 and less than or equal to 0.05; y is greater than 0 and less than or equal to 0.2. The multifunctional material disclosed by the invention is formed by mixing a certain amount of rare earth element into (K0.5Na0.5) NbO3 (KNN) host material with a perovskite structure; in the meantime, a ferroelectric material MTiO3(M is Ca, Sr and Ba) with the same structure is added to form a solid solution together with the KNN to ensure that the material has excellent luminescence property; therefore, the multifunctional material has a blue light-excited photoluminescence characteristic and has the piezoelectric property and the ferroelectric property per se at the same time and has potential application prospect in the field of optoelectronic integration devices.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

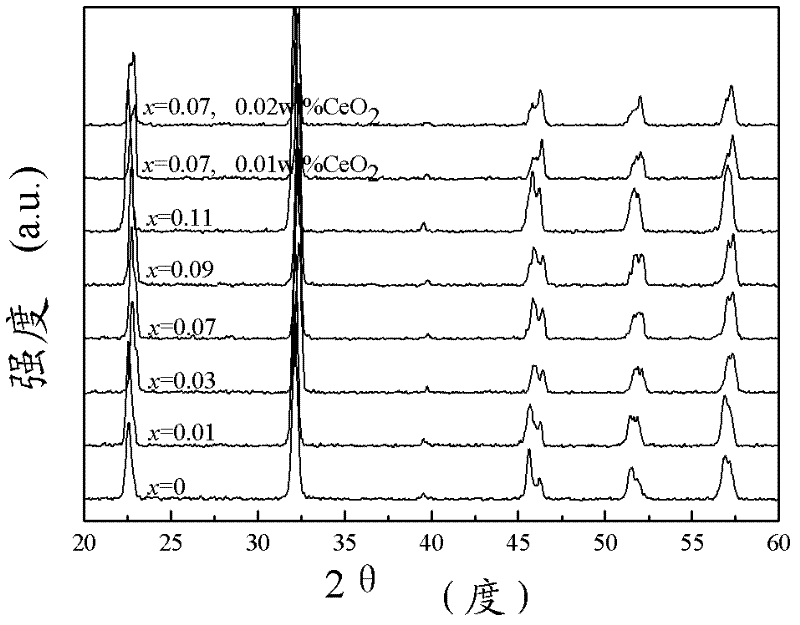

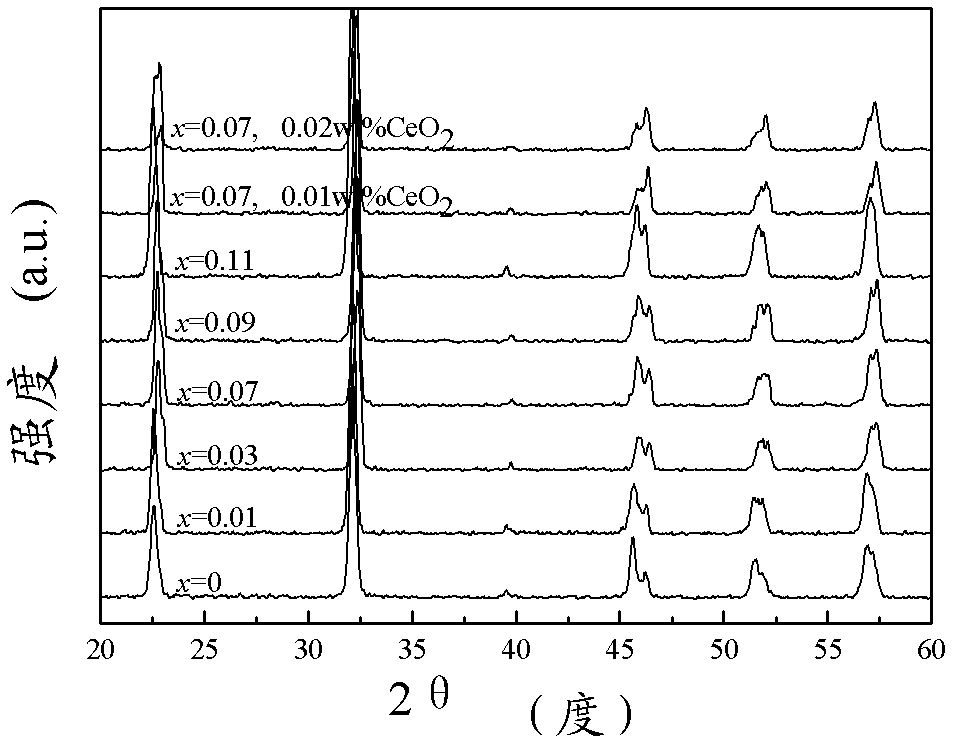

High-dielectric-strength potassium sodium niobate based lead-free piezoelectric ceramic as well as preparation method and application thereof

ActiveCN102390997AExcellent piezoelectric ferroelectric propertiesHigh compressive strengthFixed capacitor dielectricElectricityBarium strontium titanate

The invention discloses potassium sodium niobate based lead-free piezoelectric ceramic, which is characterized by having a chemical formula of [(Na0.5+xK0.5-x)0.94Li0.06][(Nb0.94Sb0.06)0.95Ta0.05]O3+ymol%TM+zmol%RE, wherein TM is MnO2, Fe2O3 or Ni2O3, RE is CeO2 or Nd2O3, the value of x is 0 or 0.01-0.11, the value of y is 0.02-0.12, and the value of z is 0-0.05. The invention further discloses a preparation method application of the ceramic. The ceramic disclosed by the invention maintains an excellent piezoelectric ferroelectric property, simultaneously has a high withstand voltage performance, has very good withstand voltage performance and temperature stability, and still maintains very high withstand voltage strength at the high temperature of 140 DEG C. The voltage withstand performance of the material is obviously superior to that of the commonly used barium strontium titanate (BST) based high-voltage ceramic capacitor material, and the withstand voltage value of the material at normal temperature is 1.7 times more than that of a BST material.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

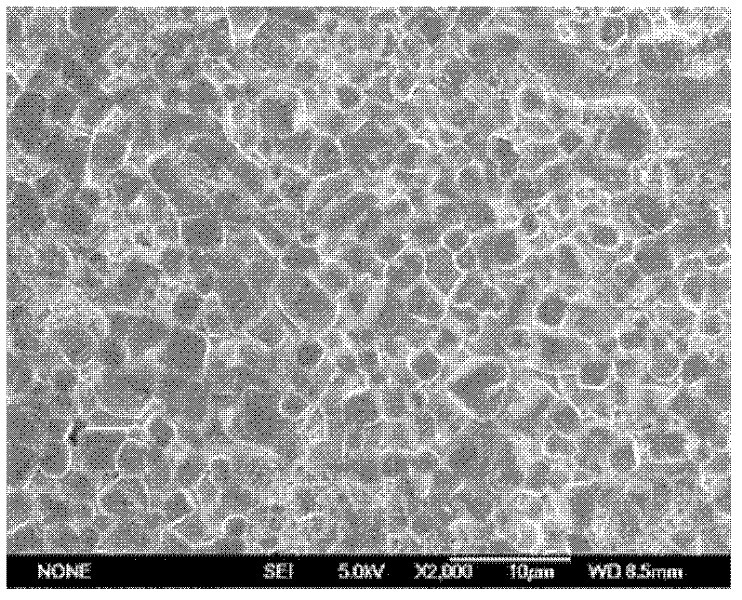

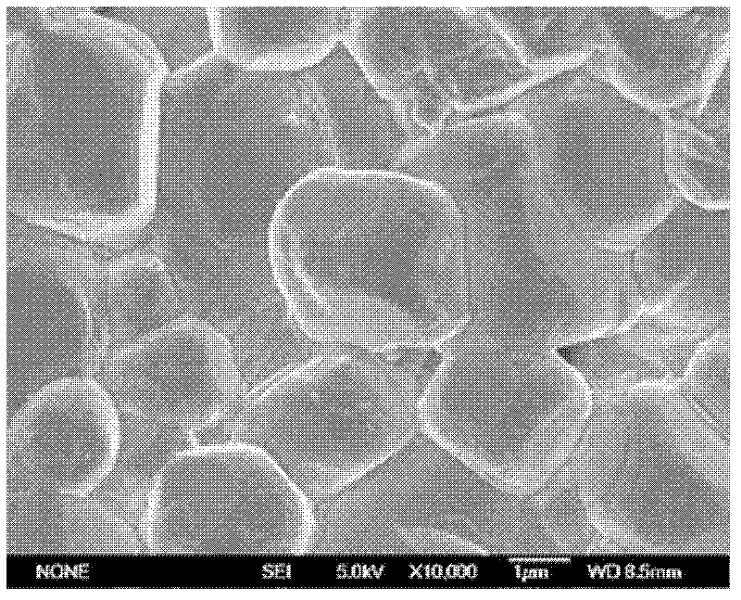

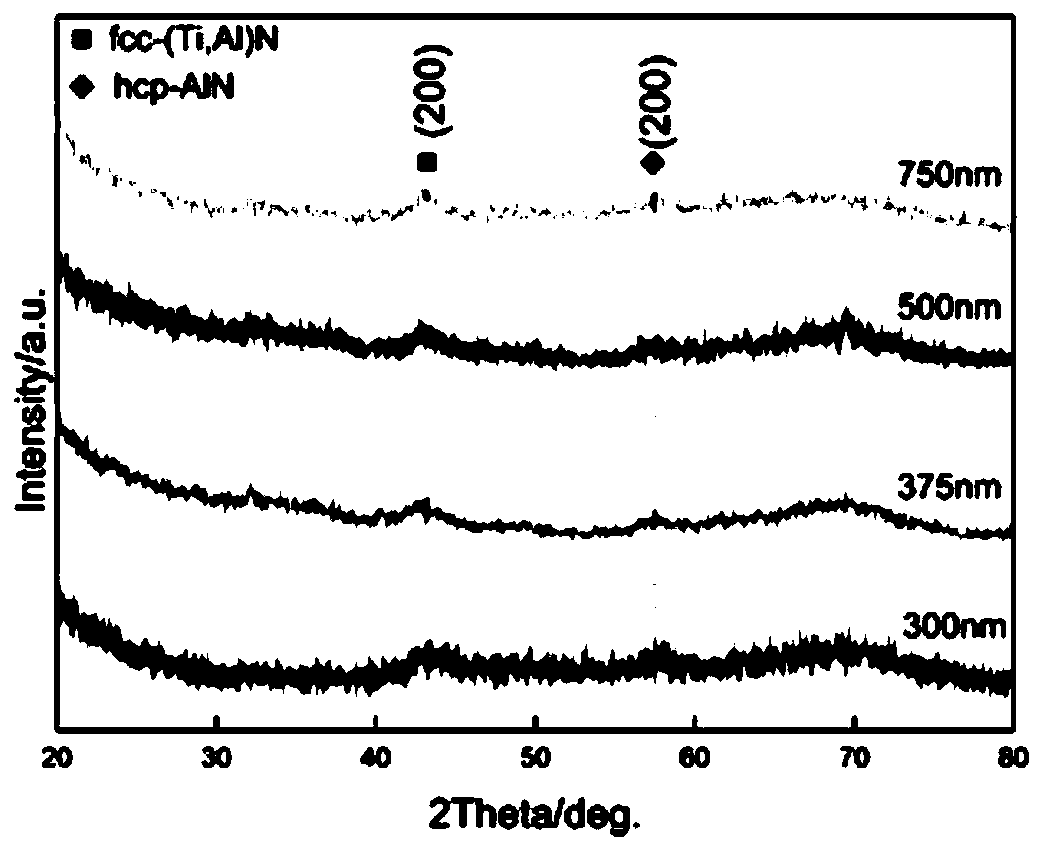

High-hardness AlTiN/AlTiSiN multi-layer nano composite coating and preparation process thereof

InactiveCN110578123AGrain refinementHigh hardnessVacuum evaporation coatingSputtering coatingNitrogenHardness

The invention discloses a high-hardness AlTiN / AlTiSiN multi-layer nano composite coating and a preparation process thereof, and belong to the technical field of composite coating preparation. The AlTiN / AlTiSiN film multi-layer nano composite coating is formed by overlaying an AlTiN layer and an AlTiSiN layer in a mutual alternated mode, the coating modulation period is 150-1000 nm, and the periodnumber is larger than to equal to 2. The composite coating is prepared by adopting an electric arc ion plating technology, and the preparation process comprises the following steps that a metal Ti target, an AlTi target and an AlTiSi target are selected, after glow cleaning and bombarding cleaning, a TiN transition layer is firstly deposited, finally nitrogen is introduced as a reaction gas, and the AlTi target and the AlTiSi target are alternately opened to deposit the composite coating according to the set modulation period. The prepared coating by using the preparation process is compact inorganizational structure, strong in binding force between the coating and a base body, high in hardness and strength and good in wear resistance.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

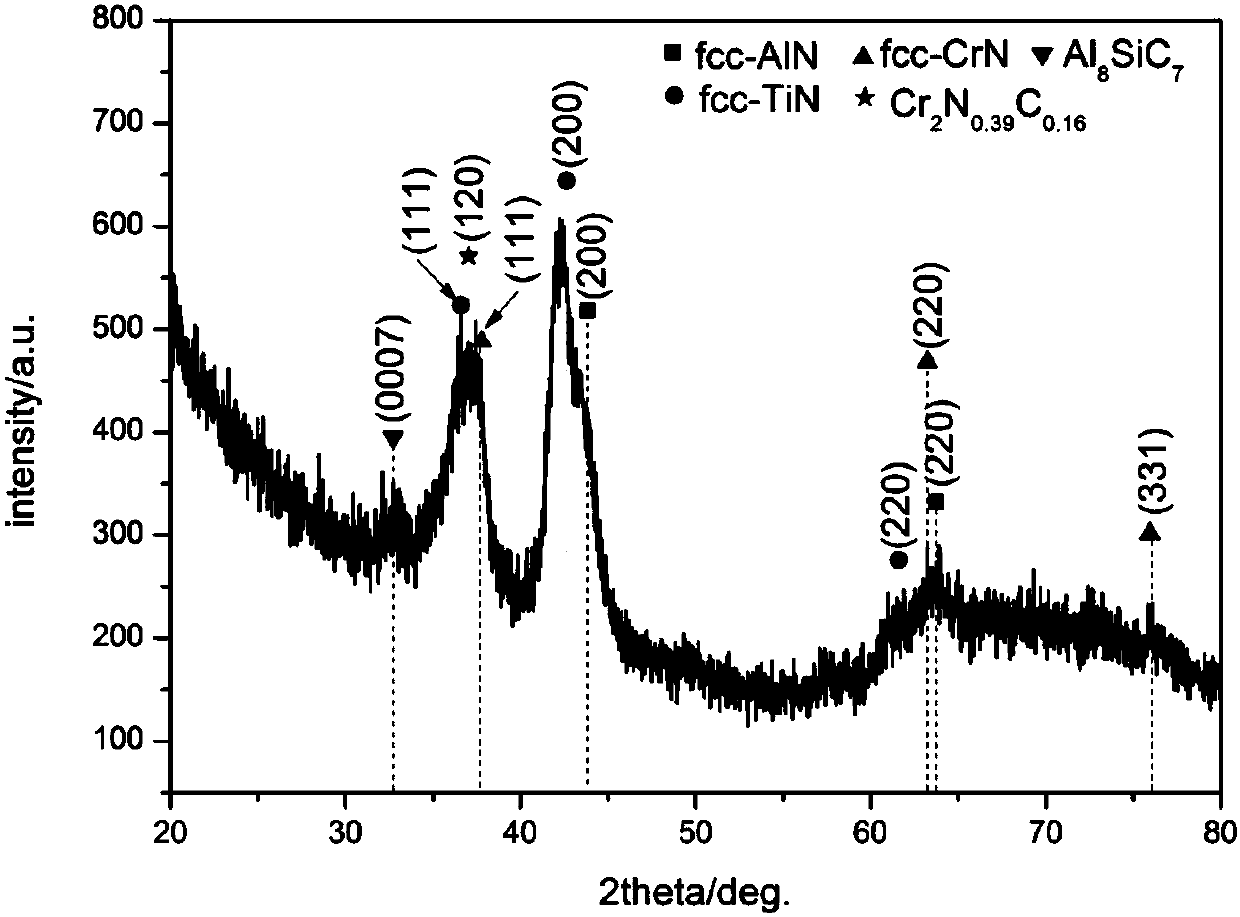

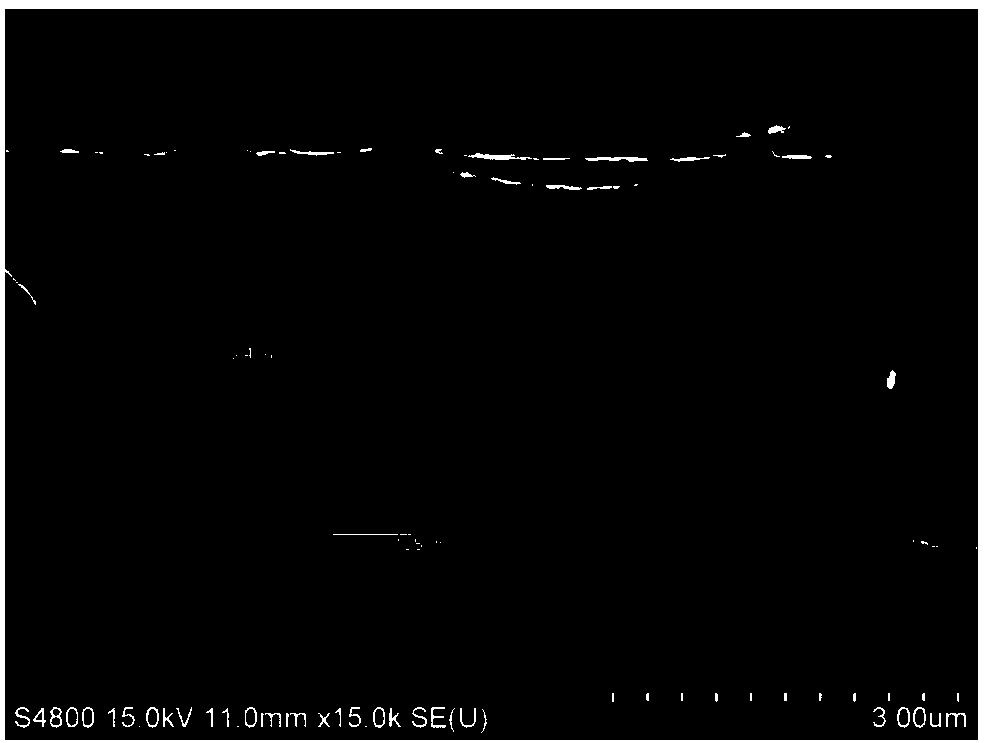

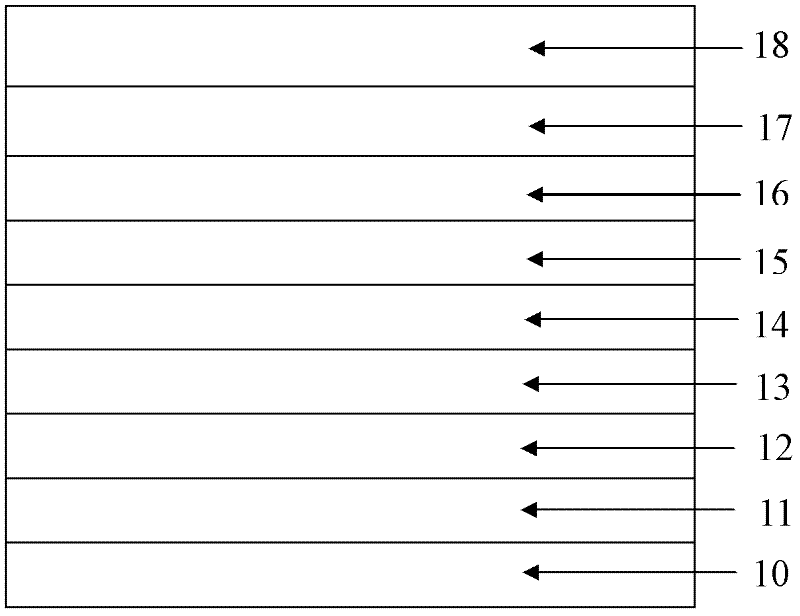

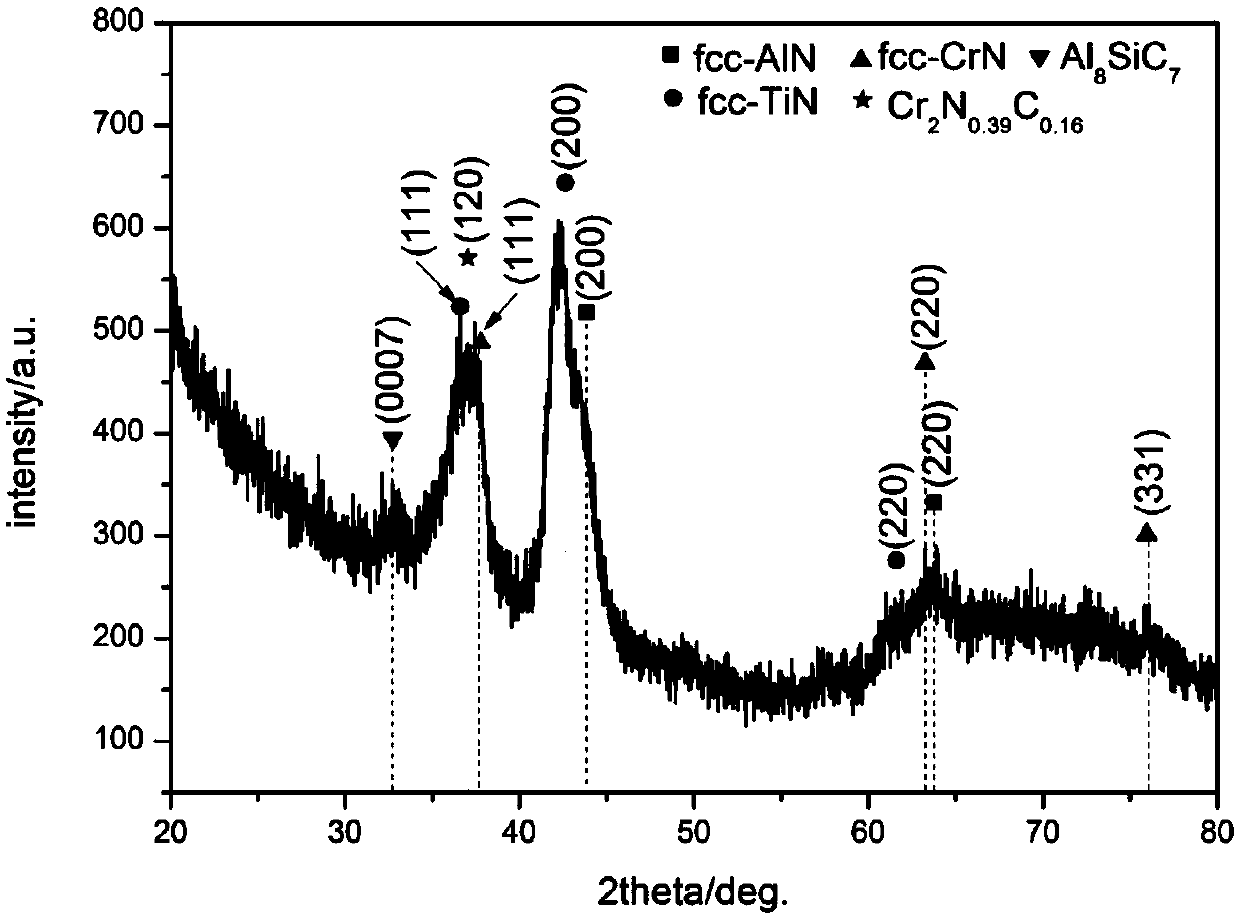

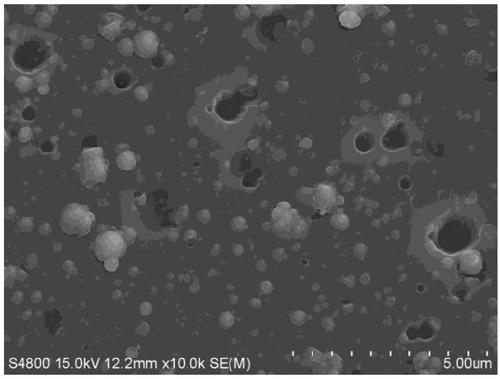

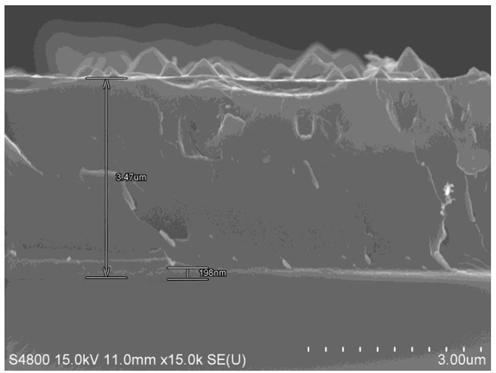

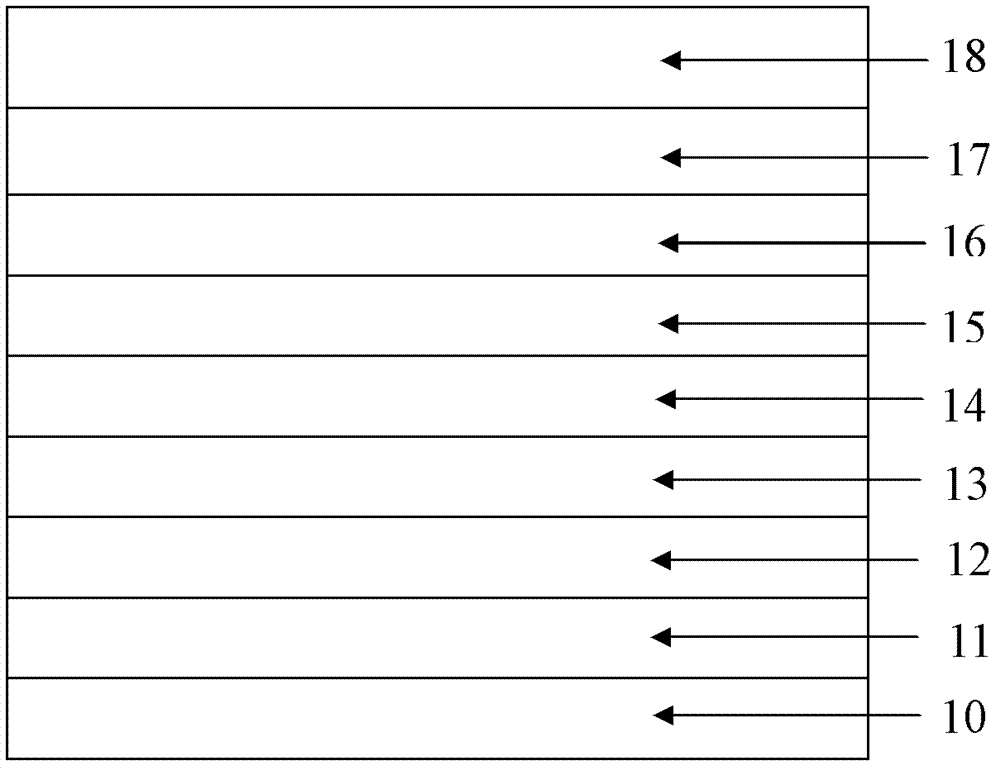

AlCrTiSiCN coating structure and preparing method thereof

ActiveCN107916402AStable chemical propertiesImprove toughnessVacuum evaporation coatingSputtering coatingAmorphous phaseHardness

The invention discloses an AlCrTiSiCN coating structure and a preparing method thereof. The AlCrTiSiCN coating structure comprises a base body, an Al-Cr-Ti alloy transition layer and an AlCrTiSiCN coating, the Al-Cr-Ti alloy transition layer and the base body are combined, the AlCrTiSiCN coating and the Al-Cr-Ti alloy transition layer are combined, and the AlCrTiSiCN coating forms a nano-compositestructure coating with amorphous phase Si3N4 wrapping nanocrystalline phases including AlN, TiN, CrN, Al8SiC7,Cr2N0.39C0.16 and the like. The nano-composite AlCrTiSiCN coating is stable in chemical properties and does not make contact with common chemical corrosive media. The nanocrystalline phases in the coating can effectively prevent generation and development of microcracks, and the coating toughness is greatly improved. The AlCrTiSiCN coating has the high hardness and toughness and is good in wear-resisting property. The AlCrTiSiCN coating is even in thickness and compact in structure, and the good bonding strength with the base body is achieved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

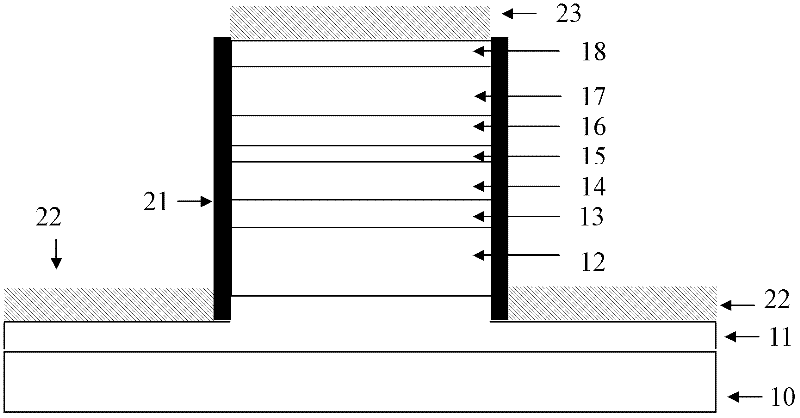

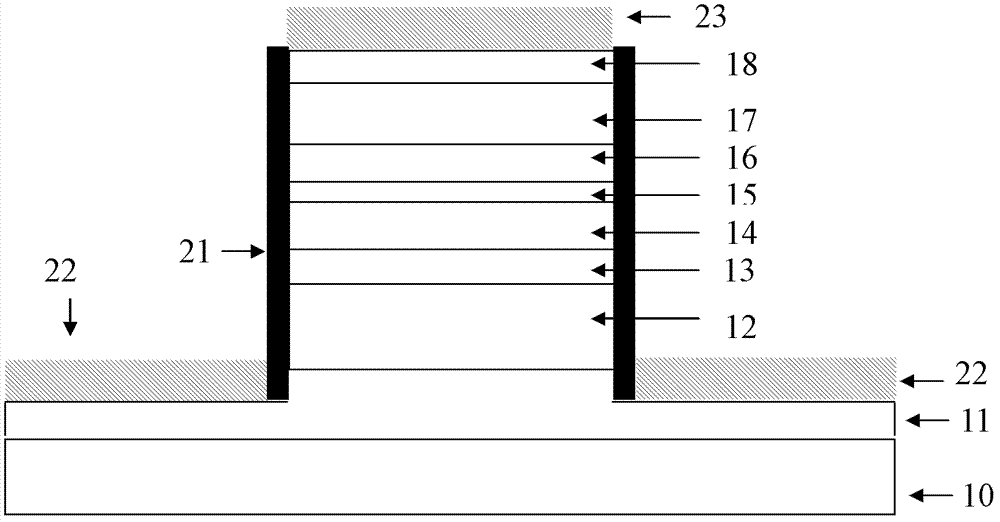

GaN-based laser and method for measuring AlGaN/GaN superlattice resistivity

InactiveCN102255244ASimple structureGood repeatability of the preparation processOptical wave guidanceLaser detailsSemiconductorLaser

The invention relates to a laser structure and a method for measuring AlGaN / GaN superlattice resistivity in a GaN-based semiconductor laser. The laser for measuring the optical confinement layer resistivity of AlGaN / GaN superlattice is divided into two types of lasers with an n-type or p-type AlGaN / GaN superlattice optical confinement layers of different thicknesses; the serial resistance of eachtype of laser is determined through measuring the I-V (current / voltage) characteristic curve of the laser; the difference of the serial resistance of the laser for the AlGaN / GaN superlattice optical confinement layers of different thicknesses is the resistance of the AlGaN / GaN superlattice of changed thicknesses, thus the resistivity of the AlGaN / GaN superlattice optical confinement layers can beobtained. Through utilizing the laser with the structure, the resistivity of the n-type and p-type AlGaN / GaN superlattice optical confinement layers in the GaN-based semiconductor laser can be measured respectively, and reference data is provided for the structural design and development manufacturing of the GaN-based semiconductor laser.

Owner:BEIJING UNIV OF CHEM TECH

Polycrystal zirconium oxide ceramic dental material and preparation thereof

InactiveCN1203830CSmall sintering shrinkageReduce distortionImpression capsArtificial teethHigh densityVolumetric Mass Density

The invention relates to a polycrystalline zirconia ceramic tooth post material and a preparation method thereof, belonging to the technical field of preparation of ceramic materials. It is characterized in that: the material contains zirconia ceramic powder as the initial raw material, a polymer binder, and a low-molecular additive, and the proportion thereof is: 80-90wt% of zirconia ceramic powder, 5-10wt% of polymer binder, 5-10wt% of low-molecular additives. The preparation method includes four steps of mixing and granulation, injection molding, thermal degreasing and sintering. The thermal degreasing temperature is 500-800°C, and the sintering temperature is 1350-1550°C. The organic binder system for injection molding of the present invention has good fluidity and high density of the molded green body, and the density of the ceramic product after sintering is greater than 6.0 g / cm 3 ;The sintering shrinkage and deformation of the formed green body are small, which ensures the dimensional accuracy of the product; the bending strength of the prepared ceramic tooth post is greater than 600MPa, and the fracture toughness is as high as 13MPa.m 1 / 2 , elastic modulus 140MPa, Vickers hardness 1050 ~ 1200MPa. The preparation process has good repeatability and is convenient for industrialized production.

Owner:TSINGHUA UNIV +1

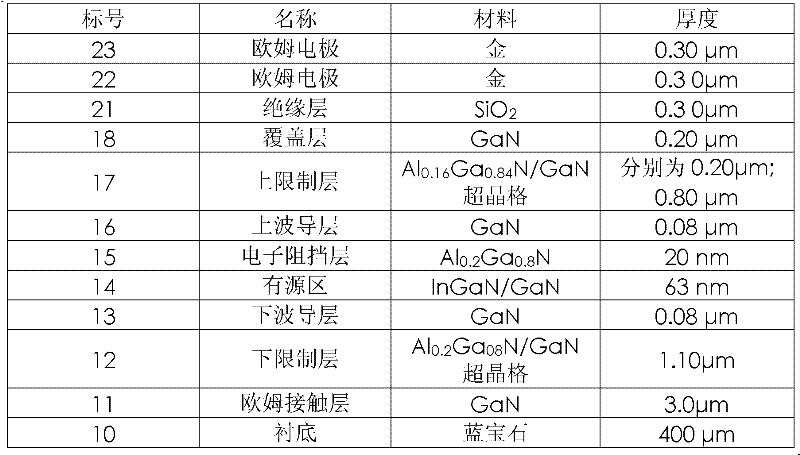

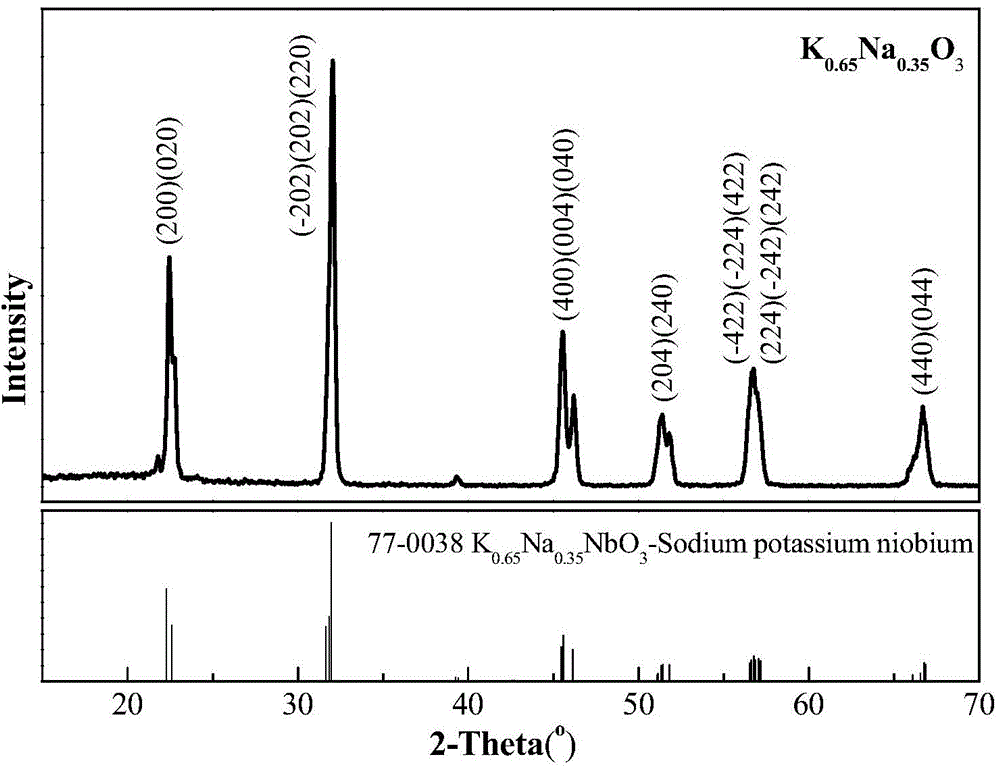

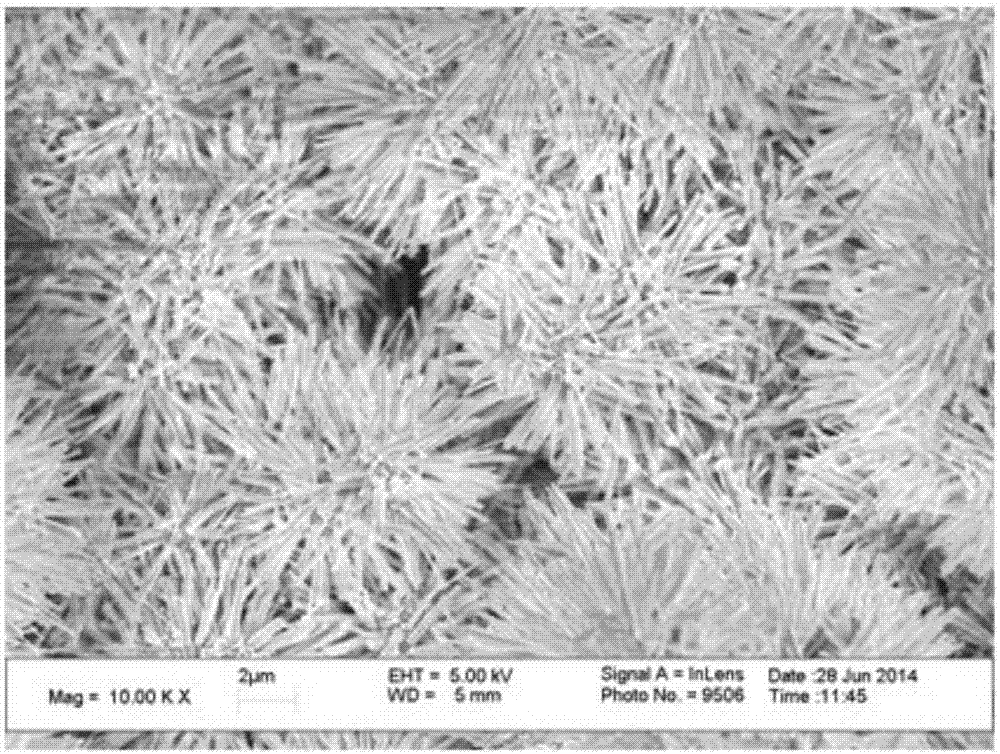

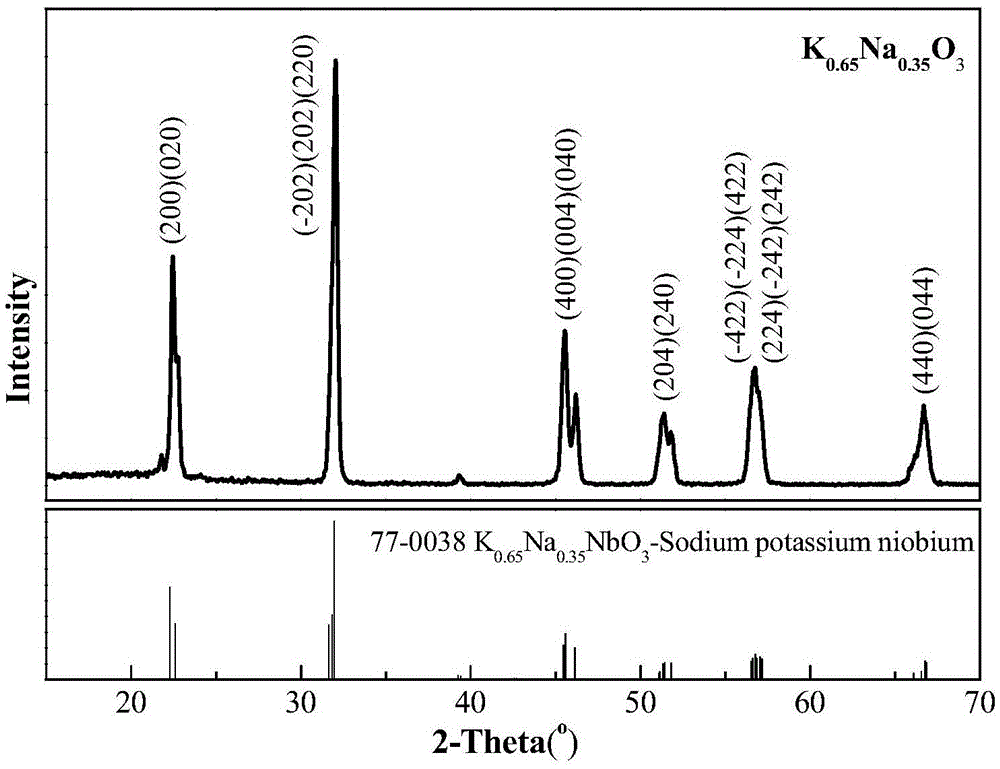

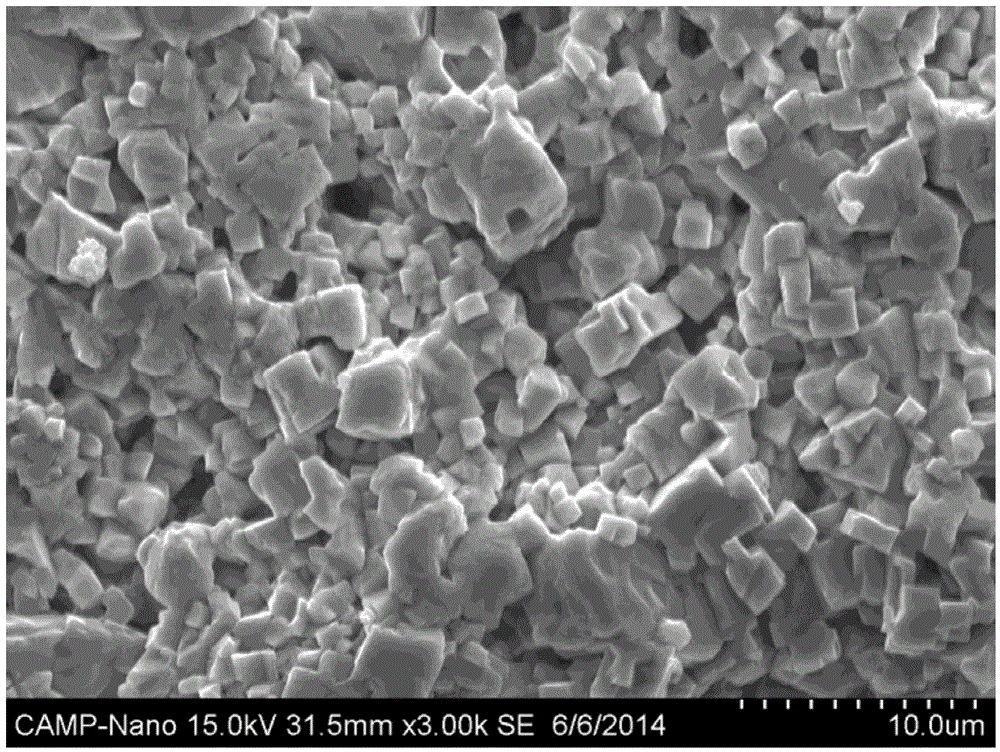

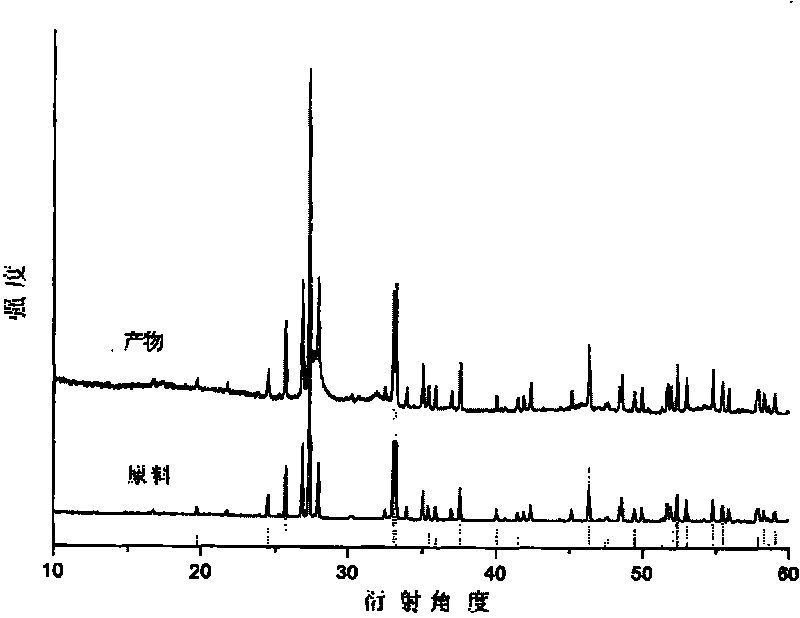

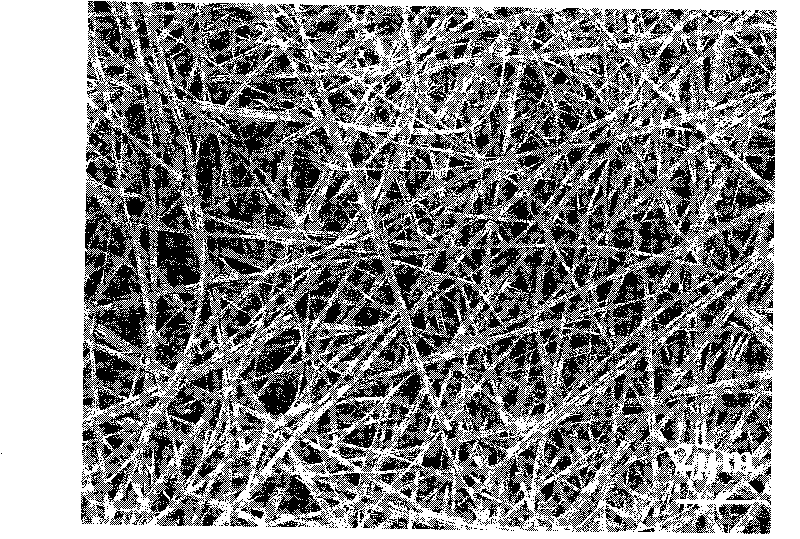

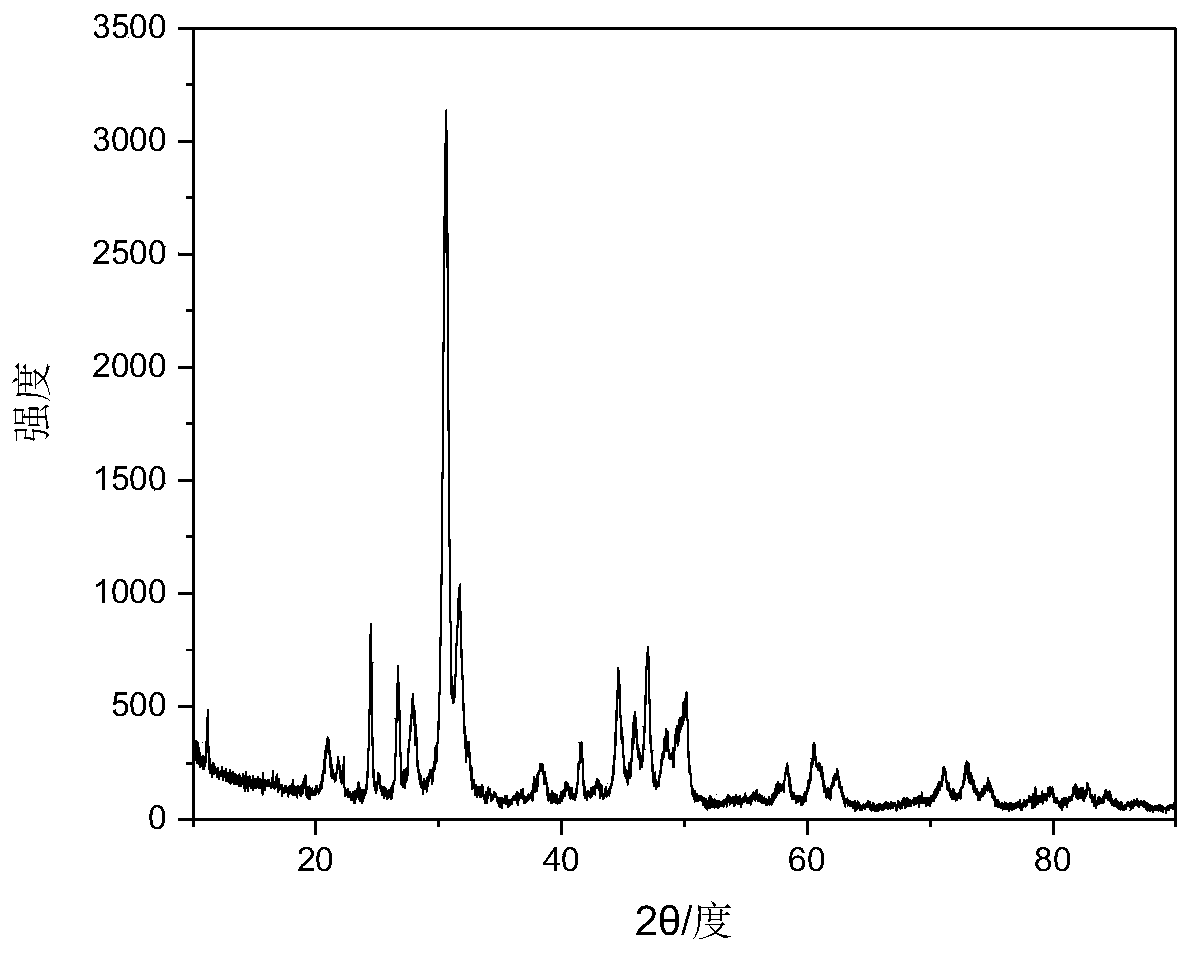

Method for synthetizing leadless piezoelectric ceramic K0.65Na0.35NbO3 powder adopting two-step hydrothermal method

The invention provides a method for synthetizing leadless piezoelectric ceramic K0.65Na0.35NbO3 powder adopting a two-step hydrothermal method. Excess potassium hydroxide and excess sodium hydroxide are taken as a potassium source and a sodium source respectively and dissolved in deionized water; then niobium pentoxide is added into the solution respectively, and precursor solutions of KNbO3 and NaNbO3 can be synthesized respectively after even stirring; the precursor solutions are sealed in a hydrothermal kettle respectively, the hydrothermal kettle is placed in a thermostat for hydrothermal synthesis at a certain temperature, cooling to the room temperature is performed after the reaction, and powder obtained through the reaction is washed with deionized water for several times and dried finally. After a grinding process, KNbO3 powder and NaNbO3 powder are accurately weighed and mixed in the deionized water; microwave oscillation is performed after stirring; the mixture is poured into a hydrothermal reaction kettle and sealed for hydrothermal synthesis, cooling to the room temperature is performed after the reaction, and a mixed liquid obtained through the reaction is fully dried to obtain the powder. According to the method, the two-step hydrothermal method is adopted to synthetize the K0.65Na0.35NbO3 powder, the preparation technology is good in repeatability, the material component proportion is accurate, the powder is good in uniformity and high in purity, and crystal grains are complete in development and even in distribution.

Owner:SHAANXI UNIV OF SCI & TECH

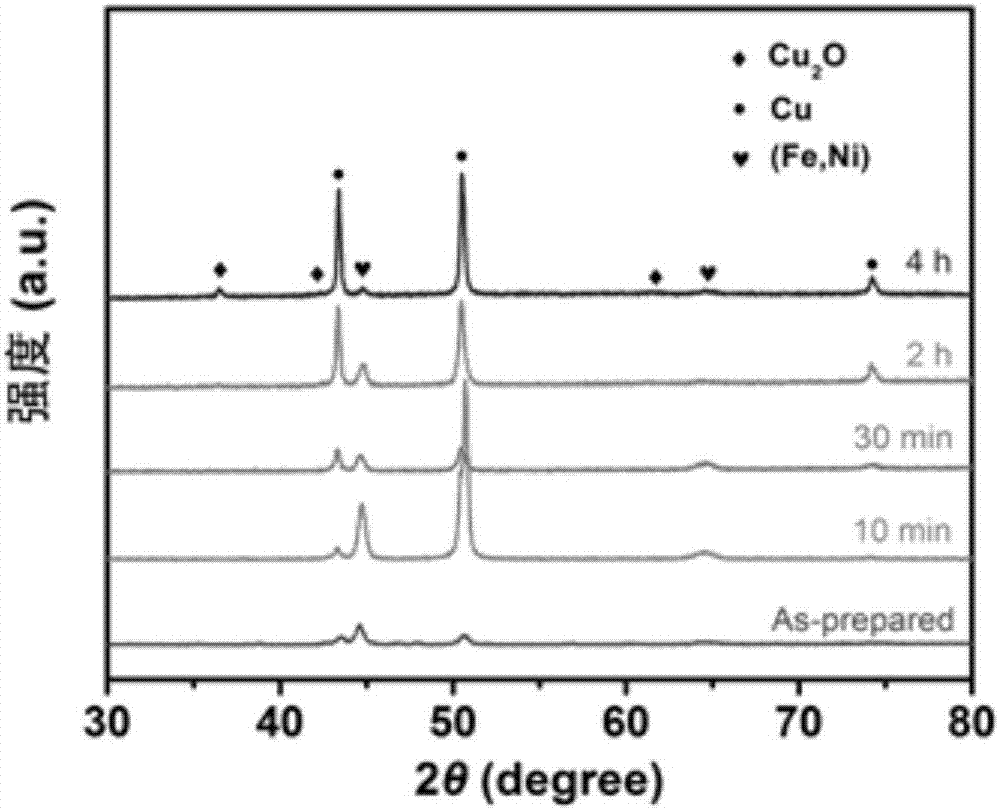

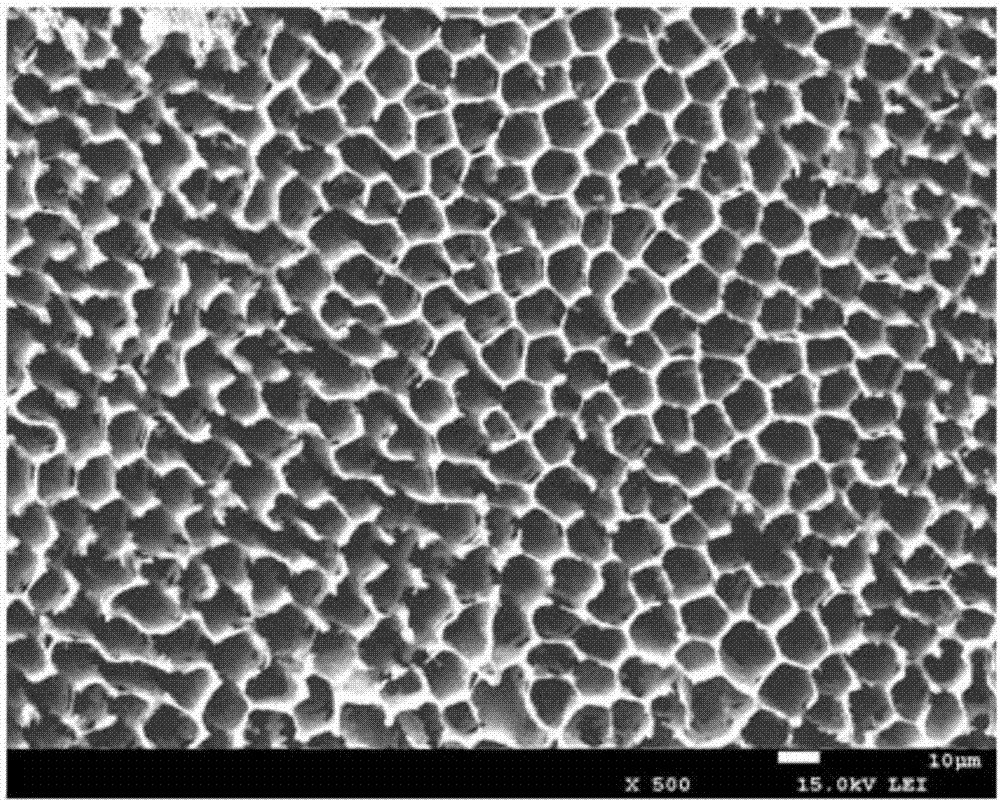

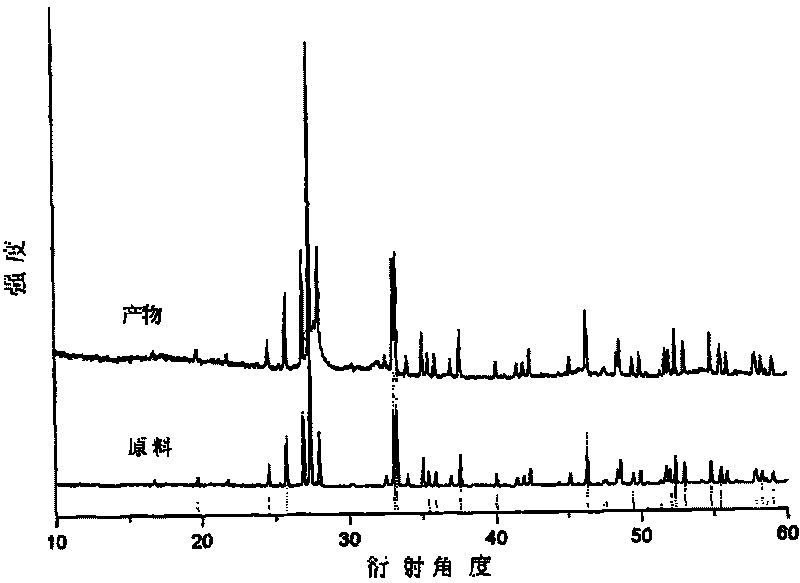

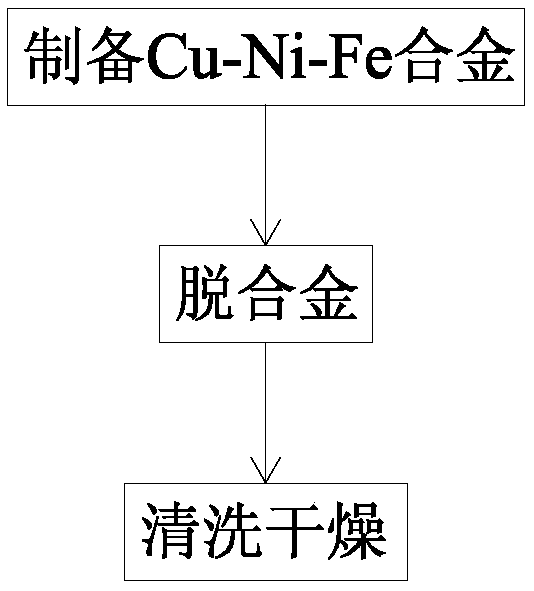

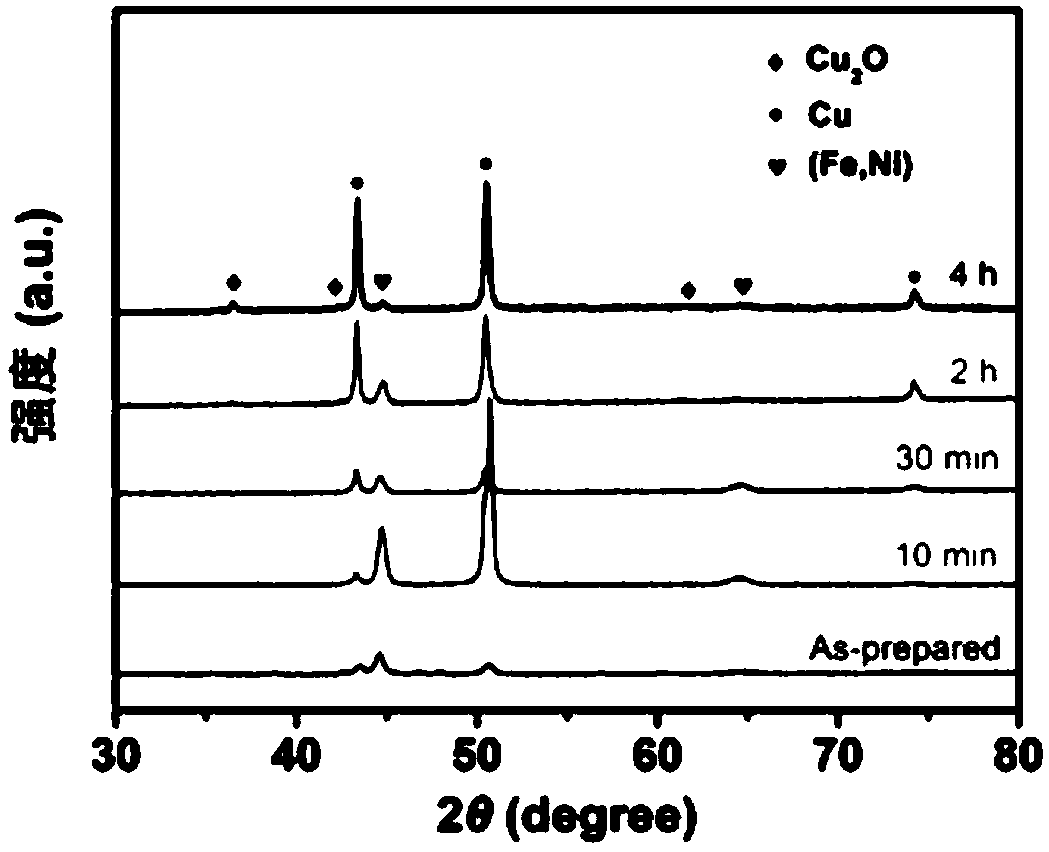

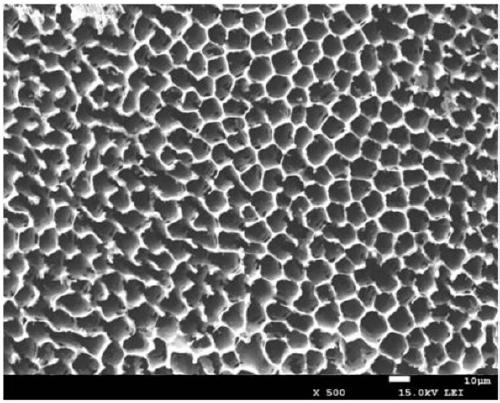

Method for preparing Cu micro-nano sheet structure through chemical dealloying

ActiveCN107398554AImprove efficiencyShort manufacturing timeAdditive manufacturing apparatusTransportation and packagingMicro nanoAlloy

The invention discloses a method for preparing a Cu micro-nano sheet structure through chemical dealloying. The method comprises the following steps that 1, a Cu-Ni-Fe semi-stable state eutectic structure is manufactured by using an additional material; pure Cu powder, pure Ni powder and pure Fe powder are mixed according to the atomic ratio of 17-18 to 17-18 to 62-68, and then the Cu-Ni-Fe semi-stable state eutectic structure is manufactured by utilizing an additional material manufacturing system; 2, dealloying is performed, the obtained Cu-Ni-Fe semi-stable state eutectic structure is put in 0.03-0.07 mol / L of nitric acid solution, standing is performed at room temperature for 2-8 hours, and chemical dealloying is performed; 3, cleaning and drying are performed, the obtained de-alloyed Cu-Ni-Fe semi-stable state eutectic structure is taken out, soaking and cleaning are performed by sequentially using deionized water and ethyl alcohol, and the Cu micro-nano sheet structure is obtained after drying. The Cu micro-nano sheet structure is prepared by utilizing a simple chemical dealloying method, and a new technical way is provided for preparation of a complicated metal micro-nano structure.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Epoxy resin-based nanometer composite material and preparation method thereof

InactiveCN103172974AGood repeatability of the preparation processThe preparation process steps are simpleVacuum pumpingEpoxy

The invention discloses an epoxy resin-based nanometer composite material. The epoxy resin-based nanometer composite material comprises the following materials in percentage by weight: 91%-99% of E-51 type epoxy resin matrix and 1%-9% of organic rectorite, wherein the E-51 type epoxy resin matrix comprises the following components in percentage by weight (based on 100% of the total weight of the components): 3.5%-5% of 2-ethyl-4-methyl imidazole and 95%-96.5% of E-51 prepolymer. The invention further discloses a preparation method of the composite material. The preparation method of the composite material comprises the following steps of: heating up the E-51 prepolymer; adding the heated E-51 prepolymer to the organic rectorite for continuously stirring and moving a beaker to an oven for 4 hours to 6 hours; dropping 2-ethyl-4-methyl imidazole for continuously stirring, and moving the beaker to the vacuum oven for vacuum-pumping; moving out the beaker and casting the reaction mixture to a mould, moving the mould to the oven for carrying out vacuum-pumping on the oven, and starting curing; and flatly placing the oven under room temperature to obtain the epoxy resin-based nanometer composite material. The prepared epoxy resin-based nanometer composite material is good in comprehensive performance, good in flame resistance and heat resistance, and can be used for conventional EP (Epoxy Resin).

Owner:XIAN UNIV OF TECH

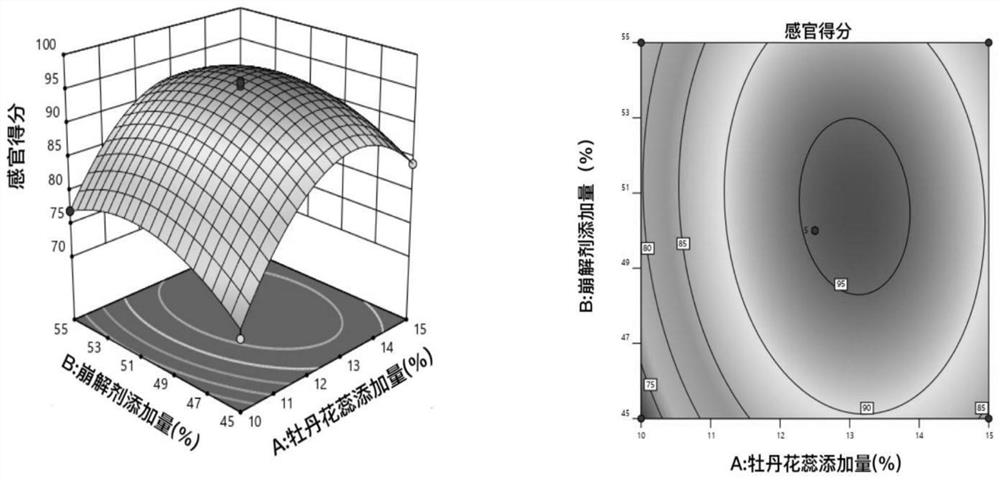

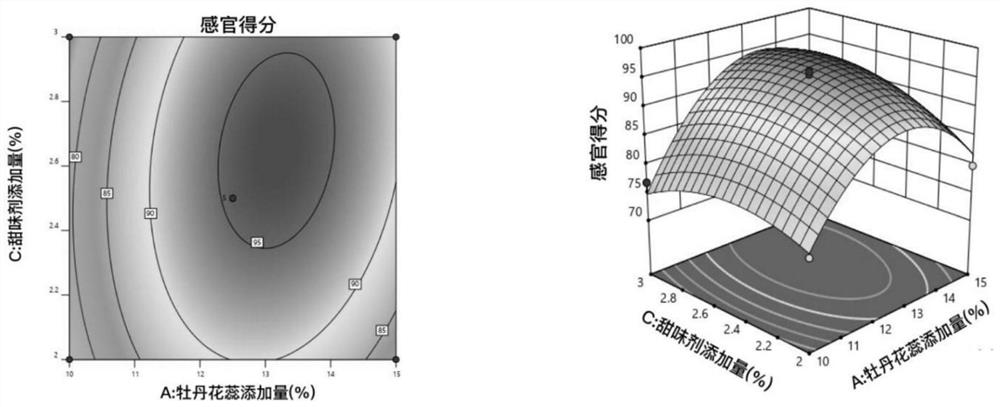

Total nutrient peony stamen effervescent tablet

PendingCN113367264AAvoid wasting resourcesEasy to carryNatural extract food ingredientsFood ingredient functionsBiotechnologyEffervescent tablet

A total nutrient peony stamen effervescent tablet comprises the following substances, by weight, 13.2 parts of a peony stamen extract, 2.7 parts of aspartame, 51 parts of a disintegrating agent, 27.8 parts of an acid source, 23.2 parts of an alkali source, 27.1 parts of lactose, 6 parts of PEG6000, a proper amount of a wetting agent and a proper amount of an adhesive. According to the effervescent tablet, peony stamens are prepared into the peony stamen total nutrient extract effervescent tablet, so that the resource waste of the peony stamens is avoided, a solid beverage which is convenient to carry and comprehensive and rich in nutrition is developed for people, and the peony stamen total nutrient extract effervescent tablet has higher social value and wide development prospect. Therefore, the peony stamen total nutrient extract is prepared from the peony stamens as a raw material through normal-temperature water extraction, vacuum concentration, ceramic membrane filtration, freeze drying, microwave sterilization and other processes, and through a single factor test and a Box-Behnken response method, the best ratio of auxiliary materials was optimized to develop a portable, ready-to-drink peony stamen total nutrient extract effervescent tablets solid beverage.

Owner:HEZE BRANCH QILU UNIV OF TECH(SHANDONG ACAD OF SCI

Self-lubricating wear-resistant AlCrN/MoS2 nanometer composite film and preparation method thereof

InactiveCN110670038AImprove the lubrication effectImprove wear resistanceVacuum evaporation coatingSputtering coatingComposite filmChemical stability

The invention discloses self-lubricating wear-resistant AlCrN / MoS2 nanometer composite film and a preparation method of the self-lubricating wear-resistant AlCrN / MoS2 nanometer composite film and belongs to the technical field of films. The AlCrN / MoS2 nanometer composite film is prepared on a cutter matrix by the adoption of high-power pulse and pulse direct current magnetic control combined filmcoating technology; in the deposition process, bias voltage is adjusted to be -50 - -150 V, and then mixed gas of N2 and Ar is fed; the work atmosphere pressure is kept at 0.5-1.0 Pa, the power of a AlCr target is kept at 0.5-1.0 kW, the power of the MoS2 target is 0.05-0.3 kW, and after deposition, the AlCrN / MoS2 nanometer composite film is obtained. The prepared AlCrN / MoS2 nanometer composite film has good lubricating performance, can significantly improve the wear resistance of the matrix and has good chemical stability, and wear debris is prone to transferring to a friction interface to form a lubricating film.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Preparation method of water-based strontium substituted hydroxyapatite colloidal liquid crystal

ActiveCN107746047AAbundant and easy to obtainGood repeatability of the preparation processMaterial nanotechnologyPhosphorus compoundsWater basedPhosphate

The invention relates to a preparation method of water-based strontium substituted hydroxyapatite colloidal liquid crystal. The method comprises the following steps that soluble strontium salt is dissolved in deionized water to form a solution A; soluble citrate is dissolved in deionized water to form a solution B; soluble phosphate is dissolved in deionized water to form a solution C; the solution B is dropwise added into the solution A; the mixed solution is stirred to form mixed liquid D; the solution C is dropwise added into the mixed liquid D; stirring is performed to form mixed liquid E;the mixed liquid E is poured into a sealed hydrothermal reactor; reaction is performed for 3 to 24h at 90 to 200 DEG C; then, natural cooling is performed to room temperature; centrifugation is performed by a high-speed centrifuge; obtained precipitates are alternately and centrifugally washed by deionized water and absolute ethyl alcohol; the washed precipitates are dispersed into the deionizedwater again; the pH is regulated; stable colloidal dispersion liquid is obtained; concentration is performed to the critical transition concentration or higher; the colloidal liquid crystal is obtained through preparation. The preparation method has the advantages that the raw materials are nontoxic and green; the resources are rich and can be easily obtained; the cost is low; the synthetic process is simple; the implementation is easy; the repeatability is good; the preparation method can be used in the fields of biomedical materials and the like.

Owner:HUBEI UNIV OF TECH

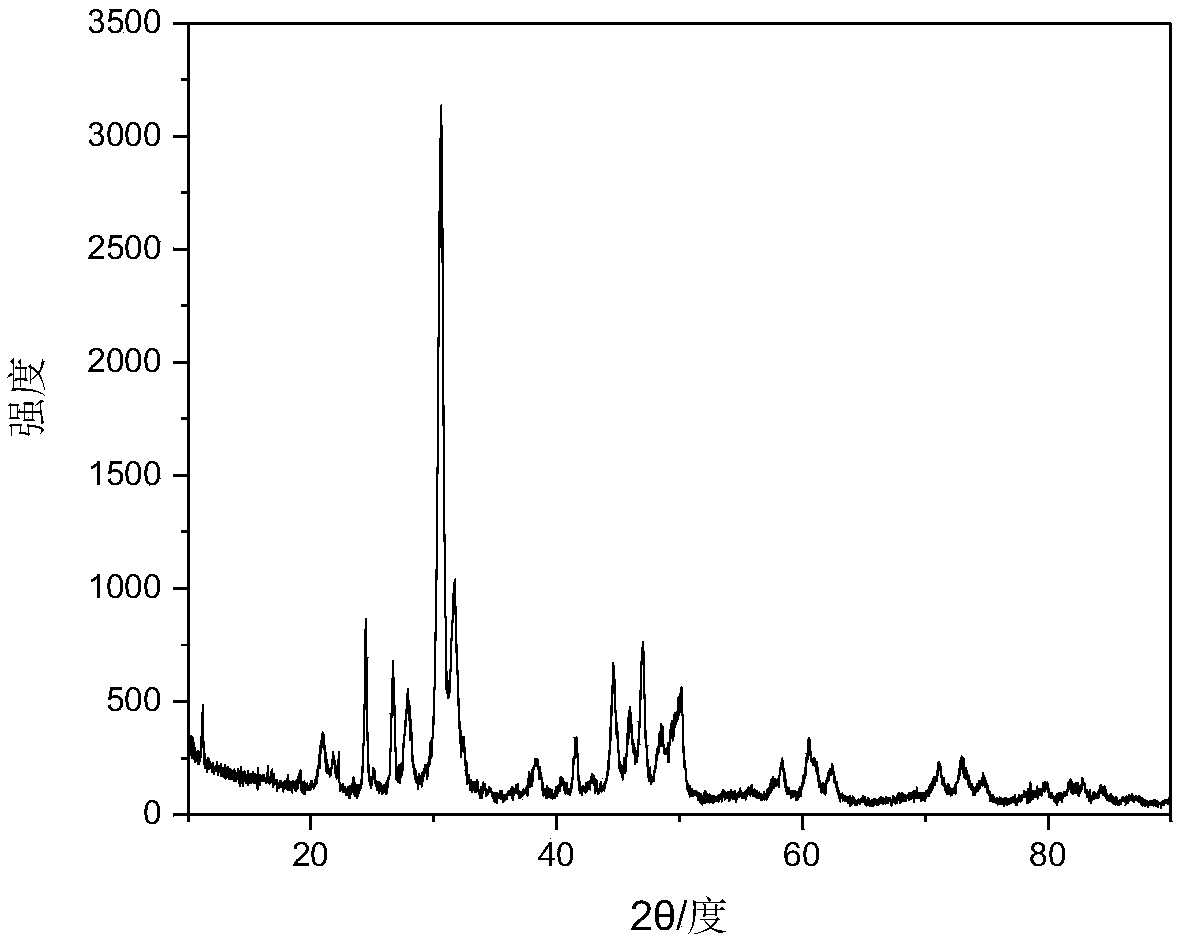

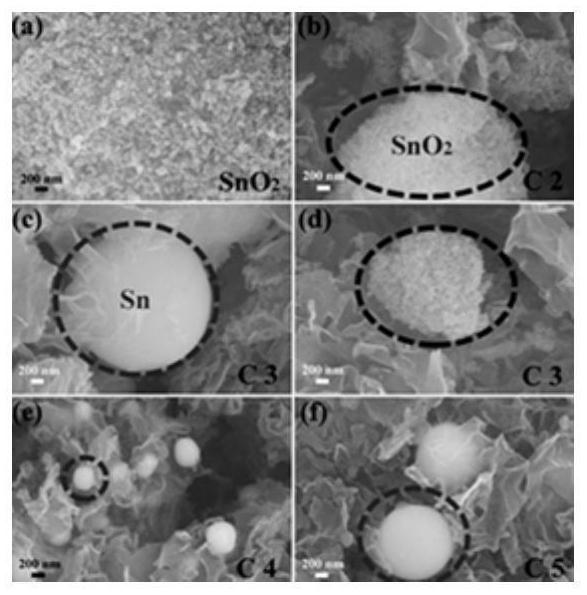

Preparation method of frequency-adjustable (SnO2/Sn/rGO) composite wave-absorbing material

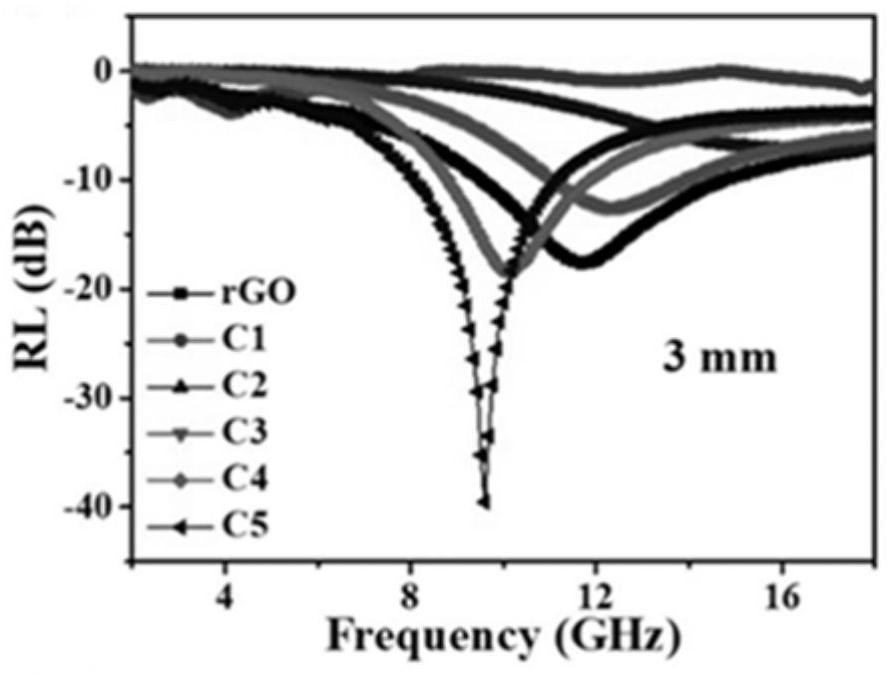

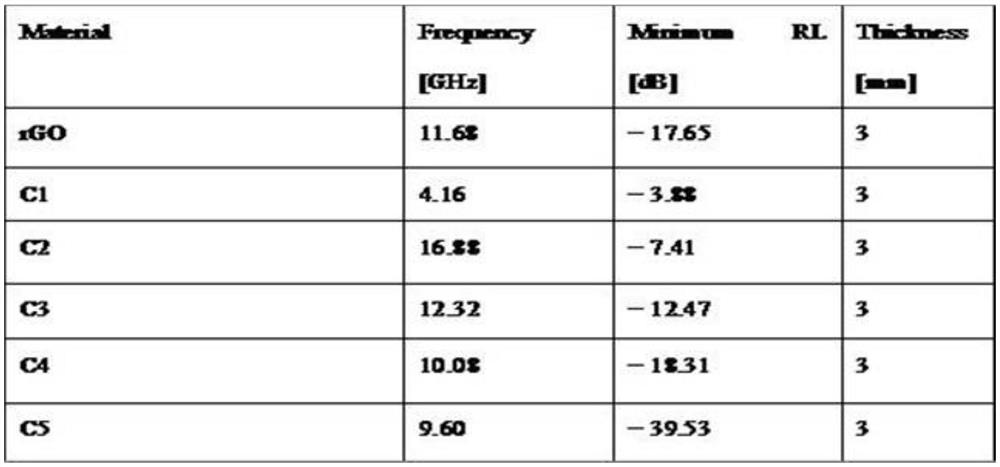

PendingCN114276782AGood absorbing performanceGood repeatabilityMaterial nanotechnologyOther chemical processesElectronic communicationComposite material

The invention aims to provide a synthesis method of a frequency-adjustable wave-absorbing material, belongs to the technical field of electronic communication, and particularly relates to a preparation method of a frequency-adjustable SnO2 / Sn / rGO wave-absorbing composite material, which comprises the following steps: preparing a nanoscale SnO2 material by a sol-gel method; finally, the SnO2 / Sn / rGO composite material with the adjustable frequency is successfully prepared by controlling an interface group and a phase structure of the material through processes of hydrothermal treatment, different calcination temperatures and the like, and the frequency modulation mechanism of the SnO2 / Sn / rGO composite material is researched. The composite material has adjustable wave absorbing performance when the thickness of the wave absorbing ring is 3mm, relaxation polarization loss is related to intrinsic carrier concentration and carrier migration, and the composite material plays a key role in microwave loss and a frequency modulation mechanism. And when the interface polarization range is (0.14-2.27), the microwave loss and low-frequency absorption of the composite material are relatively good.

Owner:HARBIN INST OF TECH

Epoxy resin-based nanometer composite material and preparation method thereof

InactiveCN103172974BGood repeatability of the preparation processThe preparation process steps are simpleVacuum pumpingEpoxy

The invention discloses an epoxy resin-based nanometer composite material. The epoxy resin-based nanometer composite material comprises the following materials in percentage by weight: 91%-99% of E-51 type epoxy resin matrix and 1%-9% of organic rectorite, wherein the E-51 type epoxy resin matrix comprises the following components in percentage by weight (based on 100% of the total weight of the components): 3.5%-5% of 2-ethyl-4-methyl imidazole and 95%-96.5% of E-51 prepolymer. The invention further discloses a preparation method of the composite material. The preparation method of the composite material comprises the following steps of: heating up the E-51 prepolymer; adding the heated E-51 prepolymer to the organic rectorite for continuously stirring and moving a beaker to an oven for 4 hours to 6 hours; dropping 2-ethyl-4-methyl imidazole for continuously stirring, and moving the beaker to the vacuum oven for vacuum-pumping; moving out the beaker and casting the reaction mixture to a mould, moving the mould to the oven for carrying out vacuum-pumping on the oven, and starting curing; and flatly placing the oven under room temperature to obtain the epoxy resin-based nanometer composite material. The prepared epoxy resin-based nanometer composite material is good in comprehensive performance, good in flame resistance and heat resistance, and can be used for conventional EP (Epoxy Resin).

Owner:XIAN UNIV OF TECH

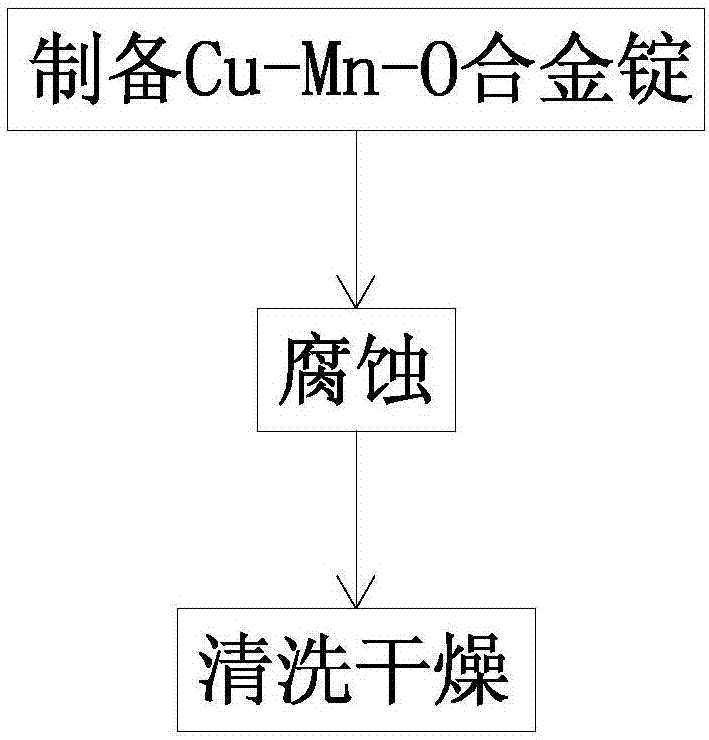

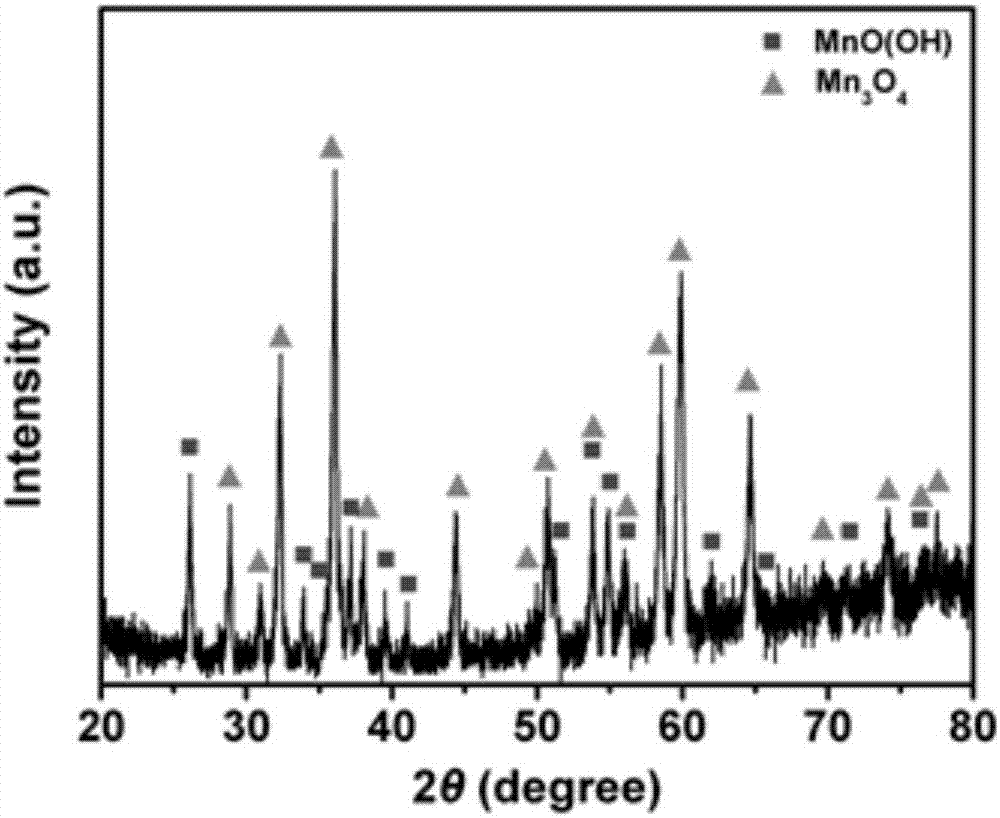

Method for preparing alkaline manganese oxide nano tube by room temperature corrosion

ActiveCN107381645AChange the corrosion processSimple processNanotechnologyManganese oxides/hydroxidesMicro nanoArgon atmosphere

The invention discloses a method for preparing an alkaline manganese oxide nano tube by room temperature corrosion. The method comprises the following steps of (1) preparing a Cu-Mn-O alloy ingot: mixing pure Cu and pure Mn at an atomic ratio of (18-20):(28-30), supplying partial air to an argon atmosphere, performing repeated smelting for more than three times, performing uniform mixing, and then performing cooling to obtain the Cu-Mn-O alloy ingot; (2) performing corrosion: placing the obtained Cu-Mn-O alloy ingot in a 0.03-0.07mol / L excessive hydrochloric acid solution, and performing the corrosion for 60-80h at a room temperature until the surface of the alloy ingot has no bubble overflow to obtain the corroded Cu-Mn-O alloy ingot; and (3) performing cleaning and drying: taking out the corroded Cu-Mn-O alloy ingot, sequentially soaking and cleaning the Cu-Mn-O alloy ingot by deionized water and alcohol, placing the Cu-Mn-O alloy ingot in the alcohol, performing ultrasonic dispersion treatment, and performing the drying to obtain an MnO(OH) micro-nano tube structure. According to the method, the MnO(OH) micro-nano tube is prepared under a room temperature condition by regulating and controlling a component and a structure of a master alloy and combining a simple room temperature corrosion method, and a novel technical approach is provided for preparing the MnO(OH) micro-nano tube.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

A two-step hydrothermal method for the synthesis of lead-free piezoelectric ceramic k 0.65 na 0.35 nbo 3 powder method

ActiveCN104098334BHigh purityPrecise control of molar ratioPiezoelectric/electrostrictive/magnetostrictive devicesPotassiumTwo step

The invention provides a two-step hydrothermal method for synthesizing lead-free piezoelectric ceramic K0.65Na0.35NbO3 powder. Excess potassium hydroxide and sodium hydroxide are used as potassium source and sodium source respectively, and are dissolved in deionized water. ; Then add niobium pentoxide to the solution and stir evenly to synthesize the precursor liquids of KNbO3 and NaNbO3 respectively; seal the precursor liquids in hydrothermal kettles and put them into a constant temperature box for hydrothermal synthesis at a certain temperature. After the reaction was completed, it was cooled to room temperature, and the powder obtained by the reaction was washed several times with deionized water and finally dried. After the grinding process, the KNbO3 and NaNbO3 powders are accurately weighed and mixed in deionized water; stir and then use microwave vibration; pour into the hydrothermal reaction kettle and seal for hydrothermal synthesis. After the reaction is completed, cool to room temperature and complete the reaction. The resulting mixed liquid is fully dried to obtain powder. In the present invention, a two-step hydrothermal method is used to synthesize K0.65Na0.35NbO3 powder. The preparation process has good repeatability, the material component ratio is accurate, the powder uniformity is good, the purity is high, and the crystal grains are fully developed and evenly distributed.

Owner:SHAANXI UNIV OF SCI & TECH

Process method for synchronous heat treatment/magnetron sputtering of TiO2 film

PendingCN114150268AGood anatase structureImprove antibacterial and antifungal effectVacuum evaporation coatingSputtering coatingStaphylococcusIon bombardment

The invention discloses a process method for synchronous heat treatment / magnetron sputtering of a TiO2 thin film, and belongs to the field of thin film preparation. The invention aims to solve the problem that subsequent high-temperature annealing treatment is needed when the TiO2 film is prepared by the existing magnetron sputtering technology. When the TiO2 film is deposited, the thermal radiation of a plasma source and the ion bombardment effect are utilized to synchronously realize the rapid high-temperature annealing treatment of the single-layer TiO2, the anode of the plasma source and the Ti target are positioned on the two sides of the substrate, and the bias value and the duration change along with the rotation position of the substrate. The sum of the values of the plasma source anode side bias voltage is higher than the Ti target side bias voltage. The deposited TiO2 film is of an anatase type crystal structure, and staphylococcus aureus is effectively inhibited.

Owner:HEILONGJIANG INST OF TECH +1

A kind of alcrtisicn coating structure and preparation method thereof

ActiveCN107916402BStable chemical propertiesImprove toughnessVacuum evaporation coatingSputtering coatingAmorphous phaseHardness

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

GaN-based laser and method for measuring AlGaN/GaN superlattice resistivity

InactiveCN102255244BSimple structureGood repeatability of the preparation processOptical wave guidanceLaser detailsSemiconductorLaser

Owner:BEIJING UNIV OF CHEM TECH

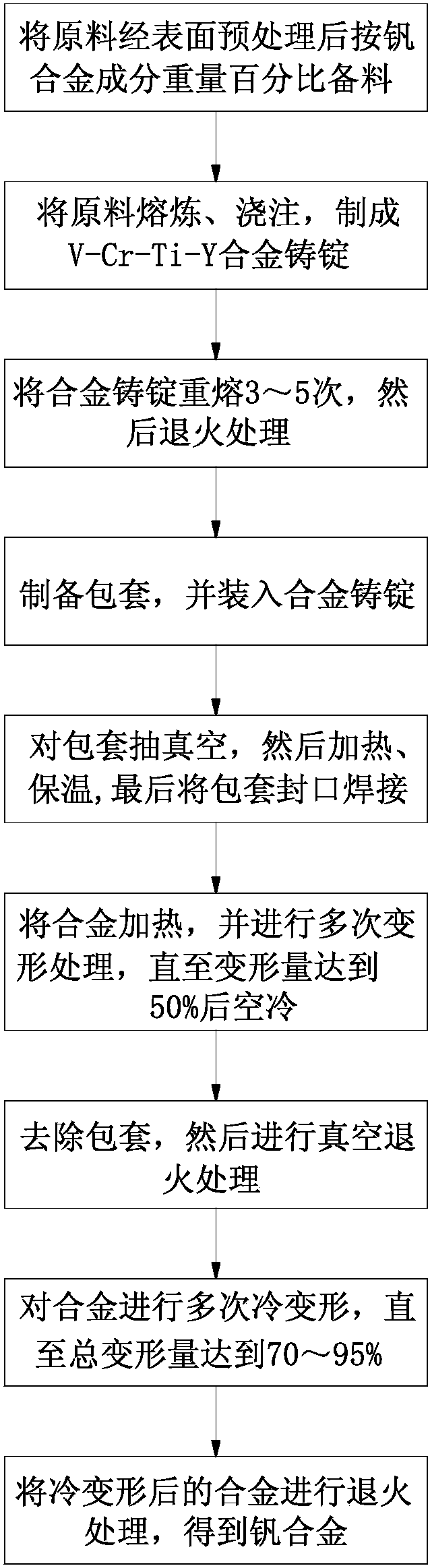

A kind of preparation method of anti-helium ion sputtering vanadium alloy

The invention discloses a novel helium ion sputtering-resistant vanadium alloy. The problem of low helium ion sputtering resistance of the prior art is solved. The alloy comprises the following components in percentage by weight: 3.0 to 6.5 percent of Cr, 3.0 to 6.5 percent of Ti, 0.1 to 2.0 percent of Y and the balance of V. In addition, the invention further provides a method for preparing the alloy. According to the vanadium alloy, on the basis of a V-Cr-Ti ternary alloy system, Cr and Ti are employed as main alloy elements, the rare earth element Y is added to reduce the content of solid solution oxygen in the vanadium alloy and reduce the dimensions of ingot crystals by virtue of a simple alloying means, and a plastic deformation machining means is combined to disperse and distribute yttrium oxide with stable high-temperature performance on a substrate and remarkably reduce and uniformize the dimensions of the annealed alloy crystals, thereby improving the toughness of the alloy and greatly enhancing the helium ion sputtering resistance of the alloy.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

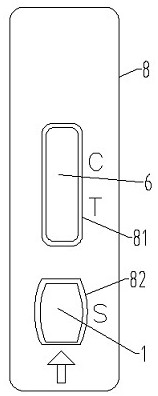

Detection card for identifying, diagnosing and detecting avian influenza virus infection and vaccine immunity and preparation method thereof

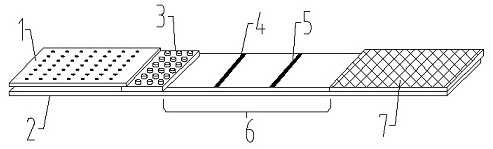

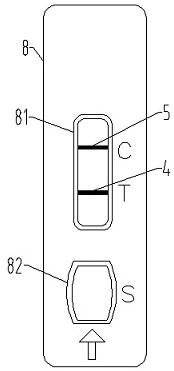

The invention belongs to the technical field of biological detection.The invention discloses an avian influenza virus infection and vaccine immunity differential diagnosis detection card and a preparation method. The avian influenza virus infection and vaccine immunity differential diagnosis detection card comprises a shell and a sample diluent used in cooperation with the shell, and a test strip is assembled in the shell and comprises a PVC bottom plate; wherein a sample pad, a marking pad, a coating film and a water absorption pad are pasted on the PVC bottom plate, and the kit is characterized in that the marking pad is a glass cellulose film and is coated with a coupling marker of a mouse anti-chicken IgG monoclonal antibody and latex microspheres; the coating membrane is a nitrocellulose membrane, and a detection line coated with purified avian influenza NS1 protein and a quality control line coated with purified recombinant streptococcus G protein are coated on the coating membrane. The kit can identify and diagnose antibodies generated by avian influenza virus infection and vaccine immunization, has good specificity and convenience, and can well identify avian influenza infected chicken flocks.

Owner:SHANDONG VOCATIONAL ANIMAL SCI & VETERINARY COLLEGE

Synthetic method for one-dimensional single crystal bismuth oxide nano material

InactiveCN101311360BLarge specific surface areaNo pollution in the processPolycrystalline material growthFrom normal temperature solutionsThermal insulationRoom temperature

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

SiC/PyC nanowire reinforced Al2O3 high-temperature-resistant wave-absorbing ceramic and preparation method thereof

InactiveCN114195539AImprove electromagnetic parametersHigh chemical purityCeramicwareNanowireGraphite

The SiC / PyC nanowire reinforced Al2O3 high-temperature-resistant wave-absorbing ceramic is composed of an Al2O3 porous ceramic matrix, a graphene interface and SiC / PyC nanowires, the Al2O3 porous ceramic is adopted as the matrix, the graphene interface and the SiC / PyC nanowires are deposited on a framework of the Al2O3 porous ceramic to form a porous structure type wave-absorbing material, and the SiC / PyC nanowire reinforced Al2O3 high-temperature-resistant wave-absorbing ceramic has the characteristics of light weight and high strength, can stably serve in a high-temperature environment, and can be used as a high-temperature-resistant wave-absorbing material. The high-temperature wave-absorbing composite material has the advantages that high-temperature wave-absorbing characteristic application is achieved, electromagnetic parameters of the composite material are optimized due to introduction of the graphene interface and the SiC / PyC nanowires, good impedance matching and attenuation coefficients can be obtained, and accordingly excellent wave-absorbing performance is obtained. Besides, Al2O3 porous ceramic is used for providing a porous structure, a graphene interface and SiC / PyC nanowires are introduced through a chemical vapor deposition method, the interface bonding force is high, the chemical purity is high, the preparation process is good in repeatability, and a new thought can be provided for large-scale production of the three-dimensional structure composite wave-absorbing material.

Owner:王云

A method of chemical dealloying to prepare Cu micro-nano sheet structure

ActiveCN107398554BImprove efficiencyShort manufacturing timeAdditive manufacturing apparatusTransportation and packagingMicro nanoAlloy

The invention discloses a method for preparing Cu micro-nano flake structure by chemical dealloying, comprising the following steps: (1) additively manufacturing Cu-Ni-Fe metastable eutectic structure: pure Cu, pure Ni and pure Fe After the powders are mixed in an atomic ratio of 17-18:17-18:62-68, the Cu-Ni-Fe metastable eutectic structure is prepared by an additive manufacturing system; (2) dealloying: the obtained The Cu-Ni-Fe metastable eutectic structure was placed in a 0.03-0.07mol / L nitric acid solution, and placed at room temperature for 2-8 hours to carry out chemical dealloying; (3) Cleaning and drying: after the obtained dealloying The Cu-Ni-Fe metastable eutectic structure was taken out, soaked and cleaned with deionized water and alcohol in turn, and dried to obtain a Cu micro-nano sheet-like structure. The preparation method obtains a Cu-Ni-Fe metastable structure through an additive manufacturing system, and uses a simple chemical dealloying method to prepare a Cu micro-nano flake structure, which provides a new technical approach for the preparation of complex metal micro-nano structures.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

High-dielectric-strength potassium sodium niobate based lead-free piezoelectric ceramic as well as preparation method and application thereof

ActiveCN102390997BThe method is universal and simpleGood process repeatabilityFixed capacitor dielectricElectricityBarium strontium titanate

The invention discloses potassium sodium niobate based lead-free piezoelectric ceramic, which is characterized by having a chemical formula of [(Na0.5+xK0.5-x)0.94Li0.06][(Nb0.94Sb0.06)0.95Ta0.05]O3+ymol%TM+zmol%RE, wherein TM is MnO2, Fe2O3 or Ni2O3, RE is CeO2 or Nd2O3, the value of x is 0 or 0.01-0.11, the value of y is 0.02-0.12, and the value of z is 0-0.05. The invention further discloses a preparation method application of the ceramic. The ceramic disclosed by the invention maintains an excellent piezoelectric ferroelectric property, simultaneously has a high withstand voltage performance, has very good withstand voltage performance and temperature stability, and still maintains very high withstand voltage strength at the high temperature of 140 DEG C. The voltage withstand performance of the material is obviously superior to that of the commonly used barium strontium titanate (BST) based high-voltage ceramic capacitor material, and the withstand voltage value of the material at normal temperature is 1.7 times more than that of a BST material.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

A kind of high hardness alcrn nanocomposite coating and its preparation technology

ActiveCN106893986BHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingHardnessCemented carbide

The invention relates to a nanocomposite coating and a preparation technology of the nanocomposite coating, in particular to a preparation process for a high-Al-content AlCrN nanocomposite coating. The AlCrN nanocomposite coating is prepared on a metal or cemented carbide substrate by the adoption of an electric arc ion plating technology. Pure metal Al and Cr are used as targets, and the content of Al and Cr in the coating is adjusted and controlled by controlling the current of the Al targets and the Cr targets. The four pure Cr targets and the four pure Al targets are evenly distributed on the inner wall of a furnace body at intervals. Ar gas is introduced firstly before film plating, the bias pressure of 600-1,000 V is adopted, glow cleaning is conducted on the substrate for 10-20 min, then the Cr targets are opened, bombardment cleaning is conducted on the substrate, the bias pressure is gradually lowered to 30-100 V, and the metal Cr layer is deposited. The preparation process of the AlCrN nanocomposite coating is simple, and industrial production is facilitated; and the prepared AlCrN coating has the high hardness and strength and good high-temperature and oxidation resistance and corrosion resistance.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

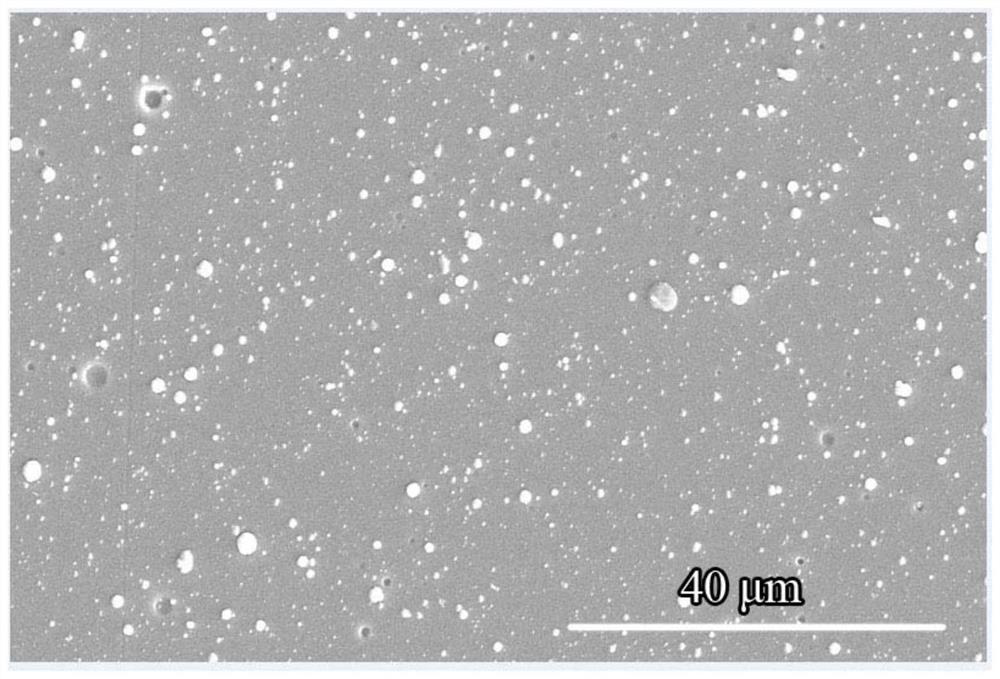

Craln nanometer gradient coating with high hardness and high binding force and its preparation process

ActiveCN110004409BCompact structureReduce particle countVacuum evaporation coatingSputtering coatingSputteringBinding force

The invention discloses a CrAlN nano-gradient coating with high hardness and high binding force and a preparation process thereof, belonging to the technical field of coating preparation. The CrAlN nano-gradient coating was prepared on the substrate by arc ion plating and magnetron sputtering composite plating technology. Ar gas was introduced before coating, and the substrate was glow-cleaned for 10-30 minutes with a bias voltage of -600-1000V. Then turn on the Cr target, and gradually reduce the bias voltage to -20 ~ -100V, deposit the metal Cr transition layer for 5 ~ 20min; 2 , keeping for 5-40min to deposit the CrN layer; turn on the Al target, increase the power of the Al target linearly, and deposit the CrAlN nanometer gradient coating with continuously changing composition. The CrAlN nano-gradient coating involved in the invention has compact structure, high hardness, high binding force with the substrate, simple preparation process, good repeatability, and easy industrial production.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

A kind of preparation method of water-based strontium hydroxyapatite colloidal liquid crystal

ActiveCN107746047BAbundant and easy to obtainGood repeatability of the preparation processMaterial nanotechnologyPhosphorus compoundsWater basedCritical transition

The invention relates to a preparation method of water-based strontium substituted hydroxyapatite colloidal liquid crystal. The method comprises the following steps that soluble strontium salt is dissolved in deionized water to form a solution A; soluble citrate is dissolved in deionized water to form a solution B; soluble phosphate is dissolved in deionized water to form a solution C; the solution B is dropwise added into the solution A; the mixed solution is stirred to form mixed liquid D; the solution C is dropwise added into the mixed liquid D; stirring is performed to form mixed liquid E;the mixed liquid E is poured into a sealed hydrothermal reactor; reaction is performed for 3 to 24h at 90 to 200 DEG C; then, natural cooling is performed to room temperature; centrifugation is performed by a high-speed centrifuge; obtained precipitates are alternately and centrifugally washed by deionized water and absolute ethyl alcohol; the washed precipitates are dispersed into the deionizedwater again; the pH is regulated; stable colloidal dispersion liquid is obtained; concentration is performed to the critical transition concentration or higher; the colloidal liquid crystal is obtained through preparation. The preparation method has the advantages that the raw materials are nontoxic and green; the resources are rich and can be easily obtained; the cost is low; the synthetic process is simple; the implementation is easy; the repeatability is good; the preparation method can be used in the fields of biomedical materials and the like.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com