High-dielectric-strength potassium sodium niobate based lead-free piezoelectric ceramic as well as preparation method and application thereof

A potassium-sodium niobate-based, lead-free piezoelectric technology, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, etc., can solve the problem of no withstand voltage characteristics, achieve high withstand voltage strength, good temperature stability, extremely The effect of easy chemical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

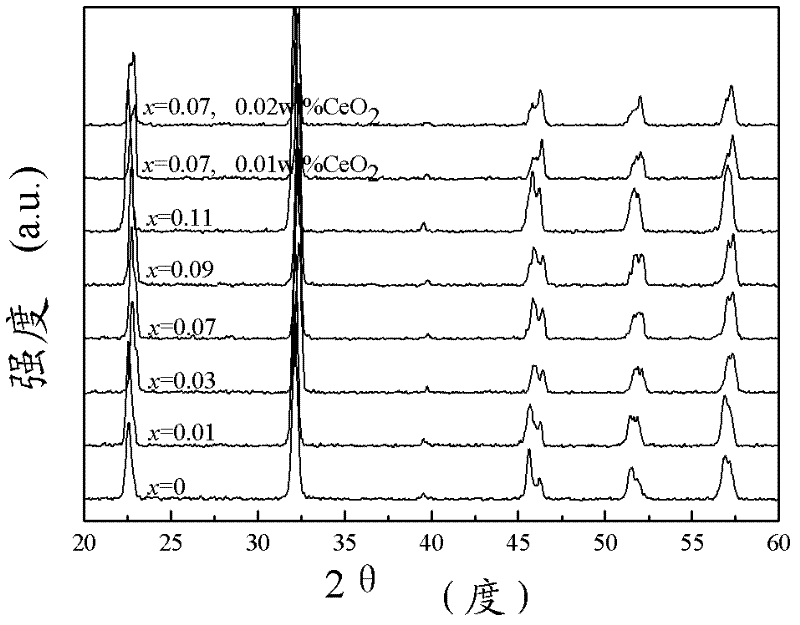

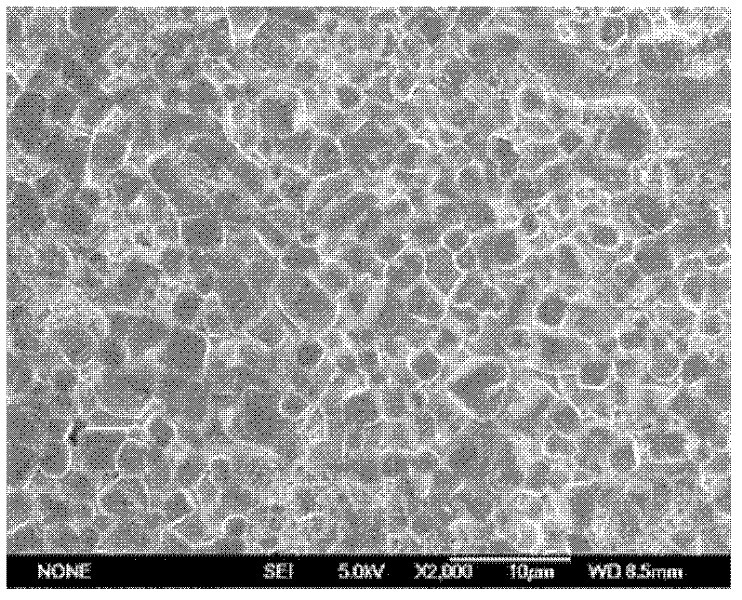

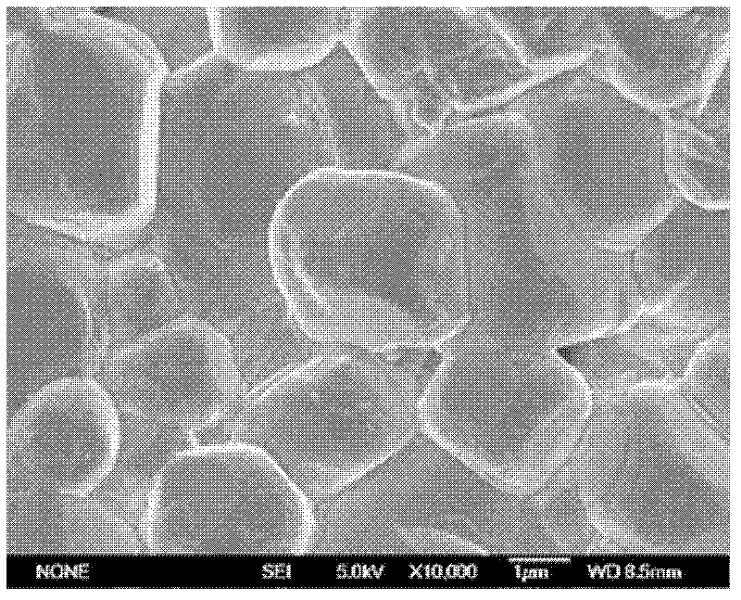

Image

Examples

Embodiment 1

[0043] The high withstand voltage potassium sodium niobate-based lead-free piezoelectric ceramic material provided in this example is prepared according to the following method:

[0044] (1), purchase chemically pure Na from the market 2 CO 3 、K 2 CO 3 , Li 2 CO 3 , Nb 2 o 5 , Sb 2 o 3 、 Ta 2 o 5 , MnO 2 As raw material, according to the chemical formula [(Na 0.5+x K 0.5-x ) 0.94 Li 0.06 ][(Nb 0.94 Sb 0.06 ) 0.95 Ta 0.05 ]O 3 +ymol%MnO 2 , where x=0, y=0.12 Weigh the raw materials; put the weighed raw materials into the ball mill jar, add the dehydrated alcohol accounting for 80% of the total weight of the above raw materials, and mix them at a speed of 140r / min on the planetary ball mill And grind for 2h;

[0045] (2), put the mixed material after ball milling in the crucible after drying at 60°C, pre-burn at 890°C, and keep it for 3.5h; After water ethanol, grind at a speed of 140r / min for 4h;

[0046] (3), dry the finely ground pre-fired synthetic po...

Embodiment 2

[0051] The high withstand voltage potassium sodium niobate-based lead-free piezoelectric ceramic material provided in this example is prepared according to the following method:

[0052] (1), purchase chemically pure Na from the market 2 CO 3 、K 2 CO 3 , Li 2 CO 3 , Nb 2 o 5 , Sb 2 o 3 、 Ta 2 o 5 , MnO 2 As raw material, according to the chemical formula [(Na 0.5+x K 0.5-x ) 0.94 Li 0.06 ][(Nb 0.94 Sb 0.06 ) 0.95 Ta 0.05 ]O 3 +ymol%MnO 2 , wherein x=0.01, y=0.08 take the raw material; put the weighed raw material in the ball mill jar, add the dehydrated alcohol accounting for 90% of the total weight of the above raw material, and mix it on the planetary ball mill at a speed of 120r / min And grind for 3h;

[0053] (2), put the ball-milled mixture in a crucible after drying at 90°C, pre-fire at 920°C, and hold for 4 hours; the pre-fired synthetic powder is added with anhydrous powder accounting for 85% of the total weight of the powder After ethanol, grind ...

Embodiment 3

[0059] The high withstand voltage potassium sodium niobate-based lead-free piezoelectric ceramic material provided in this example is prepared according to the following method:

[0060] (1), purchase chemically pure Na from the market 2 CO 3 、K 2 CO 3 , Li 2 CO 3 , Nb 2 o 5 , Sb 2 o 3 、 Ta 2 o 5 , MnO 2 As raw material, according to the chemical formula [(Na 0.5+x K 0.5-x ) 0.94 Li 0.06 ][(Nb 0.94 Sb 0.06 ) 0.95 Ta 0.05 ]O 3 +ymol%MnO 2, wherein x=0.03, y=0.02 take the raw material; put the weighed raw material in the ball mill jar, add the dehydrated alcohol accounting for 100% of the total weight of the above raw material, and mix it on the planetary ball mill at a speed of 160r / min And grind for 1.5h;

[0061] (2), put the mixed material after ball milling in the crucible after drying at 65°C, pre-fire at 905°C, and keep it for 2.5h; After water ethanol, grind at a speed of 200r / min for 3h;

[0062] (3) Dry the finely ground pre-fired synthetic powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com