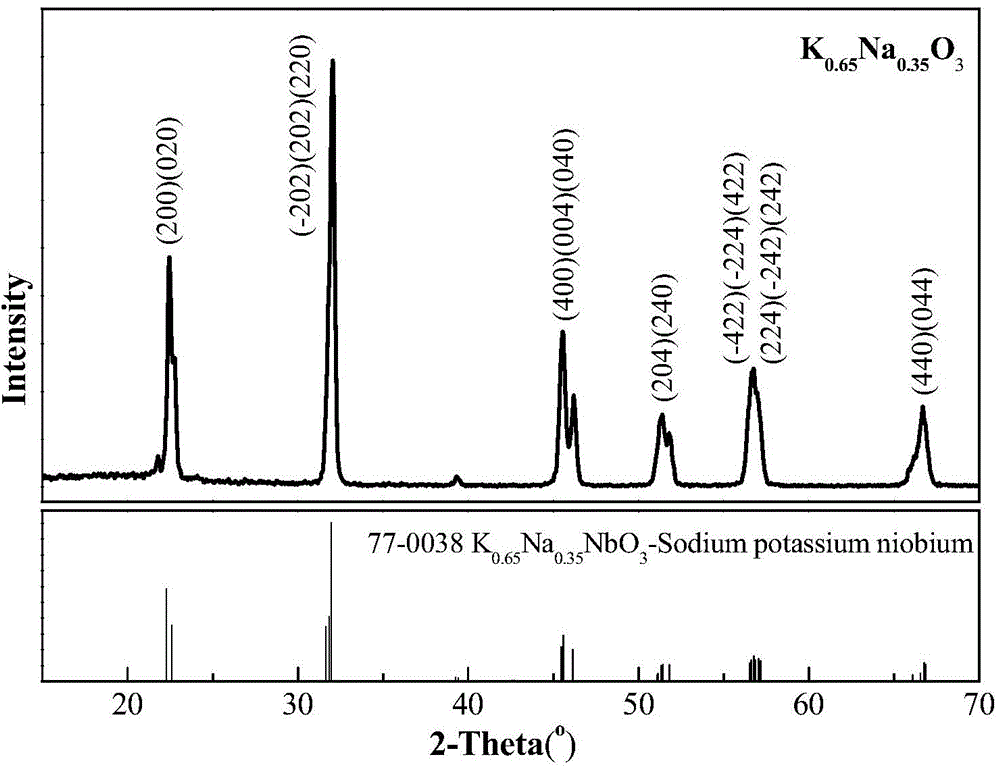

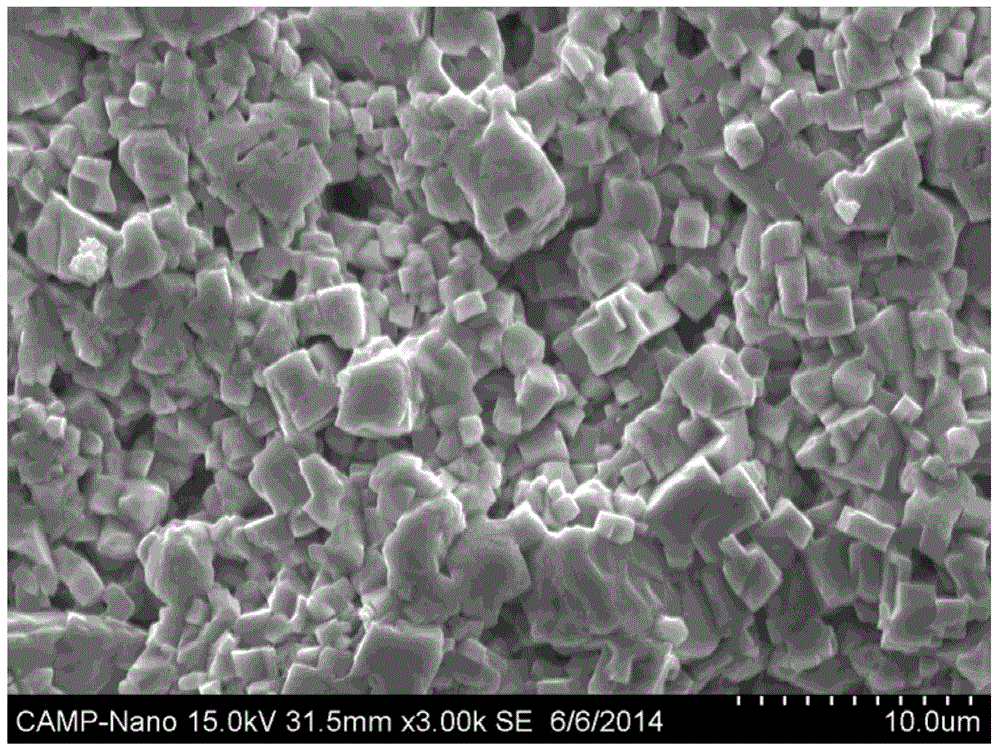

Method for synthetizing leadless piezoelectric ceramic K0.65Na0.35NbO3 powder adopting two-step hydrothermal method

A lead-free piezoelectric and hydrothermal synthesis technology, which is applied in the field of piezoelectric ceramic powder preparation, can solve the problems of large difference in bonding ability, inaccurate control, and inability to guarantee uniformity, and achieve uniform grain size, Guaranteed uniformity and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The first step, KNbO 3 , NaNbO 3 Synthesis of powder

[0034] (1) getting 20mL concentration is the potassium hydroxide solution of 3mol / L, getting 20mL concentration is the sodium hydroxide solution of 3mol / L;

[0035] (2) respectively add 0.03mol niobium pentoxide in potassium hydroxide solution, sodium hydroxide solution, make the mol ratio of potassium hydroxide and niobium pentoxide, sodium hydroxide and niobium pentoxide be 2:1; Using a magnetic stirrer, stir for 30min to form a homogeneous KNbO 3 Precursor, NaNbO 3 Precursor; KNbO 3 Precursor, NaNbO 3 The precursor solution was poured into different hydrothermal reaction kettles respectively, and the filling degree was controlled to be 90%. After sealing, it was placed in an incubator and kept at 180°C for 10 hours for hydrothermal synthesis;

[0036] (3) Cool to room temperature, take out the material in the hydrothermal reaction kettle, wash it with deionized water to neutrality, and then dry it at 70°C f...

Embodiment 2

[0041] The first step, KNbO 3 , NaNbO 3 Synthesis of powder

[0042] (1) getting 20mL concentration is the potassium hydroxide solution of 4mol / L, getting 20mL concentration is the sodium hydroxide solution of 4mol / L;

[0043] (2) respectively add 0.02mol niobium pentoxide in potassium hydroxide solution, sodium hydroxide solution, make the mol ratio of potassium hydroxide and niobium pentoxide, sodium hydroxide and niobium pentoxide be 4:1; Using a magnetic stirrer, stir for 40min to form a homogeneous KNbO 3 Precursor, NaNbO 3 Precursor; KNbO 3 Precursor, NaNbO 3 The precursor solution was poured into different hydrothermal reaction kettles respectively, and the filling degree was controlled to be 65%. After sealing, it was placed in an incubator and kept at 220°C for 8 hours for hydrothermal synthesis;

[0044] (3) Cool to room temperature, take out the material in the hydrothermal reaction kettle, wash it with deionized water to neutrality, and then dry it at 80°C fo...

Embodiment 3

[0049] The first step, KNbO 3 , NaNbO 3 Synthesis of powder

[0050] (1) getting 20mL concentration is the potassium hydroxide solution of 6mol / L, getting 20mL concentration is the sodium hydroxide solution of 6mol / L;

[0051] (2) respectively add 0.01mol niobium pentoxide in potassium hydroxide solution, sodium hydroxide solution, make the mol ratio of potassium hydroxide and niobium pentoxide, sodium hydroxide and niobium pentoxide be 12:1; Using a magnetic stirrer, stir for 50min to form a homogeneous KNbO 3 Precursor, NaNbO 3 Precursor; KNbO 3 Precursor, NaNbO 3 The precursor solution was poured into different hydrothermal reaction kettles respectively, and the filling degree was controlled to be 70%. After sealing, it was placed in an incubator and kept at 210°C for 6 hours for hydrothermal synthesis;

[0052] (3) Cool to room temperature, take out the material in the hydrothermal reaction kettle, rinse it with deionized water to neutrality, and then dry it at 90°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com