Craln nanometer gradient coating with high hardness and high binding force and its preparation process

A gradient coating and preparation process technology, applied in metal material coating technology, coating, nanotechnology, etc., can solve the problem of reducing the bonding force between the coating and the substrate, reducing the bonding force between the coating and the substrate, and increasing the coating The risk of delamination and other problems can be achieved, and the effects of high bonding force, high temperature thermal stability and corrosion resistance, high hardness and toughness can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

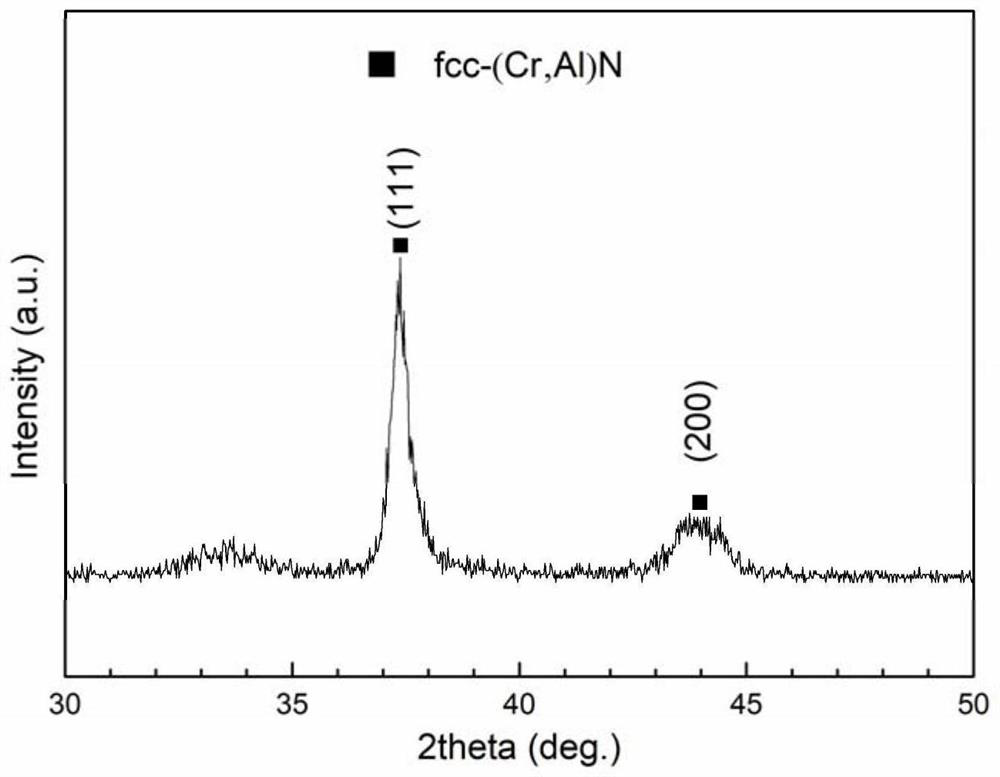

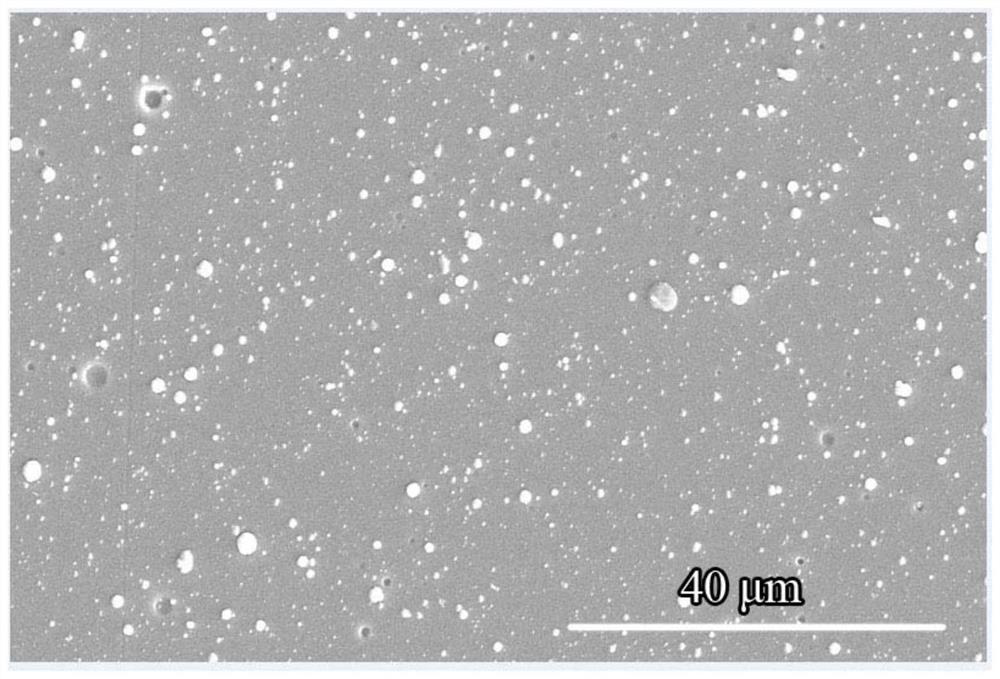

[0033] In this embodiment, a CrAlN nanometer gradient coating with continuously changing composition is deposited on a single-side polished Si wafer. The substrate was ultrasonically cleaned in acetone, alcohol and distilled water for 20 min, and then cleaned with high-purity N 2 Blow dry, place on the sample rack in the coating machine, the revolution speed of the turntable is selected as 40r / min, and the target base distance is 100mm. The targets are made of pure metal Cr and Al (99.99wt.% pure), and the working gas and reaction gas are made of high-purity Ar and N respectively. 2 (Purities are both 99.999%).

[0034] First, the background vacuum of the vacuum chamber is evacuated to 1.0×10 -3 Below Pa; turn on the heating system, raise the temperature to 400°C, and continue to evacuate until the pressure of the vacuum chamber reaches 9.0×10 -3 When Pa is lower than Pa, 200 sccm of Ar gas is introduced until the pressure in the coating chamber reaches 1.5 Pa, a negative b...

Embodiment 2

[0038] In this embodiment, a CrAlN nanometer gradient coating is deposited on a polished cemented carbide substrate YG8. The substrate was ultrasonically cleaned in acetone, alcohol and distilled water for 20 min, and then cleaned with high-purity N 2 Dry it, and then place it on the sample rack facing the target in the coating machine. The rotating speed of the turntable is selected as 40r / min, and the distance between the target and the base is 100mm. The targets are made of pure metal Cr and Al (both with a purity of wt.99.9%), and the working gas and reaction gas are made of Ar and N respectively. 2 (Purities are both 99.999%).

[0039] First, the background vacuum of the vacuum chamber is evacuated to 1.0×10 -3 Below Pa; turn on the heating system, raise the temperature to 400°C, and continue to evacuate until the pressure of the vacuum chamber reaches 9.0×10 -3 When Pa is lower than Pa, 200 sccm of Ar gas is introduced until the pressure in the coating chamber reaches...

Embodiment 3

[0043] In this embodiment, a CrAlN nanometer gradient coating is deposited on a YT15 cemented carbide indexable turning insert. The substrate was ultrasonically cleaned in acetone, alcohol and distilled water for 20 min, and then cleaned with high-purity N 2 Dry it, and then place it on the sample rack facing the target in the coating machine. The rotating speed of the turntable is selected as 40r / min, and the distance between the target and the base is 100mm. The targets are made of pure metal Cr and Al (both with a purity of wt.99.9%), and the working gas and reaction gas are made of Ar and N respectively. 2 (Purities are both 99.999%).

[0044] First, the background vacuum of the vacuum chamber is evacuated to 1.0×10 -3 Below Pa; turn on the heating system, raise the temperature to 400°C, and continue to evacuate until the pressure of the vacuum chamber reaches 9.0×10 -3 When Pa is lower than Pa, 200 sccm of Ar gas is introduced until the pressure in the coating chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com