Process method for synchronous heat treatment/magnetron sputtering of TiO2 film

A technology of magnetron sputtering and thin film technology, applied in sputtering plating, metal material coating technology, ion implantation plating, etc., can solve problems such as complex processes, achieve good repeatability, improve heat treatment efficiency, and improve antibacterial The effect of anti-mildew effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

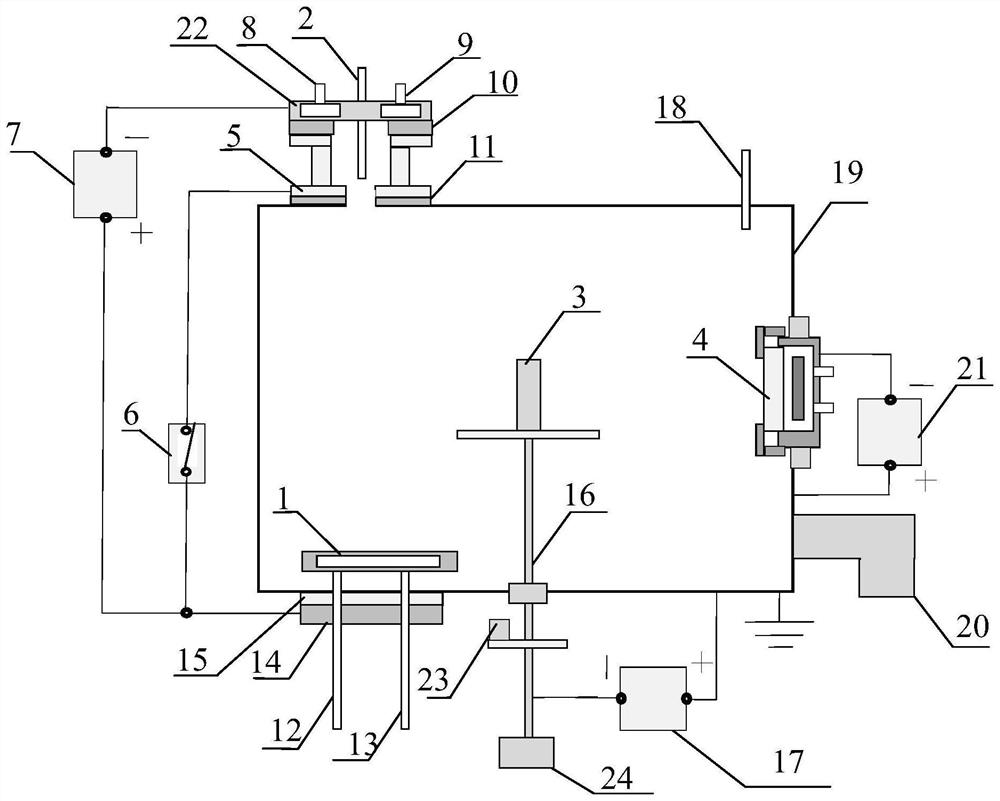

[0031] A synchronous heat treatment / magnetron sputtering TiO2 film process method, characterized in that: the substrate 3 is located in the center of the coating space and rotates, the plasma source anode 1 and the Ti target 4 are located on both sides of the substrate 3, and the TiO2 film is deposited The value and duration of the bias voltage change with the rotation position of the substrate, and the film deposition is completed under plasma heating and magnetron sputtering. The duration of the bias voltage on one side of the Ti target 4 is the rotation time of the substrate 3 within the range of 40° where the substrate 3 faces the Ti target 4; The rotation time of matrix 3 in ° range.

[0032] A kind of synchronous heat treatment / magnetron sputtering TiO2 thin film process method, comprises following preparation steps:

[0033] (1) The substrate 3 was cleaned in an oil cleaning agent at a temperature of 40-80°C for 30 minutes, then ultrasonically cleaned in acetone for 30...

Embodiment 2

[0040] A synchronous heat treatment / magnetron sputtering TiO2 film process method, characterized in that: the substrate 3 is located in the center of the coating space and rotates, the plasma source anode 1 and the Ti target 4 are located on both sides of the substrate 3, and the TiO2 film is deposited The value and duration of the bias voltage change with the rotation position of the substrate 3, and the film deposition is completed under plasma heating and magnetron sputtering. The duration of the bias on one side of the Ti target 4 is the rotation time of the substrate 3 within 100° of the substrate 3 facing the Ti target 4; The rotation time of the substrate 3 within the range of °; the rotation speed of the substrate 3 is 1 revolution / min.

[0041] A kind of synchronous heat treatment / magnetron sputtering TiO2 thin film process method, comprises following preparation steps:

[0042](1) The substrate 3 was cleaned in an oil cleaning agent at a temperature of 40-80°C for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com