A method of chemical dealloying to prepare Cu micro-nano sheet structure

A chemical dealloying and sheet-like structure technology, applied in the field of materials science and engineering, can solve the problems of difficult to realize the preparation of other complex metal micro-nano structures, limit the application of chemical dealloying method, etc., and achieve easy industrialized large-scale production and shorten the preparation time time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

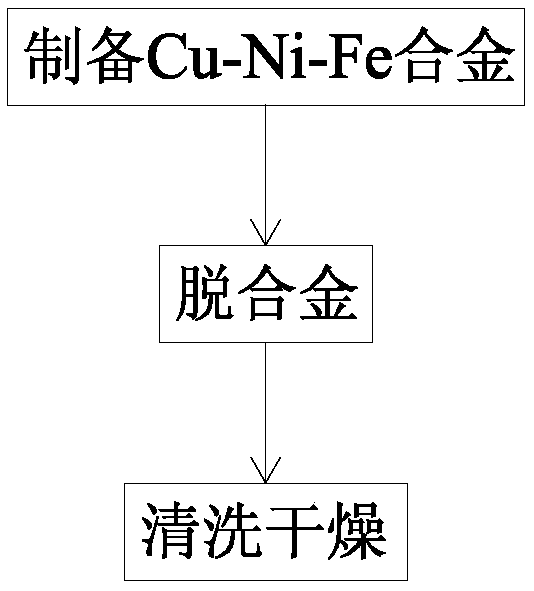

[0034] The method for preparing Cu micro-nano plate structure comprises the following steps:

[0035] (1) Additive manufacturing of Cu-Ni-Fe metastable eutectic structure: After mixing pure Cu, pure Ni and pure Fe powders at an atomic ratio of 17.5:17.5:65, when the water and oxygen content is lower than 10ppm 1. Under the protection of high-purity argon gas, the metastable eutectic structure of Cu-Ni-Fe was prepared by using the simultaneous powder feeding laser additive manufacturing system;

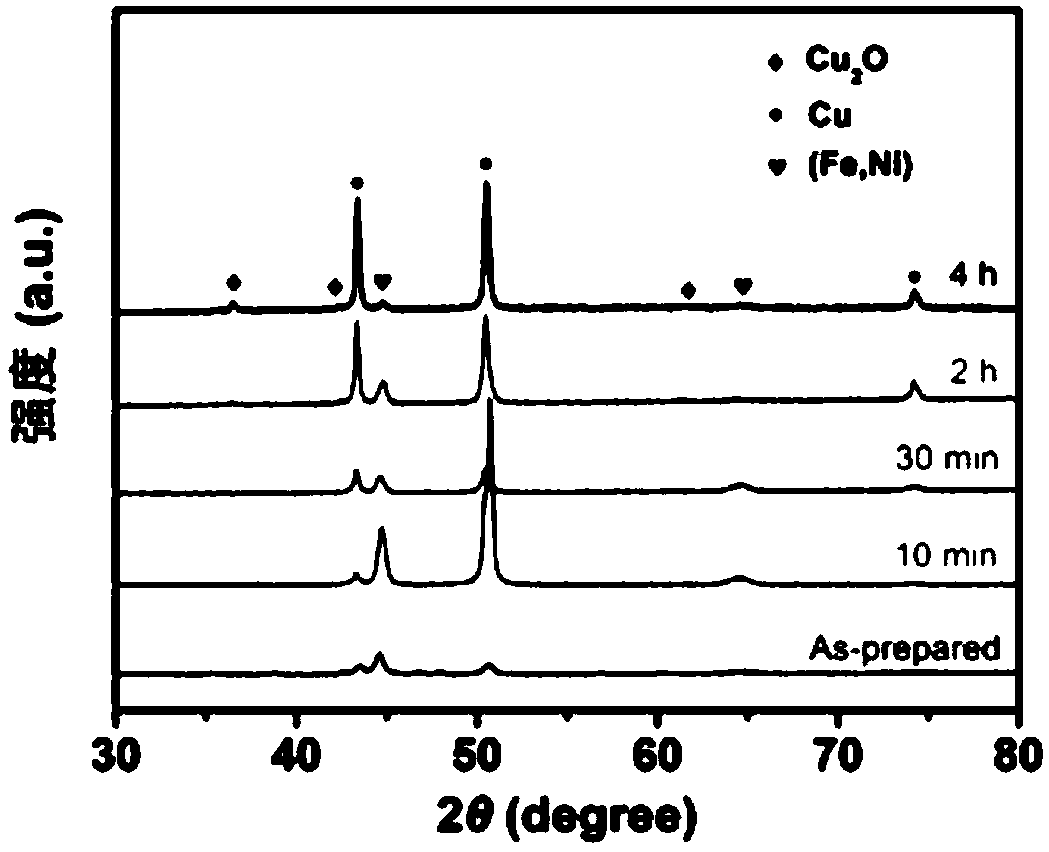

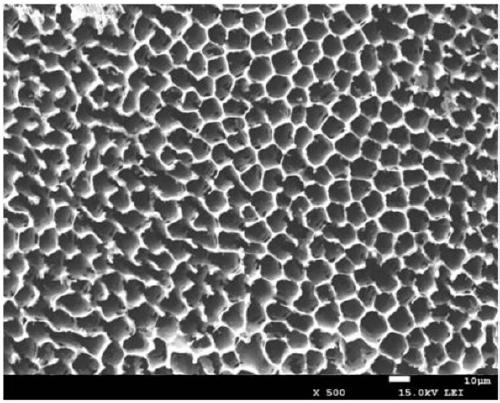

[0036] (2) Dealloying: first configure a nitric acid solution with a concentration of 0.05mol / L, then cut the Cu-Ni-Fe metastable eutectic structure obtained in step (1) into small pieces of 5mm×5mm×10mm, and place them in In the nitric acid solution, place it at room temperature for 4 hours to carry out chemical dealloying;

[0037] It is worth noting that in this process, the nitric acid solution should be slightly excessive, and then the final product is controlled by controlling t...

example 2

[0043] This example prepares the method for Cu micro-nano flake structure and comprises the following steps:

[0044](1) Additive manufacturing of Cu-Ni-Fe metastable eutectic structure: After mixing pure Cu, pure Ni and pure Fe powders at an atomic ratio of 17:17:62, the water oxygen content is lower than 10ppm 1. Under vacuum conditions, the metastable eutectic structure of Cu-Ni-Fe was prepared by using the additive manufacturing system with electron beam high energy as the energy source;

[0045] (2) Dealloying: Place the obtained Cu-Ni-Fe metastable eutectic structure in a 0.03mol / L nitric acid solution. After standing at room temperature for 6 hours, the nitric acid solution turns light yellow, that is, the chemical dealloying is completed. ;

[0046] (3) Cleaning and drying: take out the obtained dealloyed Cu-Ni-Fe metastable eutectic structure, first soak the obtained dealloyed Cu-Ni-Fe metastable eutectic structure with deionized water After cleaning for 3 times, so...

example 3

[0048] This example prepares the method for Cu micro-nano flake structure and comprises the following steps:

[0049] (1) Additive manufacturing of Cu-Ni-Fe metastable eutectic structure: After mixing pure Cu, pure Ni and pure Fe powders at an atomic ratio of 18:18:68, the water oxygen content is lower than 10ppm 1. Under the protection of high-purity argon gas, Cu-Ni-Fe metastable eutectic structure was prepared by using the additive manufacturing system with electron beam high energy as the energy source;

[0050] (2) Dealloying: Place the obtained Cu-Ni-Fe metastable eutectic structure in 0.07mol / L nitric acid solution. After standing at room temperature for 8 hours, the nitric acid solution turns light yellow, that is, the chemical dealloying is completed. ;

[0051] (3) Cleaning and drying: take out the obtained dealloyed Cu-Ni-Fe metastable eutectic structure, first soak the obtained dealloyed Cu-Ni-Fe metastable eutectic structure with deionized water After cleaning f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com