Preparation method of frequency-adjustable (SnO2/Sn/rGO) composite wave-absorbing material

A composite wave absorbing material and composite material technology, which are applied in the field of composite wave absorbing materials and their preparation, can solve the problems of undiscussed influence of thermal equilibrium properties/charge accumulation degree, complicated operation, etc., and achieve easy large-scale production, good repeatability, The effect of good absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Dissolve an appropriate amount of GO dispersion in 50mL deionized water until uniform;

[0019] (2) After adding 1mL KH-550 coupling agent, hydrothermal treatment at 180°C for 12h;

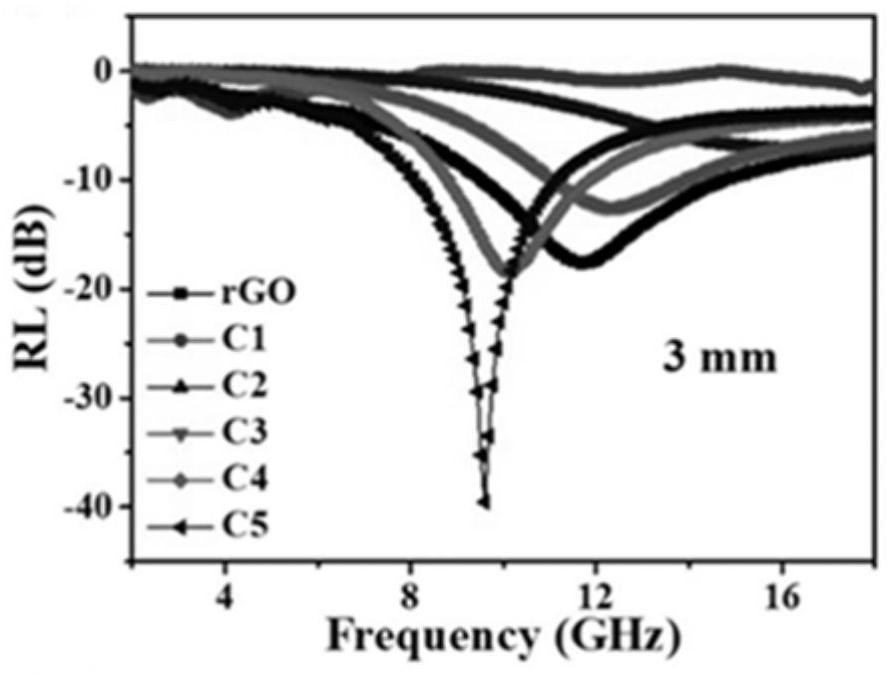

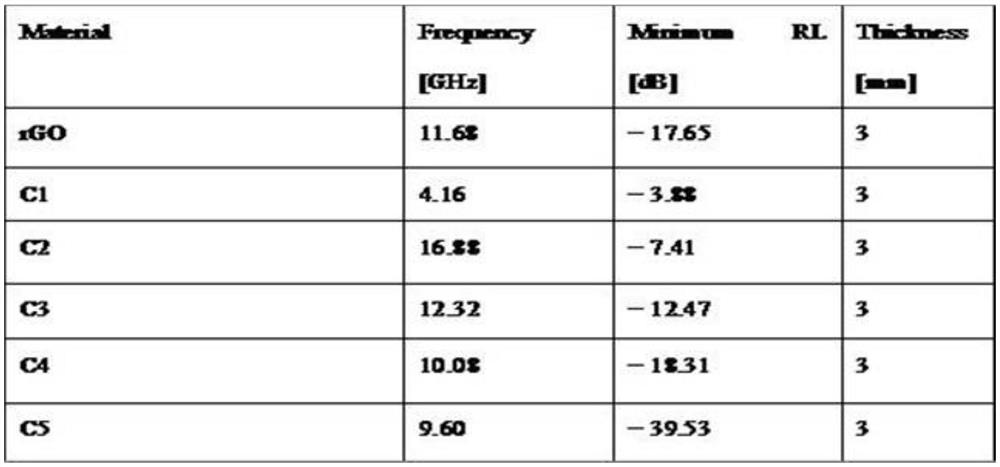

[0020] (3) Freeze-dried for 24 hours, calcined at 800°C for 2 hours in an argon atmosphere, and finally obtained rGO monomer. It was measured that its reflection loss RL value was –17.65dB (11.68GHz) when the thickness was 3mm, and it was effective in absorbing waves. The bandwidth is 5.28GHz (RL<-10dB).

Embodiment 2

[0022] (1) 11.2825g of SnCl 2 2H 2 Dissolve O in 10mL of absolute ethanol and stir for 30min; then place in 5mL of deionized water and stir for 1-2h until completely dissolved; add 4mL of tetraethyl orthosilicate (TEOS) to the above solution, stir well; seal at 70°C Aging for 2 days; after drying, soak the sample in NaOH solution (2mol / L) and stir for 30min, wash and filter, and dry at 60°C for 24h; after grinding, calcinate at 550°C, the heating rate is 10°C / min, and the holding time is 4h , to obtain nanoscale SnO 2 ;

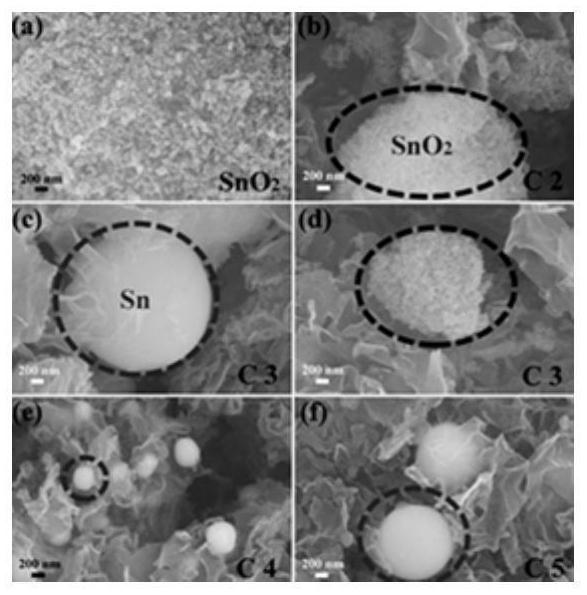

[0023] (2) 2g GO, 0.1g nano-SnO 2 Mix with 1ml KH-550 in 50ml deionized water, and obtain C1(SnO 2 / rGO) samples. It is measured that when the thickness is 3mm, the reflection loss RL value is -3.88dB (4.16GHz). Finally, calcined at 500 °C for 2 h under argon atmosphere to generate SnO 2 / rGO composite (C2). When the thickness is 3mm, the reflection loss RL value is -7.41dB (16.88GHz).

Embodiment 3

[0025] (1) Synthesize nanoscale SnO according to the method of step (1) in Example 2 2 , among them, SnCl 2 2H 2 O, the amount of absolute ethanol, deionized water and ethyl orthosilicate is 2mol, 10mL, 5mL and 4mL respectively, and the sealing aging temperature is 60°C;

[0026] (2) Synthesize SnO according to the method of step (2) in Example 2 2 / Sn / rGO composite material (C3), in which the calcination temperature is 600 ℃, the measured reflection loss RL value is -12.47dB (12.32GHz) when the thickness is 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Return loss | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com