Method for preparing Cu micro-nano sheet structure through chemical dealloying

A technology of chemical dealloying and flake structure, which is applied in the field of materials science and engineering, can solve the problems of limiting the application of chemical dealloying and the difficulty in preparing other complex metal micro-nano structures, so as to shorten the preparation time and facilitate large-scale industrialization The effect of easy production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

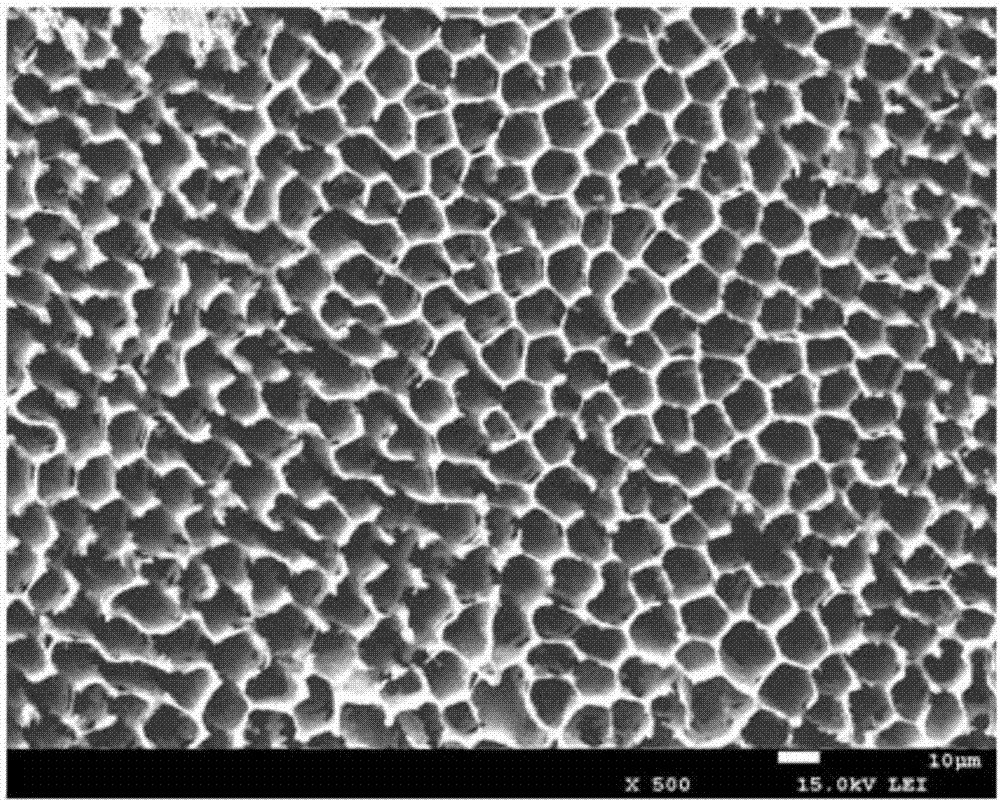

[0034] The method for preparing Cu micro-nano plate structure comprises the following steps:

[0035] (1) Additive manufacturing of Cu-Ni-Fe metastable eutectic structure: After mixing pure Cu, pure Ni and pure Fe powders at an atomic ratio of 17.5:17.5:65, when the water and oxygen content is lower than 10ppm 1. Under the protection of high-purity argon gas, the metastable eutectic structure of Cu-Ni-Fe was prepared by using the simultaneous powder feeding laser additive manufacturing system;

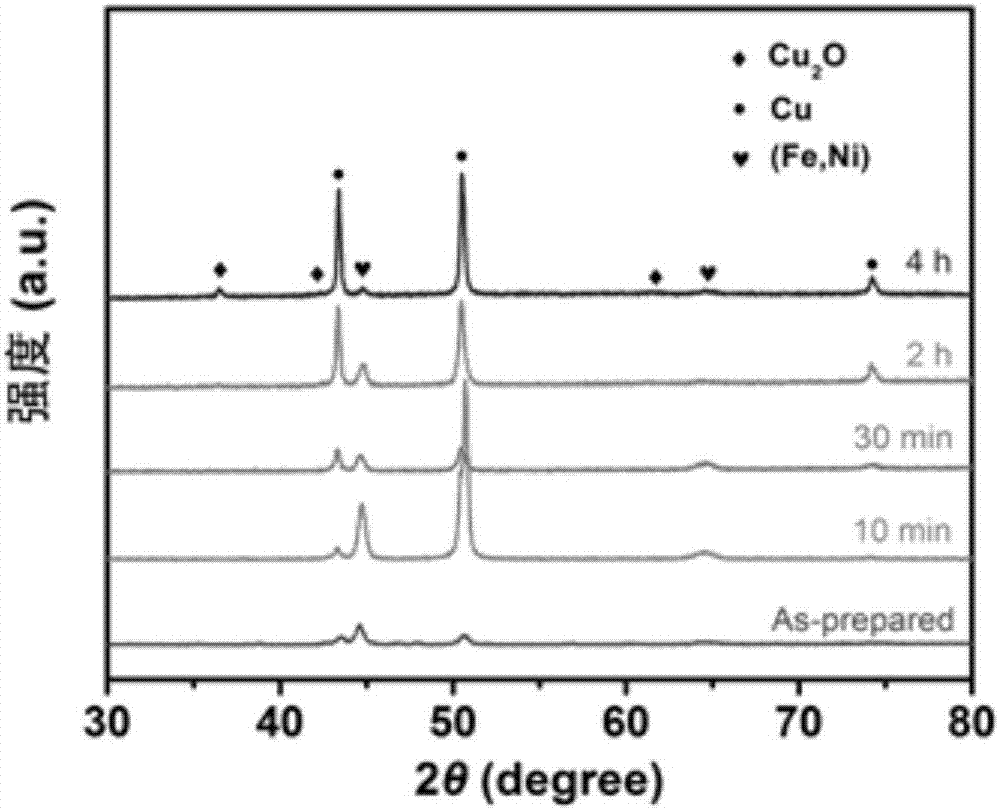

[0036] (2) Dealloying: first configure a nitric acid solution with a concentration of 0.05mol / L, then cut the Cu-Ni-Fe metastable eutectic structure obtained in step (1) into small pieces of 5mm×5mm×10mm, and place them in In the nitric acid solution, place it at room temperature for 4 hours to carry out chemical dealloying;

[0037] It is worth noting that in this process, the nitric acid solution should be slightly excessive, and then the final product is controlled by controlling t...

example 2

[0043] This example prepares the method for Cu micro-nano flake structure and comprises the following steps:

[0044](1) Additive manufacturing of Cu-Ni-Fe metastable eutectic structure: After mixing pure Cu, pure Ni and pure Fe powders at an atomic ratio of 17:17:62, the water oxygen content is lower than 10ppm 1. Under vacuum conditions, the metastable eutectic structure of Cu-Ni-Fe was prepared by using the additive manufacturing system with high electron beam energy as the energy source;

[0045] (2) Dealloying: Place the obtained Cu-Ni-Fe metastable eutectic structure in 0.03mol / L nitric acid solution. After 6 hours at room temperature, the nitric acid solution turns light yellow, which means chemical dealloying is completed. ;

[0046] (3) Cleaning and drying: take out the obtained dealloyed Cu-Ni-Fe metastable eutectic structure, first soak the obtained dealloyed Cu-Ni-Fe metastable eutectic structure with deionized water After cleaning for 3 times, soak and wash with...

example 3

[0048] This example prepares the method for Cu micro-nano plate structure and comprises the following steps:

[0049] (1) Additive manufacturing of Cu-Ni-Fe metastable eutectic structure: After mixing pure Cu, pure Ni and pure Fe powders at an atomic ratio of 18:18:68, the water oxygen content is lower than 10ppm 1. Under the protection condition of high-purity argon gas, the Cu-Ni-Fe metastable eutectic structure was prepared by using the additive manufacturing system with electron beam high energy as the energy source;

[0050] (2) Dealloying: Place the obtained Cu-Ni-Fe metastable eutectic structure in a 0.07mol / L nitric acid solution. After standing at room temperature for 8 hours, the nitric acid solution turns light yellow, that is, the chemical dealloying is completed. ;

[0051] (3) Cleaning and drying: take out the obtained dealloyed Cu-Ni-Fe metastable eutectic structure, first soak the obtained dealloyed Cu-Ni-Fe metastable eutectic structure with deionized water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com