GaN-based laser and method for measuring AlGaN/GaN superlattice resistivity

A laser and superlattice technology, applied in lasers, laser components, semiconductor lasers, etc., can solve problems such as limiting the development of GaN-based laser technology, large impact differences, and difficulty in optimizing AlGaN/GaN superlattice structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

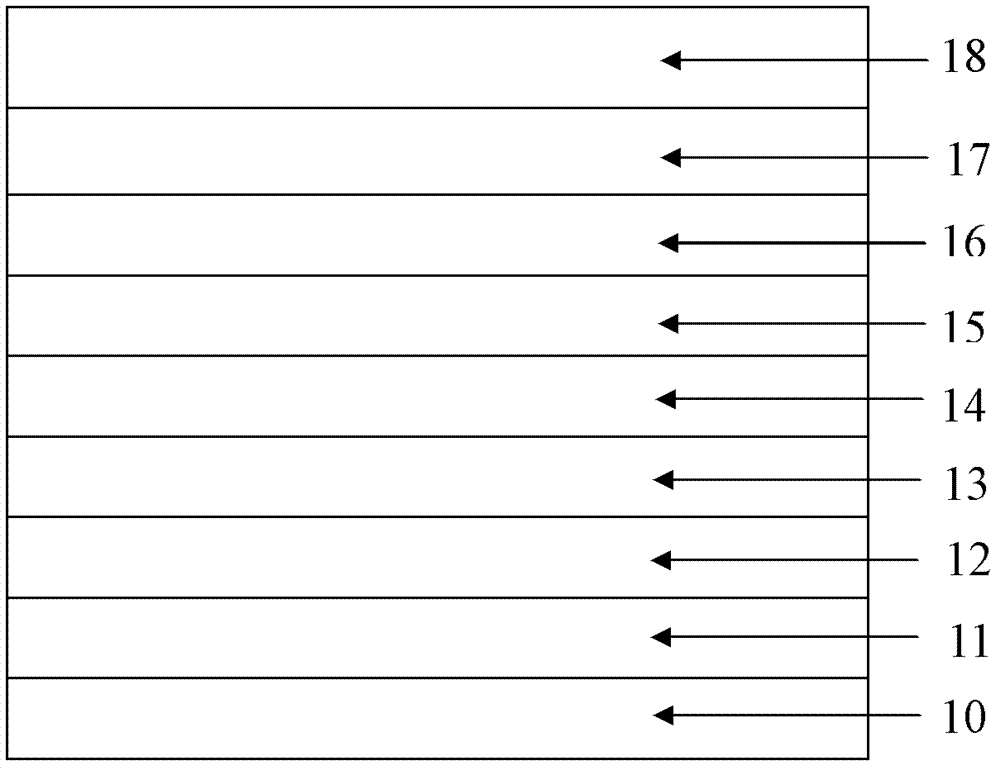

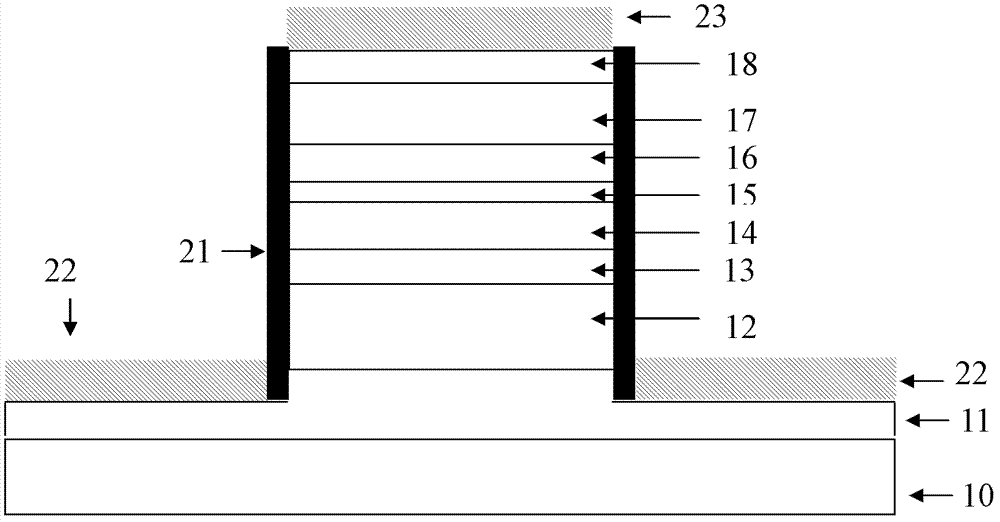

[0075] In order to further illustrate the effect of the device structure, we take a GaN-based laser with an operating wavelength of 405nm as an example to illustrate the preparation process of the device structure. The material and thickness of each layer are shown in Table 1. The details are as follows: the device structure is grown on the (0001) plane sapphire substrate 10 by MOCVD method. The structure includes an n-type ohmic contact layer 11 (thickness is 3.0 μm, doping concentration is 6.5×10 15 cm -3 ), n-type Al 0.2 Ga 0.8 N / GaN superlattice lower confinement layer 12 (thickness is 1.10 μ m, GaN well width is 2.0 nm, Al 0.2 Ga 0.8 N barrier width is 2.0nm, doping concentration is 3.0×10 18 cm -3 ), n-type GaN lower waveguide layer 13 (thickness is 0.08 μm, doping concentration is 5.0×10 15 cm -3 ), In 0.15 Ga 0.85 N / GaN active region layer 14 (multiple quantum wells are 5 periods, InGaN well width is 3nm, GaN barrier width is 8nm, doping concentration is 3.0...

Embodiment 2

[0078] In order to further illustrate the effect of the device structure, we take a GaN-based laser with an operating wavelength of 405nm as an example to illustrate the preparation process of the device structure. The material and thickness of each layer are shown in Table 2. The details are as follows: the device structure is grown on the (0001) plane sapphire substrate 10 by MOCVD method. The structure includes an n-type ohmic contact layer 11 (thickness is 3.0 μm, doping concentration is 6.5×10 15 cm -3 ), n-type Al 0.2 Ga 0.8 N / GaN superlattice lower confinement layer 12 (thicknesses of the layers in the two epitaxial wafers are 0.3 μm and 1.1 μm respectively, Ga N well width is 2.0 nm, Al 0.2 Ga 0.8 N barrier width is 2.0nm, doping concentration is 3.0×10 18 cm -3 ), n-type GaN lower waveguide layer 13 (thickness is 0.08 μm, doping concentration is 5.0×10 15 cm -3 ), In 0.15 Ga 0.85 N / GaN active region layer 14 (multiple quantum wells are 5 periods, InGaN well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com