Self-lubricating wear-resistant AlCrN/MoS2 nanometer composite film and preparation method thereof

A nano-composite, wear-resistant technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem of low deposition rate, achieve low friction coefficient, good chemical stability, and enhance wear resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

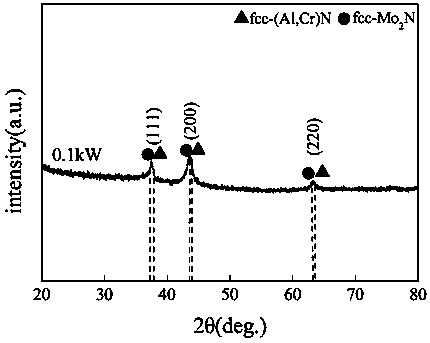

Image

Examples

Embodiment 1

[0037] In this embodiment, a high-power pulsed magnetron sputtering and pulsed DC magnetron sputtering composite coating system is used to deposit AlCrN / MoS 2 film. The specific operation steps are as follows:

[0038] (1) The substrate was ultrasonically cleaned in acetone and alcohol solutions for 30 minutes, and then cleaned with high-purity N 2 (purity is 99.999%) blow dry, and then fix the substrate on the turntable in the coating chamber.

[0039] (2) AlCr alloy target connected to high power pulsed magnetron sputtering power supply, MoS 2 The target is connected to the pulsed DC magnetron sputtering power supply; the background vacuum is pumped to 3.0×10 -3 Above Pa, then heat the substrate to 300°C, then apply -780V bias, pass Ar (purity 99.999%) into the vacuum chamber, the flow rate is 110sccm, control the throttle valve to maintain the working pressure at 1.1Pa, glow discharge Wash for 10 minutes to remove impurities on the surface of the substrate.

[0040] ...

Embodiment 2

[0051] In this example, a composite coating system of high-power pulsed magnetron sputtering and pulsed DC magnetron sputtering is used to deposit AlCrN / MoS 2 film. The specific operation steps are as follows:

[0052] (1) The substrate was ultrasonically cleaned in acetone and alcohol solutions for 30 minutes, and then cleaned with high-purity N 2 Blow dry, and then fix the substrate on the turntable in the vacuum coating chamber.

[0053] (2) Connect AlCr alloy target to high power pulsed magnetron sputtering power supply, MoS 2 The target is connected to the pulsed DC magnetron sputtering power supply; the background vacuum is higher than 3.0×10 -3 Pa, then heat the substrate to 300°C, apply a bias voltage of -785V, feed Ar into the vacuum chamber with a flow rate of 150 sccm, adjust the throttle valve to maintain the working pressure at 1.2 Pa, and glow clean for 10 minutes to remove impurities on the surface of the substrate.

[0054] (3) Adjust the Ar flow rate to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com