Preparation method of water-based strontium substituted hydroxyapatite colloidal liquid crystal

A strontium hydroxyapatite, liquid crystal technology, applied in chemical instruments and methods, phosphorus compounds, nanotechnology for materials and surface science, etc., to achieve the effects of low cost, abundant sources and easy availability, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

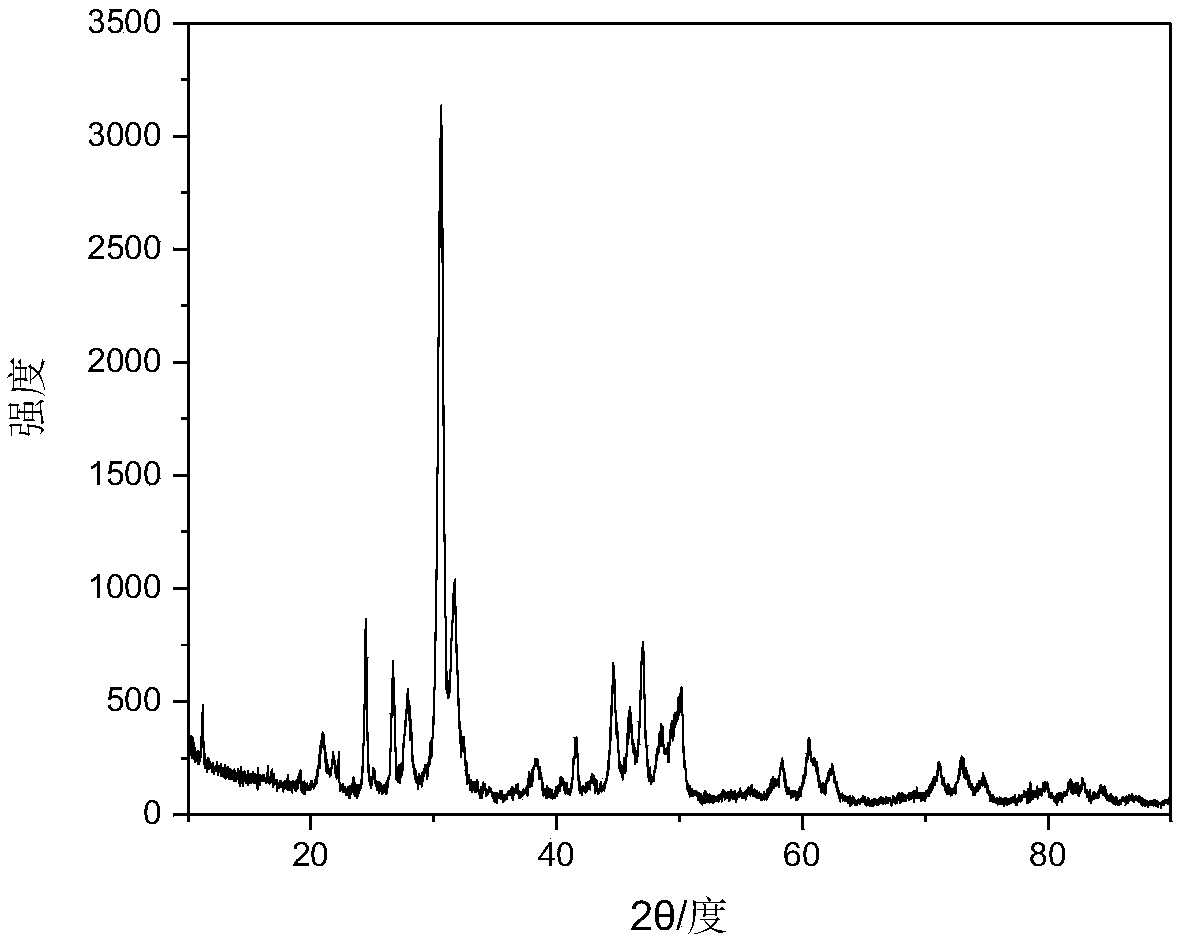

Image

Examples

Embodiment 1

[0028] 1) 0.01mol of strontium nitrate was dissolved in 10 grams of deionized water to form solution A;

[0029] 2) 0.005mol potassium citrate was dissolved in 10 grams of deionized water to form solution B;

[0030] 3) Dissolving 0.006mol of sodium phosphate in 10 grams of deionized water to form solution C;

[0031] 4) Add the solution B obtained in step 2) to the solution A obtained in step 1) dropwise at room temperature, and fully stir for 15 minutes to form a mixed solution D;

[0032] 5) Add the solution C obtained in step 3) to the mixed solution D obtained in step 4) dropwise at room temperature, and fully stir for 15 minutes to form the mixed solution E;

[0033] 6) Transfer the mixed solution E obtained in step 5) to a closed hydrothermal reactor, react at 90° C. for 24 hours, and then naturally cool to room temperature to obtain a reaction solution;

[0034] 7) Use a high-speed centrifuge to centrifuge the reaction solution in step 6) to obtain a precipitate, and...

Embodiment 2

[0036] Embodiment 2, with embodiment 1, the difference is,

[0037] 1) 0.01mol of strontium nitrate was dissolved in 10 grams of deionized water to form solution A;

[0038] 2) 0.005mol potassium citrate was dissolved in 10 grams of deionized water to form solution B;

[0039] 3) Dissolving 0.006moll of ammonium phosphate in 10 grams of deionized water to form solution C;

[0040] 6) Transfer the mixed solution E obtained in step 5) to a closed hydrothermal reactor, react at 120° C. for 18 hours, and then naturally cool to room temperature to obtain a reaction solution;

[0041] 7) Use a high-speed centrifuge to centrifuge the reaction solution in step 6) to obtain a precipitate, and use deionized water and absolute ethanol to alternately centrifuge and wash three times to remove excess electrolyte in the system, then redisperse in deionized water, and adjust the pH to 8.5 , to obtain a stable strontium hydroxyapatite colloidal dispersion;

[0042] The concentration of the ...

Embodiment 3

[0043] Embodiment 3, with embodiment 1, the difference is,

[0044] 1) 0.01mol of strontium nitrate was dissolved in 10 grams of deionized water to form solution A;

[0045] 2) 0.005mol ammonium citrate was dissolved in 10 grams of deionized water to form solution B;

[0046] 3) Dissolving 0.006moll potassium phosphate in 10 grams of deionized water to form solution C;

[0047] 6) Transfer the mixed solution E obtained in step 5) to a closed hydrothermal reactor, react at 150° C. for 12 hours, and then naturally cool to room temperature to obtain a reaction solution;

[0048] 7) Use a high-speed centrifuge to centrifuge the reaction solution in step 6) to obtain a precipitate, then use deionized water and absolute ethanol to alternately centrifuge and wash three times to remove excess electrolyte in the system, then redisperse in deionized water, and adjust the pH to 9.0 , to obtain a stable strontium hydroxyapatite colloidal dispersion;

[0049] The concentration of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com