Patents

Literature

31results about How to "Small sintering shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of multilayer semitransparent zirconia full-porcelain dental repair material

InactiveCN103121840AHigh molding densitySmall sintering shrinkageChemical compositionRepair material

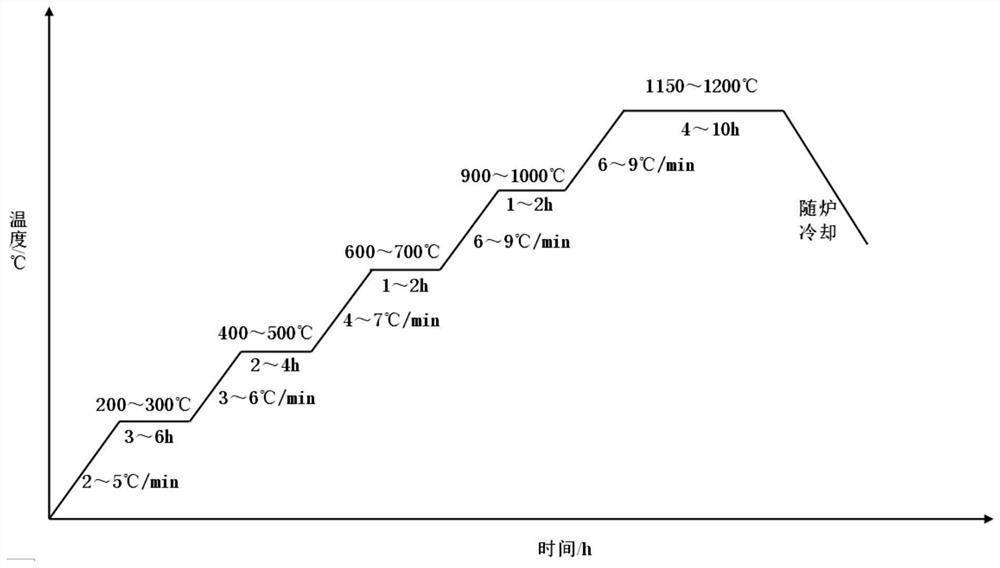

The invention belongs to the field of porcelain materials and preparation thereof, and in particular relates to a multilayer semitransparent zirconia full-porcelain dental repair material and a preparation method thereof. The material comprises the chemical ingredients such as magnesium oxide and part stable square-phase zirconia, wherein the molecular contents of the magnesium oxide and the zirconia are respectively 2-10% and 90-98%; the part stable square-phase zirconia is added with a modifying agent to be modified, wherein the molar ratio of the modifying agent and the part stable square-phase zirconia is 1: (0.01-0.1); and a coloring agent is added into the modified zirconia repair material, and the coloring agent and the modified zirconia repair material respectively account for 0.1-1% and 99-99.9%. The method comprises the following steps of power preparing, mixing and granulating, two-step forming, plastic discharging and sintering. Compared with the prior art, the material has the advantages of good producing technology repeatability, stable quality, reliable performance and convenience in production.

Owner:ZXTGY BEIJING TECH

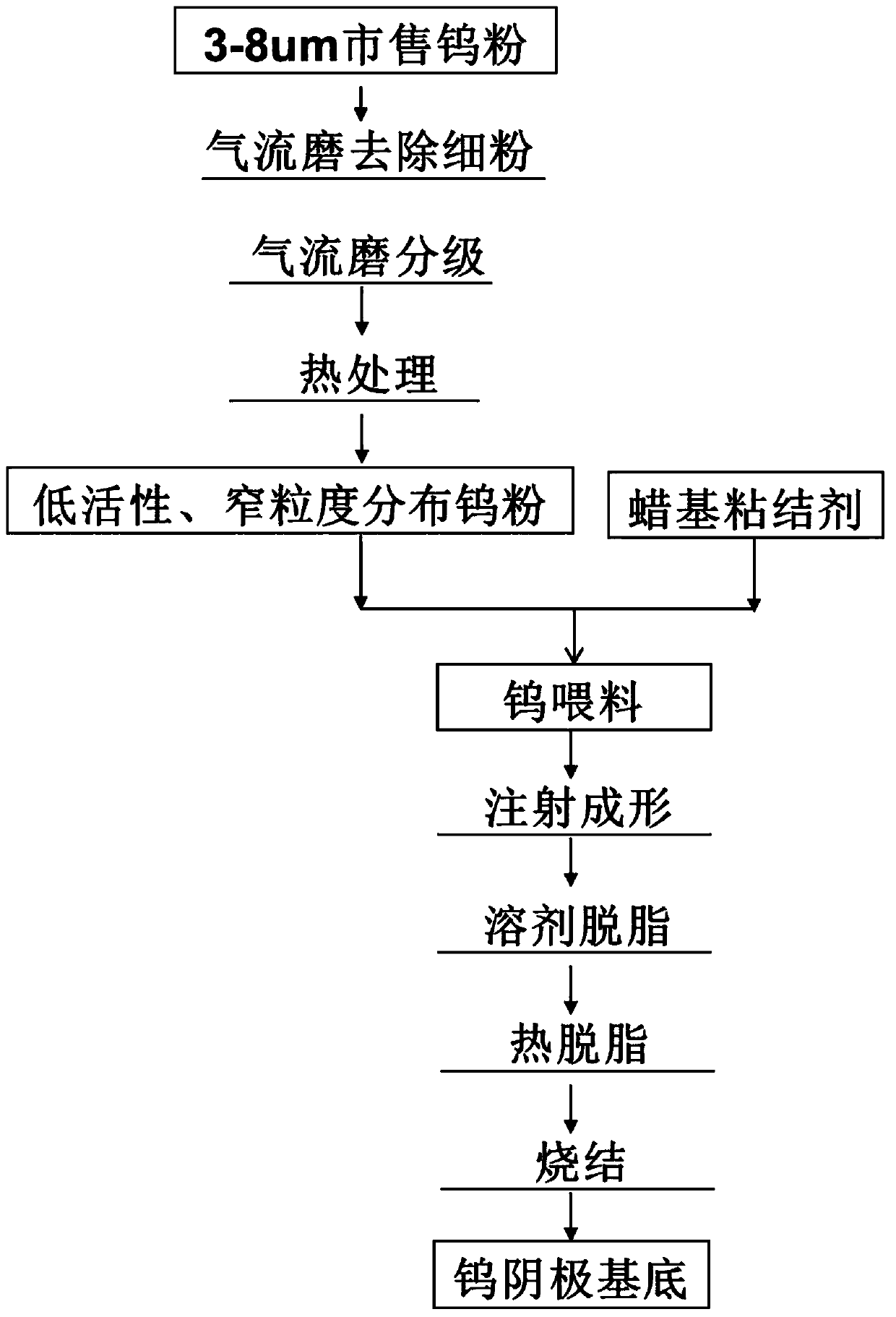

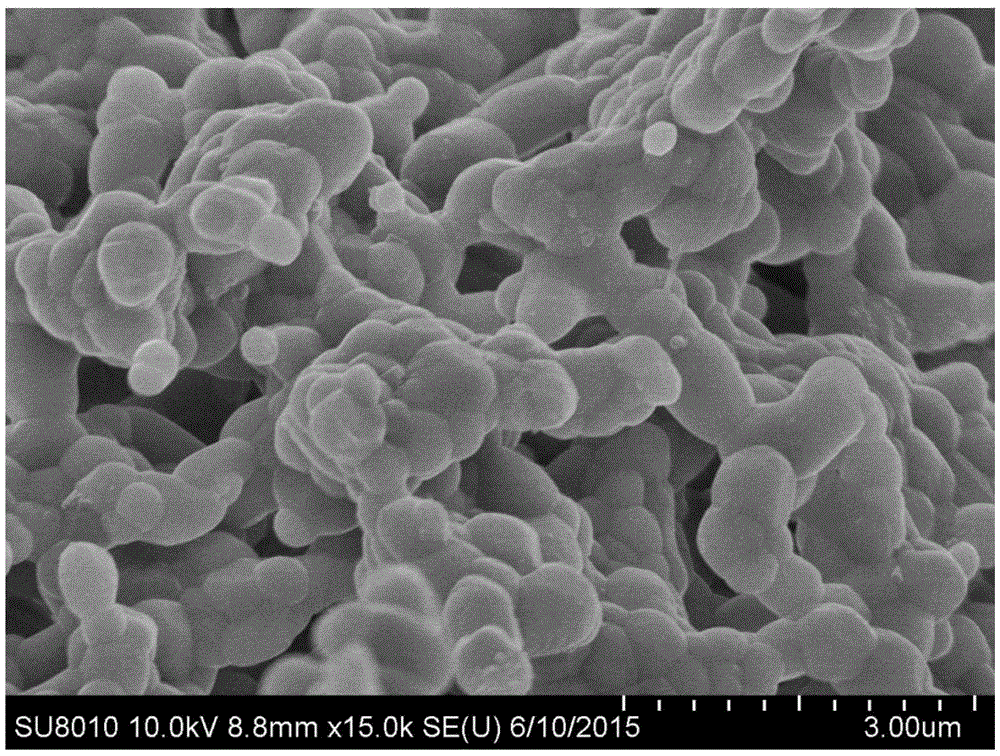

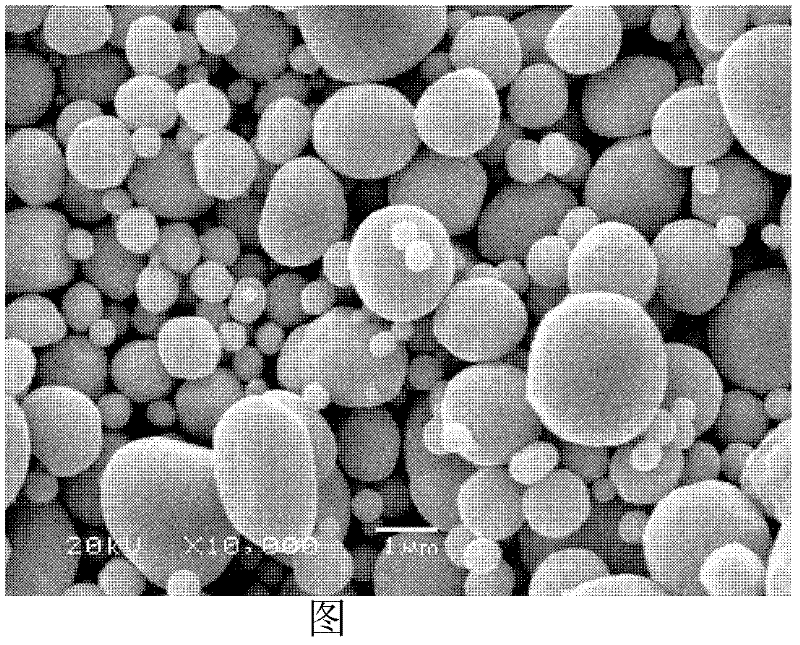

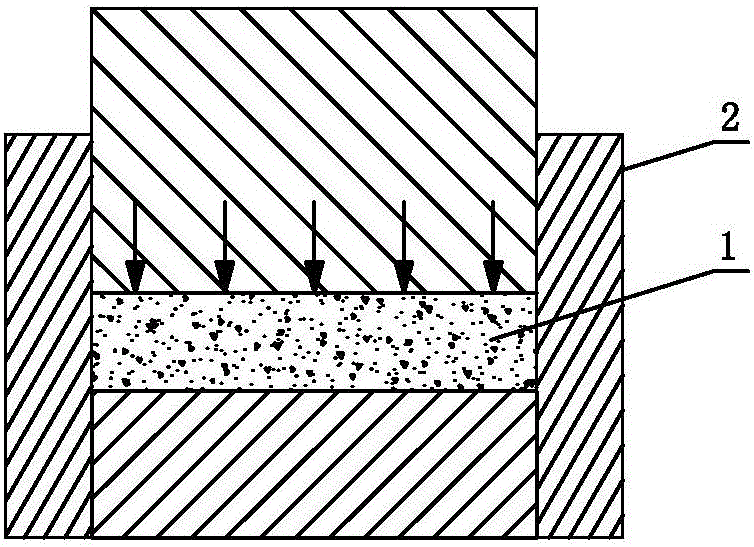

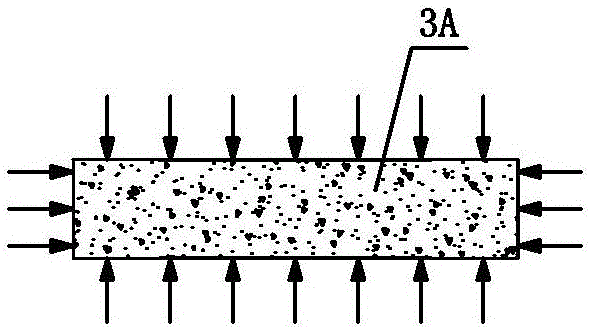

Method for preparing specially-shaped porous tungsten product with uniform pores

ActiveCN105499574AIncrease profitLow costTransportation and packagingMetal-working apparatusPore distributionAlloy

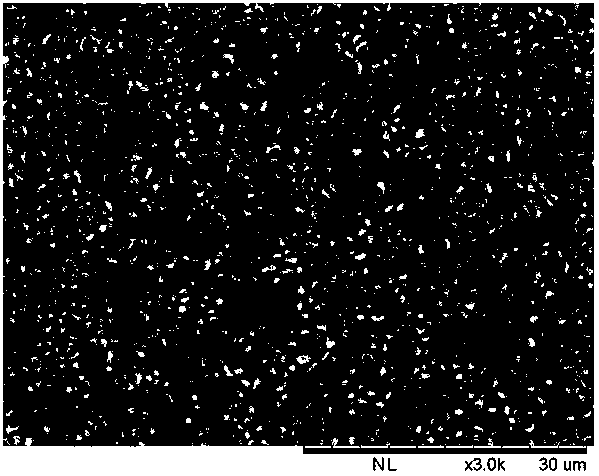

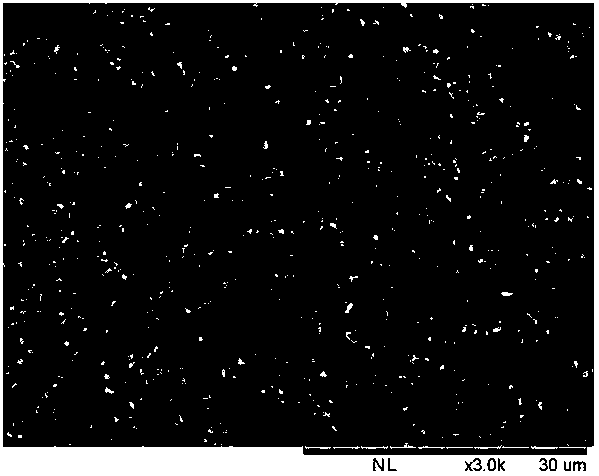

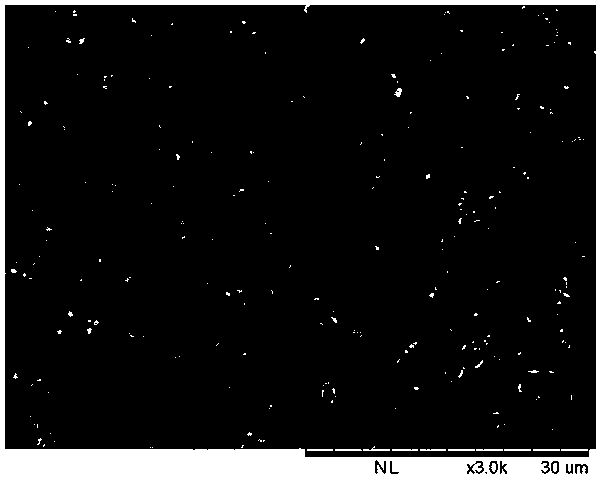

The invention provides a method for preparing a specially-shaped porous tungsten product with uniform pores, and belongs to the technical field of preparation of porous high-temperature alloy. After high-purity tungsten powder is dispersed, aggregates of the tungsten can be opened, and ultrafine particles (particle size being smaller than 2 mum) in original tungsten powder are collected and removed; after stage treatment is carried out, tungsten powder with narrow size distribution can be obtained; after thermal treatment is carried out, the tungsten powder can be purified, and the activity of the tungsten powder can be reduced to obtain nearly spherical powder with narrow size distribution, so that liquidity and tap density of the powder are improved, the loading amount of injection-molded powder is correspondingly improved, shrinkage deformation of a product in a sintering process is reduced, and a porous cathode substrate with high dimension precision is obtained; and the powder size distribution is narrow, and ultrafine powder is absent, so that the obtained cathode substrate is uniform in pore distribution. The porous tungsten product with a complex shape and high dimension precision can be directly prepared by combining jet-milling multi-time treatment with an injection molding process.

Owner:UNIV OF SCI & TECH BEIJING

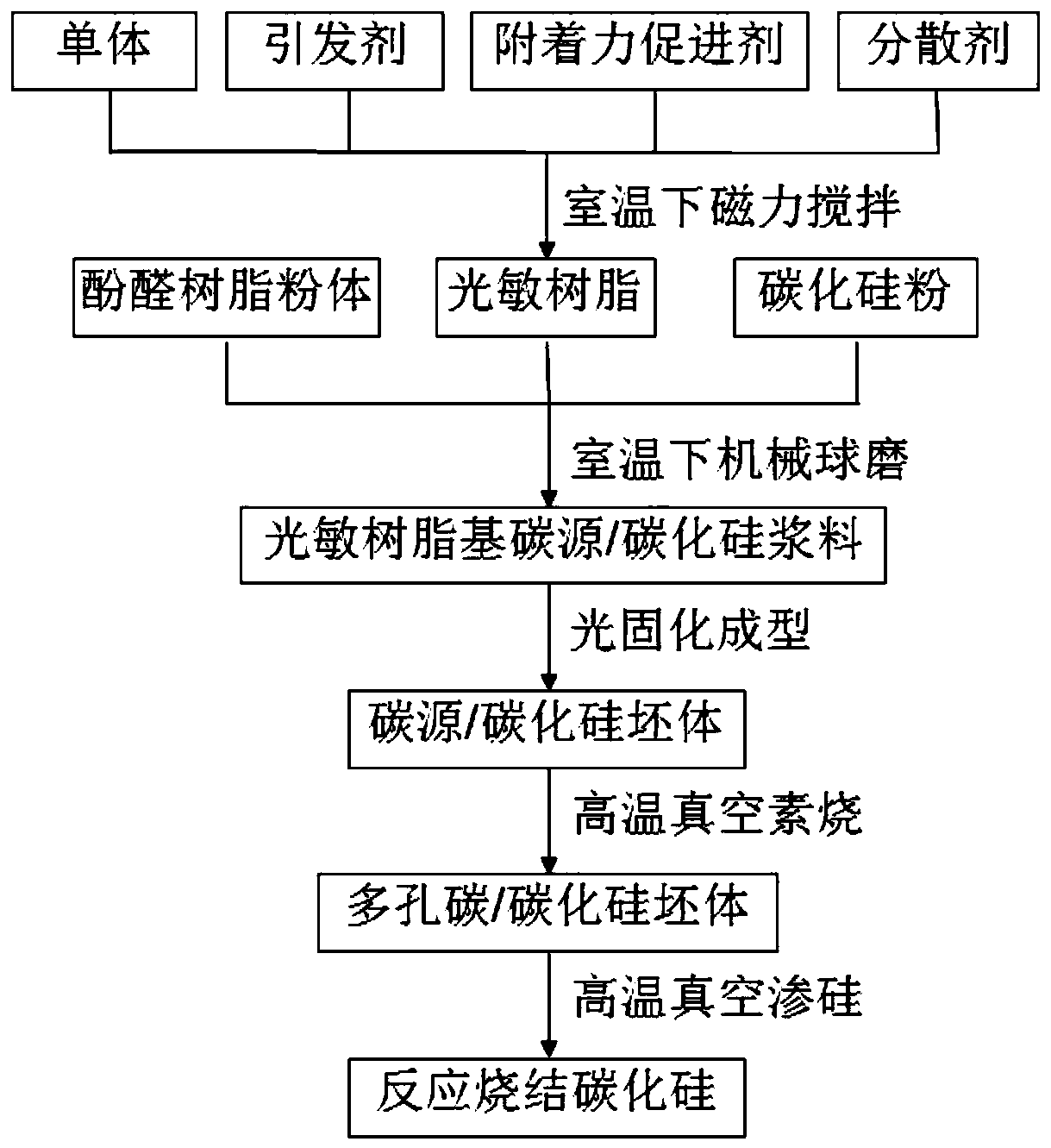

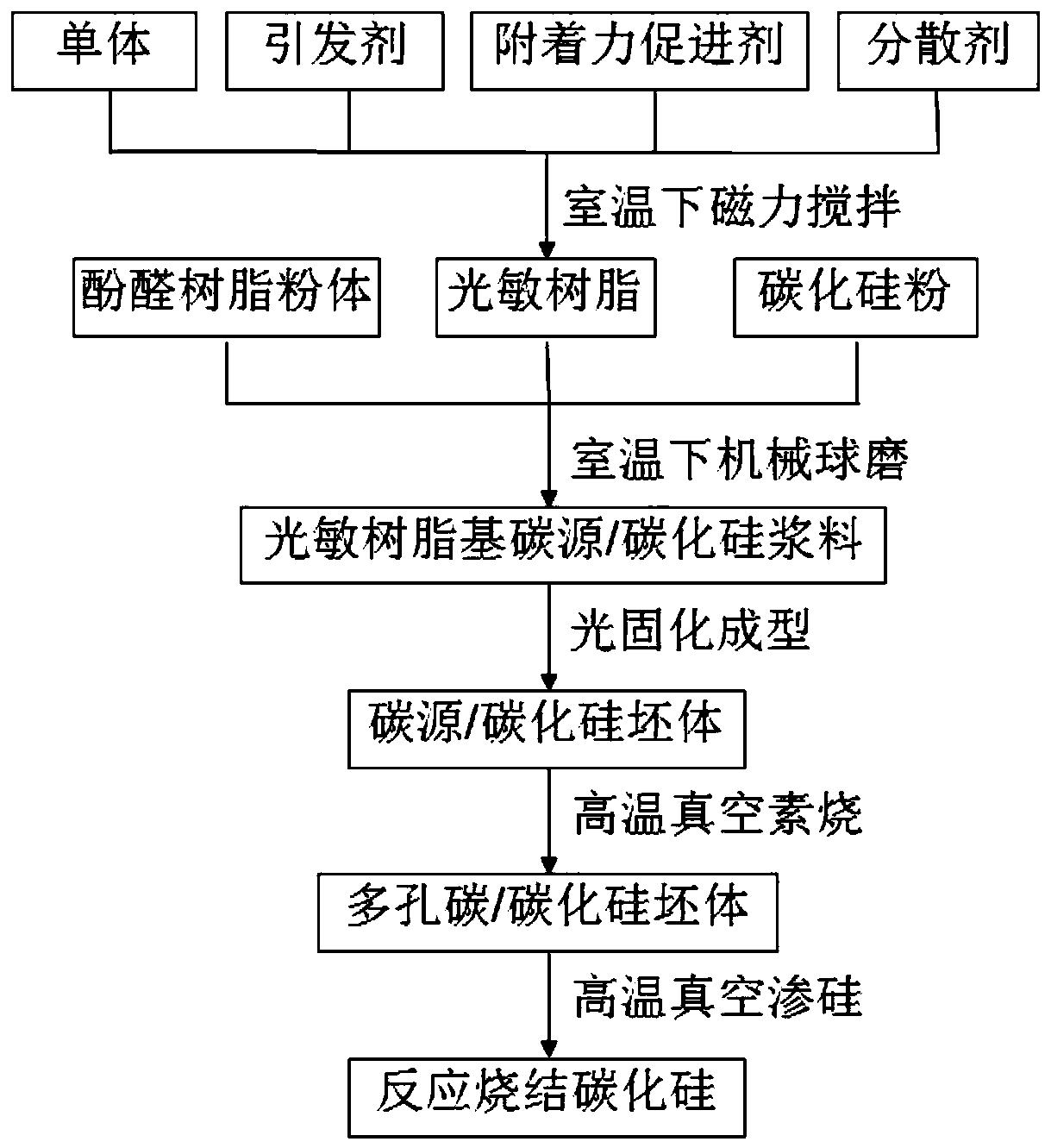

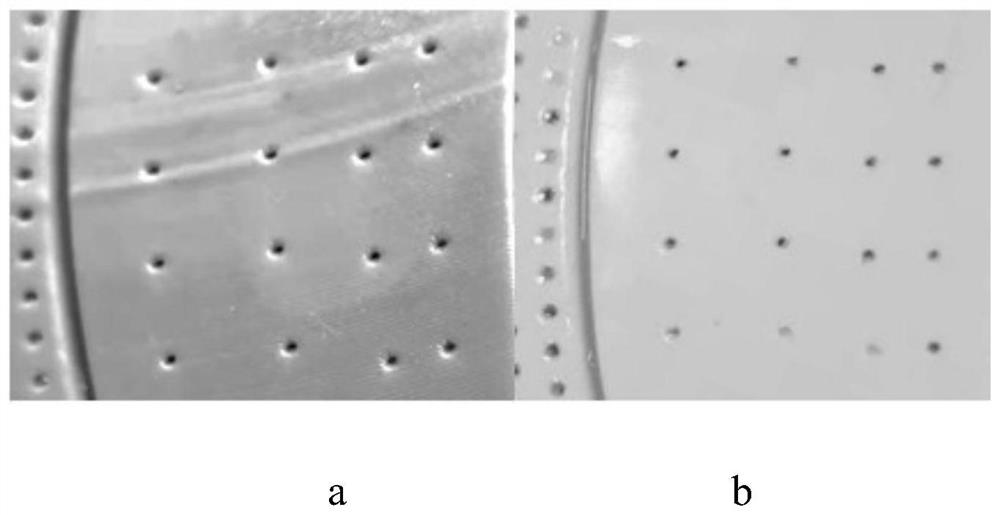

Photosensitive resin-based carbon source/silicon carbide ceramic slurry, method for preparing porous carbon/silicon carbide green body, structural member and preparation method of structural member

InactiveCN111116205AReduce viscosityHigh activityAdditive manufacturing apparatusCarbide siliconPorous carbon

The invention mainly aims to provide a photosensitive resin-based carbon source / silicon carbide ceramic slurry, a method for preparing a porous carbon / silicon carbide green body, a reaction sintered silicon carbide structural member and a preparation method of the reaction sintered silicon carbide structural member. The photosensitive resin-based carbon source / silicon carbide ceramic slurry comprises 50-70% of photosensitive resin and 30-50% of a powder material; the powder material comprises silicon carbide powder and phenolic resin powder; and the photosensitive resin comprises a monofunctional monomer, a bifunctional monomer, a trifunctional monomer, a photoinitiator, an adhesion promoter and a polymer dispersant. The preparation method of the porous carbon / silicon carbide green body comprises the following steps: preparing the photosensitive resin-based carbon source / silicon carbide ceramic slurry, carrying out photocuring 3D printing molding, and carrying out vacuum biscuiting; and carrying out high temperature siliconizing sintering. The technical problem to be solved is that a high-density and high-strength reactive sintering silicon carbide structural member can be manufactured, the density of the structural member is greater than or equal to 2.7 g / cm<3>, and the bending strength is greater than or equal to 270.0 MPa, so that the structural member is practical.

Owner:CHINA BUILDING MATERIALS ACAD

Low-temperature preparation method of high-strength mullite ceramic

The invention provides a low-temperature preparation method of high-strength mullite ceramic. Kaolin, aluminum sol and aluminum oxide are taken as raw materials, under the action of a mineralizing agent and sintering aids, mullite porous ceramic with needle-shaped crystal whiskers is firstly synthesized under low temperature, space is provided for the growth of the crystal whiskers by using internal pores of the materials to allow the crystal whiskers grow fully, mullite precursors with higher reaction activities are soaked, and finally the high-strength mullite ceramic is obtained through secondary low-temperature sintering. The method has the advantages that the prices of the raw materials are cheap, sources of the raw materials are extensive and easy to obtain, the costs are lower, andthe preparation temperature is lower, so that production consumption is greatly reduced, the process is simple, equipment demands are low, the improvement of material strength and toughness are achieved simultaneously by the in-situ growing crystal whiskers, during the sintering process, the shrinkage of products is less, and net size shaping can be achieved.

Owner:HARBIN INST OF TECH

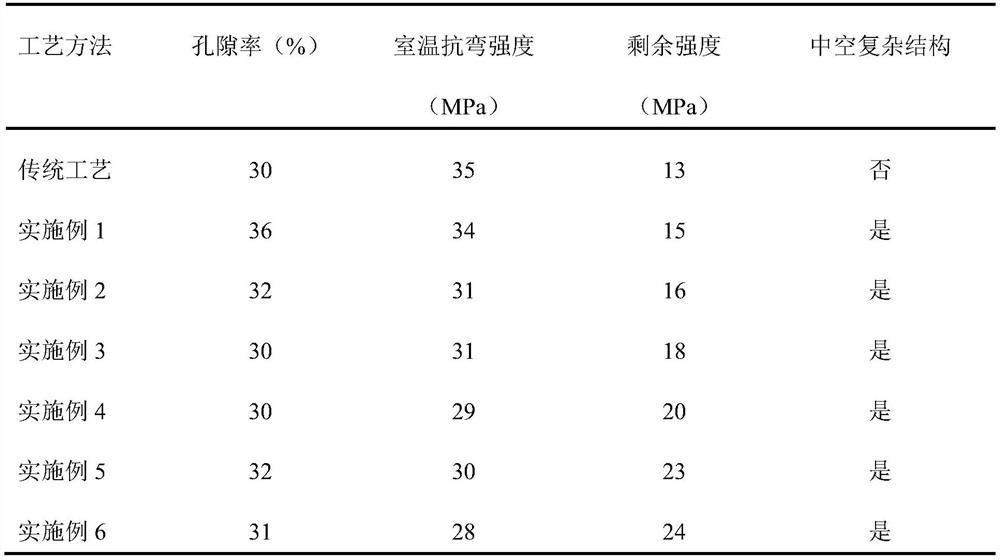

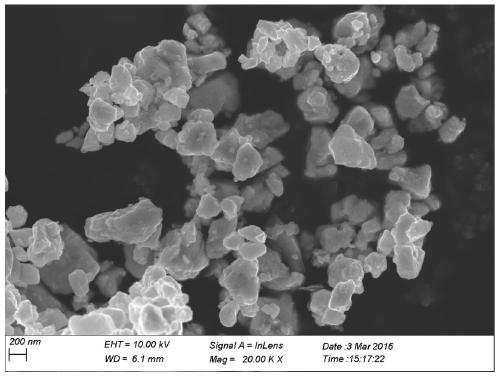

Silica-based ceramic mold core and preparation method thereof

ActiveCN106747369ASmall deformation at high temperatureSmall sintering shrinkageUltimate tensile strengthSintering shrinkage

The invention provides a silica-based ceramic mold core and a preparation method thereof. The silica-based ceramic mold core and the preparation method are used for solving the problems of insufficient high-temperature intensity, great high-temperature deflection and the like of the silica-based ceramic mold core in the prior art. The invention provides the silica-based ceramic mold core with high high-temperature intensity, low high-temperature deformation and low sintering shrinkage, and the preparation method.

Owner:成都航大新材料有限公司

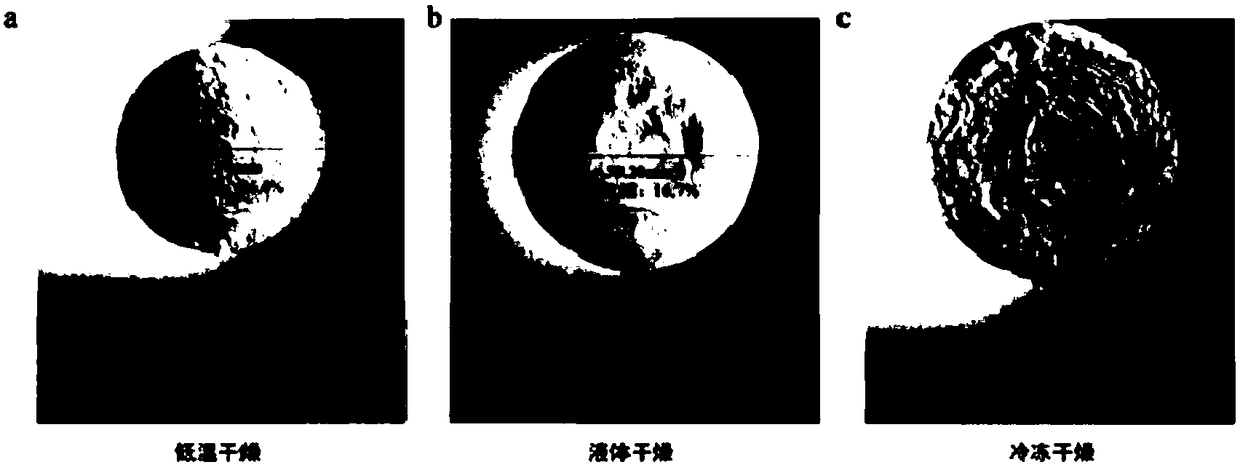

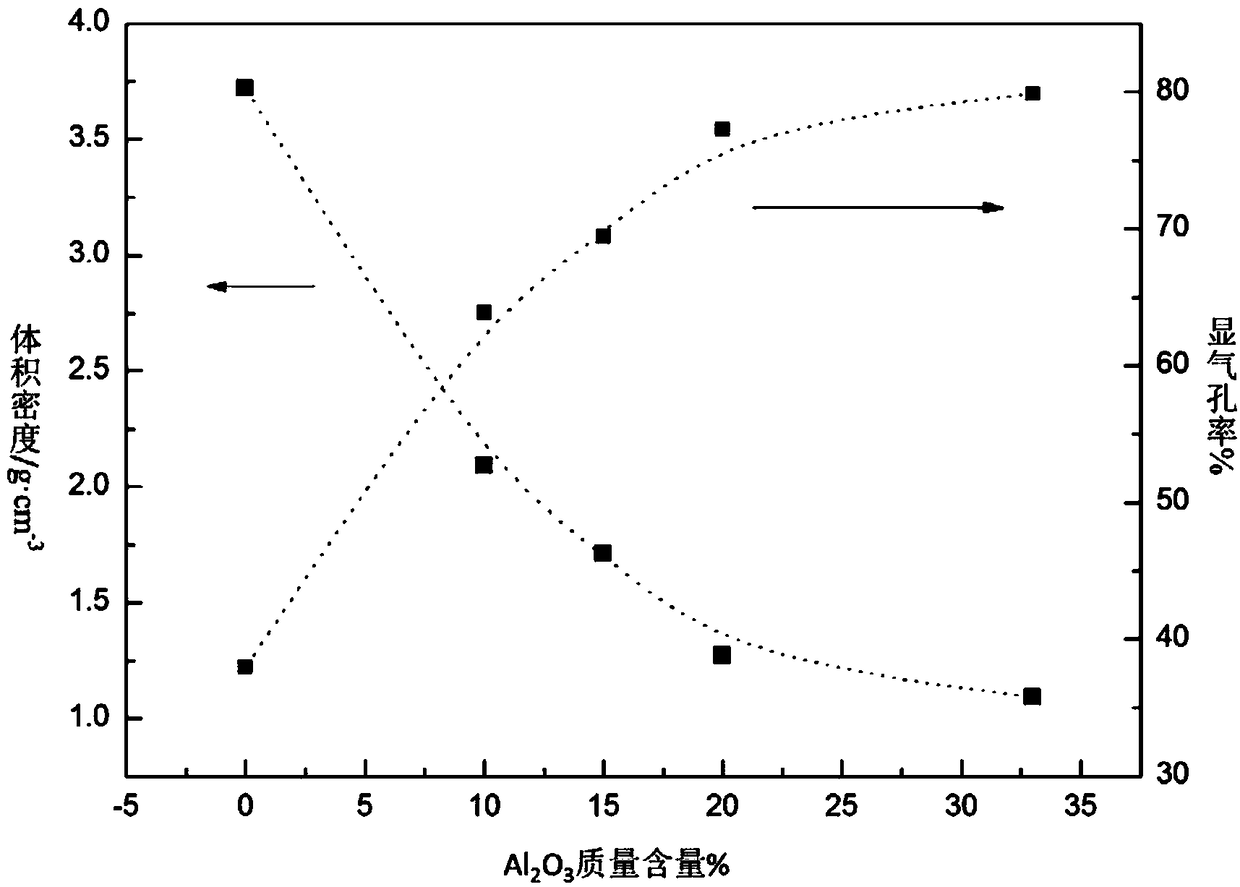

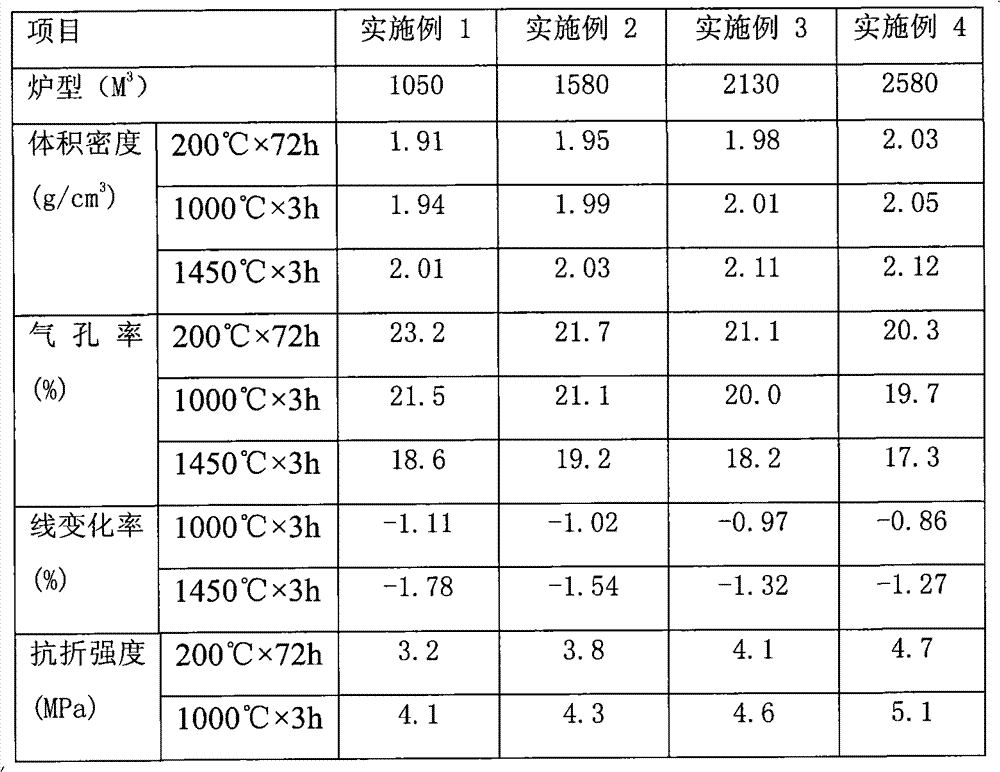

Preparation method of large-size zirconia-based heat insulation material

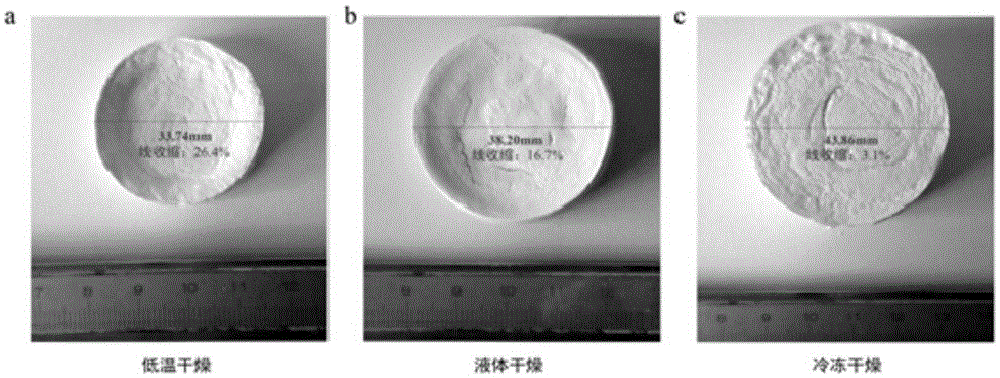

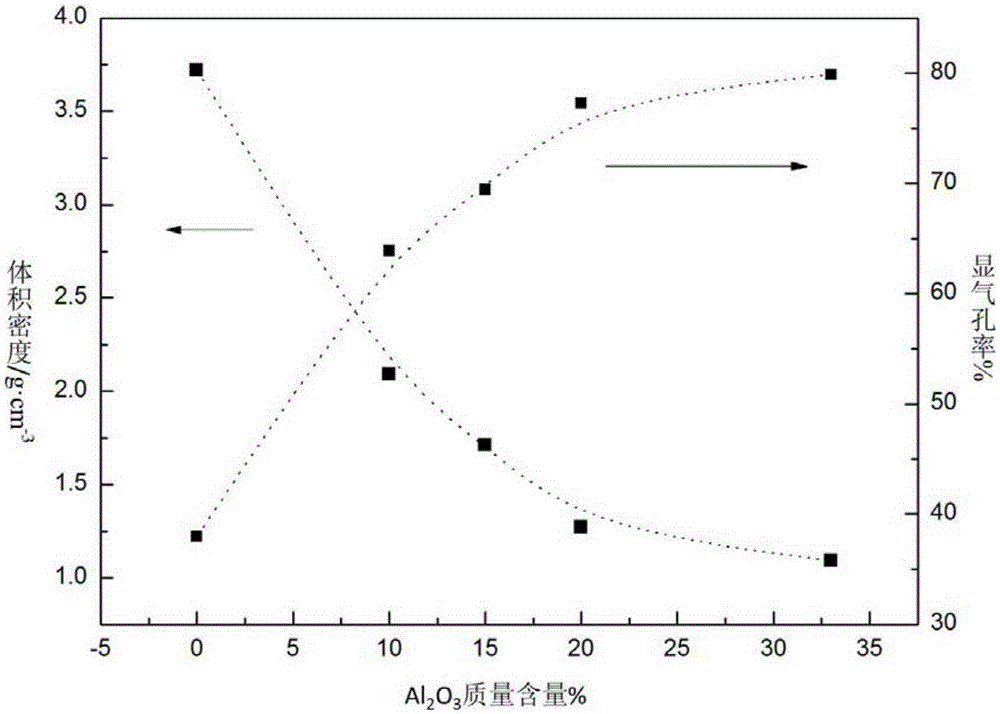

The invention provides a preparation method of a large-size zirconia-based heat insulation material, and the heat insulation prepared by adopting the method. The preparation method comprises the following steps: 1, mixing deionized water, organic monomers and a cross-linking agent, adding alpha-Al2O3 powder, ZrO2 powder and a dispersant, and carrying out ball milling by adopting a zirconium dioxide ball to obtain a slurry; 2, adding an initiator and a catalyst to the slurry obtained in step 1, stirring, injecting the obtained mixture to a die, solidifying, and cooling to obtain a wet green body; and 3, drying the wet green body obtained in step 2, and sintering. The preparation method comprises special blank molding treatment according to the formula of specific powder, so the problem of adverseness of too large shrinkage in the zirconia sintering process to pore maintenance is effectively solved, the deformation and cracking problems appearing in the drying process of gel injection molded large-size green body are avoided, and the obtained green body has the advantages of high uniformity and small drying shrinkage.

Owner:SINOMA SYNTHETIC CRYSTALS CO LTD +1

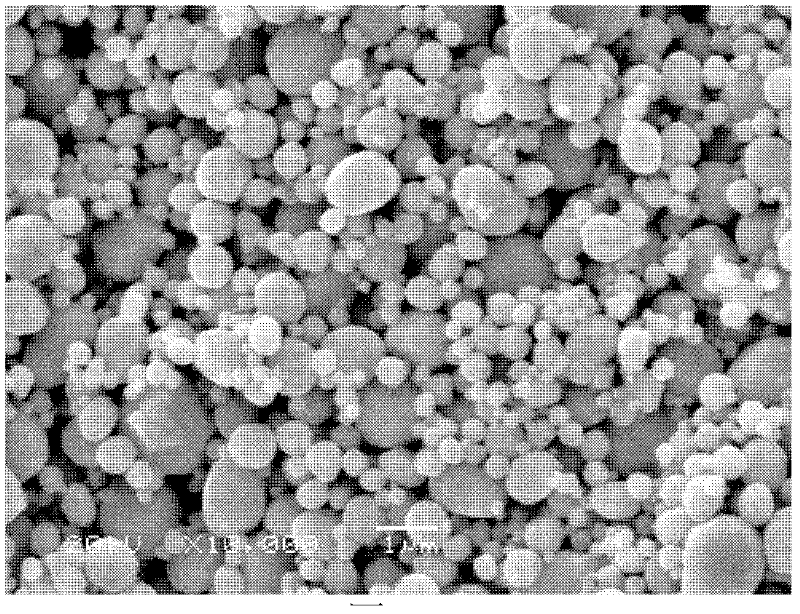

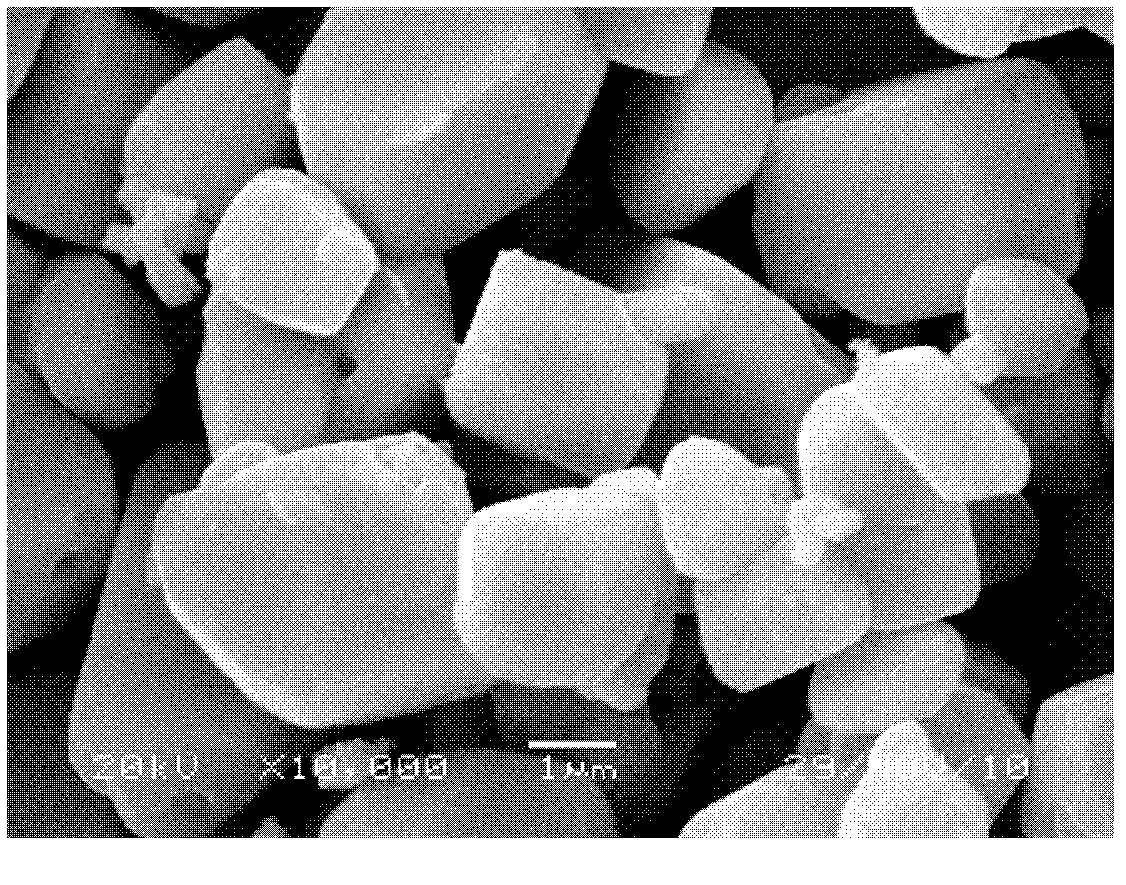

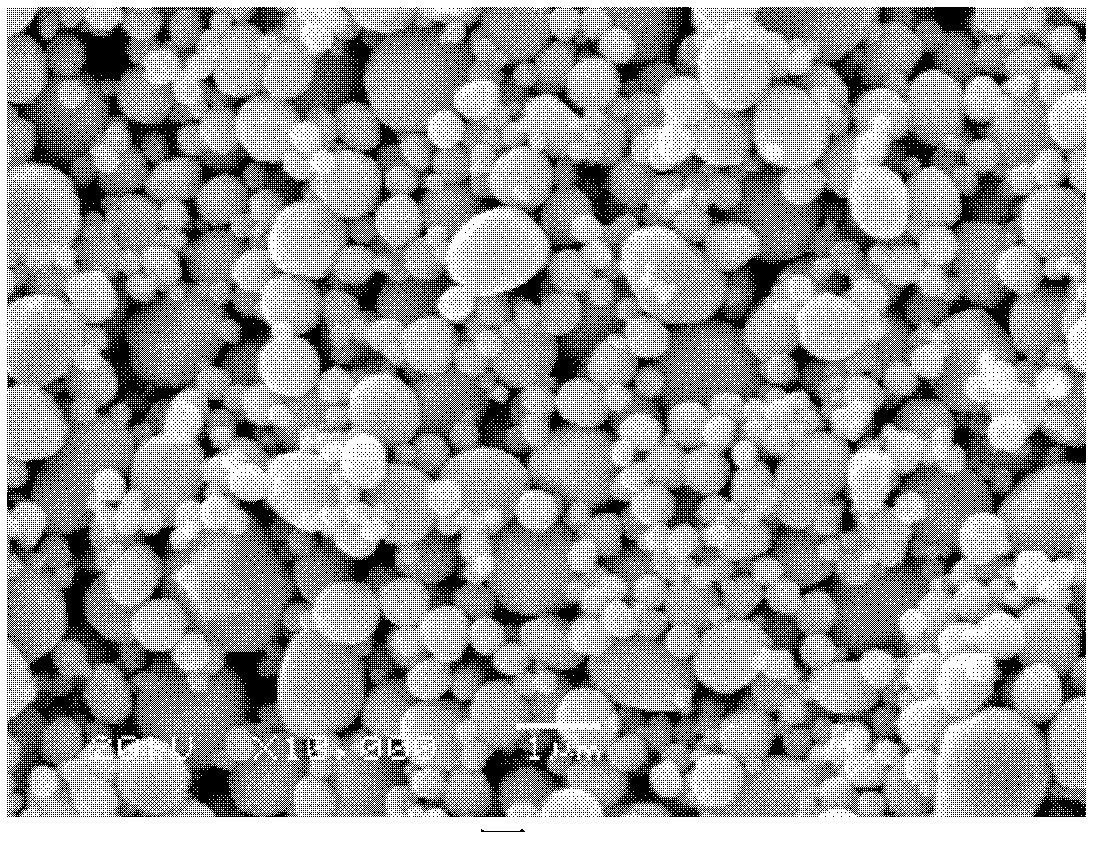

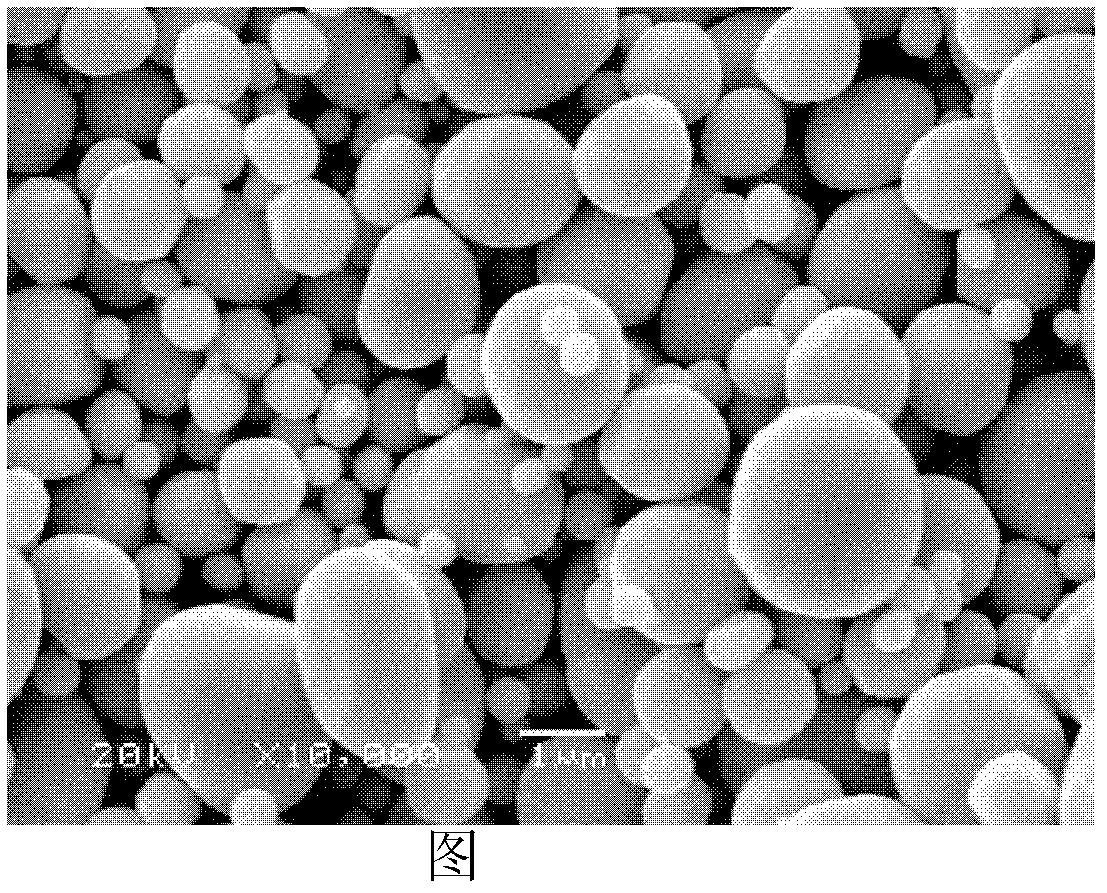

Preparation method for high-crystallinity silver powder

The invention relates to a preparation method for high-crystallinity silver powder. The preparation method is characterized by comprising the following steps of: firstly, synthesizing a silver carbonate precursor; uniformly coating the silver carbonate precursor by using a coating agent; and performing low-temperature crystal water removing, high-temperature thermal decomposition, densification sintering and washing on the coated silver carbonate precursor to obtain high-crystallinity silver powder. Due to the adoption of the method disclosed by the invention, high-crystallinity silver powder of which the particle diameter is 0.1-5 mu m and the tap density is 3.0-7.0 g / cm<3> can be finally obtained; the silver powder can be used for preparing silver slurry or silver paste for fine threads and high-accuracy printed galvanic circles; the silver powder has the advantages of high dispersity, high crystallinity, superior degree of sphericity, uniform particle size distribution, easiness for dispersing in silver slurry or silver paste and high filling characteristic, so that high-accuracy fine thread printing can be realized; and meanwhile, an obtained silver thick film has low sintering concentration rate and low bulk resistivity.

Owner:宁夏中色新材料有限公司

Silicon-based ceramic core slurry and application thereof

ActiveCN112500143AHigh thermal shock resistancePromote absorptionAdditive manufacturing apparatusFoundry mouldsSilicon oxidePhoto curing

The invention discloses a preparation method and application of a silicon-based ceramic core. Mixed slurry obtained according to the mixing ratio is formed by using a photocuring method to obtain a mold core biscuit, the mold core biscuit is degreased and then impregnated with a ceramic slurry, the impregnated mold core biscuit is dried, and the dried mold core biscuit is sintered in an air atmosphere by using a buried powder sintering method to obtain the silicon-based ceramic core. By means of the method, forming of a high-surface-precision silicon-based ceramic core blank can be achieved, the forming precision of the silicon-based ceramic core is improved, the production process of the ceramic core is accelerated, and the forming difficulty of the silicon-based ceramic core of a complexstructure is lowered. Degreasing and sintering treatment are carried out on the mold core biscuit obtained through the photocuring method, dipping lifting treatment is carried out on the mold core biscuit through the silicon oxide inorganic slurry, and the surface precision of the silicon-based ceramic mold core blank can be effectively improved. The method is simple, and the forming difficulty of the silicon-based ceramic mold core with a complex structure is reduced.

Owner:西安国宏天易智能科技有限公司

Preparation method of high-performance sintered insulation brick

ActiveCN110078530ARealize industrial productionSmall sintering shrinkageCeramic materials productionCeramicwareCompression moldingBrick

The invention provides a preparation method of a high-performance sintered insulation brick. The method comprises the following steps: step one, concentrating, pressing-filtering and drying sludge ofurban sewage treatment plant or sludge of the paper mill; step two, naturally airing, crushing, grinding and sieving the clay and sludge; step three, uniformly mixing various raw materials to obtain amixture drier, adding water to stir uniformly; step four, performing ageing treatment on the wet mixture, wherein the ageing time needs to exceed 24 hours; step five, performing compression molding on the brickmaking blank to obtain the green brick; step six, naturally drying the green brick under room temperature, and then feeding into a tunnel drying kiln to dry; step seven; directly feeding the green brick into a tunnel sintering kiln after the drying, wherein the sintering temperature is 950-1100 DEG C, wherein the heat preservation time of the brick body at the highest sintering temperature is 1-3 hours. The defects that the traditional insulation brick is poor in mechanical performance and high in heat conductivity are overcome; the production of the high-performance insulation brick with large sludge dosage is realized; the raw material sources are wide; the cost is low; various production and domestic sludge are greatly consumed.

Owner:SOUTHEAST UNIV

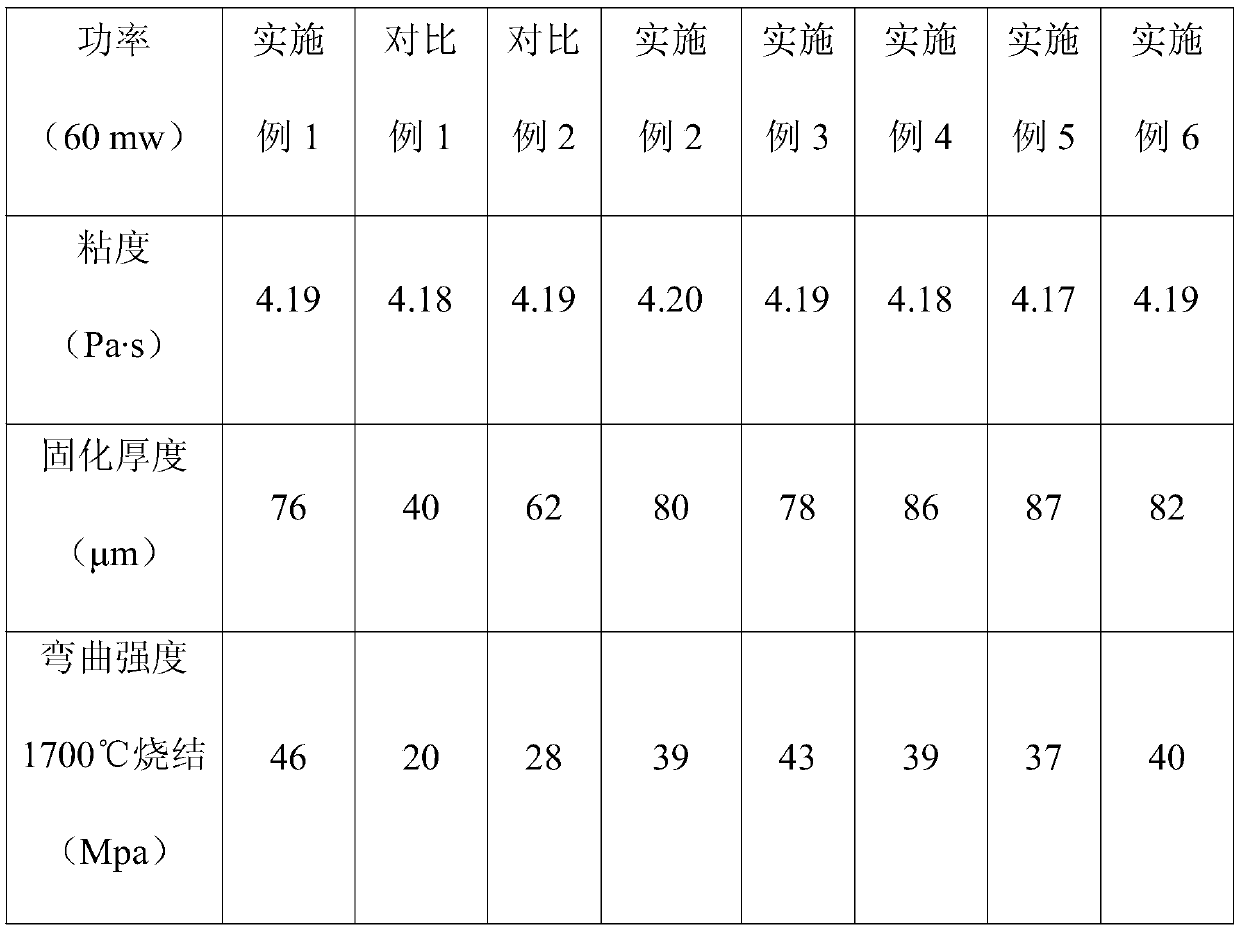

Slurry for photocuring 3D printing and preparation method thereof, and silicon nitride ceramic

InactiveCN110357642ALow refractive indexReduce scatterAdditive manufacturing apparatusSlurryPhotoinitiator

The invention provides a slurry for photocuring 3D printing and a preparation method thereof, and a silicon nitride ceramic to overcome problems in conventional silicon nitride ceramic slurry for photocuring 3D printing and preparation processes thereof. The preparation method comprises the following steps: pretreatment of silicon nitride powder: dispersing the silicon nitride powder in an appropriate amount of an alkaline solution to obtain an alkaline suspension, adding an appropriate amount of a mixed salt solution containing Y<3+> and Mg<2+> into the alkaline suspension, carrying out a reaction to obtain coated silicon nitride powder, subjecting the coated silicon nitride powder to post-treatment, and then carrying out calcination at a temperature of 500-600 DEG C to obtain pretreatedsilicon nitride powder; and preparation of the slurry: mixing the pretreated silicon nitride powder with a resin monomer, a dispersant and a photoinitiator to obtain the silicon nitride ceramic slurry.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Polycrystal zirconium oxide ceramic dental material and preparation thereof

InactiveCN1203830CSmall sintering shrinkageReduce distortionImpression capsArtificial teethHigh densityVolumetric Mass Density

The invention relates to a polycrystalline zirconia ceramic tooth post material and a preparation method thereof, belonging to the technical field of preparation of ceramic materials. It is characterized in that: the material contains zirconia ceramic powder as the initial raw material, a polymer binder, and a low-molecular additive, and the proportion thereof is: 80-90wt% of zirconia ceramic powder, 5-10wt% of polymer binder, 5-10wt% of low-molecular additives. The preparation method includes four steps of mixing and granulation, injection molding, thermal degreasing and sintering. The thermal degreasing temperature is 500-800°C, and the sintering temperature is 1350-1550°C. The organic binder system for injection molding of the present invention has good fluidity and high density of the molded green body, and the density of the ceramic product after sintering is greater than 6.0 g / cm 3 ;The sintering shrinkage and deformation of the formed green body are small, which ensures the dimensional accuracy of the product; the bending strength of the prepared ceramic tooth post is greater than 600MPa, and the fracture toughness is as high as 13MPa.m 1 / 2 , elastic modulus 140MPa, Vickers hardness 1050 ~ 1200MPa. The preparation process has good repeatability and is convenient for industrialized production.

Owner:TSINGHUA UNIV +1

A method for preparing high-strength mullite ceramics at low temperature

The invention provides a low-temperature preparation method of high-strength mullite ceramic. Kaolin, aluminum sol and aluminum oxide are taken as raw materials, under the action of a mineralizing agent and sintering aids, mullite porous ceramic with needle-shaped crystal whiskers is firstly synthesized under low temperature, space is provided for the growth of the crystal whiskers by using internal pores of the materials to allow the crystal whiskers grow fully, mullite precursors with higher reaction activities are soaked, and finally the high-strength mullite ceramic is obtained through secondary low-temperature sintering. The method has the advantages that the prices of the raw materials are cheap, sources of the raw materials are extensive and easy to obtain, the costs are lower, andthe preparation temperature is lower, so that production consumption is greatly reduced, the process is simple, equipment demands are low, the improvement of material strength and toughness are achieved simultaneously by the in-situ growing crystal whiskers, during the sintering process, the shrinkage of products is less, and net size shaping can be achieved.

Owner:HARBIN INST OF TECH

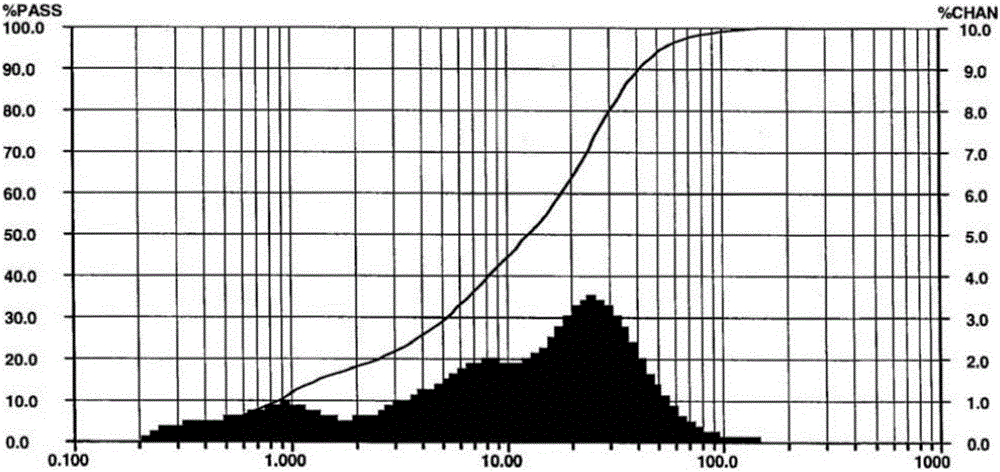

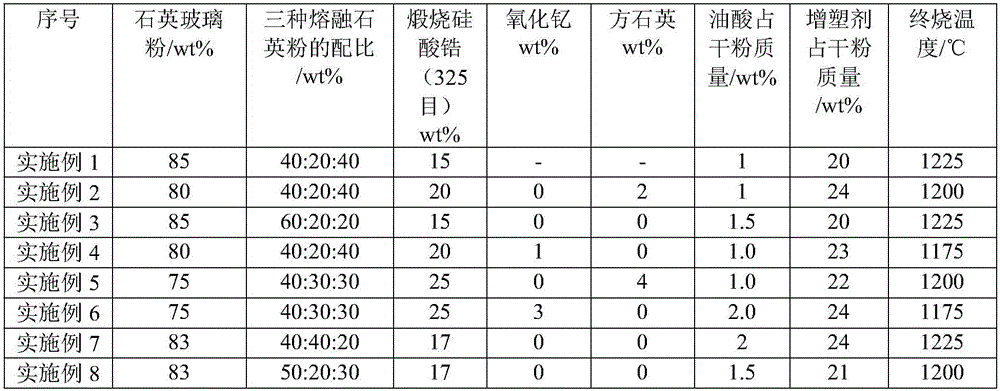

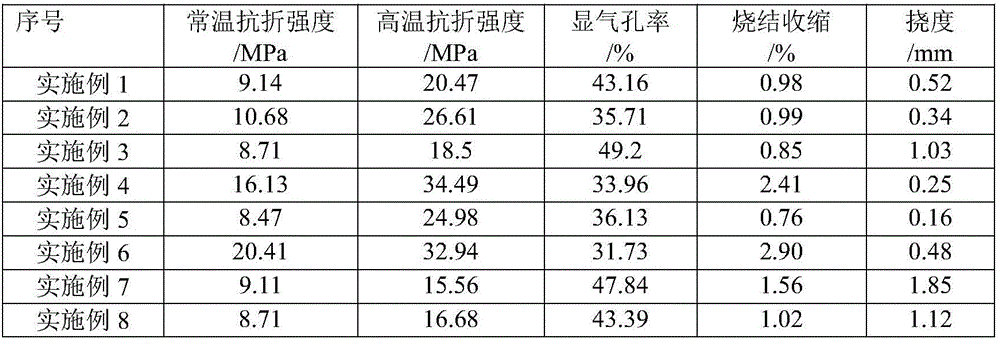

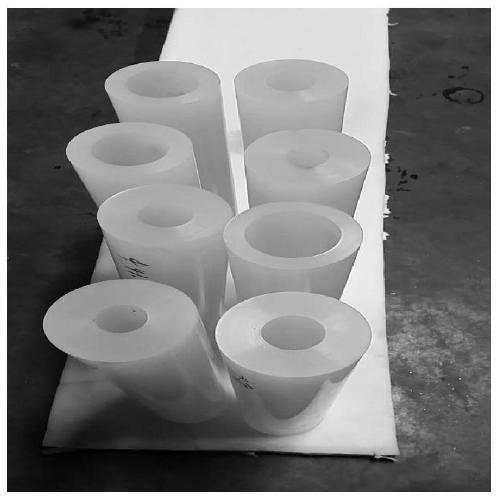

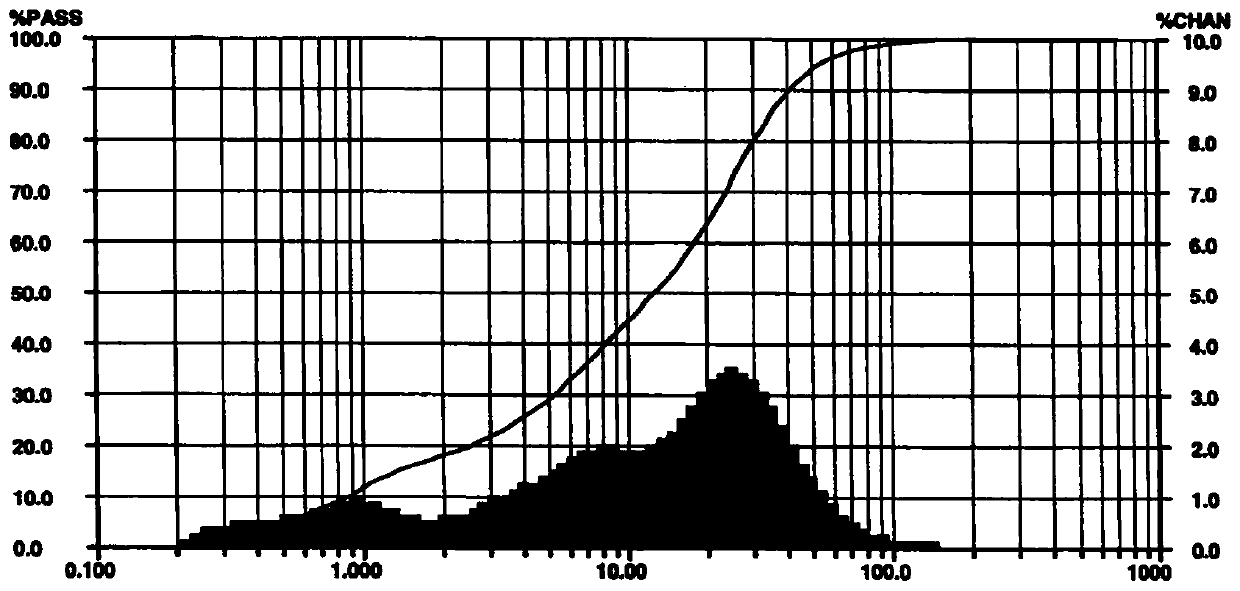

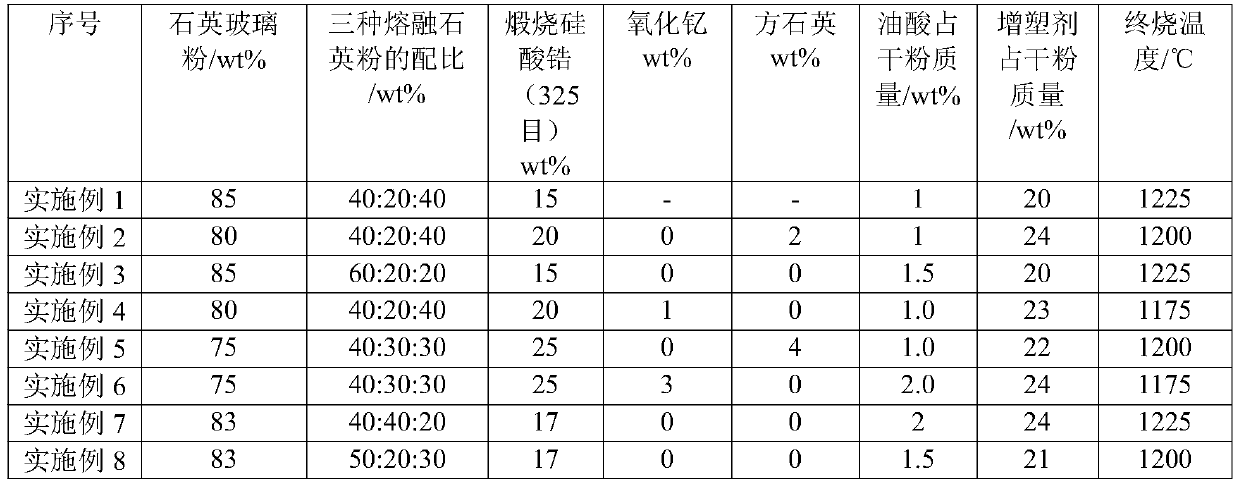

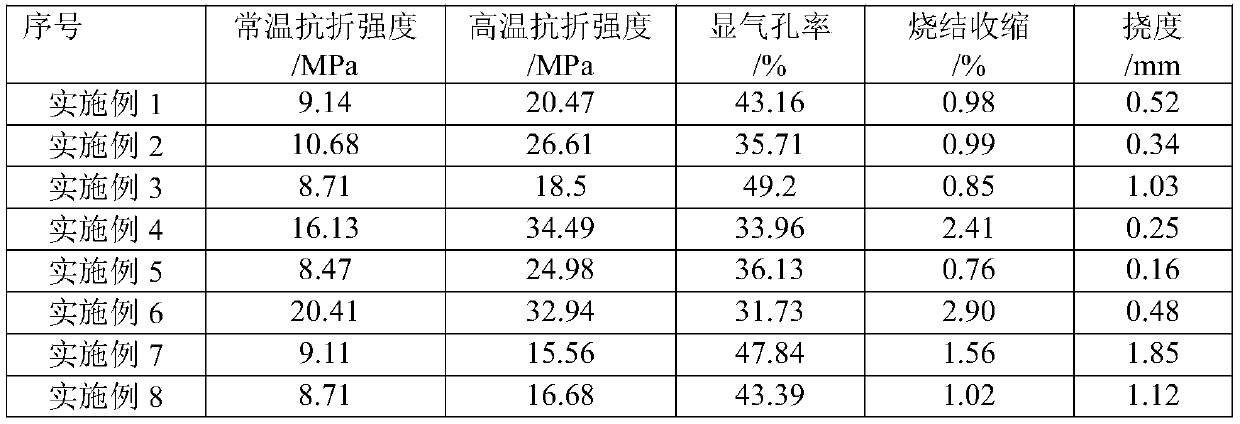

Silicon oxide-based ceramic core for large-size directional hollow blade of heavy-duty gas turbine and preparation of silicon oxide-based ceramic core

PendingCN114249588APrevent viscous flowFiring shrinkage is smallFoundry mouldsFoundry coresMolding machinePlasticizer

The invention relates to a silicon oxide-based ceramic core for a large-size directional hollow blade of a heavy gas turbine and a preparation method of the silicon oxide-based ceramic core. The silicon oxide-based ceramic core adopts quartz glass powder as a base material, and adopts zircon powder, alumina powder and calcium oxide powder as mineralizing agents. The powder comprises the following components in percentage by weight: 60-95% of quartz glass powder, 1-30% of zircon powder, 0.5-5% of alumina powder and 0.1-5% of calcium carbonate powder. Paraffin, beeswax, polyethylene and polyethylene glycol are used as plasticizers for hot-press injection molding. The preparation method comprises the following steps: ball-milling and uniformly mixing the powder materials, putting the powder materials into a molten plasticizer for mixing, and carrying out hot-press injection molding on a ceramic core molding machine. A quartz glass rod / tube is pre-arranged in the position, corresponding to the thick and large section of the mold core, in the mold core mold before pressure injection, and the ceramic mold core formed through hot pressure injection molding is put into a box-type resistance furnace to be roasted after being trimmed and corrected. The silicon oxide-based ceramic core prepared by the invention has the characteristics of high high-temperature strength, good creep resistance, small firing shrinkage, stable size and high core removal efficiency.

Owner:SHENYANG RES INST OF FOUNDRY

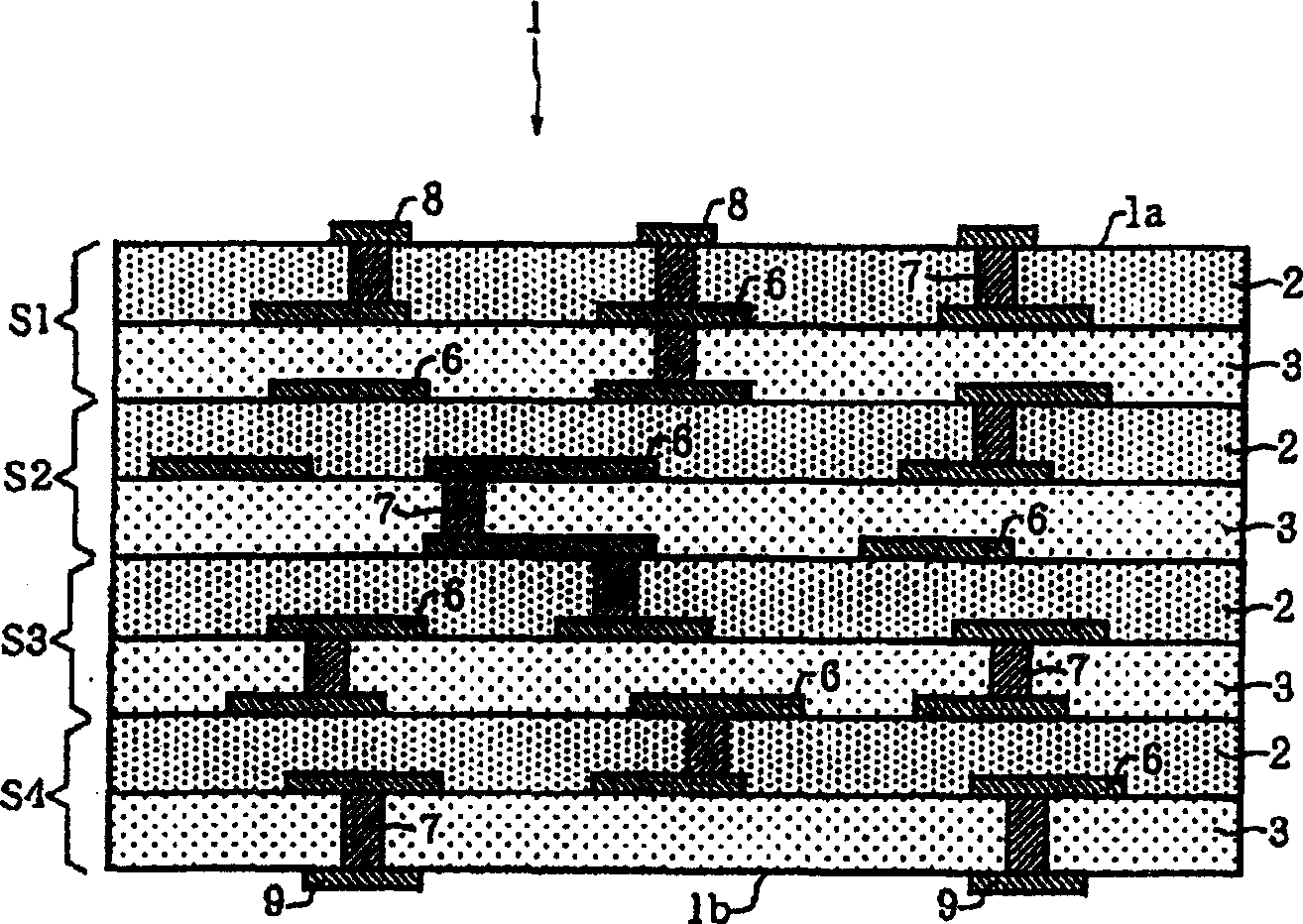

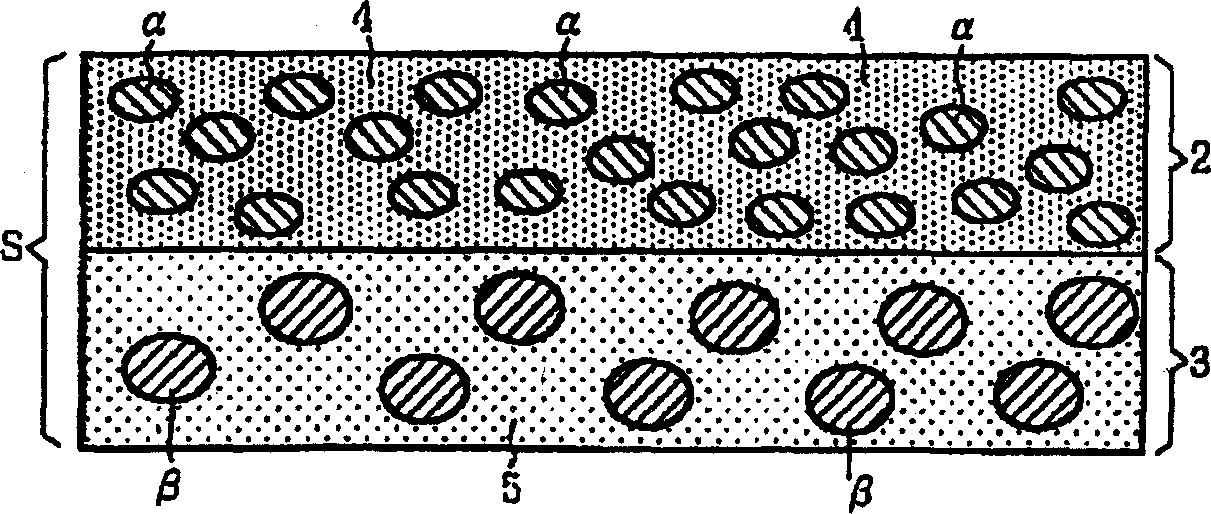

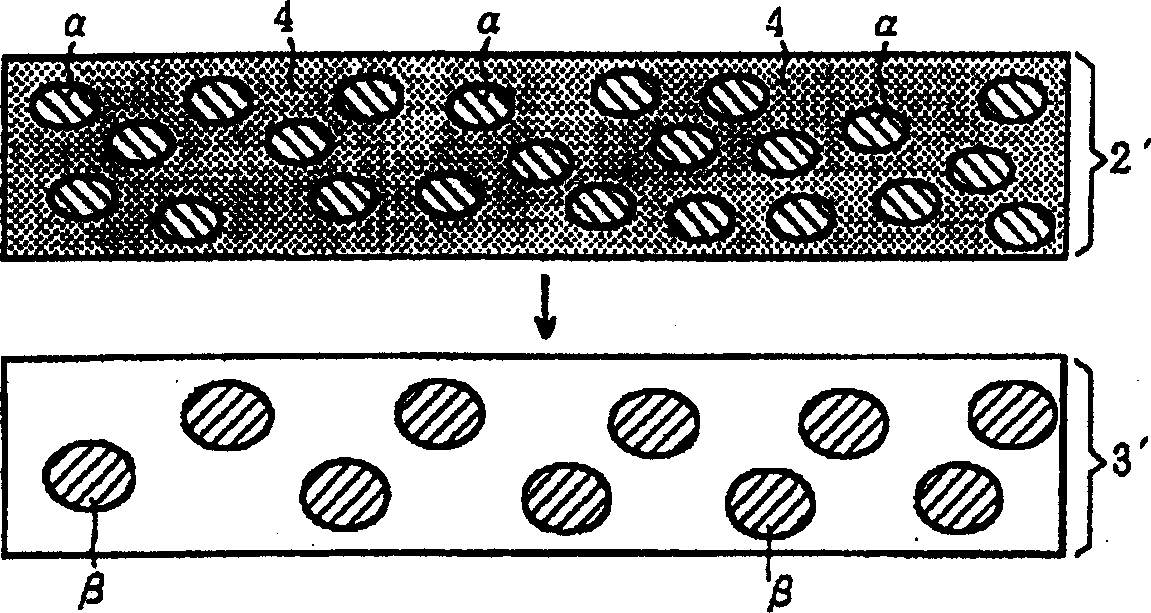

Wiring board and its mfg. method

InactiveCN1499913AScale Accuracy GuaranteeSmall sintering shrinkageSemiconductor/solid-state device detailsPrinted circuit aspectsMetallurgyMaterials science

A wiring board including a laminate comprising: a low-temperature fired layer (2) comprising ceramic particles ± and a glass component (4); and a ceramic layer (3) comprising ceramic particles ² that do not sinter at the firing temperature of the low temperature fired layer (2) and a glass component (5), wherein the ceramic particles ² have a mean particle size larger than that of the ceramic particles ± and a specific surface area smaller than that of the ceramic particles ±.

Owner:NGK SPARK PLUG CO LTD

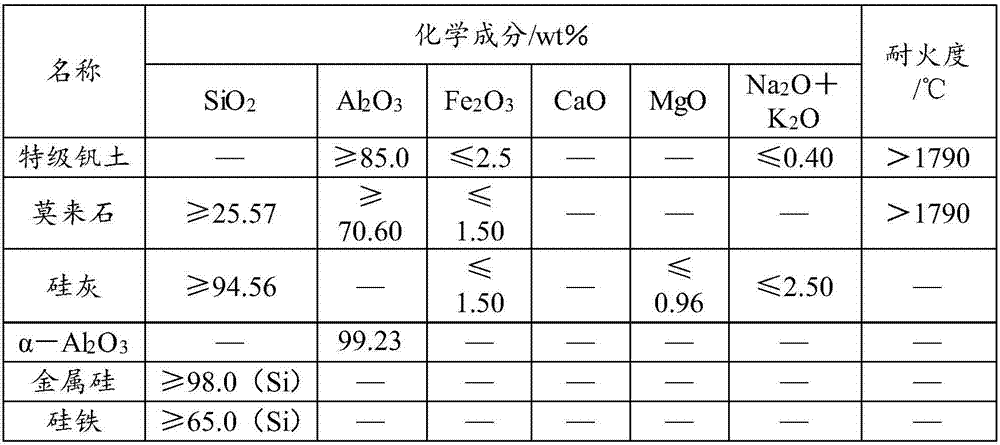

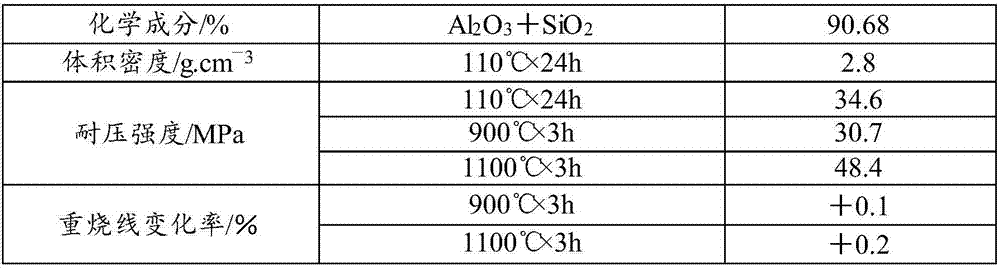

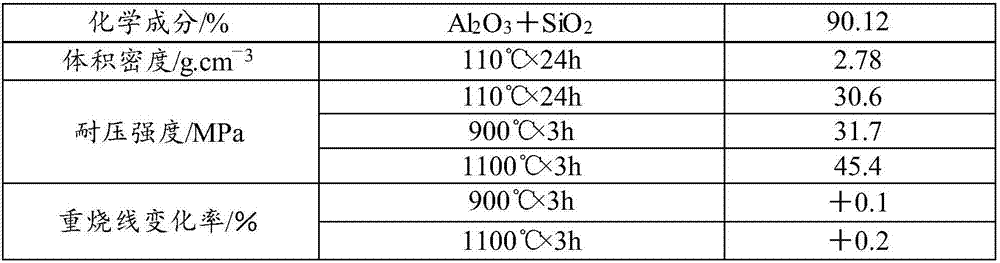

Aluminum-silicon castable prepared by adjusting aggregate ratio and preparation method of aluminum-silicon castable

The invention discloses an aluminum-silicon castable prepared by adjusting the aggregate ratio and a preparation method thereof, and the aluminum-silicon castable comprises the following raw materials in percentage by mass: 35-40% of calcium aluminate cement, 1-4% of floating beads, 10-15% of sinking beads, 3-6% of silicon micro powder, 20%-32% of perlite aggregate, and 15%-25% of ceramsite aggregate. According to the aluminum-silicon castable by adjusting the aggregate proportion and the preparation method of the aluminum-silicon castable, the perlite is used as the aggregate, so that the aluminum-silicon castable is light, porous, environment-friendly, pollution-free, capable of absorbing sound and noise, heat-insulating, non-combustible, good in free-running property, excellent in compressive strength and the like, the fluidity of the castable can be remarkably improved by adding the electric smelting ceramsite sand, the strength is improved, and the sintering shrinkage is reduced; and the composite aggregate perlite and the capacitor ceramsite sand are added, so that performance advantages are complementary, and the performance of the aluminum-silicon castable is improved.

Owner:泰兴市恒信特种耐火材料有限公司

Production method of high-strength and high-compactness fused quartz

The invention discloses a production method of high-strength and high-compactness fused quartz. The production method comprises the following steps: (1) producing a fused quartz raw material; (2) preparing slurry, namely performing ball milling on the fused quartz raw material and cordierite by adopting a ball mill at the rotating speed of 250-300r / min in a forward and reverse ball milling mannerfor 6-10h, sieving the powder by using a 500-mesh sieve, adding the powder subjected to ball milling into a precursor solution, adding a dispersing agent, adjusting the pH value to 3-4 through lacticacid and ammonia water, and preparing slurry with the solid phase content of 60-65% through mechanical stirring; (3) conducting gel curing; (4) conducting drying; and (5) conducting microwave sintering. According to the production method of the high-strength and high-compactness fused quartz, the production method is simple and efficient, the influence of impurity elements on the chemical stability, strength and compactness of the high-strength and high-compactness fused quartz is avoided, and the prepared fused quartz has good breaking strength, high compactness, good chemical stability and wide application prospects.

Owner:徐州赛诺石英有限公司

Refractory brick and preparation method thereof

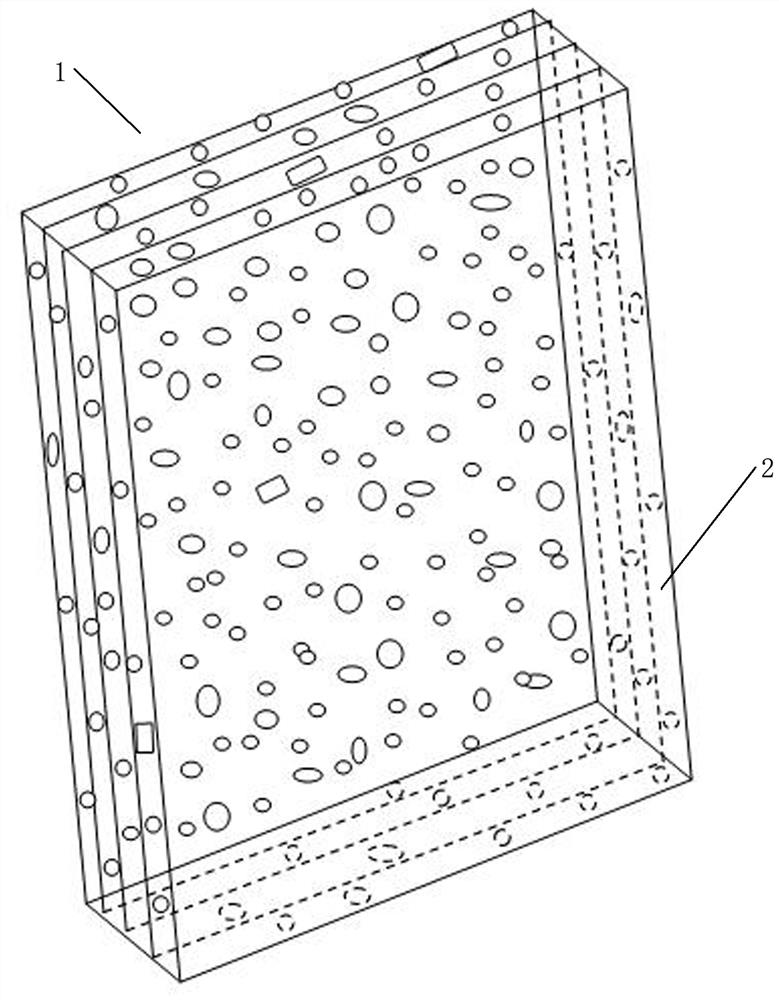

The invention provides a refractory brick. The refractory brick is prepared from alumina, mullite, silica powder, silicon metal, silicon iron, Al2O3 and sodium phosphate. Compared with the prior art, alumina, mullite, Al2O3 and other main raw materials in the refractory brick have good refractory properties, weakly react with sodium salt at the use temperature and are not prone to excessive sintering or over-sintering; the refractory brick contains silicon metal and silicon iron, so that oxidation appears at the use temperature, and certain volume expansion can be generated, and contraction caused by sintering can be partly counteracted. Under the combined action of the various raw materials, the refractory brick has little sintering contraction when slag of vanadium and chromium is calcined for sodium modification. The invention further provides a preparation method of the refractory brick.

Owner:攀钢冶金材料有限责任公司

Bionic lamellar thermal insulation material

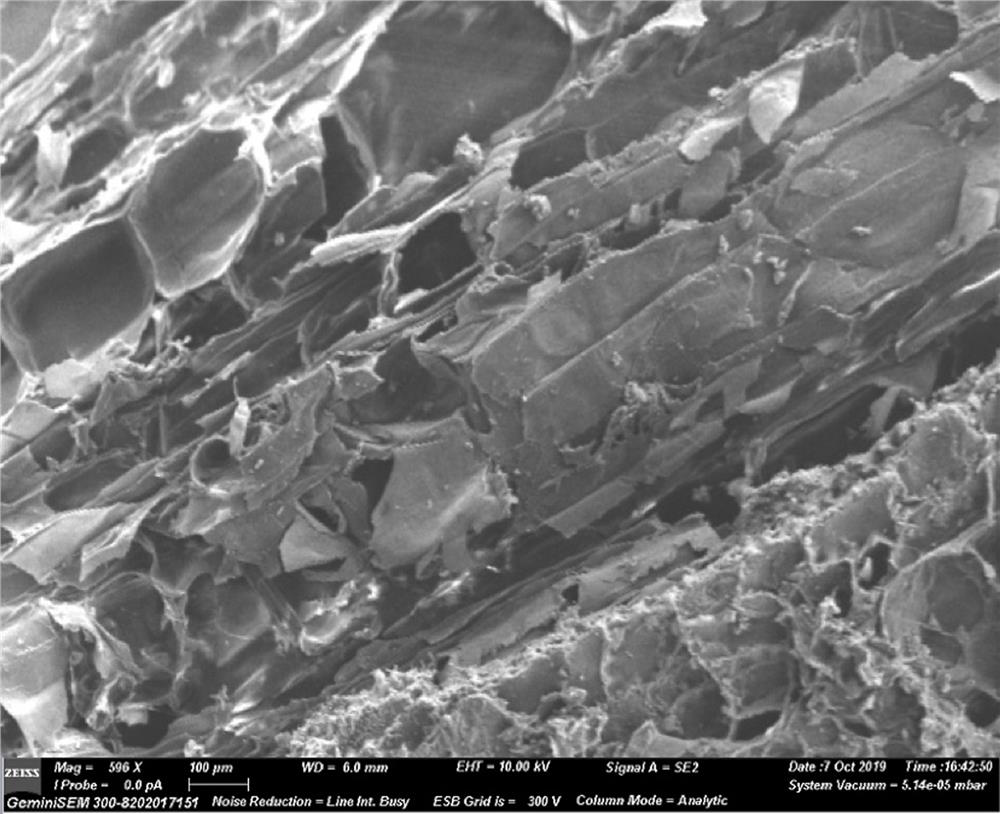

ActiveCN112297532AReduce conductionWith strengthLamination ancillary operationsLaminationThermal breakThermal insulation

The invention discloses a bionic lamellar thermal insulation material which simulates a fireproof, corrosion-resistant and excellent-thermal-insulation-performance American redwood bark multi-thin-layer laminated and thin-layer microporous structure, adopts low-thermal-conductivity microporous powder as a main raw material, and is supplemented with a reinforcing agent, a plasticizer and a pore-forming agent to form a microporous thin-layer unit, and the thin-layer units are boned to prepare the lamellar thermal insulation material. The heat conductivity coefficient of the finished product is as low as 0.02-0.05 W / m.k, and the finished product is good in heat-insulating property and mechanical property, can be used within the temperature range of 1000 DEG C or below, has better heat-insulating and energy-saving effects and toughness compared with common heat-insulating materials, remarkably reduces the thickness of the heat-insulating layer, and is suitable for large-scale popularization and application. The material can be widely applied to the fields of industrial kilns, thermotechnical devices, heat preservation pipelines and the like.

Owner:ZHENGZHOU UNIV

A kind of preparation method of large-size zirconia-based thermal insulation material

The invention provides a preparation method of a large-size zirconia-based heat insulation material, and the heat insulation prepared by adopting the method. The preparation method comprises the following steps: 1, mixing deionized water, organic monomers and a cross-linking agent, adding alpha-Al2O3 powder, ZrO2 powder and a dispersant, and carrying out ball milling by adopting a zirconium dioxide ball to obtain a slurry; 2, adding an initiator and a catalyst to the slurry obtained in step 1, stirring, injecting the obtained mixture to a die, solidifying, and cooling to obtain a wet green body; and 3, drying the wet green body obtained in step 2, and sintering. The preparation method comprises special blank molding treatment according to the formula of specific powder, so the problem of adverseness of too large shrinkage in the zirconia sintering process to pore maintenance is effectively solved, the deformation and cracking problems appearing in the drying process of gel injection molded large-size green body are avoided, and the obtained green body has the advantages of high uniformity and small drying shrinkage.

Owner:SINOMA SYNTHETIC CRYSTALS CO LTD +1

A kind of preparation method of high-performance sintered insulation brick

ActiveCN110078530BRealize industrial productionSmall sintering shrinkageCeramic materials productionCeramicwareBrickThermal insulation

The invention provides a method for preparing high-performance sintered heat insulating bricks, which comprises the following steps: step 1, sludge from urban domestic sewage treatment plants or paper mill sludge is concentrated, filtered and dried; step 2, clay, sludge Carry out natural drying, crushing, crushing and sieving; step 3, mix the raw materials evenly to obtain the dry mixture, add water and stir evenly; step 4, carry out aging treatment on the wet mixture, and the aging time should exceed 24h; step 5 1. The brick blanks are molded to obtain bricks; step 6, the bricks are dried naturally at room temperature and then sent to the tunnel drying kiln for drying; step 7, after drying, the bricks are directly sent to the tunnel sintering kiln, the sintering temperature is 950 ~ 1100 ℃, The holding time of the brick body at the highest sintering temperature is 1 to 3 hours. The invention overcomes the disadvantages of poor mechanical properties and high thermal conductivity of traditional thermal insulation bricks, and realizes the production of high-performance thermal insulation bricks with a large amount of sludge; the source of raw materials is wide, the cost is low, and various production and domestic sludges are consumed in large quantities.

Owner:SOUTHEAST UNIV

Zirconium oxide sintering pure porcelain teeth

InactiveCN100574723CSimple methodSmall sintering shrinkageArtificial teethZirconia ceramicSintering shrinkage

The invention relates to a method for using zirconia to sinter full-ceramic tooth, which uses zirconia powder to be sintered at 1500-1900Deg. C to obtain the zirconia ceramic powder, to be grinded into powder or pulp, then adds some sintering agent and flexibilizer, to be sintered in mold secondary to obtain the full-ceramic tooth. The invention has simple process, less contraction, high strength, and low cost as 2% of foreign product.

Owner:王玉元

A low sintering temperature power type piezoelectric ceramic material and its preparation method

ActiveCN106565239BLower sintering temperatureImprove piezoelectric performancePiezoelectric/electrostrictive/magnetostrictive devicesElectromechanical coupling coefficientDielectric loss

The invention relates to a low sintering temperature power type piezoelectric ceramic material and a preparation method thereof. The general chemical formula of the piezoelectric ceramic material is: Pb 1‑x M x (Ni 1 / 2 W 1 / 2 ) y (Mn 1 / 3 sb 2 / 3 ) z (Zr e Ti f ) 1‑y‑z O 3 +awt%Fe 2 O 3 +bwt%Sm 2 O 3 +cwt%MnO 2 + dwt%CuO, where: M is Sr 2+ and / or Ba 2+ ; c=0.01~0.4, d=0.1~0.4. The low sintering temperature piezoelectric ceramic material of the present invention has the advantages of low sintering temperature, high piezoelectric performance, high mechanical quality factor, high electromechanical coupling coefficient, moderate dielectric constant and small dielectric loss.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

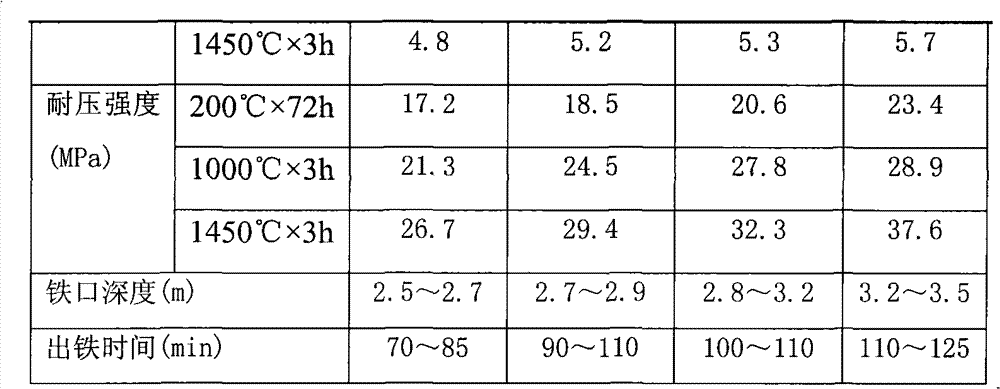

Stemming utilizing waste refractory material and preparation method thereof

InactiveCN102060548BImprove workabilitySmall sintering shrinkageBlast furnace componentsBlast furnace detailsSlagErosiveness

The invention provides a stemming utilizing a waste refractory material and a preparation method thereof. The stemming comprises the following raw materials: silicon carbide particles or fine powder, high-temperature fine asphalt powder, Jilin fine clay powder, coke particles, industrial grade corundum particles or fine powder, wherein recovered aluminum and magnesium material particles or fine powder used for an electric furnace is added; and tar serves as a bonding agent. The preparation method comprises the following steps of: preparing the raw materials according to a proportion; after uniformly stirring particle materials in a stirring machine for 1 to 10 minutes, adding 20 to 30 percent of the tar; stirring for 5 to 10 minutes; adding fine powder materials; stirring for 5 to 15 minutes; adding the remaining tar and stirring for 25 to 40 minutes; and extruding by using a stemming extruder and packaging. The stemming has the following advantages: high operating performance, low stemming sintering shrinkage, rapid sintering property, high scour resistance and slag iron erosiveness. The invention provides a way for regenerating and utilizing the waste refractory material, and contributes to saving resources and protecting environment.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

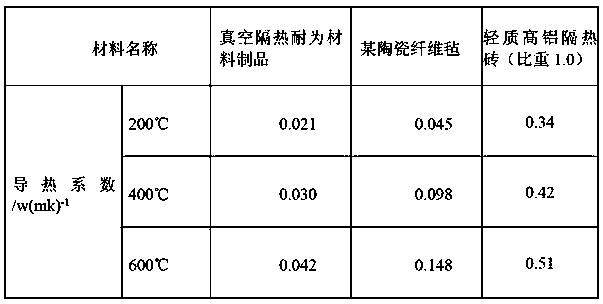

A vacuum heat-insulating refractory product and its preparation method

ActiveCN106631065BImprove insulation performanceLow thermal conductivityLinings repairGlass shaping apparatusThermal transmittanceKiln burner

The invention discloses a vacuum insulating refractory product and a preparation method thereof. The vacuum insulating refractory product is composed of a core material and a high-resistance film wrapped on the exterior of the core material, wherein the core material is formed by uniformly dispersing and then pressing 95-70wt% of low heat-conducting micro-pore powder and 5-30wt% of dispersed fire-resistant staples; a high-temperature resisting airtight film which is prepared from an inorganic material used as a main component in the manner of tape casting is served as the high-resistance film; the vacuum insulating refractory product is prepared after the pressed and molded core material is wrapped with the high-resistance film and then the vacuum hot-pressing packaging is performed; the product can be used under a temperature condition at 500-1200 DEG C, can maintain a vacuum structure and has ultralow thermal conductivity and high performance cost ratio; and the vacuum insulating refractory product is suitable for large-scale production, is convenient in mounting and use, can be matched with lightweight and heavy refractory materials and has an obvious energy-saving effect in effectively insulating the liner compound of a high-temperature industrial furnace.

Owner:ZHENGZHOU UNIV

Zirconia ceramic preparation method and zirconia ceramic prepared according to method

InactiveCN109836152AIncrease particle size distributionSmall sintering shrinkageNH3 compoundParticle-size distribution

The invention relates to a zirconia ceramic preparation method, which comprises: sequentially carrying out forward drip co-precipitation and reverse drip co-precipitation by controlling the concentrations of a ZrOCl2.8H2O solution and ammonia water, washing the precipitate, drying, calcining to obtain primary zirconia powder with wide particle size distribution, carrying out ball milling, granulating, molding, sintering, and annealing to obtain the zirconia ceramic. With the preparation method of the present invention, the sintering shrinkage rate of the zirconia ceramic can be effectively reduced while the high fracture toughness can be maintained. The present invention further relates to the zirconia ceramic prepared according to the preparation method.

Owner:山西朔神新材料科技有限公司

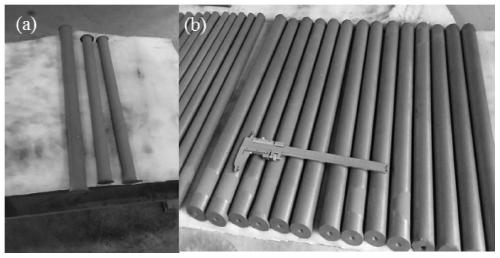

A method for preparing superhard cemented carbide rods using wc-co composite powder as raw material by dry bag isostatic pressing and low pressure sintering

Owner:HEFEI UNIV OF TECH

f-ca-lu doped aluminum nitride composite ceramic green body and its preparation process

The invention relates to a F-Ca-Lu-doped aluminum nitride composite ceramic green body with high thermal conductivity and a casting process thereof. The ceramic green body is prepared by a casting process, and organic solvents, binders, nitriding Aluminum powder, sintering aid, dispersant, anti-sedimentation agent, plasticizer and other raw materials are uniformly dispersed and stirred, and sand-milled to obtain casting slurry, and the slurry is subjected to vacuum defoaming, casting plate making, isostatic pressing and other processes The multi-phase ceramic green body with high flatness and small sintering shrinkage can be obtained through advanced processing, and at the same time meet the industrial needs of rapid, large-scale, and stable quality manufacturing of green bodies; the obtained aluminum nitride ceramic substrate is widely used in the field of integrated circuits, high-power devices and Optoelectronic engineering fields such as high-power LED lighting have broad application prospects.

Owner:福建臻璟新材料科技有限公司

A kind of silicon-based ceramic core and preparation method thereof

ActiveCN106747369BSmall deformation at high temperatureSmall sintering shrinkageUltimate tensile strengthSintering shrinkage

The invention provides a silica-based ceramic mold core and a preparation method thereof. The silica-based ceramic mold core and the preparation method are used for solving the problems of insufficient high-temperature intensity, great high-temperature deflection and the like of the silica-based ceramic mold core in the prior art. The invention provides the silica-based ceramic mold core with high high-temperature intensity, low high-temperature deformation and low sintering shrinkage, and the preparation method.

Owner:成都航大新材料有限公司

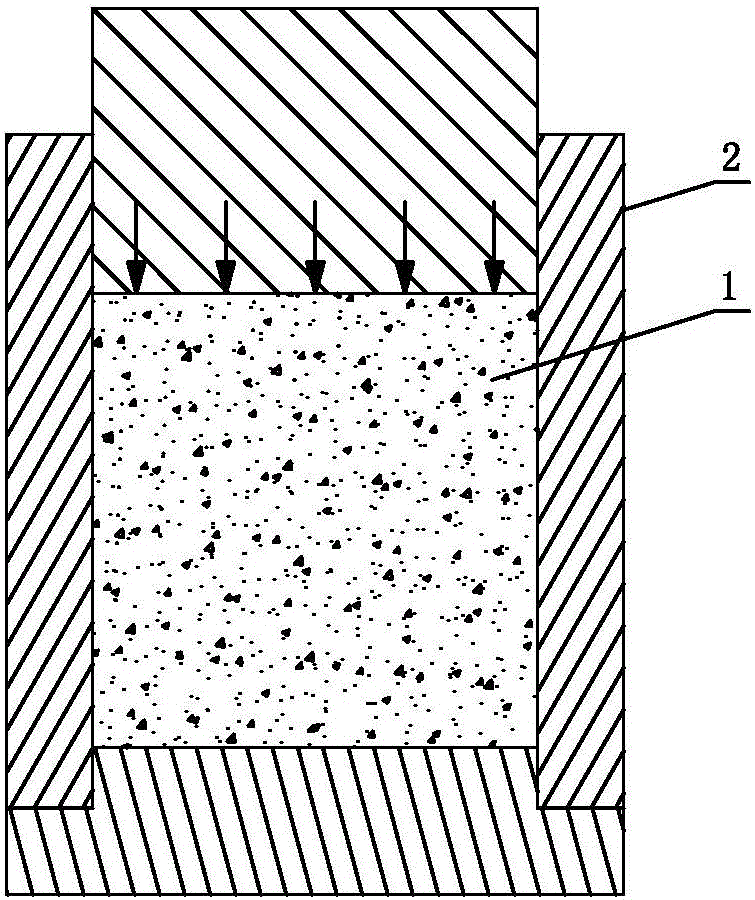

High-density super-hard material manufacturing method

InactiveCN106495698AHigh densityHigh strengthTransportation and packagingMetal-working apparatusVacuum pumpingHigh density

A high-density super-hard material manufacturing method includes the steps: weighing formula raw materials; uniformly stirring the formula raw materials in a mixer; pre-forming the formula raw materials by a hydraulic former; performing vacuum pumping seal in a flexible film bag; performing isostatic pressing secondary pressure shaping in a high-pressure container; demolding; performing normal pressure sintering in an electric furnace; forming products. The manufacturing method has the advantages that product blanks are more compact and higher in strength and damage to semi-finished products is low in the production process as the product blanks in the high-pressure container are secondarily pressurized and shaped in different directions by the aid of pressurizing media, the product blanks are uniform in density, low in sintering shrinkage and high in dimensional precision, so that high compactness and high strength of the products are ensured, the yield of the products is improved, hot pressed sintering of the product blanks in the intermittent electric furnace is omitted, so that the product blanks can be sintered in a continuous electric kiln, the labor intensity of workers is greatly relieved, production efficiency is improved, and production cost is reduced.

Owner:眉山市奔朗新材料科技有限公司

Preparation method for high-crystallinity silver powder

The invention relates to a preparation method for high-crystallinity silver powder. The preparation method is characterized by comprising the following steps of: firstly, synthesizing a silver carbonate precursor; uniformly coating the silver carbonate precursor by using a coating agent; and performing low-temperature crystal water removing, high-temperature thermal decomposition, densification sintering and washing on the coated silver carbonate precursor to obtain high-crystallinity silver powder. Due to the adoption of the method disclosed by the invention, high-crystallinity silver powder of which the particle diameter is 0.1-5 mu m and the tap density is 3.0-7.0 g / cm<3> can be finally obtained; the silver powder can be used for preparing silver slurry or silver paste for fine threads and high-accuracy printed galvanic circles; the silver powder has the advantages of high dispersity, high crystallinity, superior degree of sphericity, uniform particle size distribution, easiness for dispersing in silver slurry or silver paste and high filling characteristic, so that high-accuracy fine thread printing can be realized; and meanwhile, an obtained silver thick film has low sintering concentration rate and low bulk resistivity.

Owner:宁夏中色新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com