A method for preparing superhard cemented carbide rods using wc-co composite powder as raw material by dry bag isostatic pressing and low pressure sintering

A composite powder and low-pressure sintering technology, which is applied in the field of preparation of superhard cemented carbide rods, can solve the problems of reducing the strength and density of the alloy, the impossibility of completely removing the forming agent, and affecting the quality of the cemented carbide. Internal stress, preventing incomplete removal, and reducing the effect of processing aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

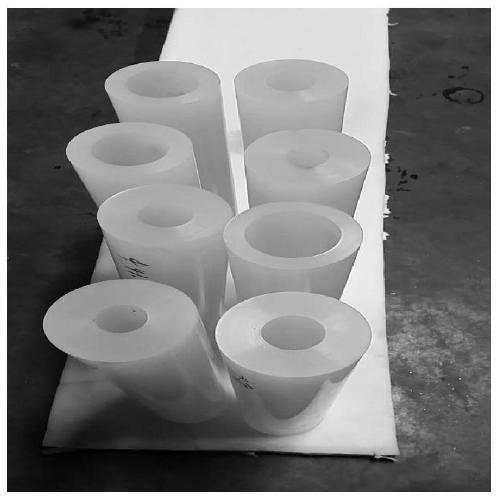

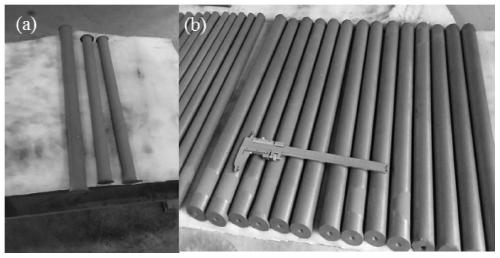

[0037] 1) Dry bag isostatic pressing:

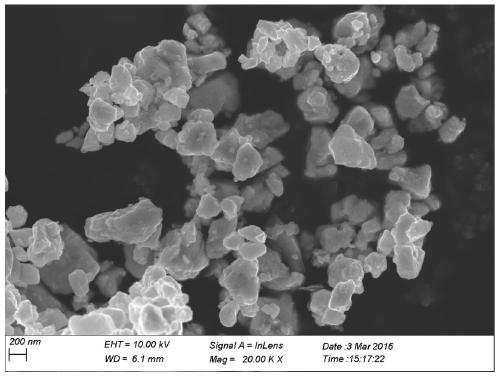

[0038] 2.53 kg of nano-WC-6Co composite powder with a Co mass content of 6% purchased from Anhui Rongda Composite Powder Technology Co., Ltd. was put into the cavity mold. permanent polyurethane; beat and vibrate the powder loaded into the mold, and cover with the upper cover plate; then use the process of five-stage pressurization and three-stage pressure relief to press and form to obtain a pressed blank;

[0039] The five-stage pressurization process is as follows: the first stage of pressing pressure is 300bar, the pressurization time is 10s, and the pressure holding time is 5s; 20s, holding pressure 15s; the fourth stage pressing pressure 1000bar, pressing time 40s, holding pressure 20s; fifth stage pressing pressure 1200bar, pressing time 60s, holding pressure 60s.

[0040]The three-stage pressure relief process is as follows: the first stage is to release pressure to 800bar, the pressure relief time is 30s, and the pressure is ma...

Embodiment 2

[0056] 1) Dry bag isostatic pressing:

[0057] Put 2.25 kg of nano-WC-8.5Co composite powder with a Co mass content of 8.5% purchased from Anhui Rongda Composite Powder Technology Co., Ltd. into the cavity mold. The mold size is Φ8.2×370mm in diameter, and the mold material is Modified polyurethane; beat and vibrate the powder loaded into the mold, and cover it with a cover plate; then press molding by five-stage pressurization and three-stage pressure relief to obtain a pressed blank;

[0058] The five-stage pressurization process is as follows: the first stage of pressing pressure is 300bar, the pressurization time is 10s, and the pressure holding time is 5s; 20s, holding pressure 15s; the fourth stage pressing pressure 1000bar, pressing time 40s, holding pressure 20s; fifth stage pressing pressure 1200bar, pressing time 60s, holding pressure 60s.

[0059] The three-stage pressure relief process is as follows: the first stage is to release pressure to 800bar, the pressure r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com