Wiring board and its mfg. method

A manufacturing method and a wiring board technology, applied in the field of wiring boards, can solve the problem of high cost and achieve the effect of stable dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

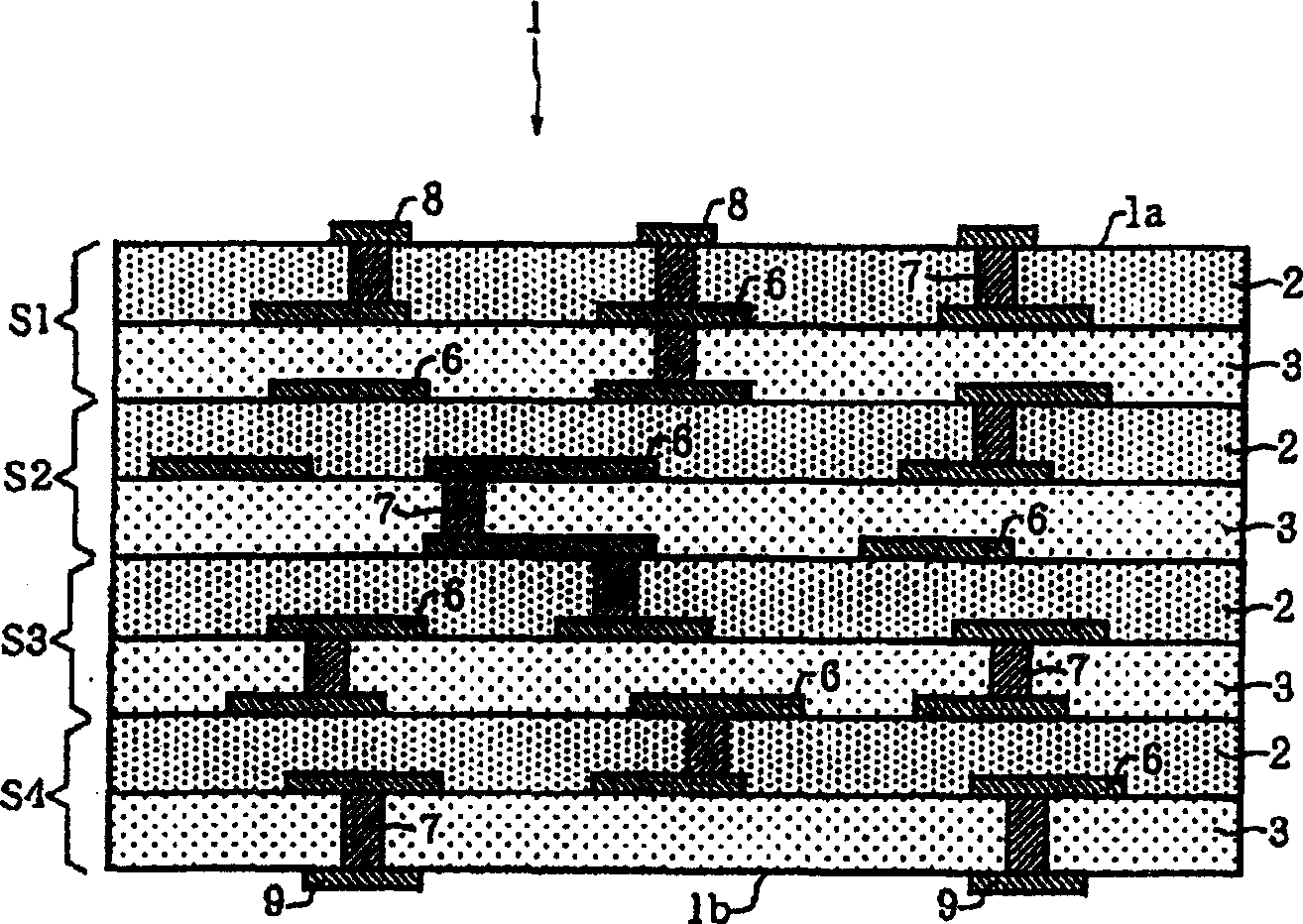

Method used

Image

Examples

example

[0056] Specific examples of the present invention will be described below by way of comparative examples.

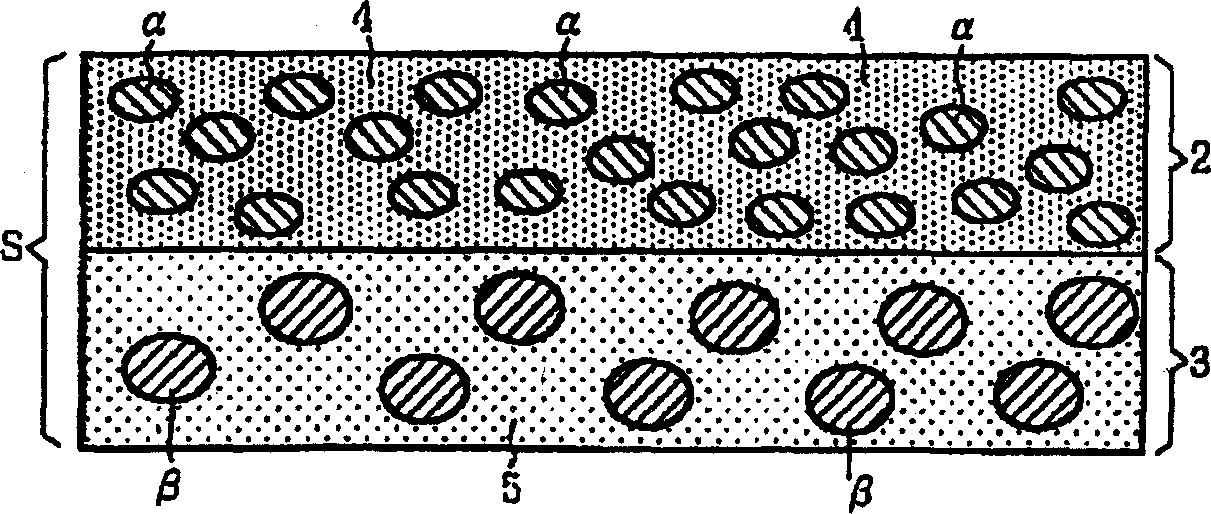

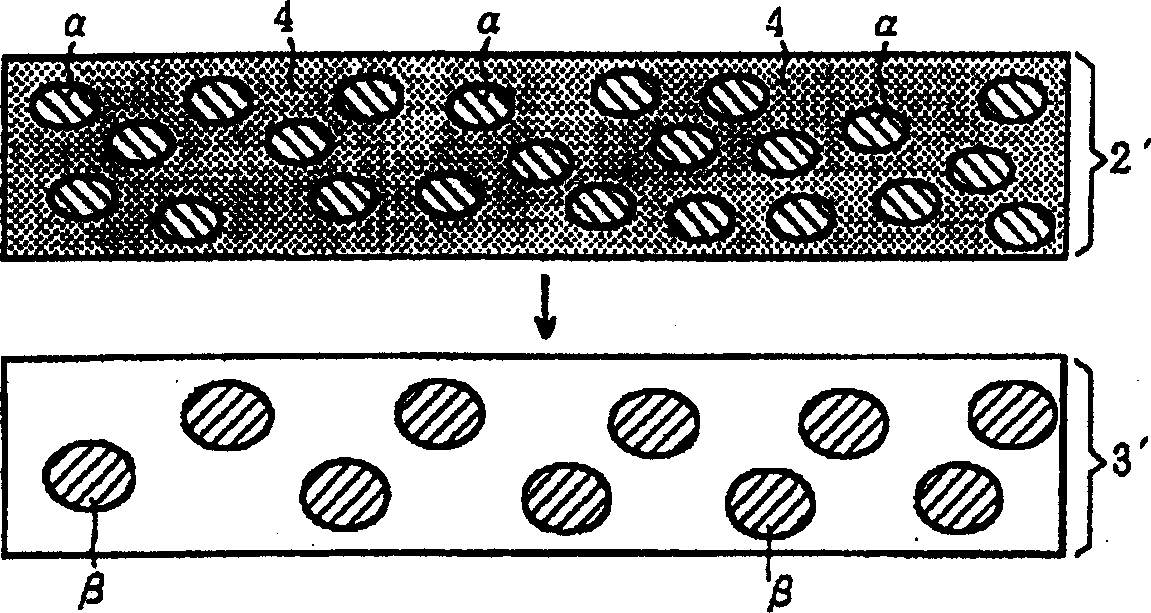

[0057] Green sheet (2') of low temperature firing layer:

[0058] In each example (Examples 1-5 and Comparative Examples 1-3), Al with the average particle size and specific surface area shown in Table 1 was prepared. 2 o 3 (alumina) and including SiO 2 (Silicon dioxide), Al 2 o 3 (Al2O3) and B 2 o 3 (Diboron trioxide) Borosilicate glass powder (4) as the main component is used as ceramic particles α and glass powder, respectively. In addition, an acrylic adhesive and DOP (dioctyl phthalate) are prepared as an adhesive component and a plasticizer component, respectively, when forming a low-temperature firing layer green sheet (2').

[0059] Mix ceramic particles α(Al 2 o 3 Al2O3) and glass powder (4) (in Table 1, the upper row indicates weight percent, and the lower row indicates volume percent), and 12 parts by weight are packed into a jar, on the basis of 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com