Preparation method for high-crystallinity silver powder

A high-crystallinity, spherical technology, applied in the preparation of high-crystallinity spherical silver powder, carbonate or bicarbonate-coated silver carbonate precursor, can solve the problem of reducing the tap density and filling characteristics of silver powder, and the monodispersity of silver powder particles Good monodispersity, wide particle size distribution and good dispersion can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

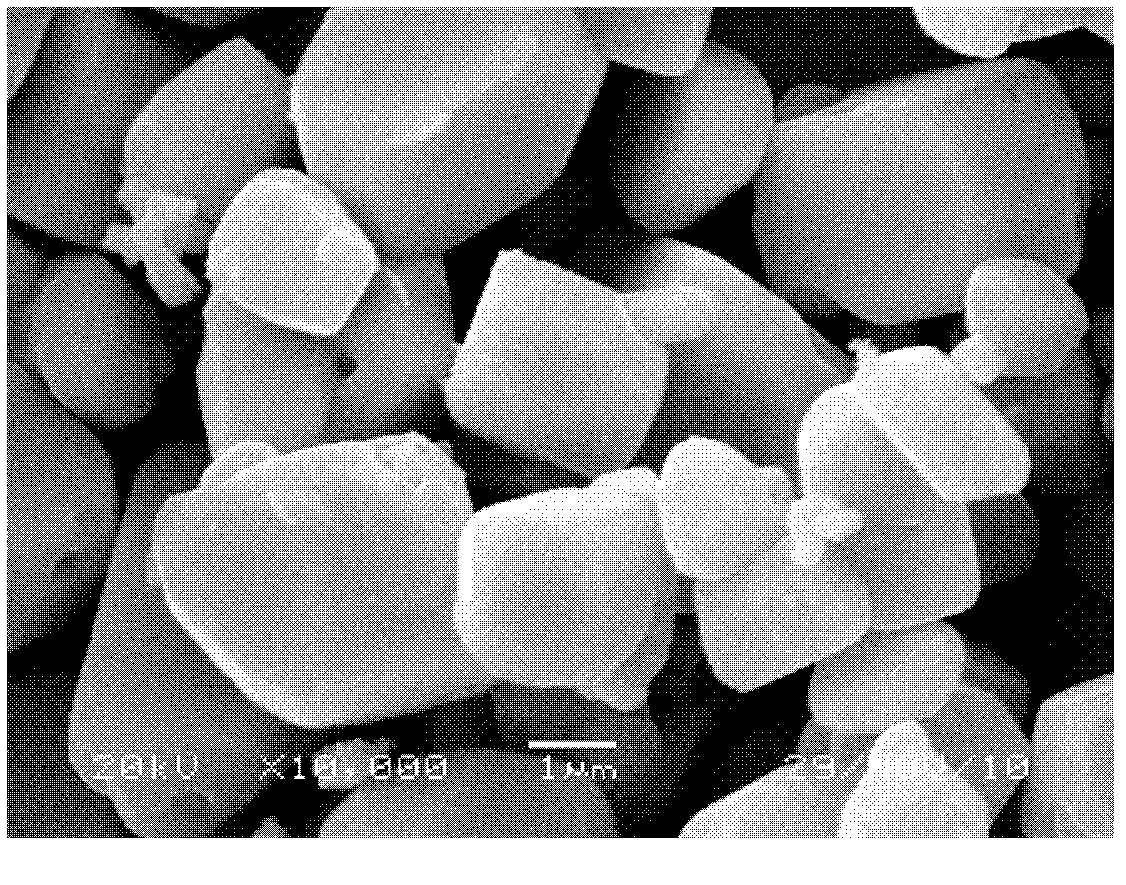

Embodiment 1

[0034] Add 170g of analytically pure silver nitrate to 1000ml of pure water to dissolve, then add 58.3g of sodium carbonate to 500ml of pure water to dissolve, quickly add the silver nitrate solution to the sodium carbonate solution and stir for 10min, react for 20min, let it stand for clarification, and then suction filter to obtain carbonic acid Silver cake.

[0035] Add 138g of analytically pure potassium carbonate into 130ml of water and stir until dissolved. Add the silver carbonate filter cake to the potassium carbonate solution and stir vigorously to mix, use physical methods to remove the water in the potassium carbonate solution so that the potassium carbonate takes silver carbonate as the nucleus and crystallizes on its surface, and the coated product is suction filtered , The obtained filter cake was dried at 60° C. for 24 hours. The dried product was calcined at 600°C for 1.5h. The calcined product was added into 1000ml of pure water, stirred and washed thoroughl...

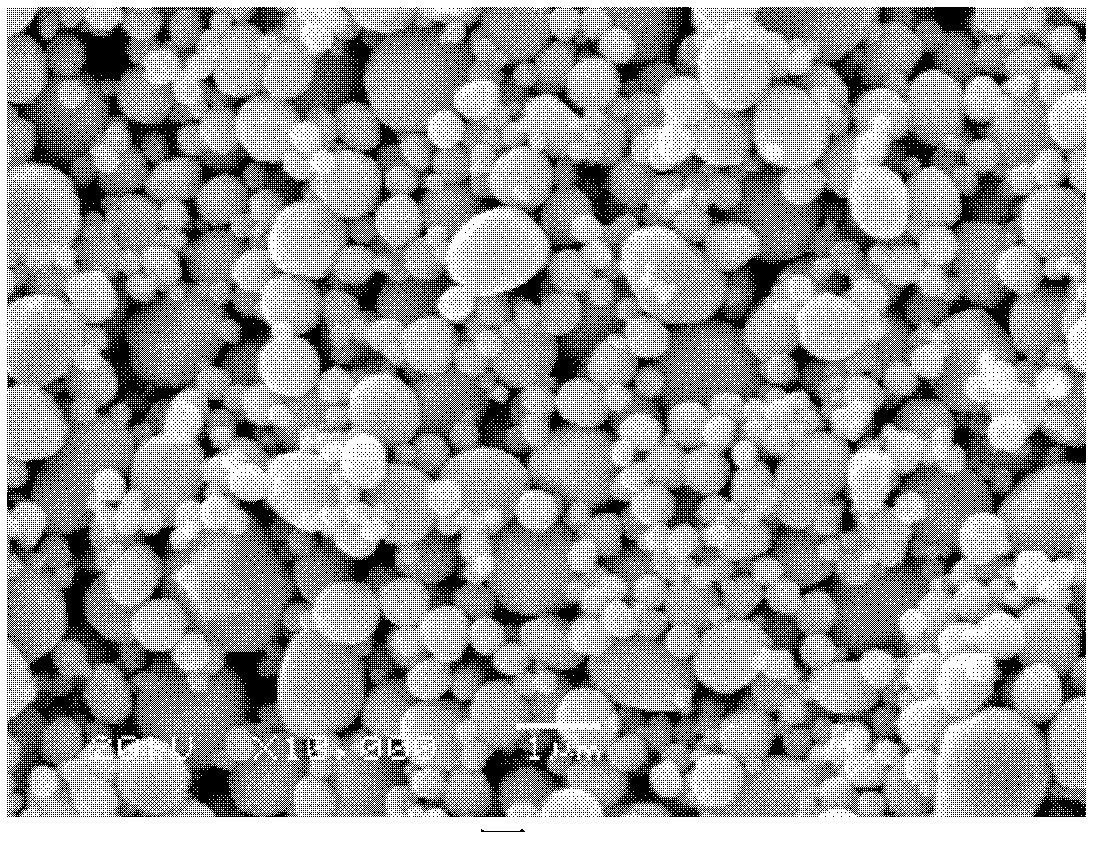

Embodiment 2

[0038] Add 85g of analytically pure silver nitrate to 2000ml of pure water to dissolve, then add 30g of sodium carbonate to 1000ml of pure water to dissolve, slowly add silver nitrate solution to it while stirring the sodium carbonate solution, react for 30min, let it stand for clarification, and then suction filter to obtain Silver Carbonate Filter Cake.

[0039] Add 65g of sodium bicarbonate into 620ml of water and stir to dissolve, then add the silver carbonate filter cake into the sodium bicarbonate solution and stir vigorously to mix, use physical methods to slowly dehydrate the sodium bicarbonate solution so that the sodium bicarbonate is evenly crystallized on the silver carbonate , suction filtered to obtain the coated product filter cake and dried at 60° C. for 24 hours. The dried product was calcined at 660°C for 2h. The calcined product was added into 1000ml of pure water, stirred and washed thoroughly to obtain silver powder, and the silver powder was vacuum-dried...

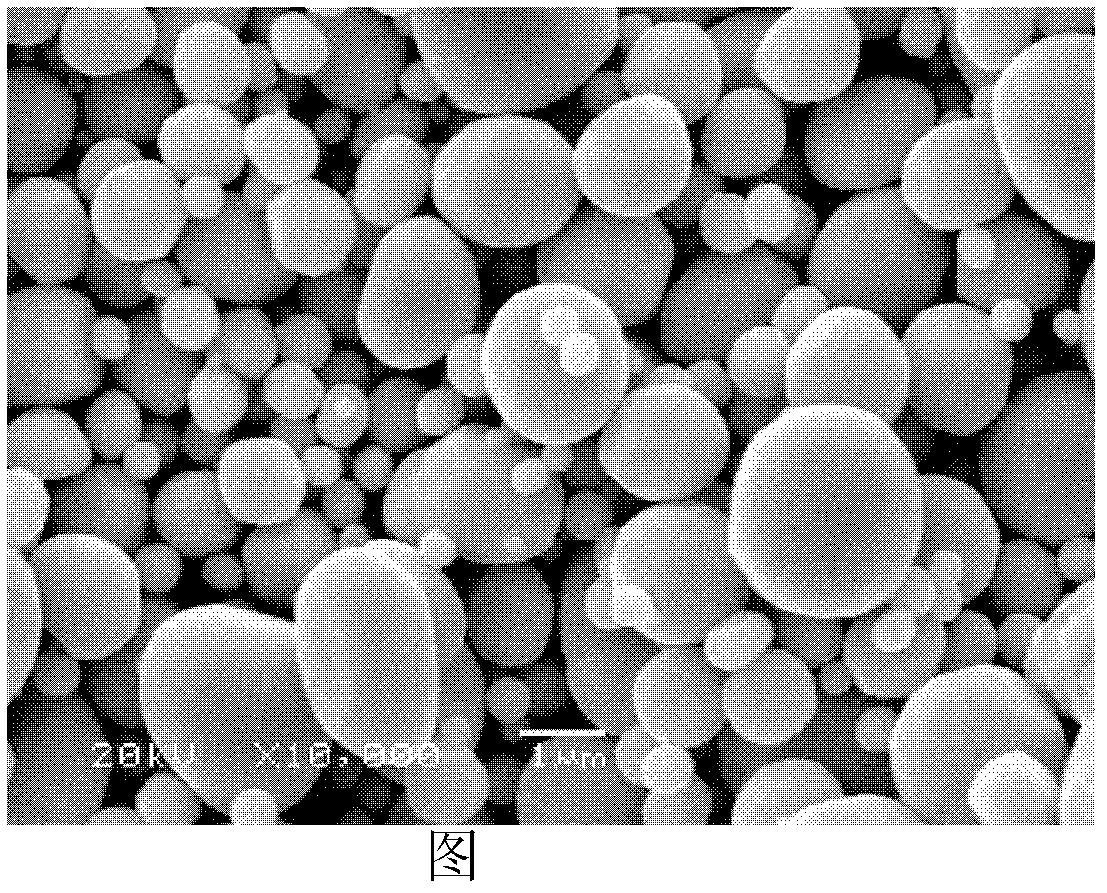

Embodiment 3

[0042] Add 340g of analytically pure silver nitrate to 1500ml of pure water to dissolve, then add 120g of sodium carbonate to 1000ml of pure water to dissolve, quickly add the silver nitrate solution to the sodium carbonate solution and stir for 10min, react for 20min, let it stand for clarification, and then filter to obtain silver carbonate filter cake.

[0043] Add 414g of analytically pure potassium carbonate to 350ml of water and stir until dissolved. Add the silver carbonate filter cake to the potassium carbonate solution and stir vigorously to mix, use physical methods to remove the water in the potassium carbonate solution so that the potassium carbonate takes silver carbonate as the nucleus and crystallizes on its surface, and the coated product is suction filtered , The obtained filter cake was dried at 120° C. for 24 hours. The dried product was calcined at 750°C for 1.5h. The calcined product was added into 1000ml of pure water, stirred and washed thoroughly to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com