Preparation method of tin oxide nanotubes

A technology of nanotubes and tin oxide, applied in the field of preparation of tin oxide nanotubes, can solve the problems of impurity of tin oxide nanotubes, easy introduction of impurities, messy structure of tin oxide nanotubes, etc., and achieves low cost and simple process control process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Take by weighing 113 milligrams of analytically pure stannous chloride and 0.3 gram of urea respectively and join in 40 milliliters of absolute ethanol alcohol, stir and mix under normal temperature for subsequent use;

[0018] (2) Transfer the mixed solution of the dehydrated ethanol obtained above to 100 milliliters of high-temperature reaction kettle (polytetrafluoroethylene lining);

[0019] (3) Put the high-temperature reactor of step (2) into a constant temperature drying oven and keep it warm at 150° C. for 12 hours, and naturally cool to room temperature;

[0020] (4) Wash the white precipitate obtained in step (3) repeatedly with deionized water or absolute ethanol several times, and then dry it in a drying oven at 60°C for 10 hours to prepare the porous structure tube wall tin oxide nanometer Tube.

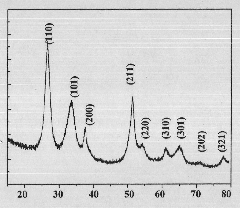

[0021] The prepared tin oxide nanotube with a porous tube wall structure has monodispersity, the inner diameter of the tin oxide nanotube is 50-60 nanometers...

Embodiment 2

[0023] (1) Take by weighing 225 milligrams of analytically pure stannous chloride and 0.6 gram of urea respectively and join in 40 milliliters of dehydrated ethanol alcohol, stir and mix evenly at room temperature for subsequent use;

[0024] (2) Transfer the mixed solution of the dehydrated ethanol obtained above to 100 milliliters of high-temperature reaction kettle (polytetrafluoroethylene lining);

[0025] (3) Put the high-temperature reaction kettle of step (2) into a constant temperature drying oven and keep it warm at 180° C. for 15 hours, and naturally cool to room temperature;

[0026] (4) Wash the white precipitate obtained in step (3) repeatedly with deionized water or absolute ethanol several times, and then dry it in a drying oven at 80°C for 12 hours to prepare the porous structure tube wall tin oxide nanometer Tube.

[0027] The prepared tin oxide nanotube with porous tube wall structure has monodispersity, the inner diameter of the tin oxide nanotube is 60-70 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com