Patents

Literature

81 results about "Bulk resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

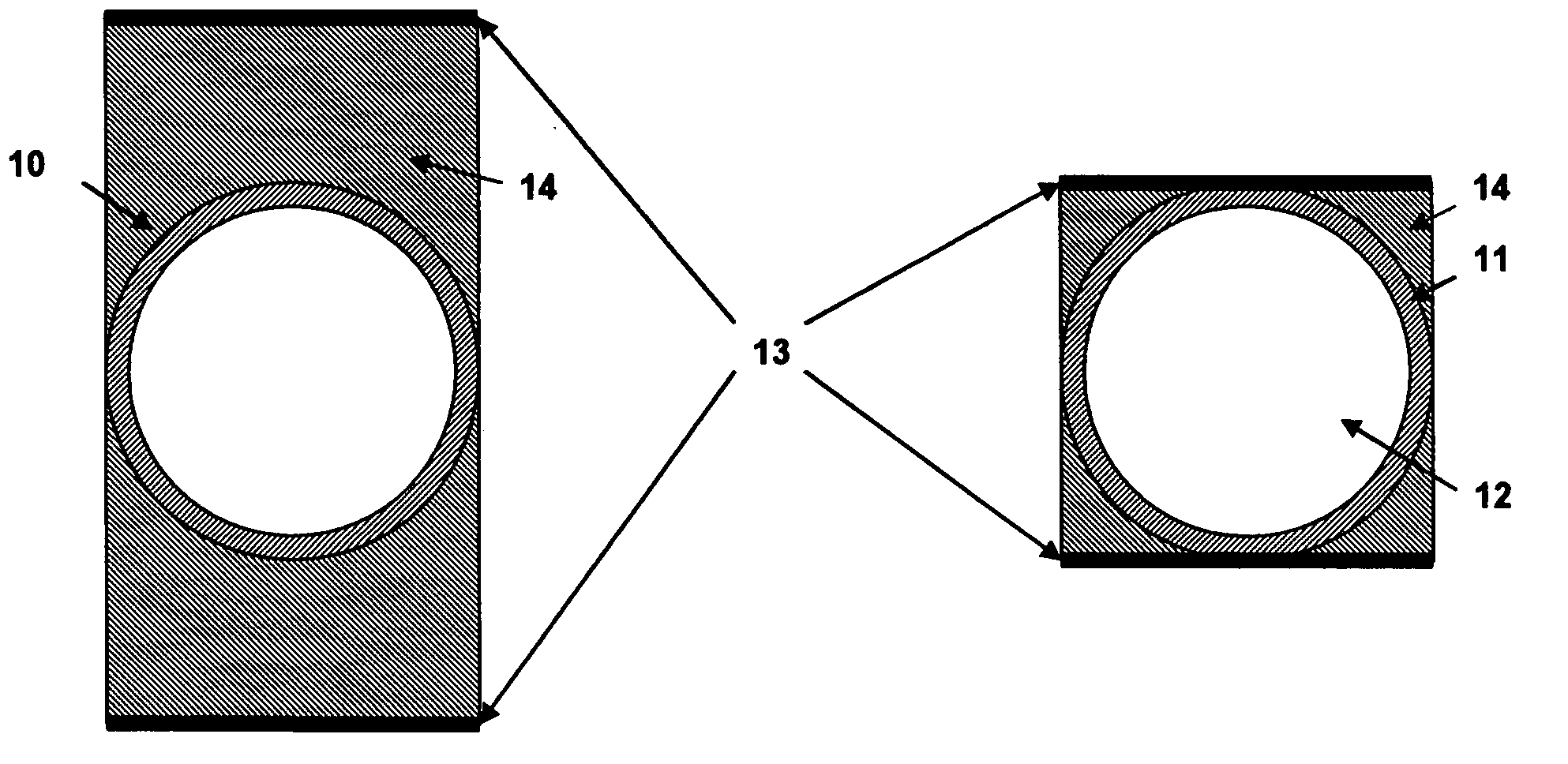

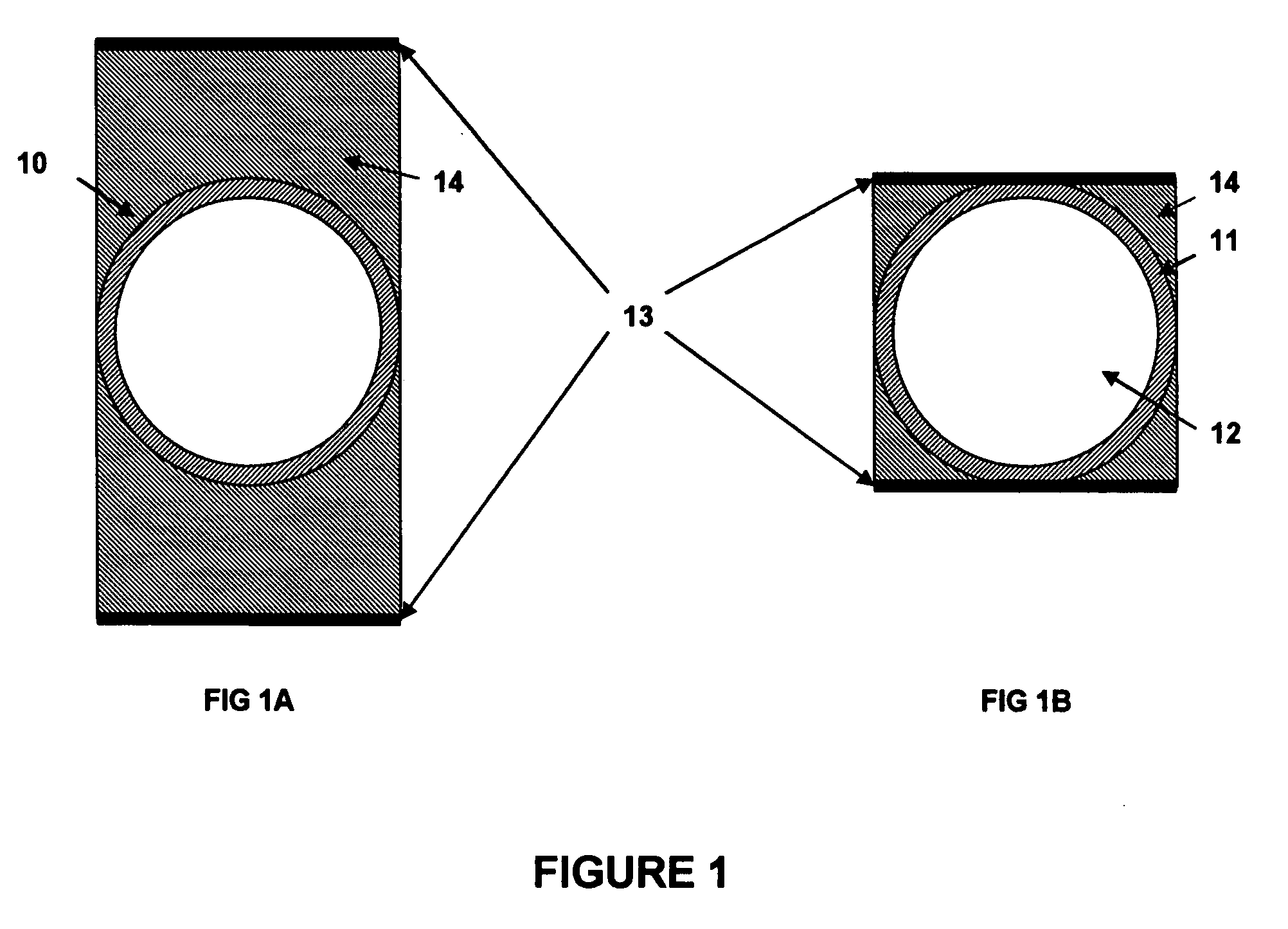

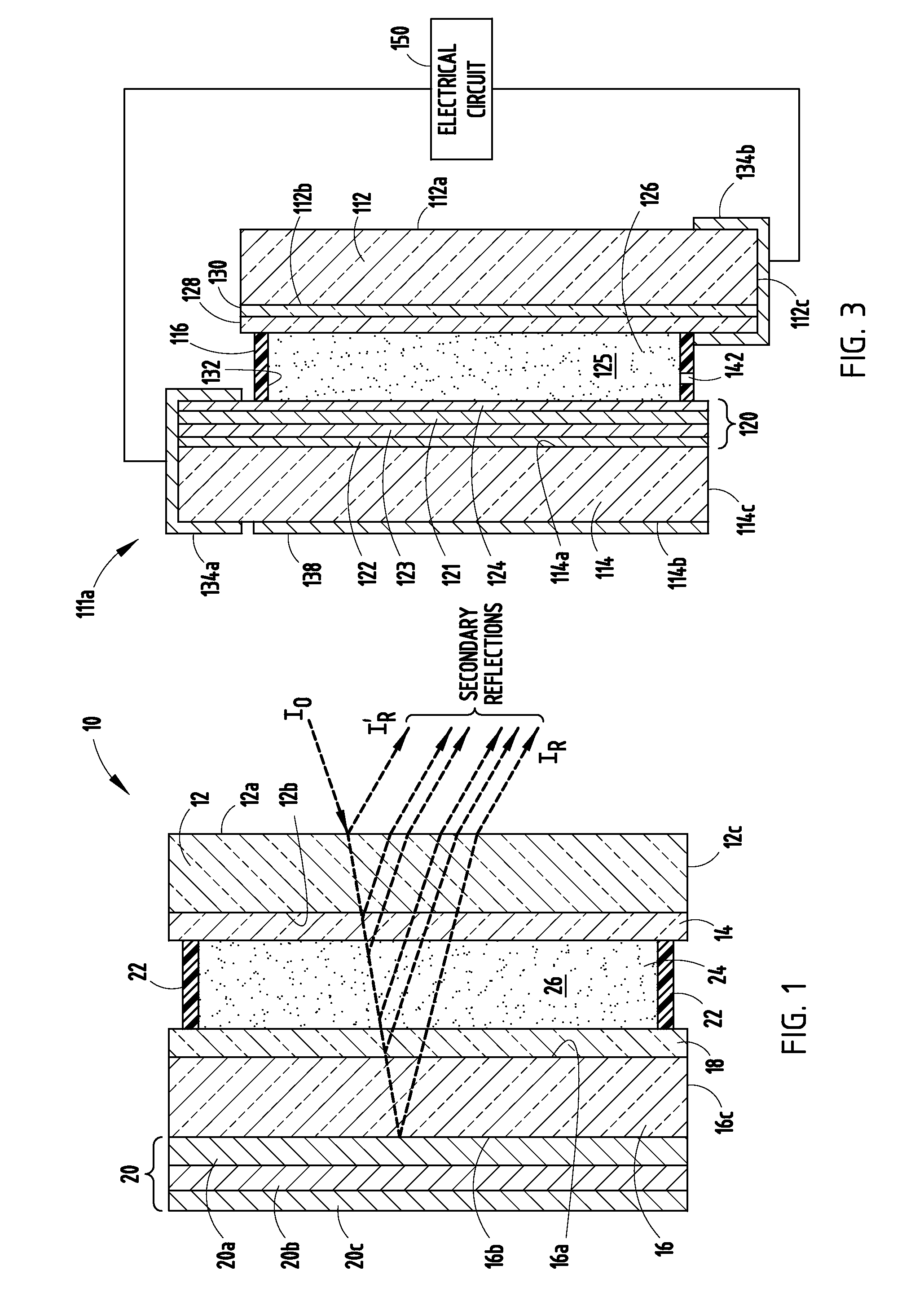

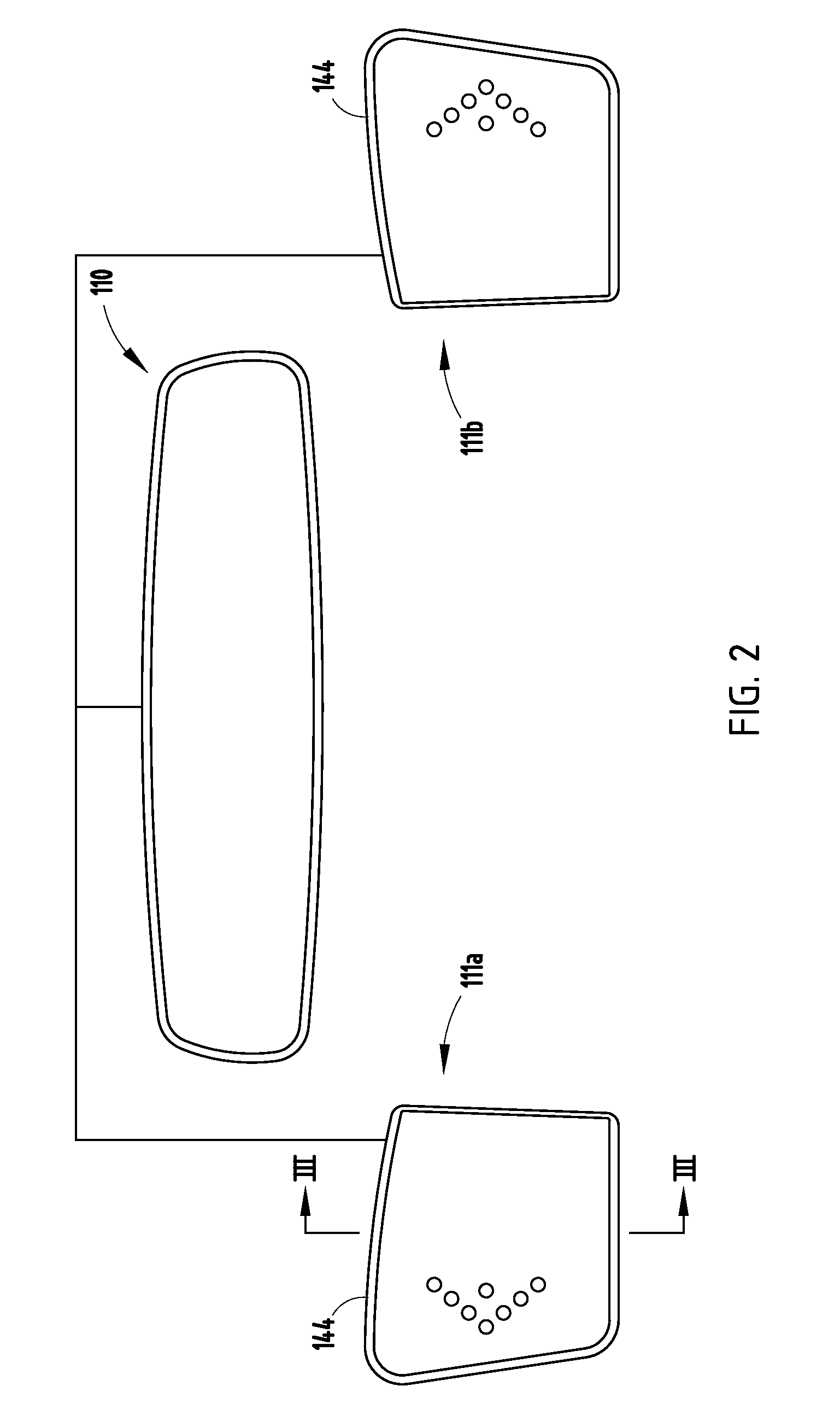

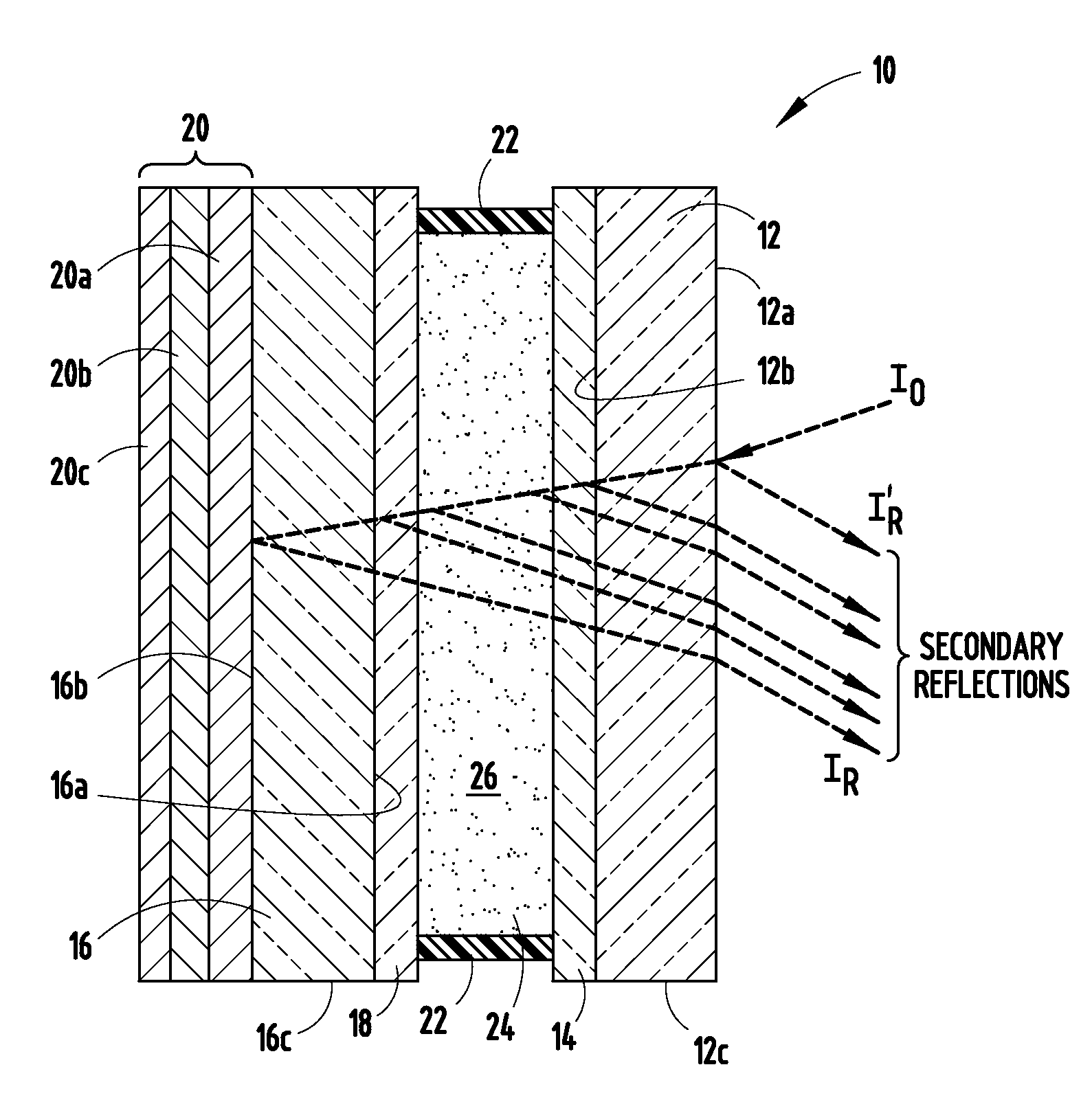

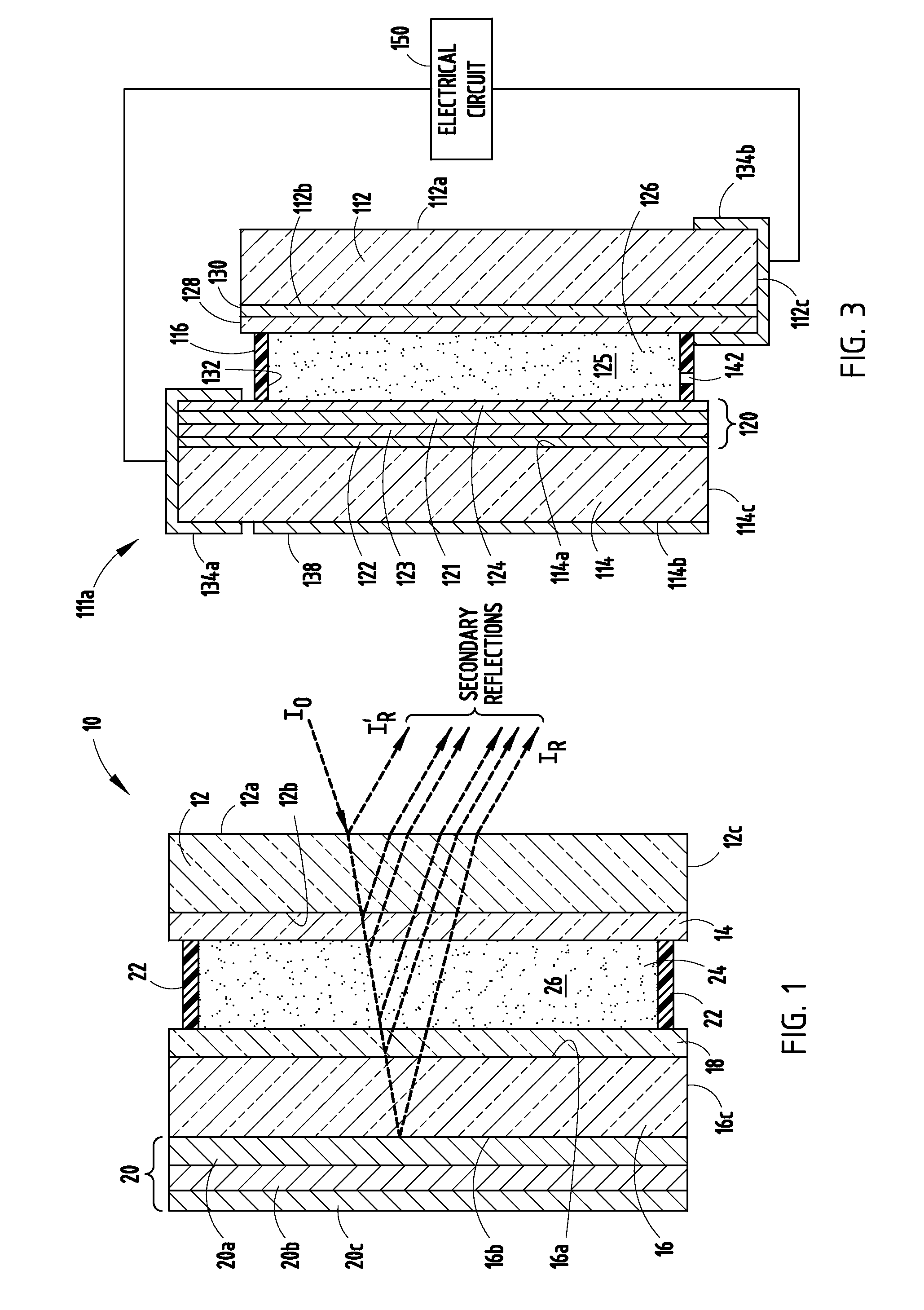

Electro-Optical Element Including Metallic Films and Methods For Applying The Same

A method for manufacturing an electrochromic element comprises providing a first substrate having first and second surfaces and a first edge surface, providing a second substrate having third and fourth surfaces and a second edge surface, the third surfaces facing the second surface, providing an electrochromic medium located between the first and second substrates, the medium having a light transmittance that is variable upon application of electric field thereto, applying a conductive layer on a portion of at least one of the surfaces, wherein applying the layer is accomplished at substantially atmospheric pressure, and applying at least one of metallic particles, an organometallic, a metallo-organic, and combinations thereof, wherein the conductive layer has a bulk resistivity of greater than or equal to 150 μΩ·cm. The conductive layer may be applied via ink jetting, ultrasonic spraying, auger or jet pumping.

Owner:GENTEX CORP

Electro-optical element including metallic films and methods for applying the same

A method for manufacturing an electrochromic element comprises providing a first substrate having first and second surfaces opposite one another and a first edge surface, providing a second substrate having third and fourth surfaces opposite one another and a second edge surface, wherein the third surfaces faces the second surface, and providing an electrochromic medium located between the first and second substrates, wherein the electrochromic medium has a light transmittance that is variable upon the application of electric field thereto. The method further complies applying a conductive layer on at least a portion of at least a select one of a first, second, third, and fourth surfaces and the first and second edge surfaces, wherein applying the conductive layer is accomplished at substantially atmospheric pressure and including applying at least a select one of metallic particles, an organometallic, a metallo-organic, and combinations thereof, and wherein the conductive layer has a bulk resistivity of less than or equal to 150 μΩ·cm. Other aspects of this invention comprise applying the conductive layer via ink jetting, ultrasonic spraying, auger pumping and jet pumping.

Owner:GENTEX CORP

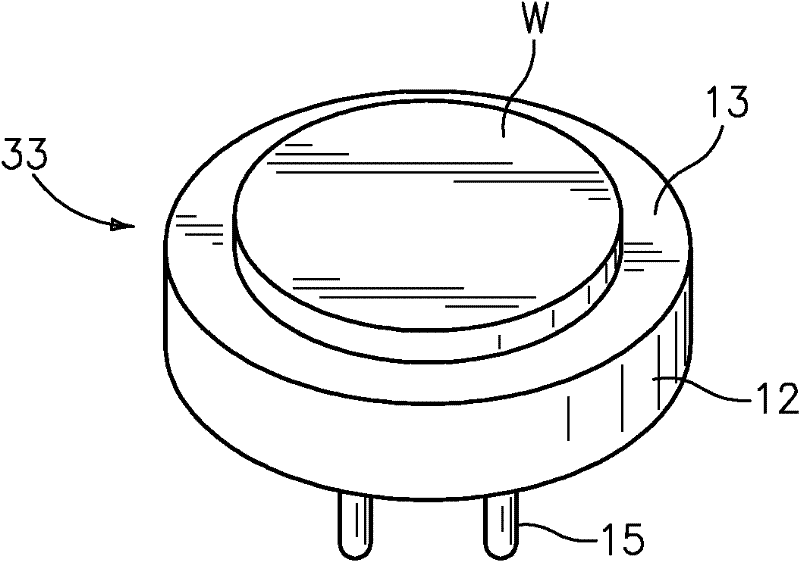

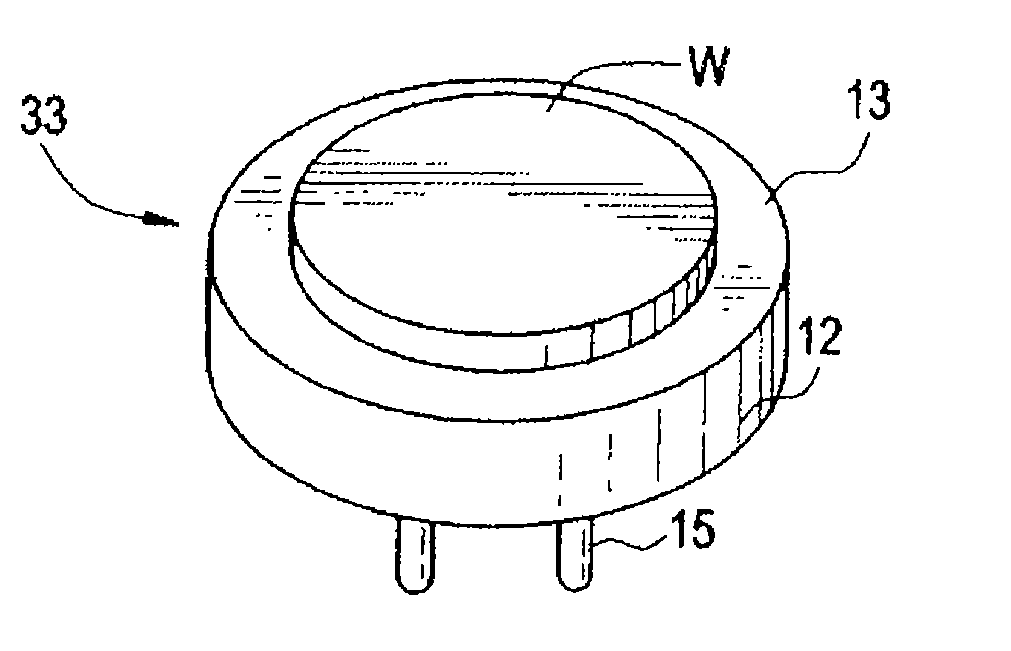

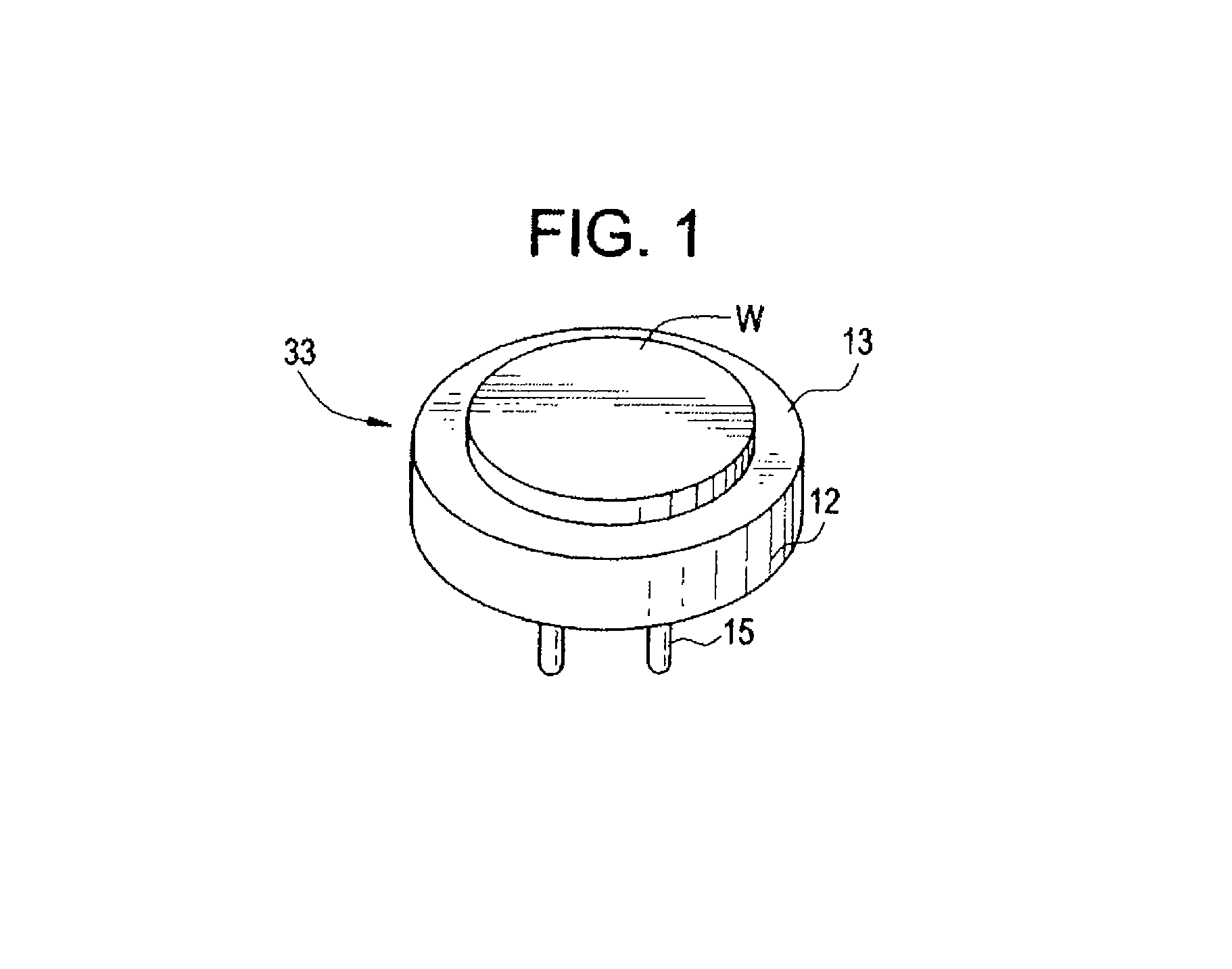

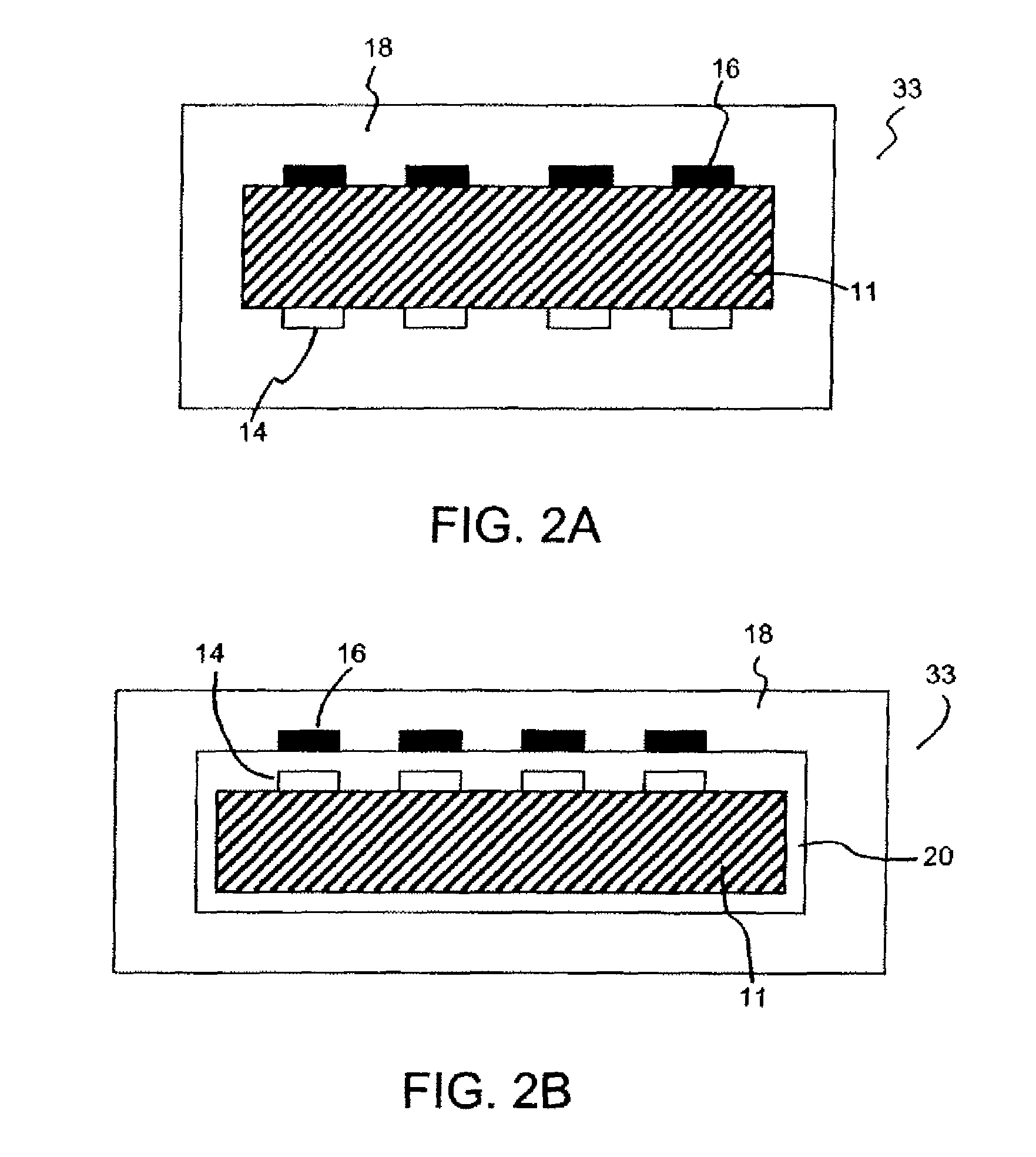

Wafer processing apparatus having a tunable electrical resistivity

InactiveUS20100053841A1Semiconductor/solid-state device manufacturingElectrical resistance and conductanceElectromagnetic shielding

An article with an etch resistant coating is disclosed. The article is a heating element, wafer carrier, or electrostatic chuck. The article has a base substrate made of a ceramic or other material, and further has one or more electrodes for resistance heating or electromagnetic chucking or both. The eth resistant coating has a plurality of regions made from materials having different electrical volume resistivities, such that the overall coating has a bulk resistivity that can be tailored by varying the relative size of each region.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

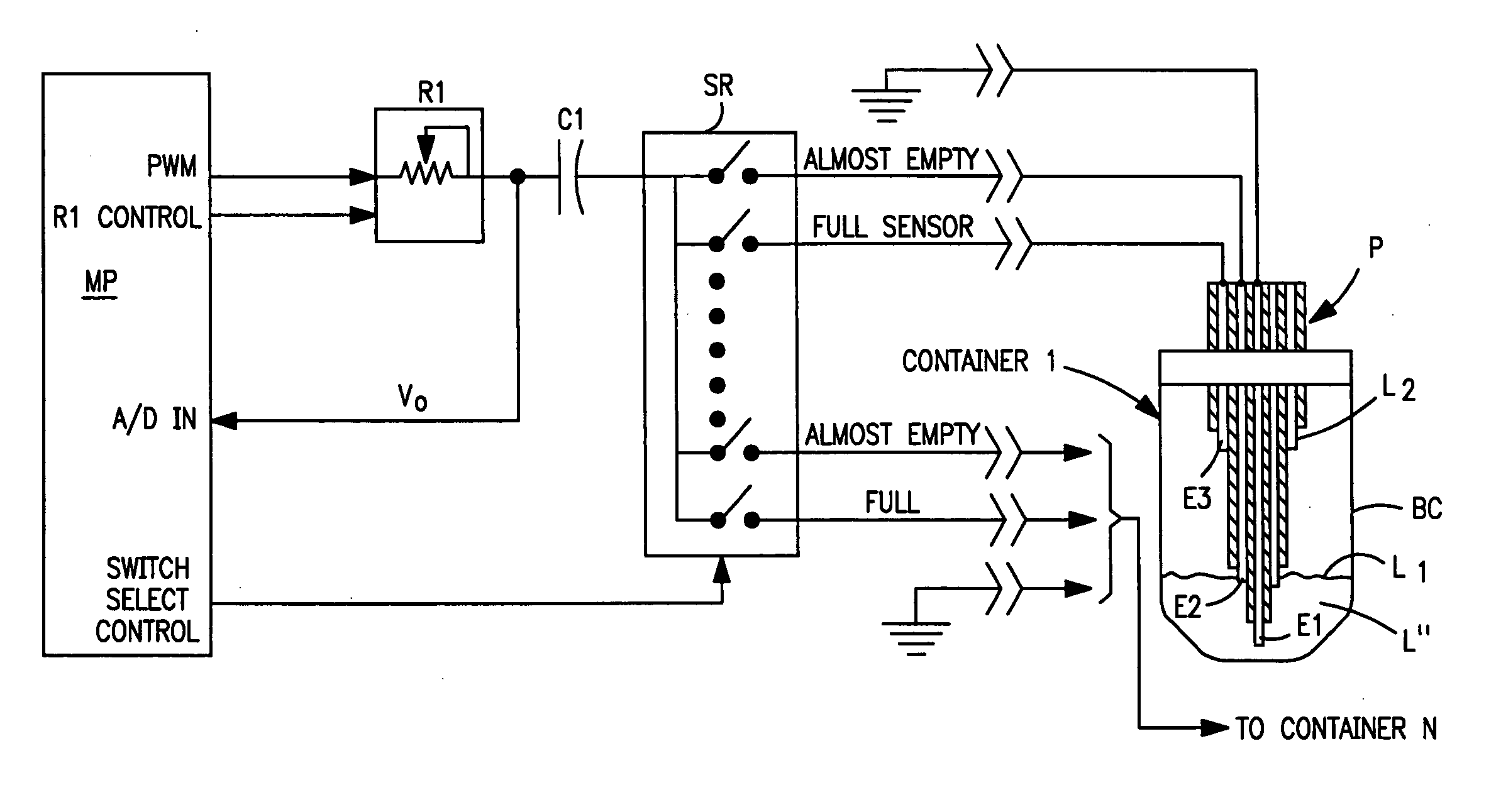

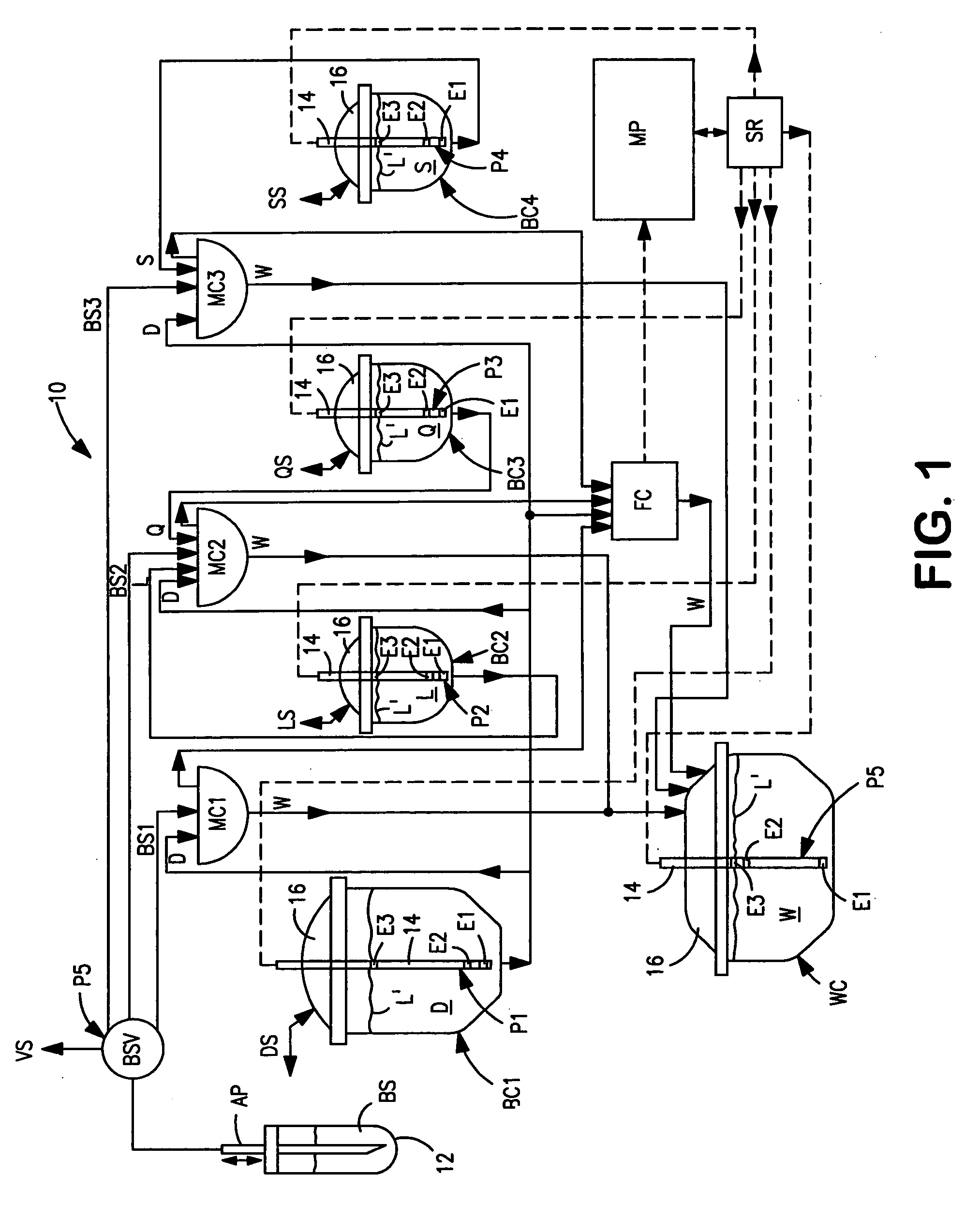

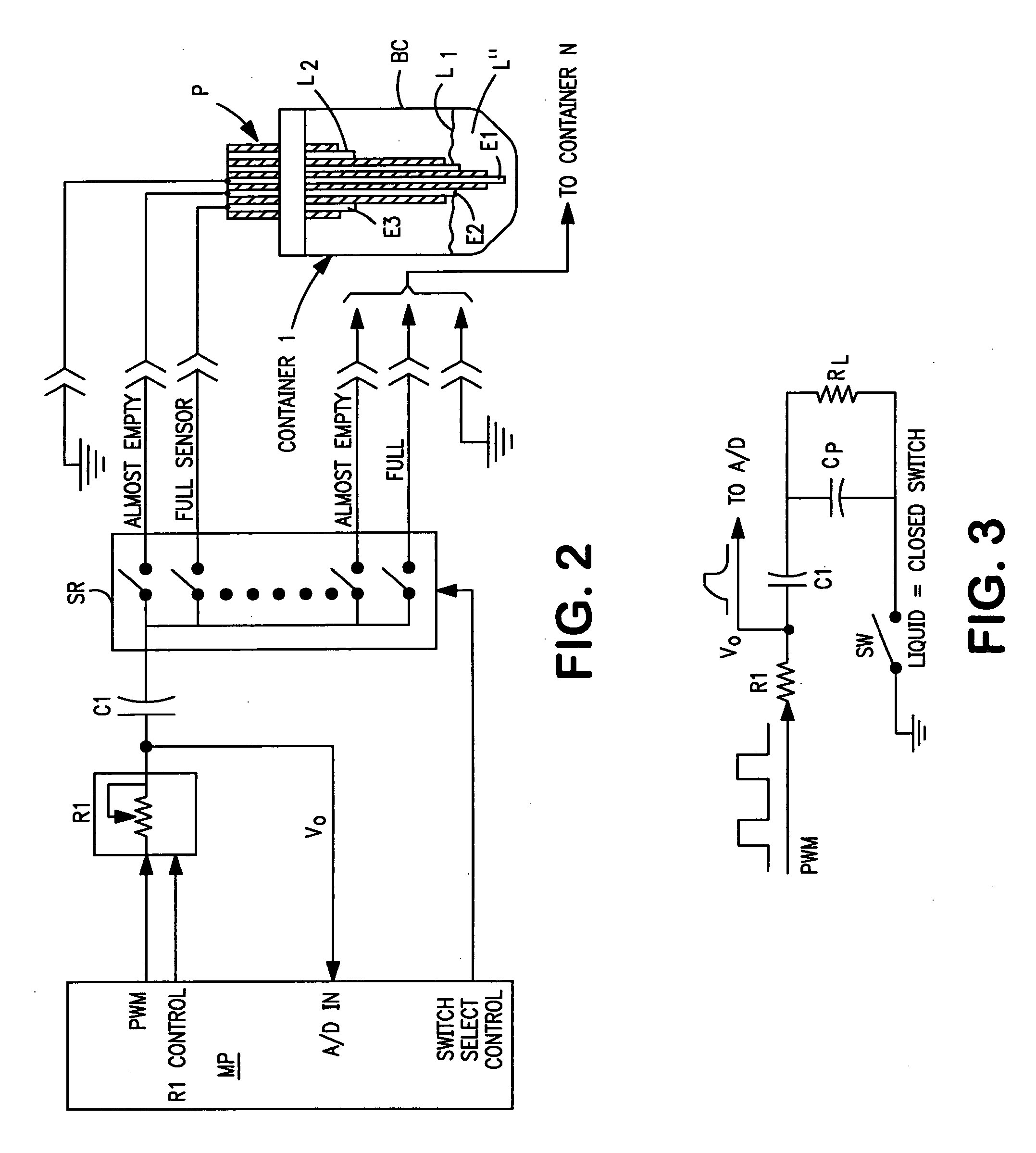

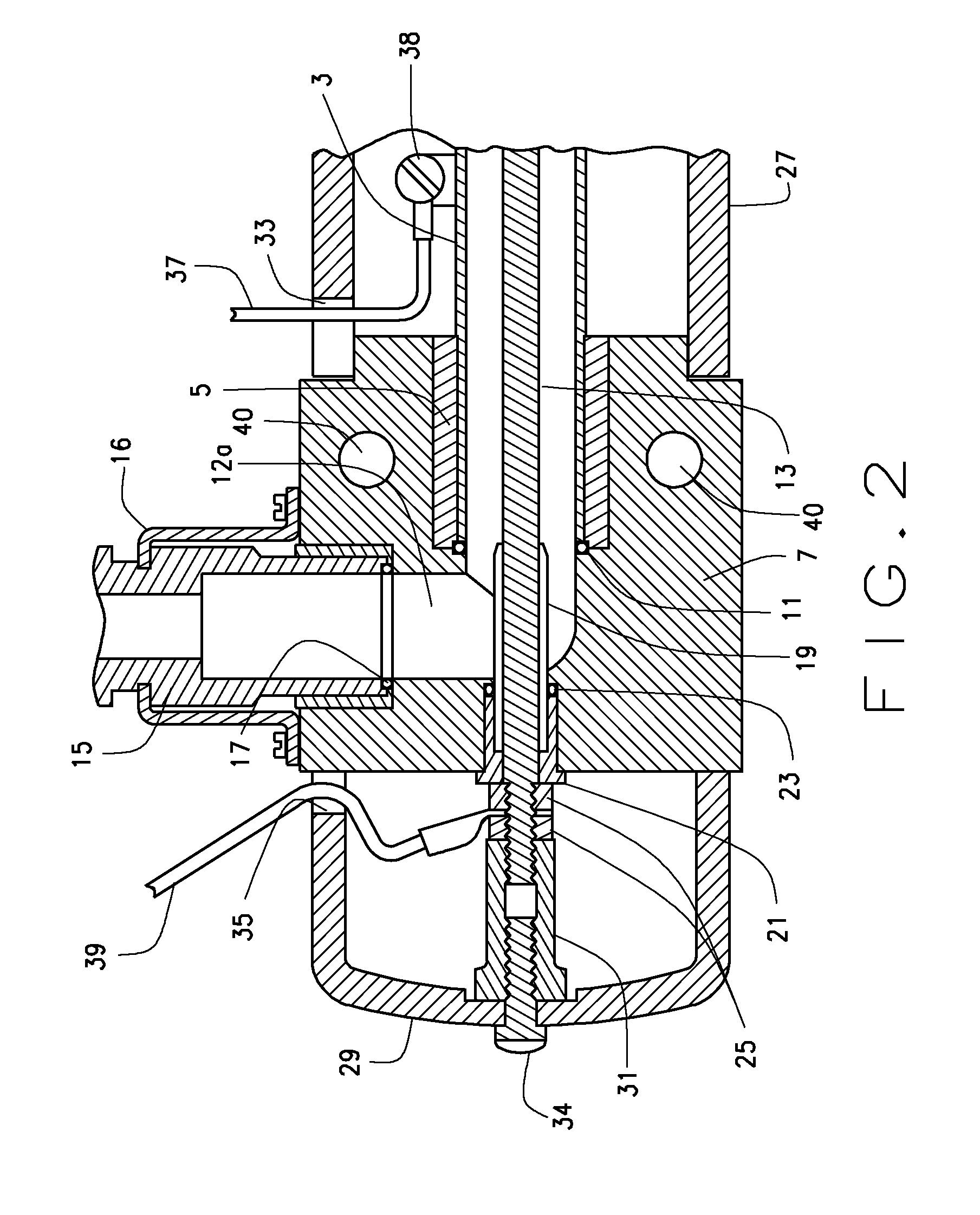

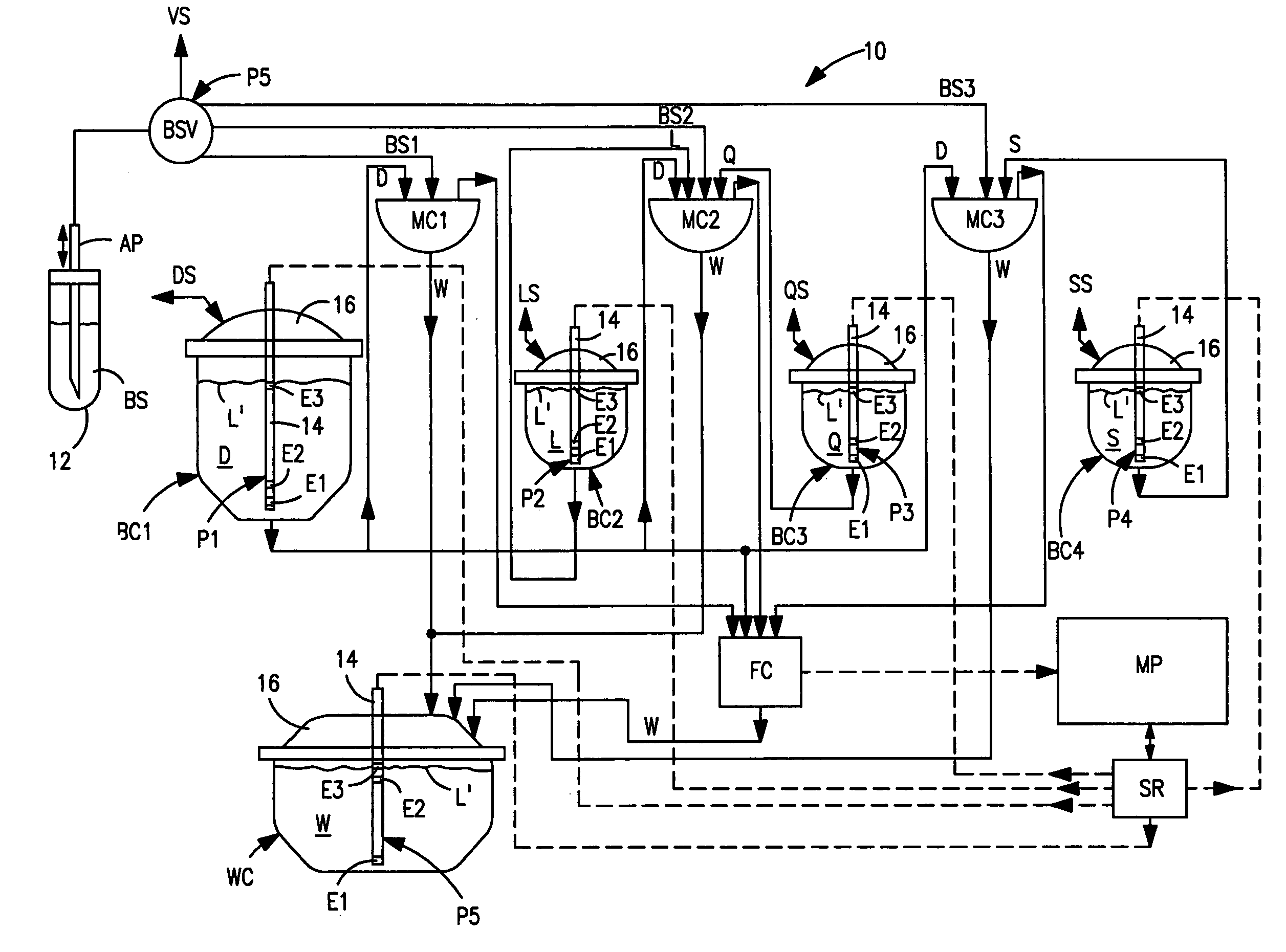

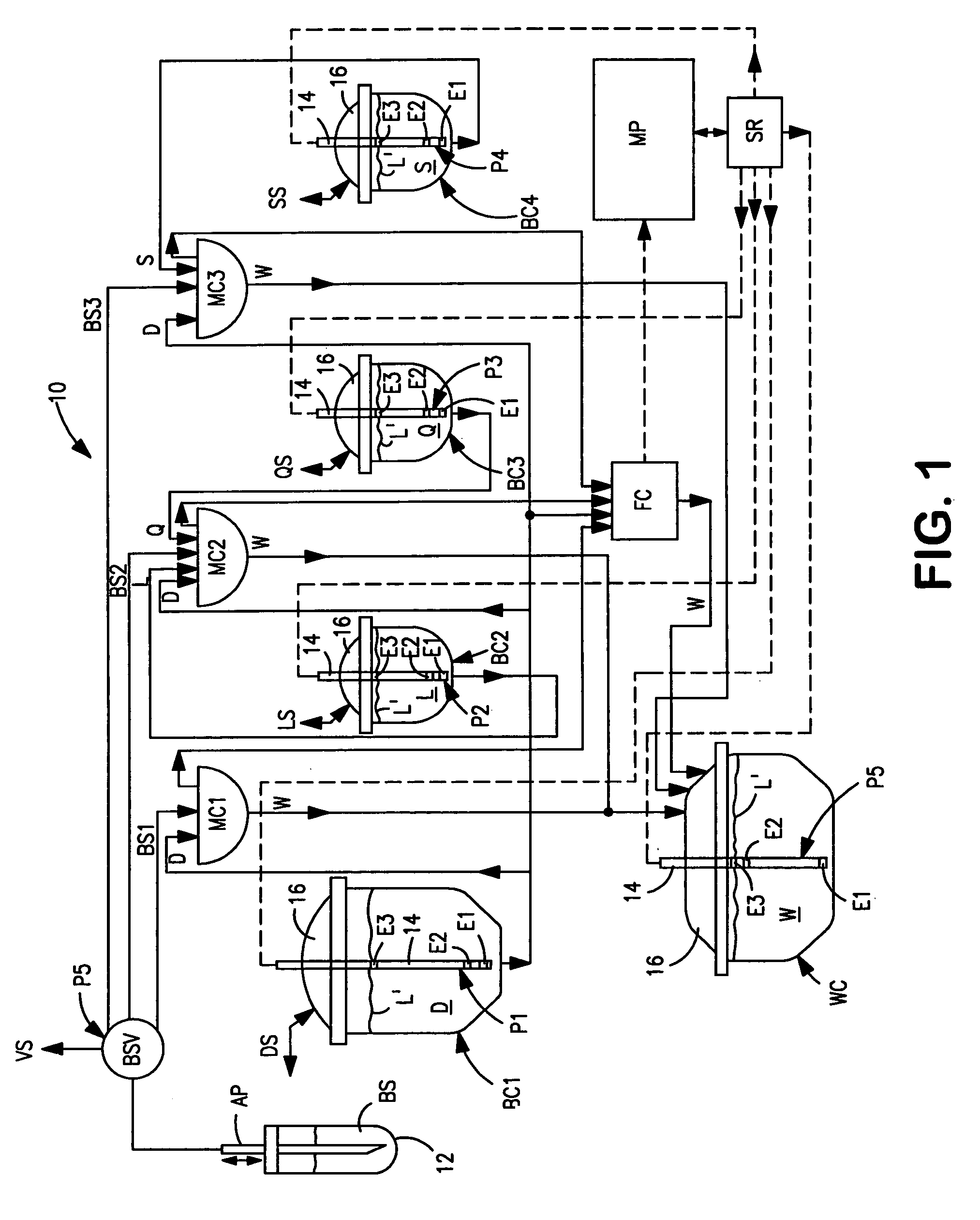

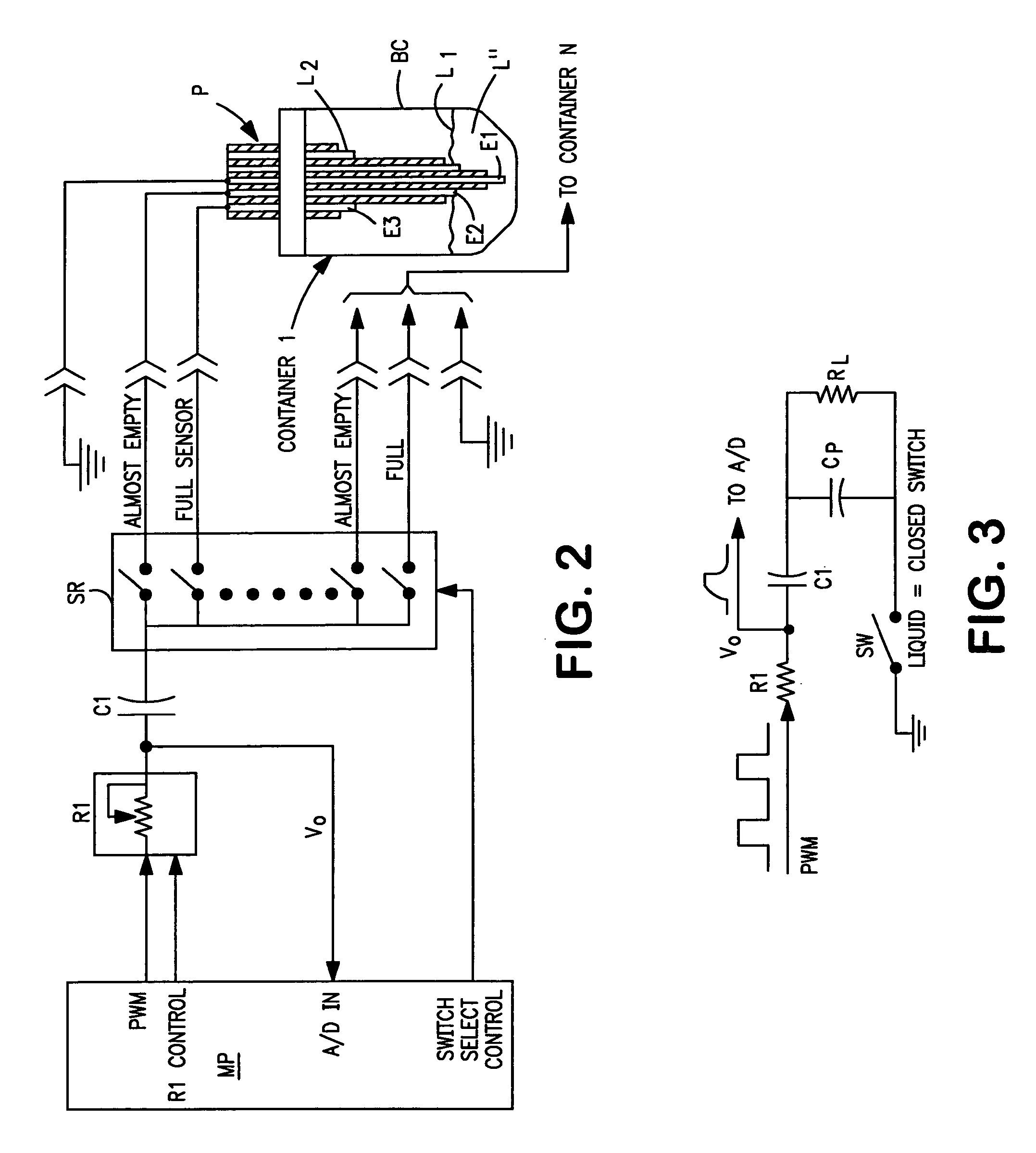

Method and apparatus for detecting liquid levels in liquid-storage containers

ActiveUS20070079653A1Improve reliabilityDifferent typeMachines/enginesAlarmsEngineeringElectrode pair

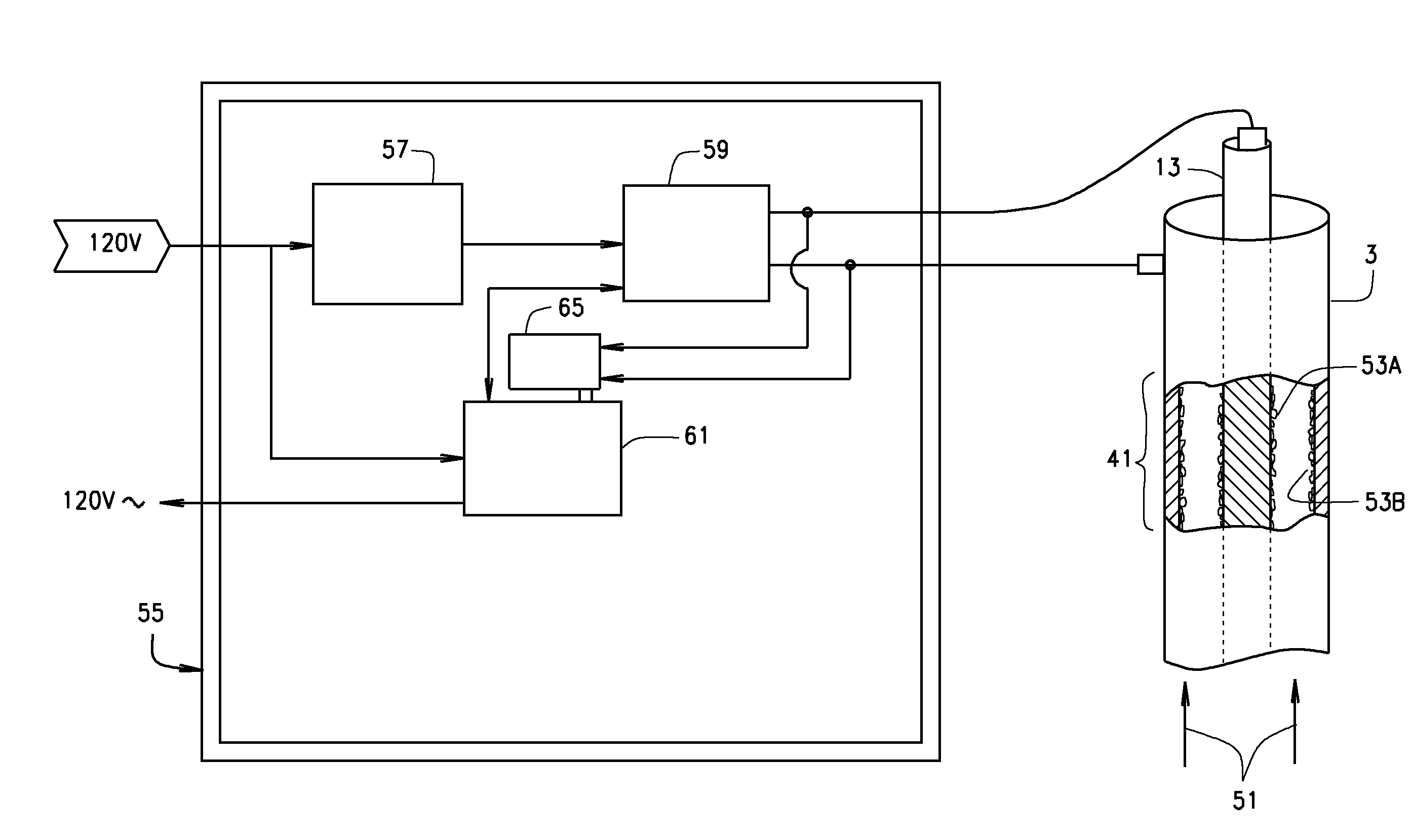

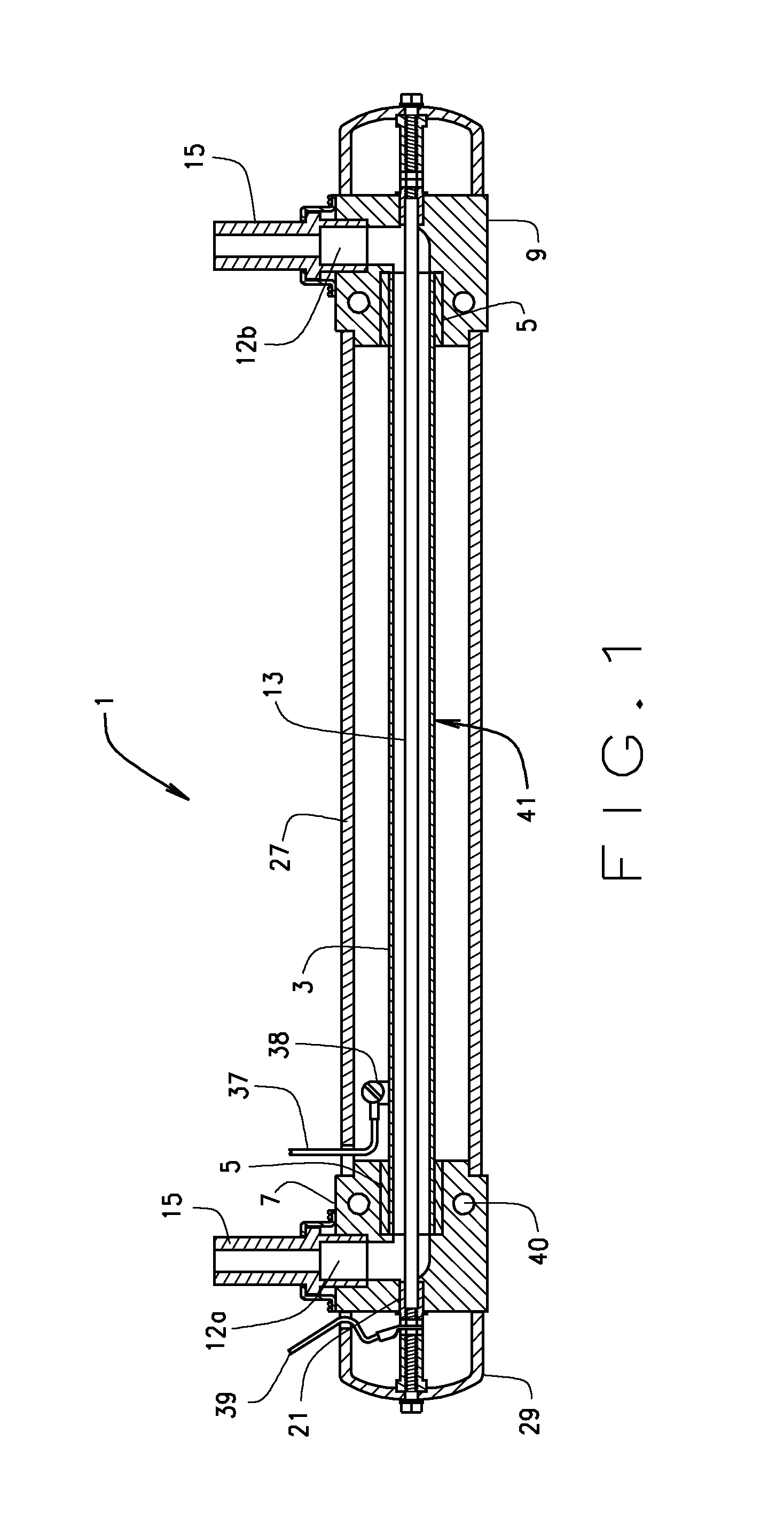

A method and apparatus for sensing different levels of liquids in their respective containers in a liquid-consuming and / or producing instrument system. According to a preferred embodiment, an elongated liquid-sensing probe having axially spaced electrodes adapted to sense liquid at multiple levels is arranged in each container of liquid. A controller, e.g. a suitably programmed microprocessor, operates to selectively poll different pairs of electrodes carried by the probe to determine whether or not the polled electrode pairs are immersed in the contained liquid. Preferably, the polling circuit comprises an electronically-controlled resistor that serves to normalize the level-sensing output signal for liquids of different bulk resistivity.

Owner:BECKMAN COULTER INC

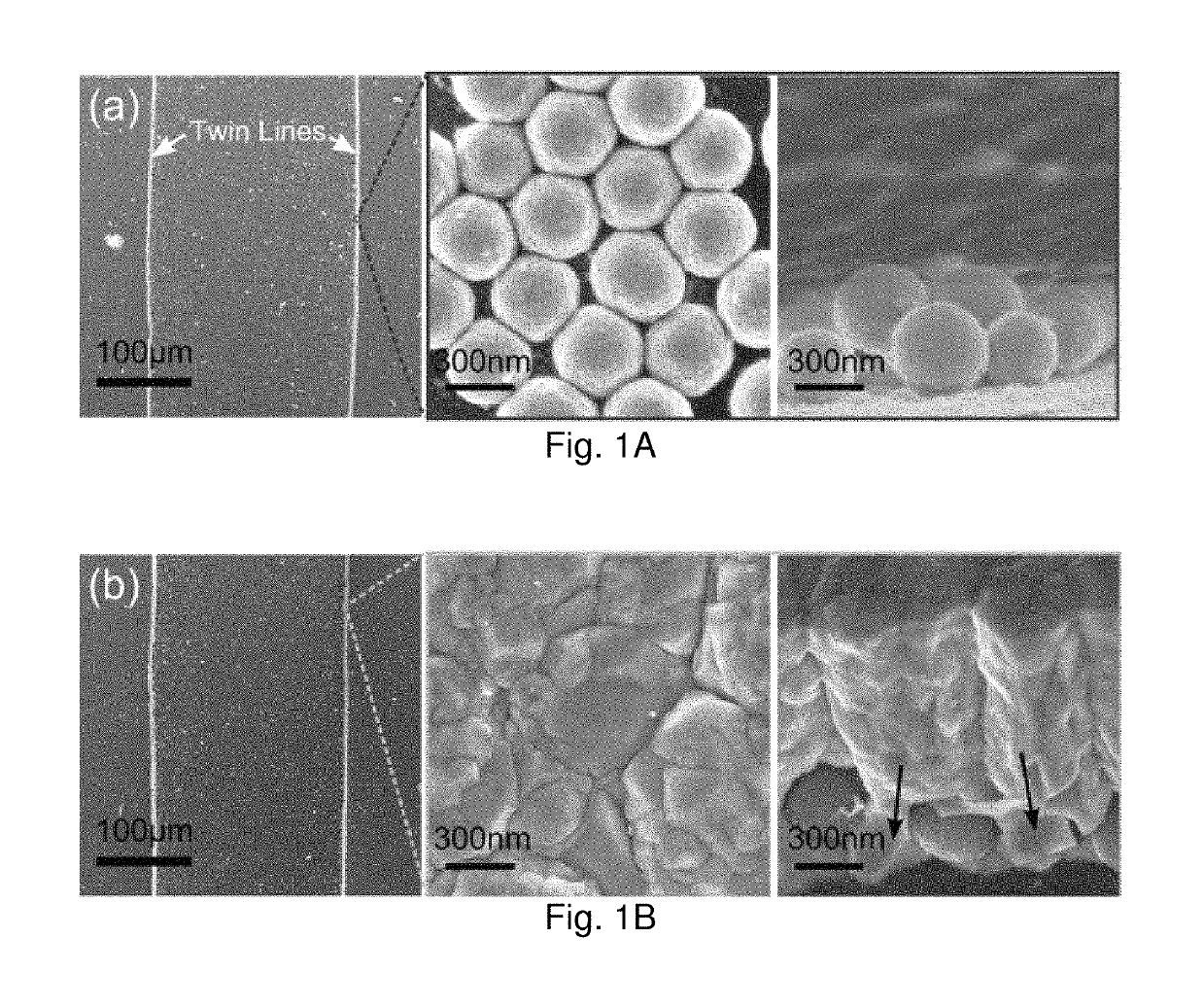

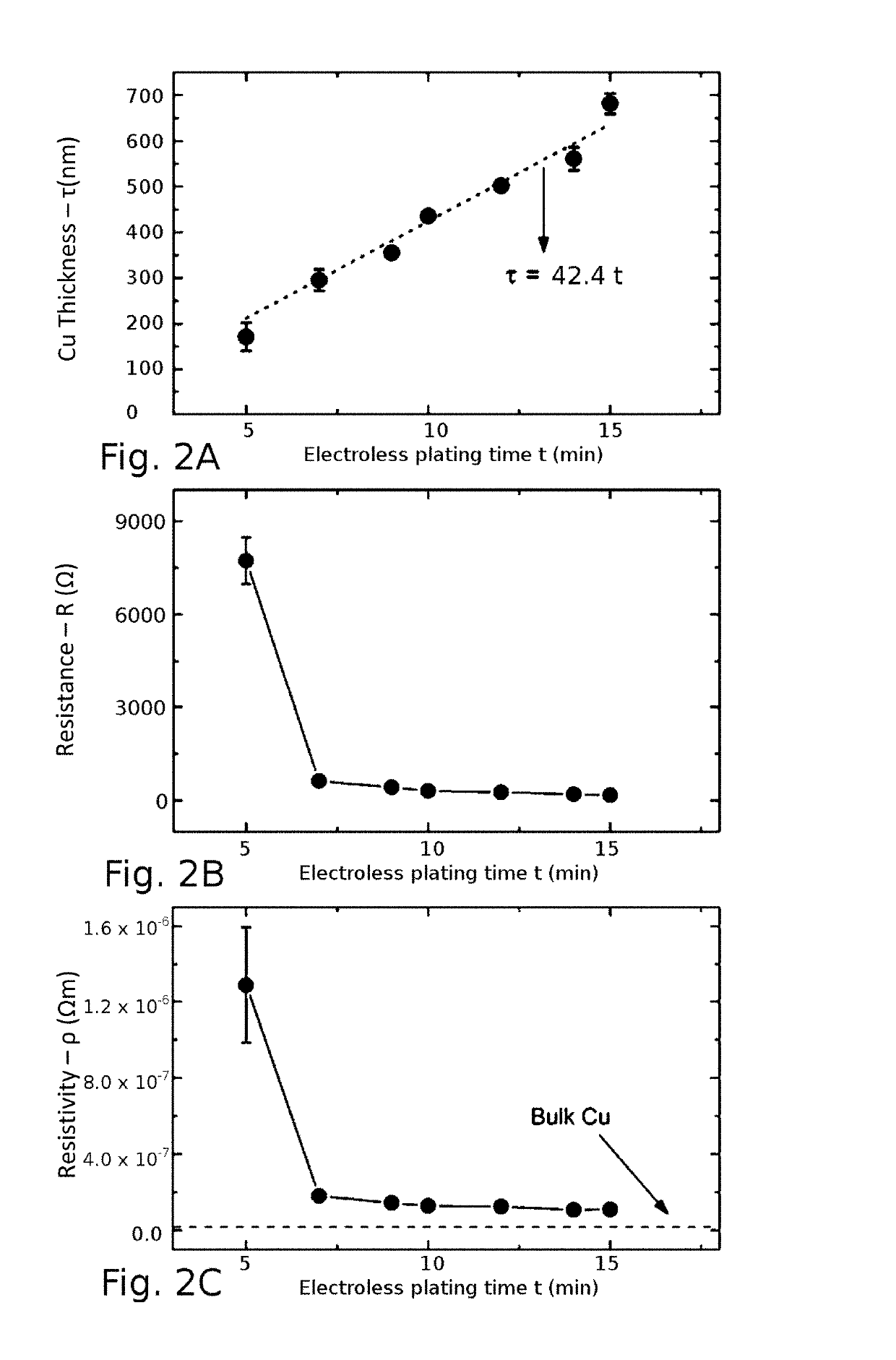

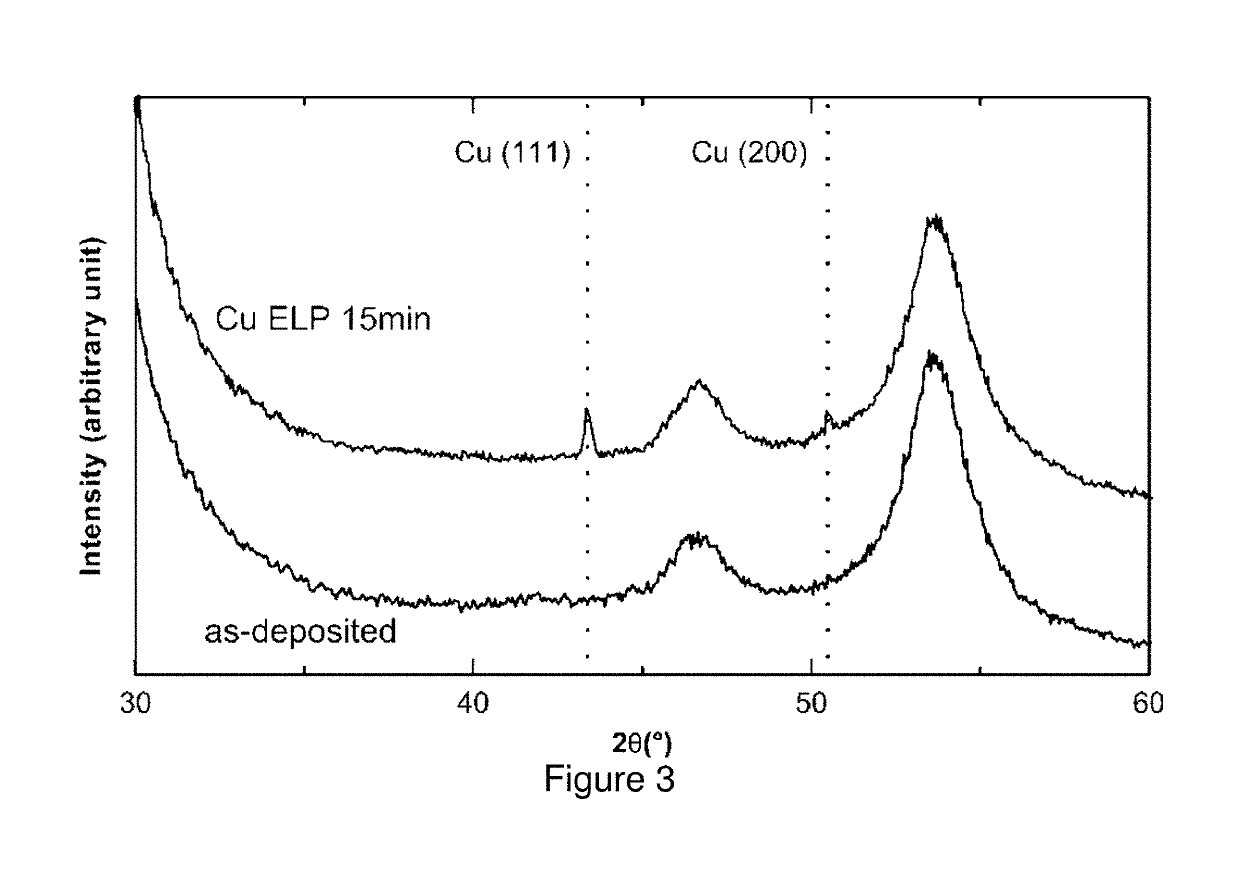

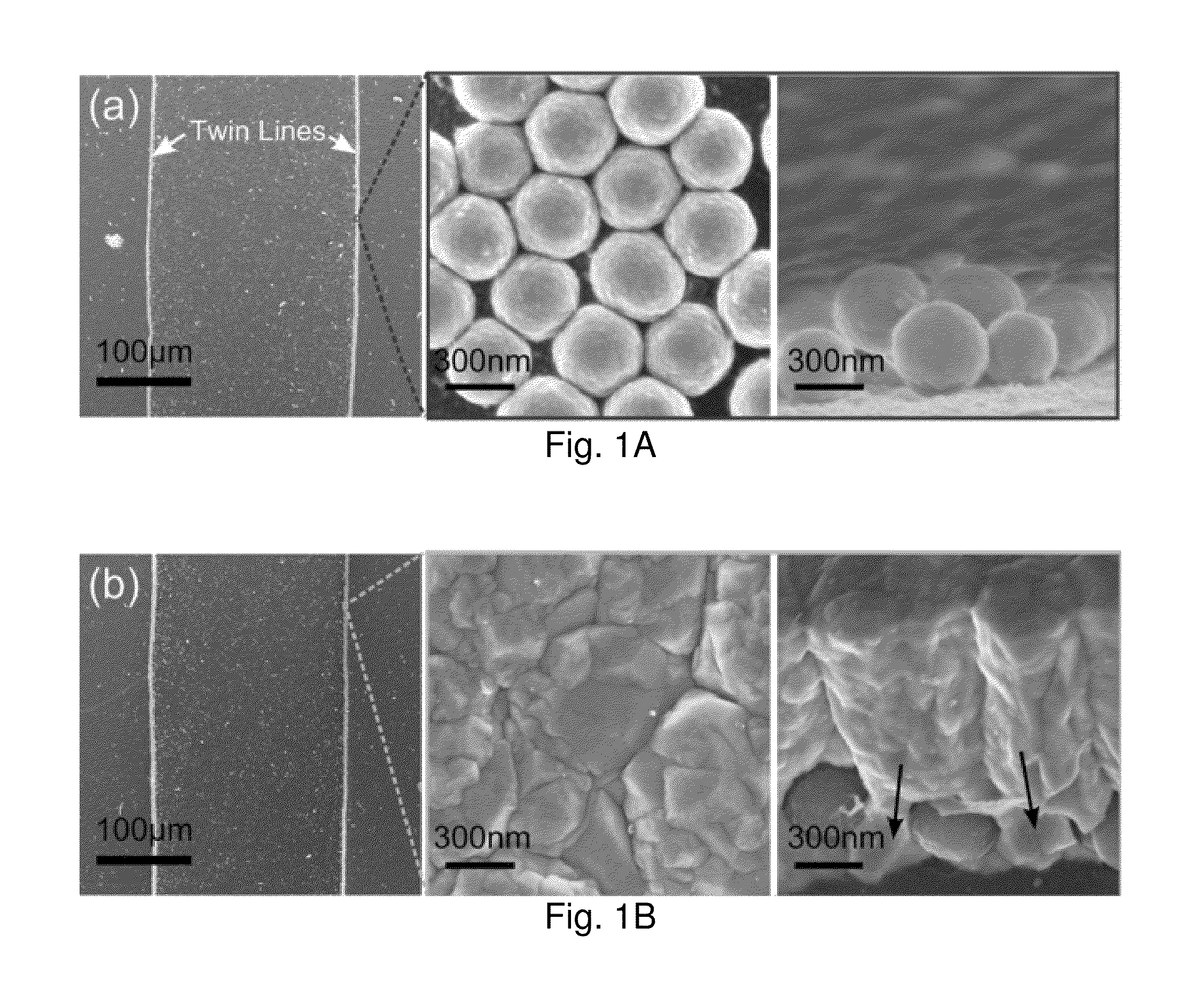

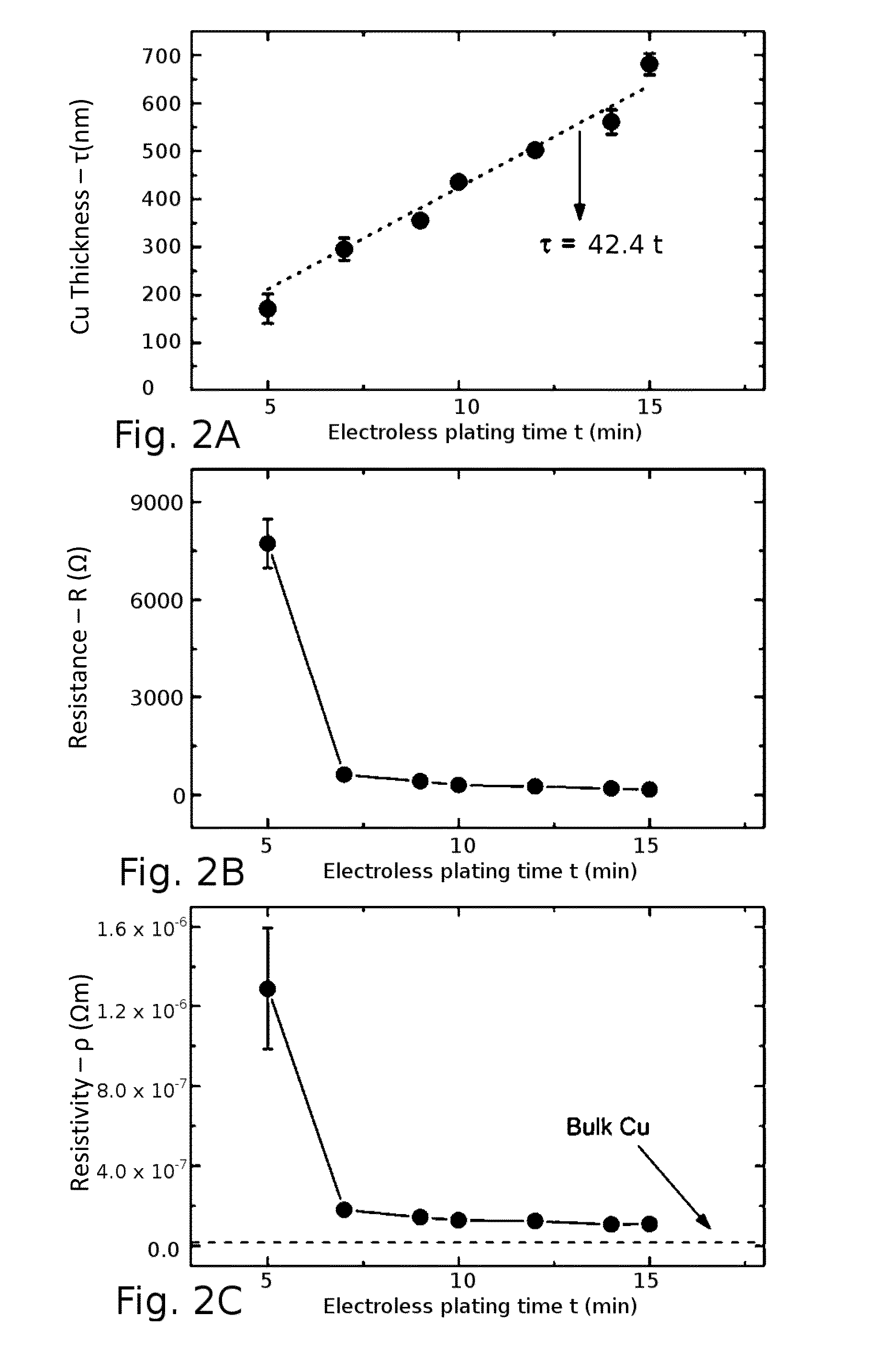

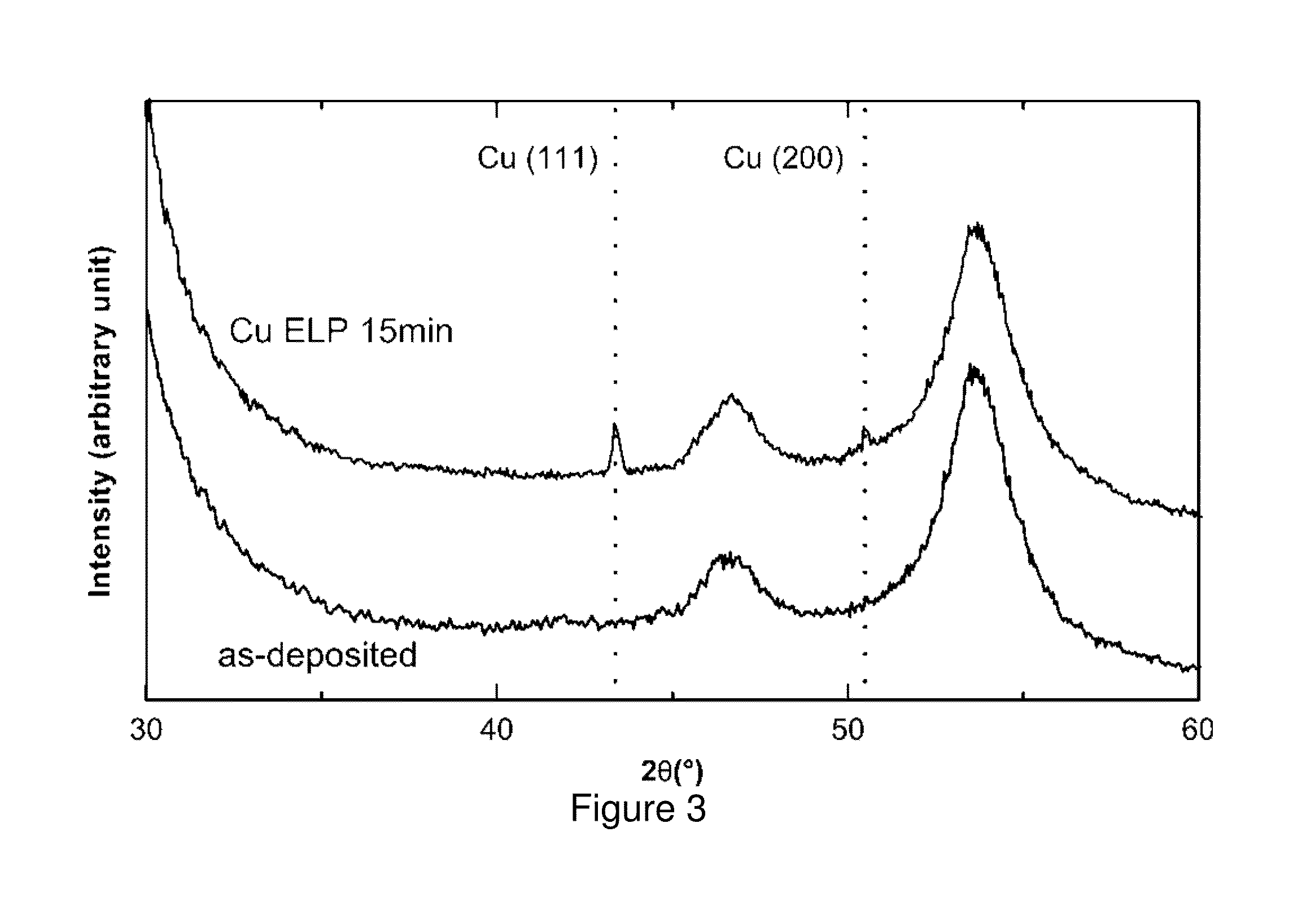

Electroless copper plating polydopamine nanoparticles

ActiveUS20160168715A1Increase concentrationLow costPrinted circuit aspectsPattern printingCopper platingFlexible electronics

Aqueous dispersions of artificially synthesized, mussel-inspired polyopamine nanoparticles were inkjet printed on flexible polyethylene terephthalate (PET) substrates. Narrow line patterns (4 μm in width) of polydopamine resulted due to evaporatively driven transport (coffee ring effect). The printed patterns were metallized via a site-selective Cu electroless plating process at a controlled temperature (30° C.) for varied bath times. The lowest electrical resistivity value of the plated Cu lines was about 6 times greater than the bulk resistivity of Cu. This process presents an industrially viable way to fabricate Cu conductive fine patterns for flexible electronics at low temperature, and low cost.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

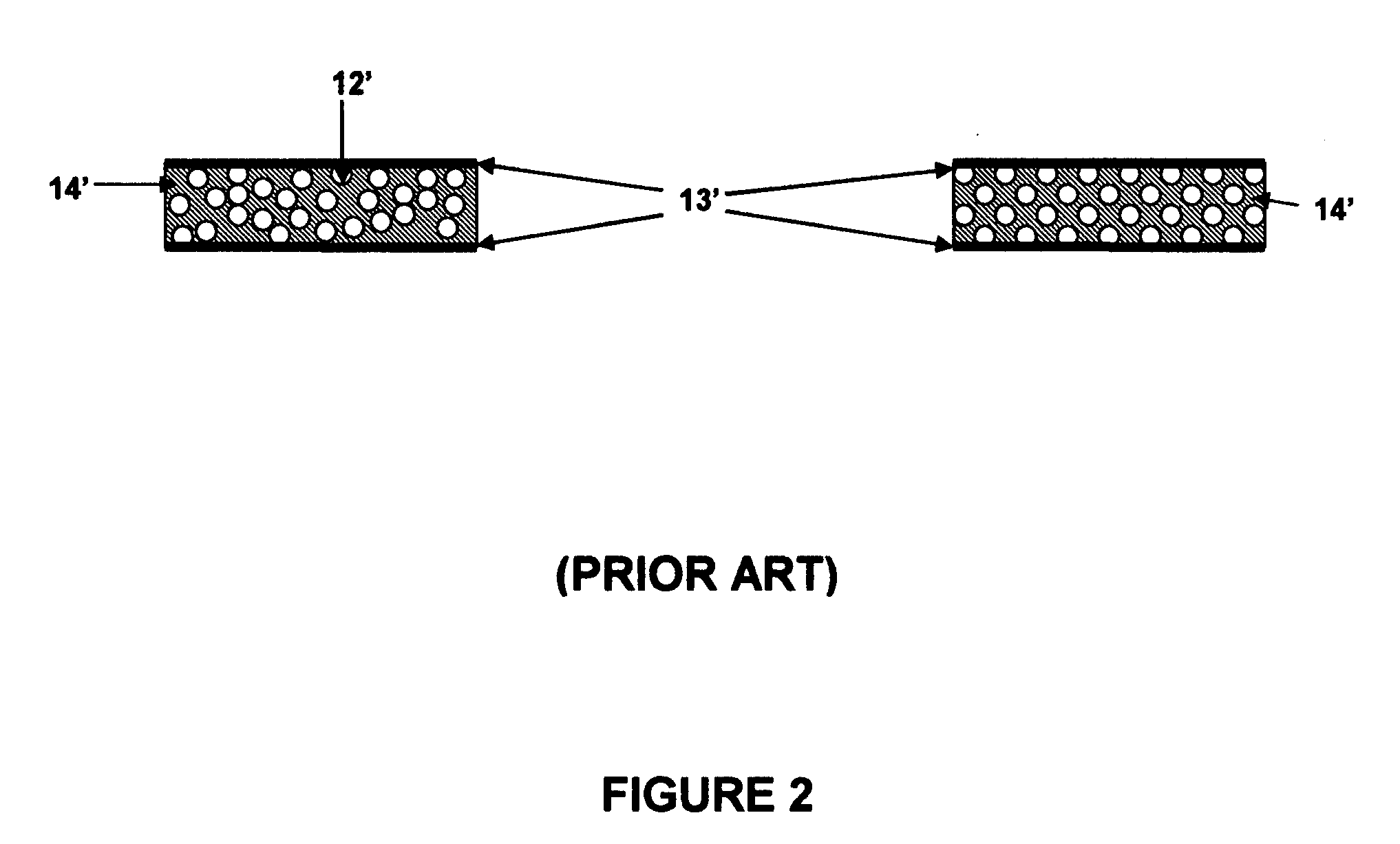

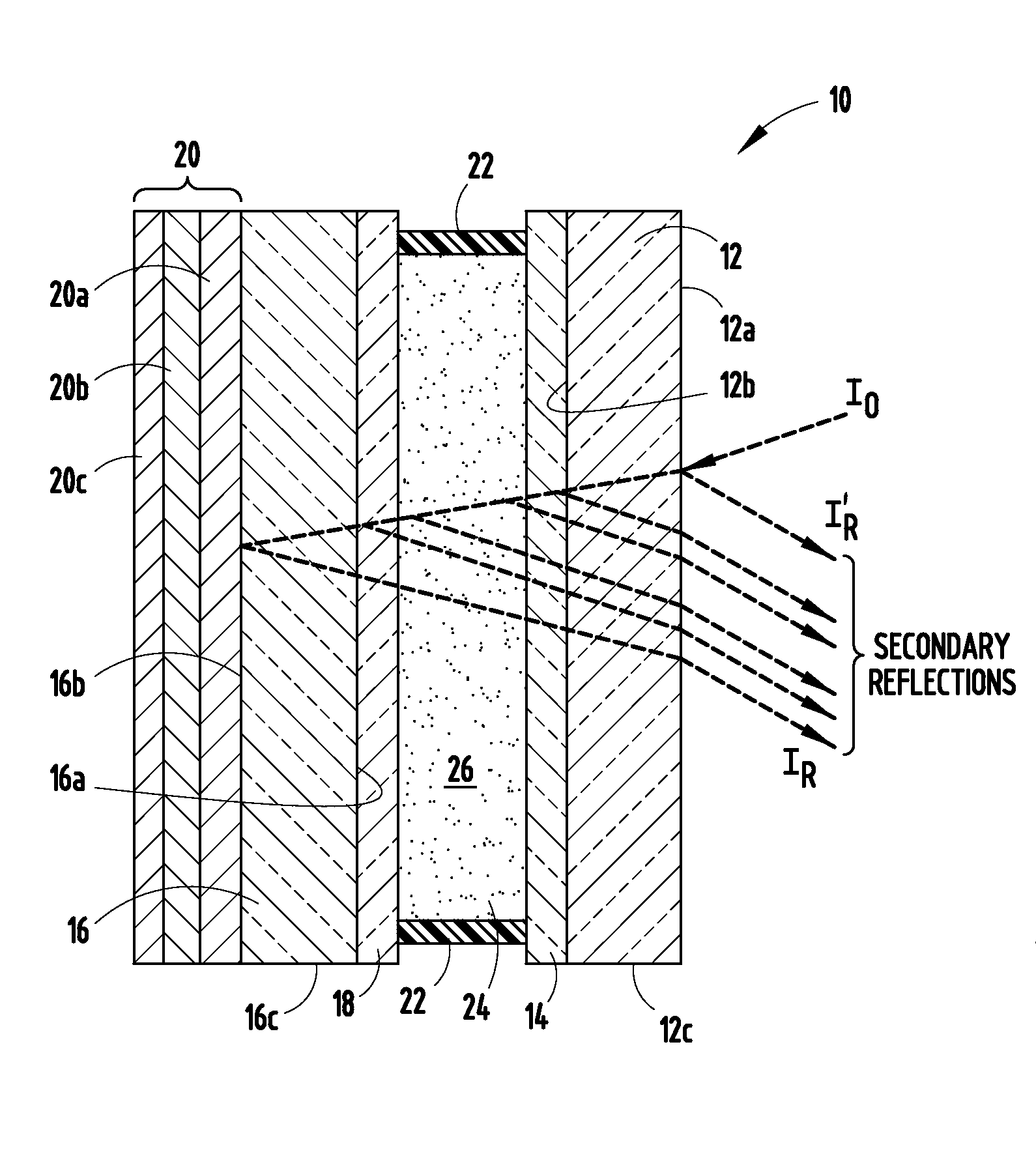

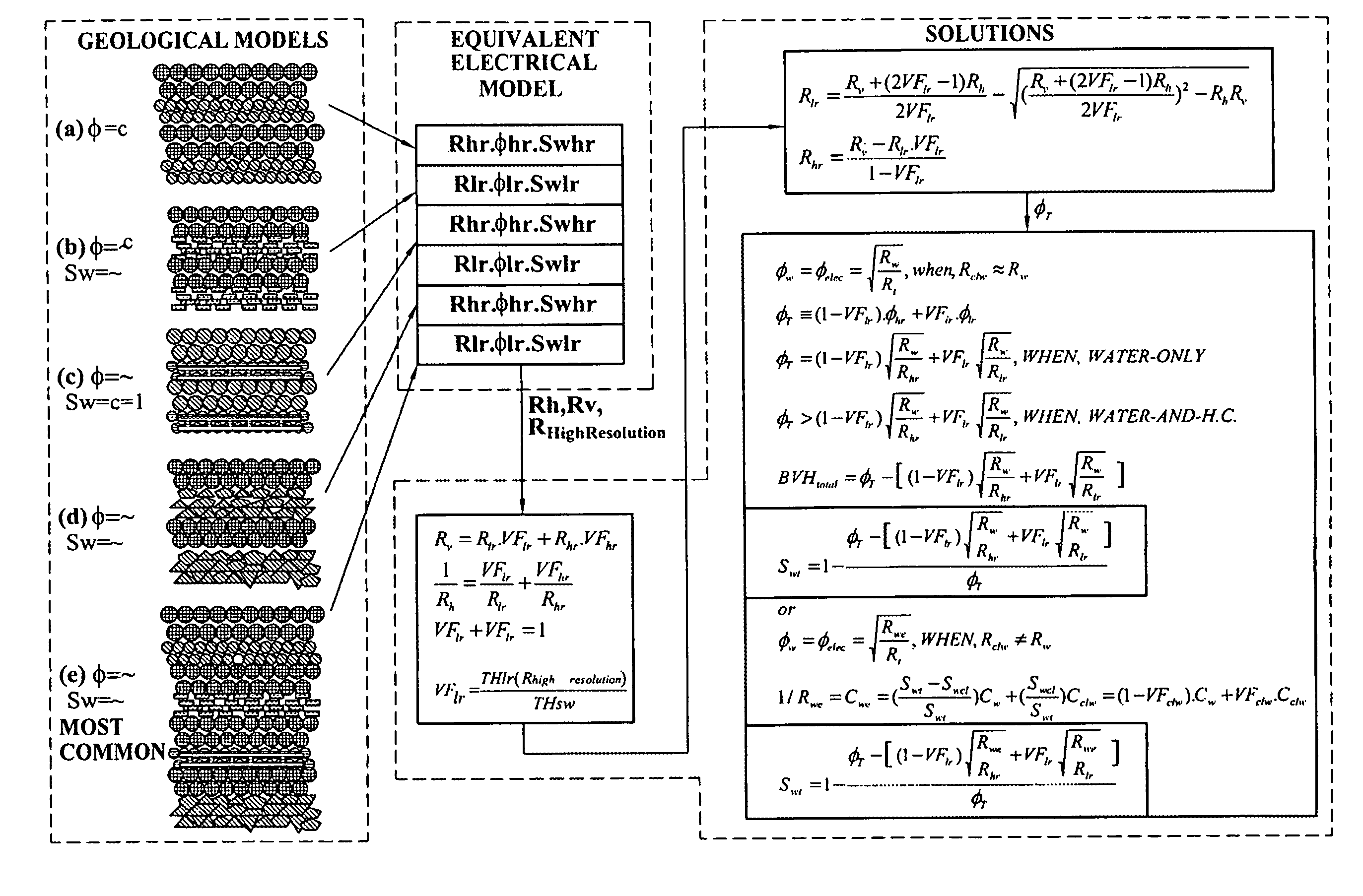

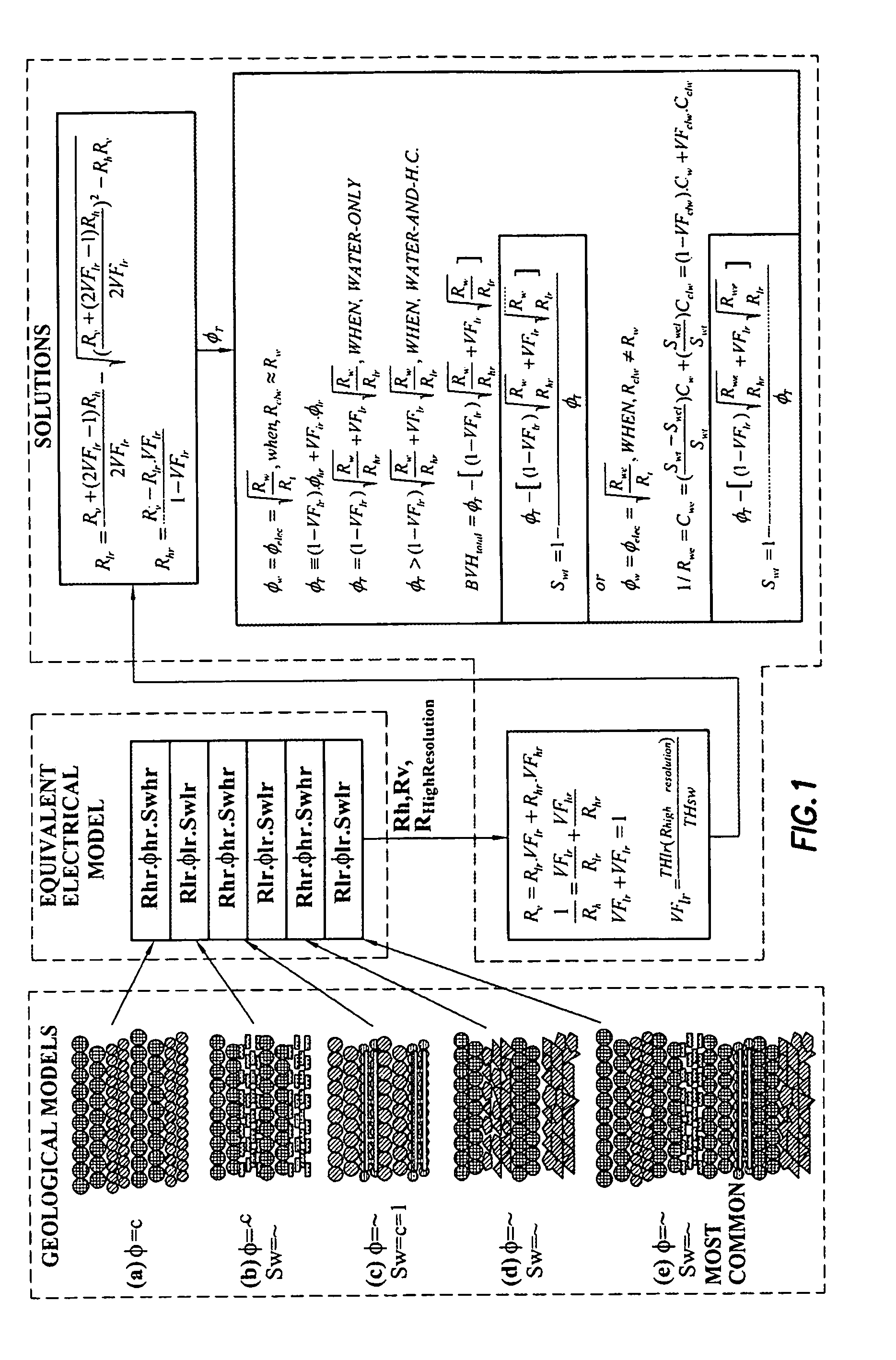

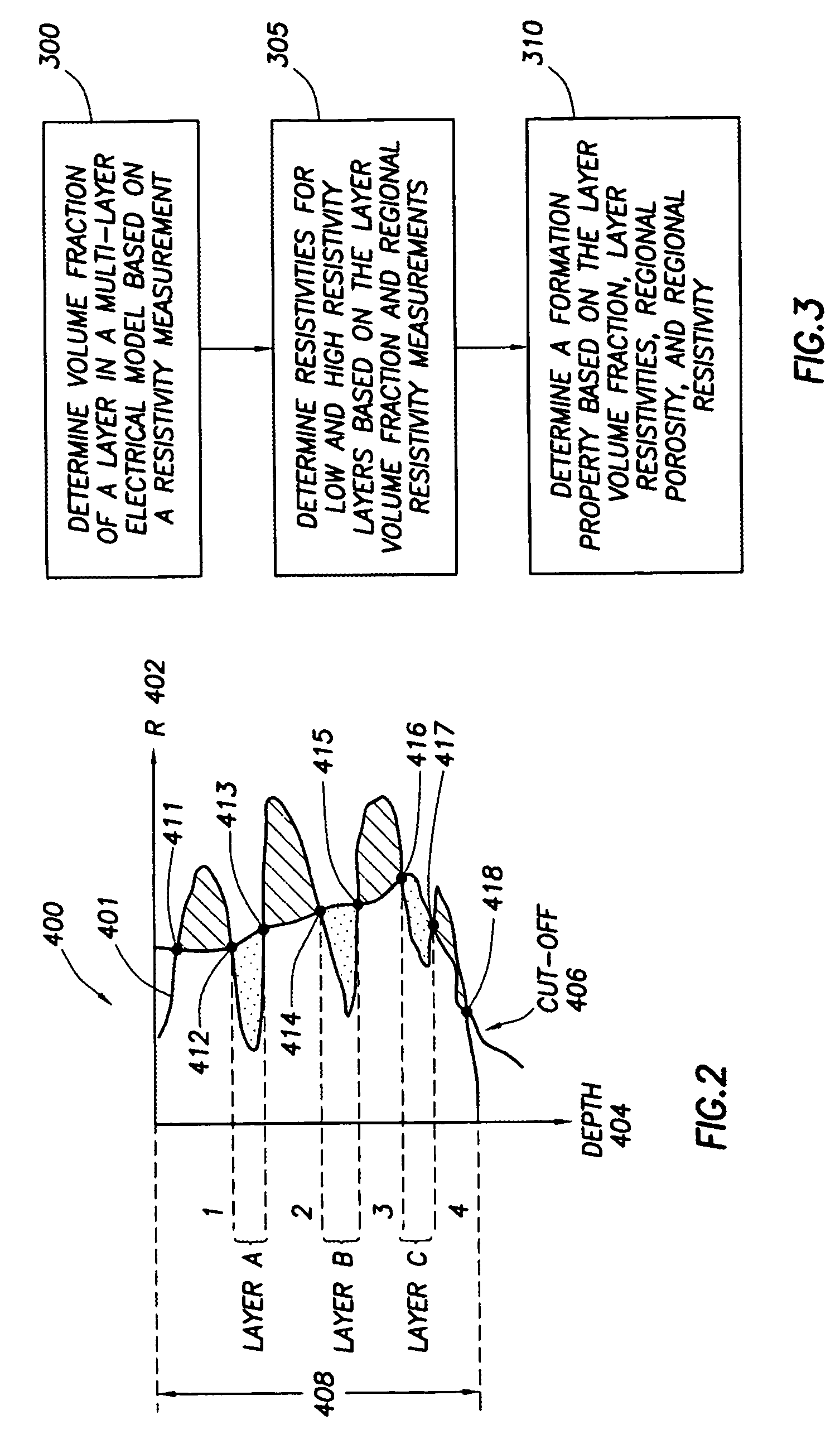

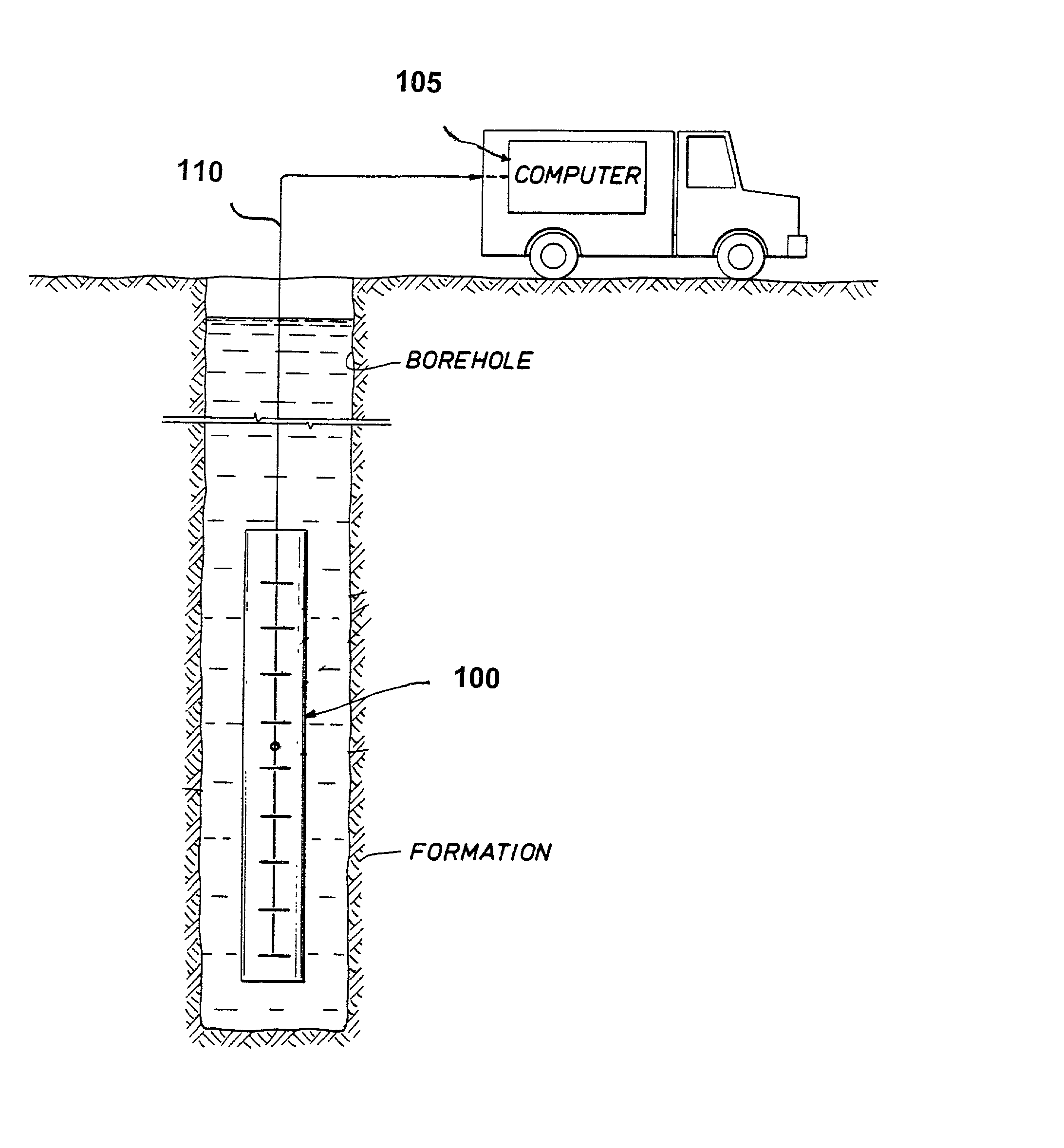

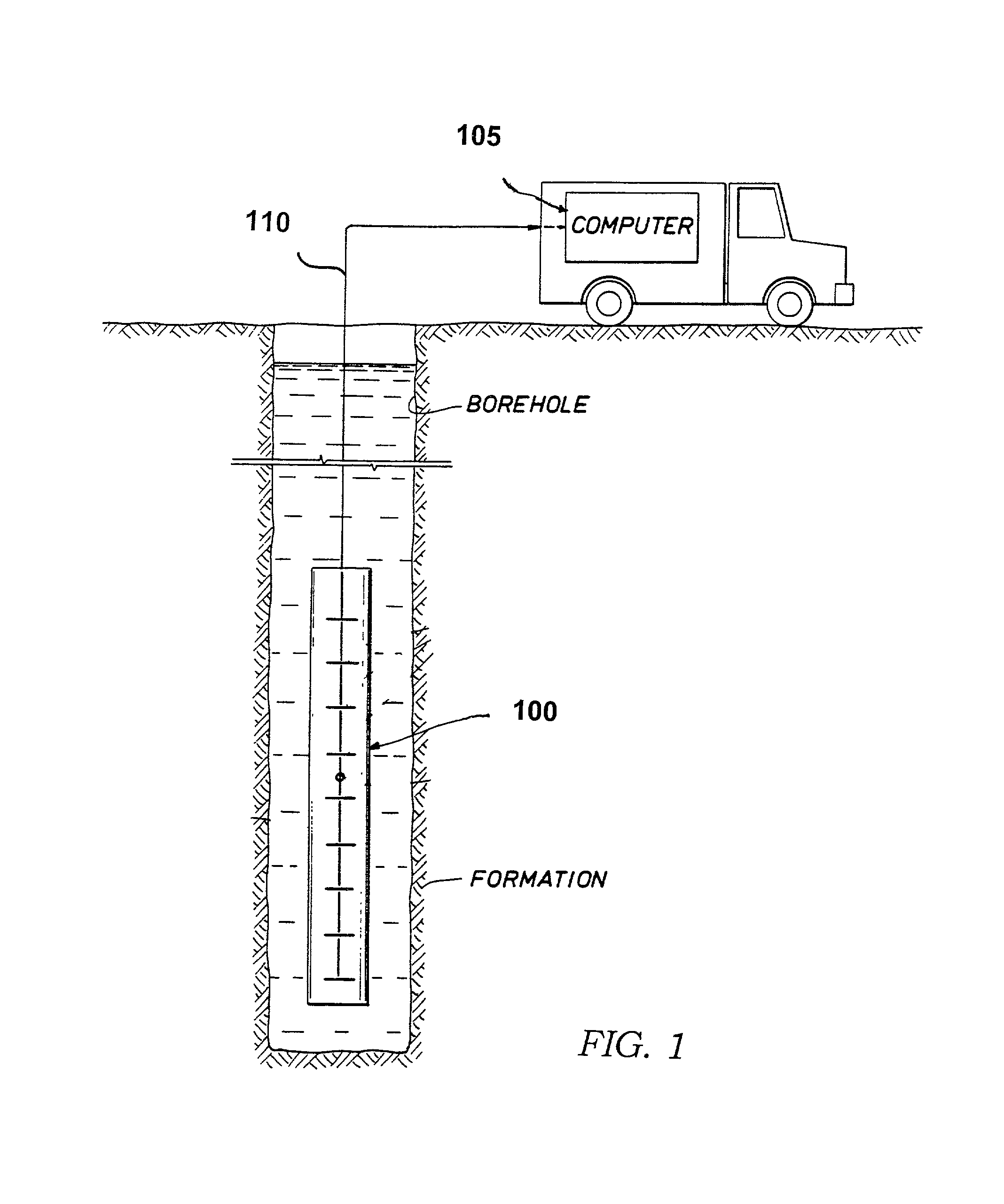

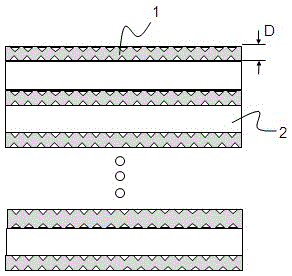

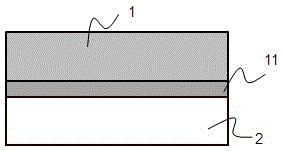

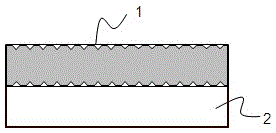

Methods and systems for resistivity anisotropy formation analysis

ActiveUS6950748B2Electric/magnetic detection for well-loggingSeismology for water-loggingElectricityPorosity

Techniques for determining a formation property by simplifying various two-geological-layer or multi-geological-layer models into a multi-electrical-layer model. A volume fraction of a layer in a multi-electrical-layer model is determined for an anisotropic region (sliding window) of the formation. The multi-electrical-layer electrical model includes a relative-lower-resistivity layer and a relative-higher-resistivity layer. A high-resolution resistivity measurement is used in the determination and resistivities for the relative-lower-resistivity layer and for the relative-higher-resistivity layer based on the volume fraction and bulk resistivity measure ments of the anisotropic region are determined. The formation property is based on the volume fraction, the resistivity of the relative-lower-resistivity layer, the resistivity of the relative-higher-resistivity layer, a total porosity of the anisotropic region, and bulk resistivity measurements of the region.

Owner:SCHLUMBERGER TECH CORP

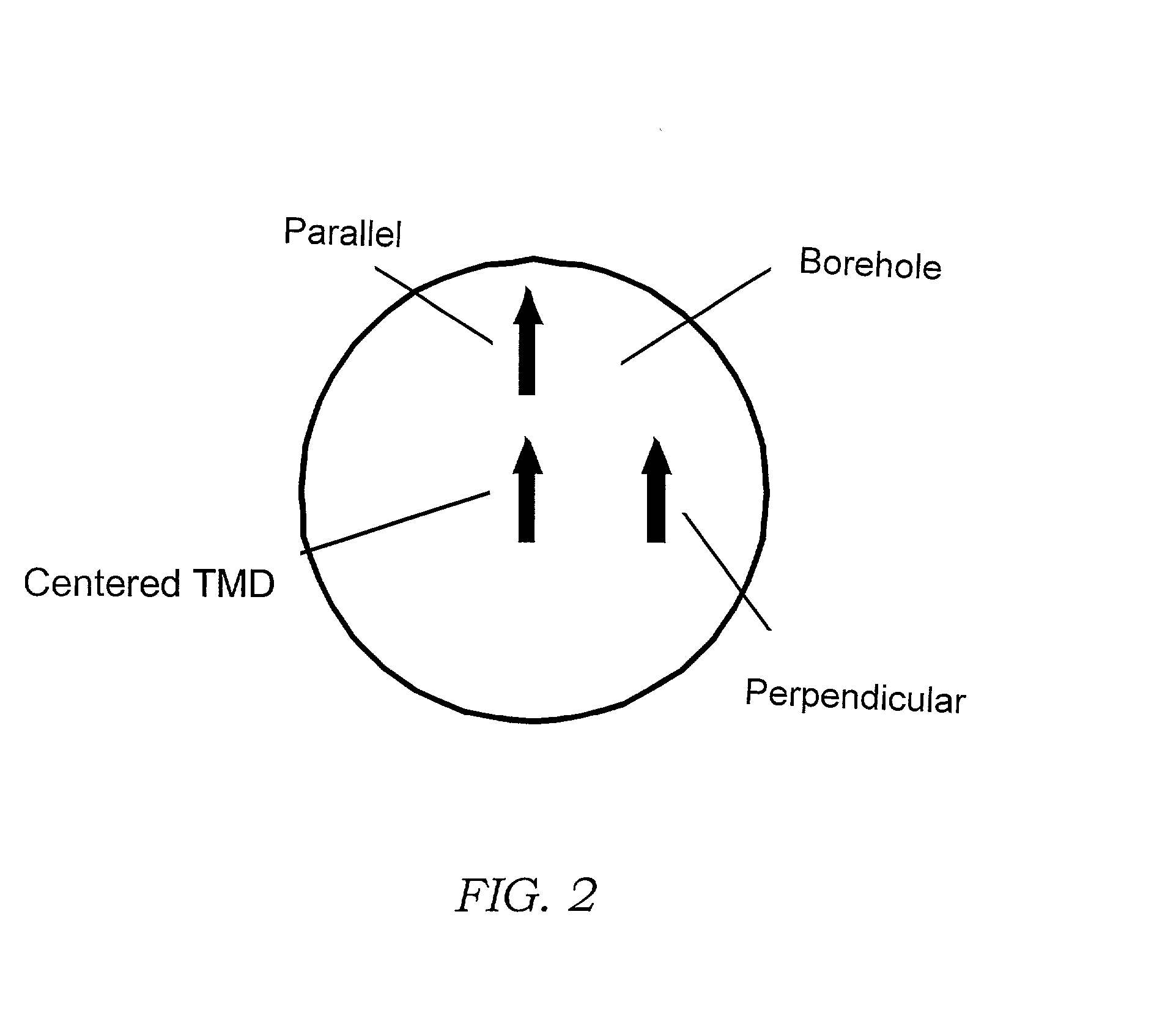

Multi-coil electromagnetic focusing methods and apparatus to reduce borehole eccentricity effects

InactiveUS20020113592A1Electric/magnetic detection for well-loggingAcoustic wave reradiationGround layerPhysics

Methods and apparatus are disclosed for canceling or eliminating borehole eccentricity effects on a formation resistivity measurement obtained with transmitter and / or receiver antennas which are substantially time varying magnetic dipoles with their dipole moments aligned at an angle to the axis of the borehole. Various apparatus are configured with a plurality of antennas having tilted or transverse magnetic dipole moments, at least one current sensor, means for conducting alternating current through one or more of the antennas, and means for calculating a scaling factor from signal measurements and for scaling the alternating current with the factor. One method includes scaling an alternating current and passing said current through one or more antennas to obtain the resistivity measurement. Another method includes calculating scaling factors based on spacings between antennas and / or current sensors disposed on an instrument and passing alternating currents scaled by said factors through one or more antennas to obtain the resistivity measurement. Another embodiment includes inputting a borehole fluid resistivity value to derive the formation resistivity.

Owner:SCHLUMBERGER TECH CORP

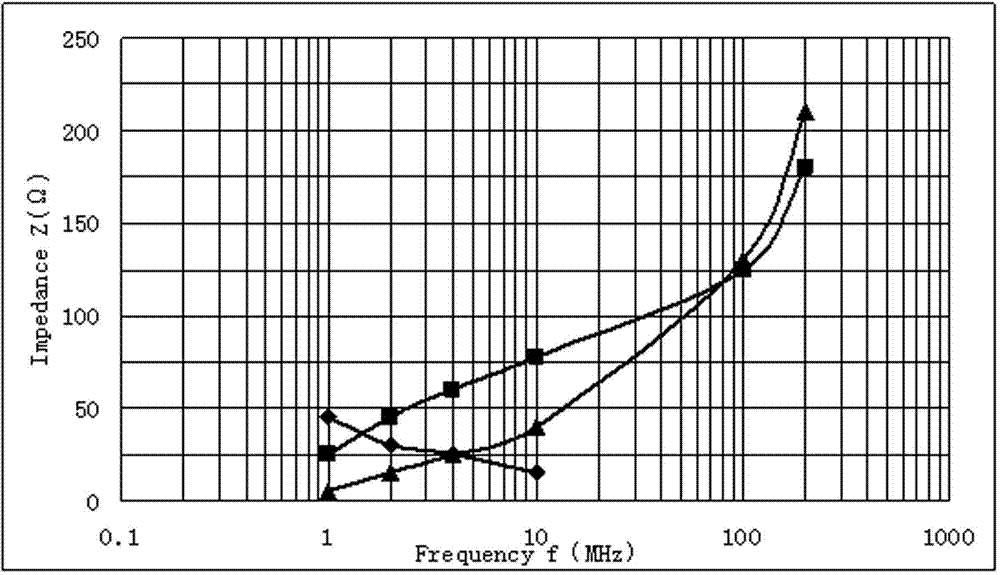

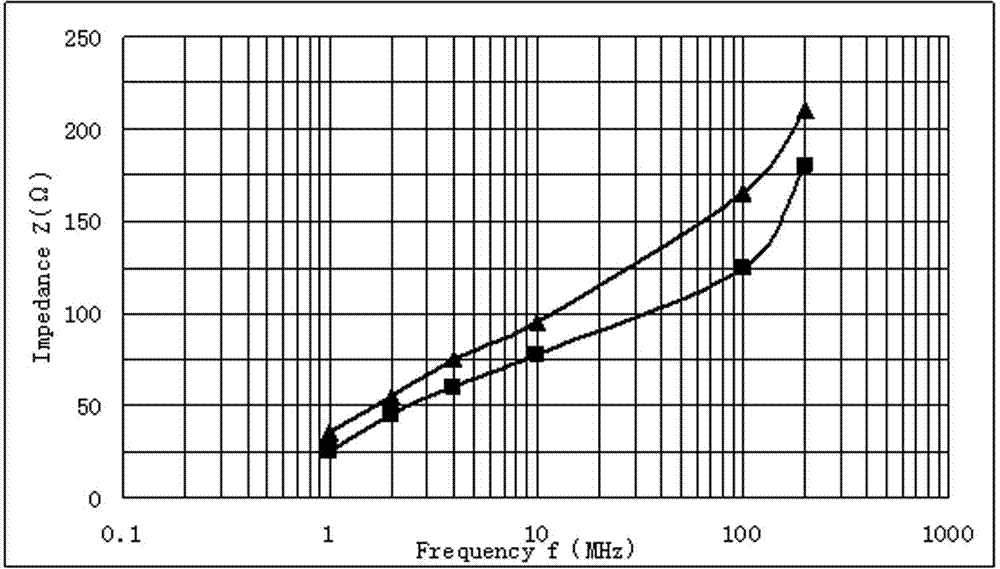

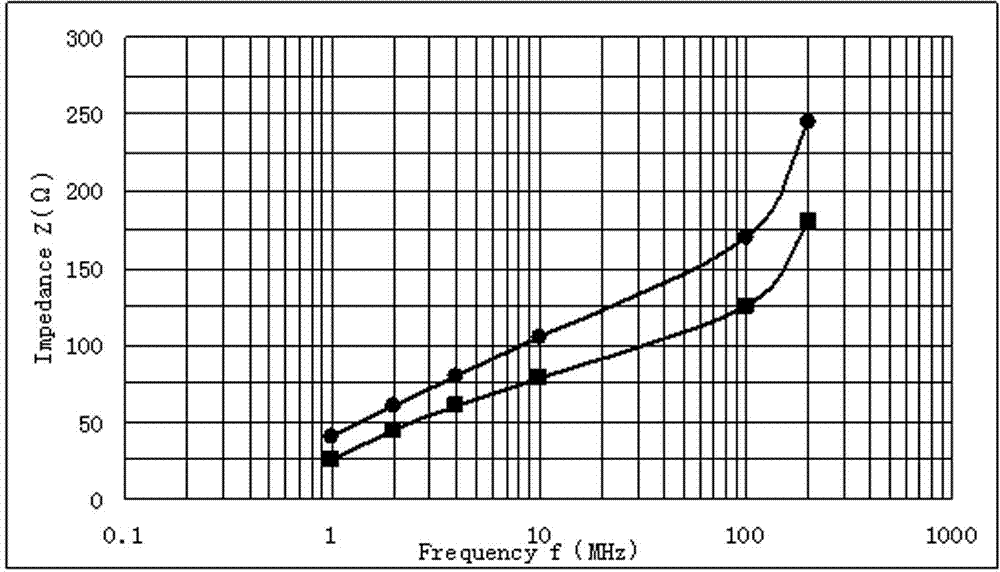

Anti-EMI (electromagnetic interference) ferrite material and preparation method thereof

InactiveCN104261812AImprove permeabilityImprove impedance characteristicsInitial permeabilityElectromagnetic interference

The invention discloses an anti-EMI (electromagnetic interference) ferrite material and a preparation method thereof. The initial permeability of the ferrite material provided by the invention at the normal temperature is over 2000, the volume resistivity is over 100 ohm, and the ferrite material has an excellent impedance characteristic in a frequency band of 1-100M and can be used for effectively reducing electromagnetic wave interference of electronic equipment. The anti-EMI ferrite material disclosed by the invention can be produced and prepared by adopting conventional equipment and is simple in process, low in energy consumption and strong in adaptability of raw materials.

Owner:麦格磁电科技(珠海)有限公司

Conductive Carbon Material Dispersing Agent and High-Conductivity Slurry for Lithium Battery

ActiveUS20200106090A1Good effectEffective dispersionElectrochemical processing of electrodesLi-accumulatorsPolyvinyl alcoholCarbon nanotube

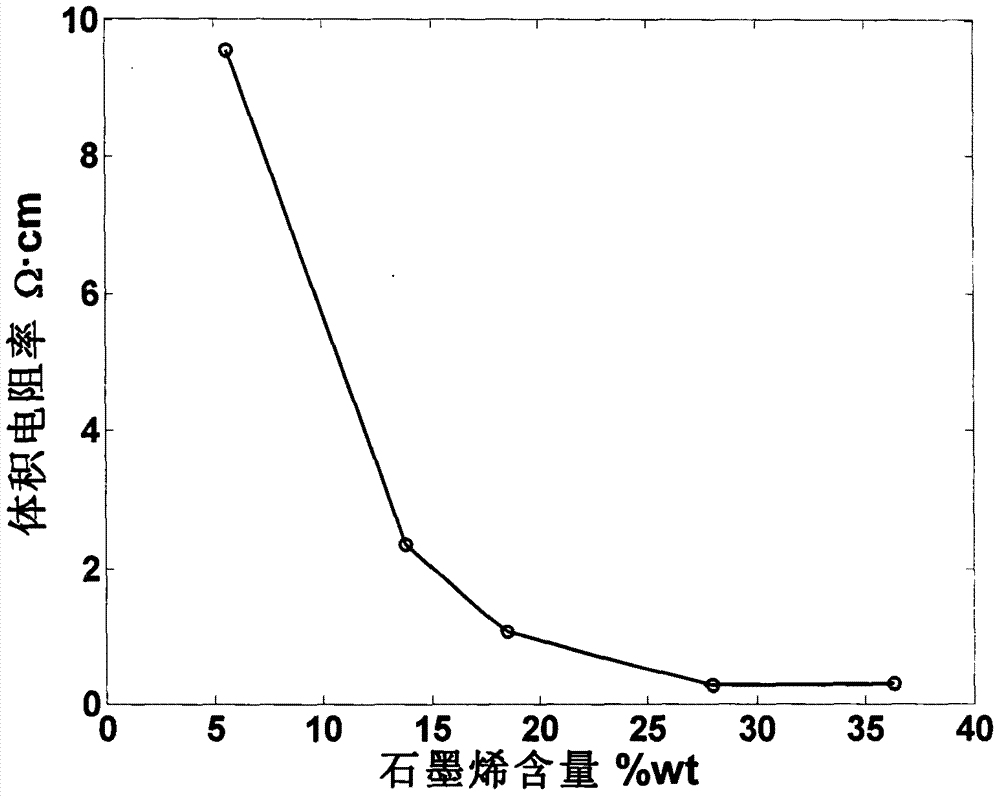

The invention relates to the technical field of lithium battery slurry materials, in particular to a conductive carbon material dispersing agent which comprises one of modified polyvinyl alcohol, alkyl ammonium salt copolymer, olefin block maleic anhydride copolymer and pyrrolidone copolymer, or mixtures thereof, and can effectively disperse carbon nanotube, graphene and other conductive carbon materials in a solvent to obtain uniform conductive slurry; further disclosed is a high-conductivity slurry for the lithium battery, which comprises 0.5-15.0% by weight of a conductive carbon material and 0.1-3.0% by weight of a dispersing agent, and can remarkably reduce the bulk resistivity of a positive electrode system of the lithium battery and improve the conductivity of a pole piece.

Owner:JIANGSU CNANO TECHNOLOGY CO LTD

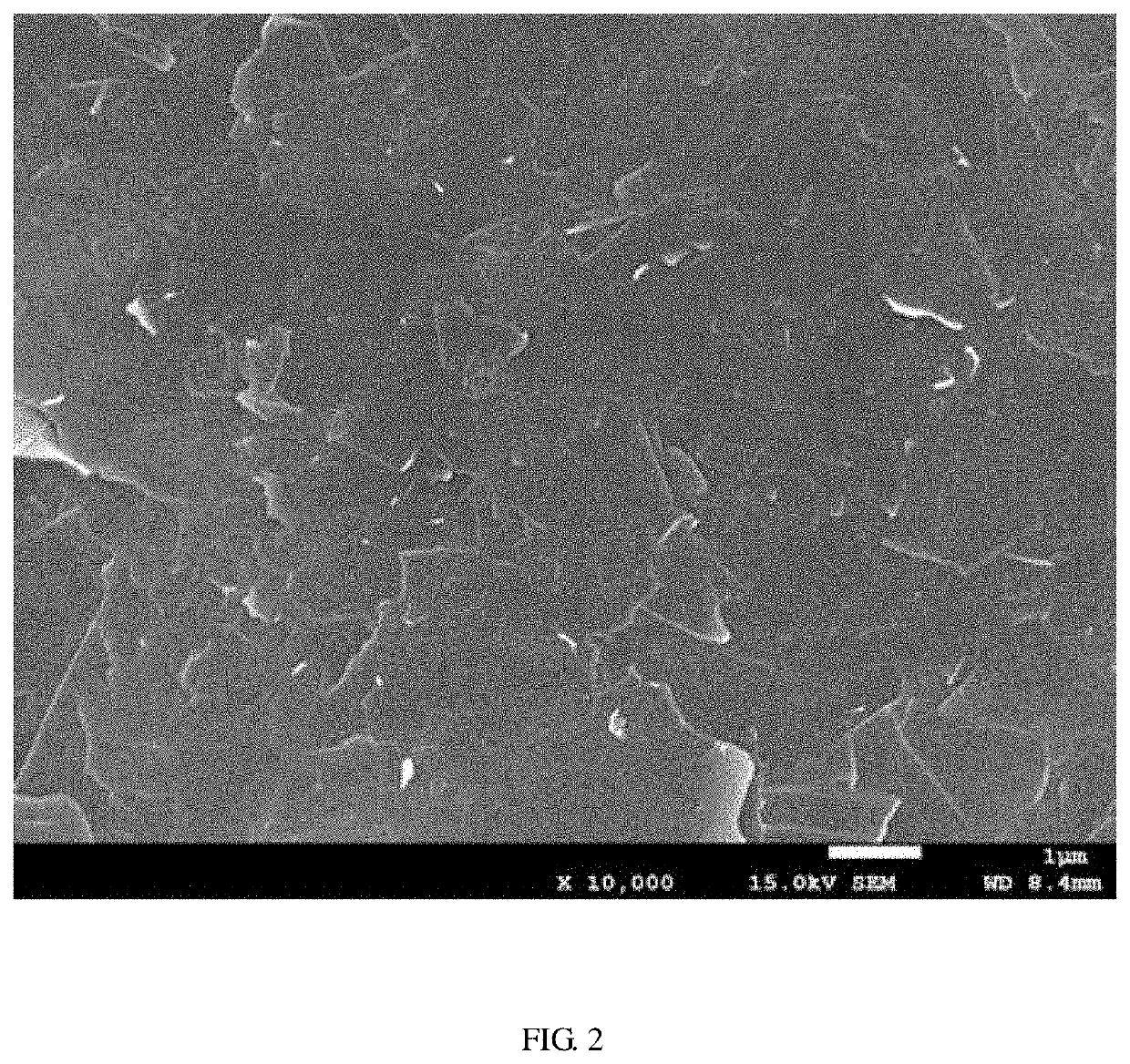

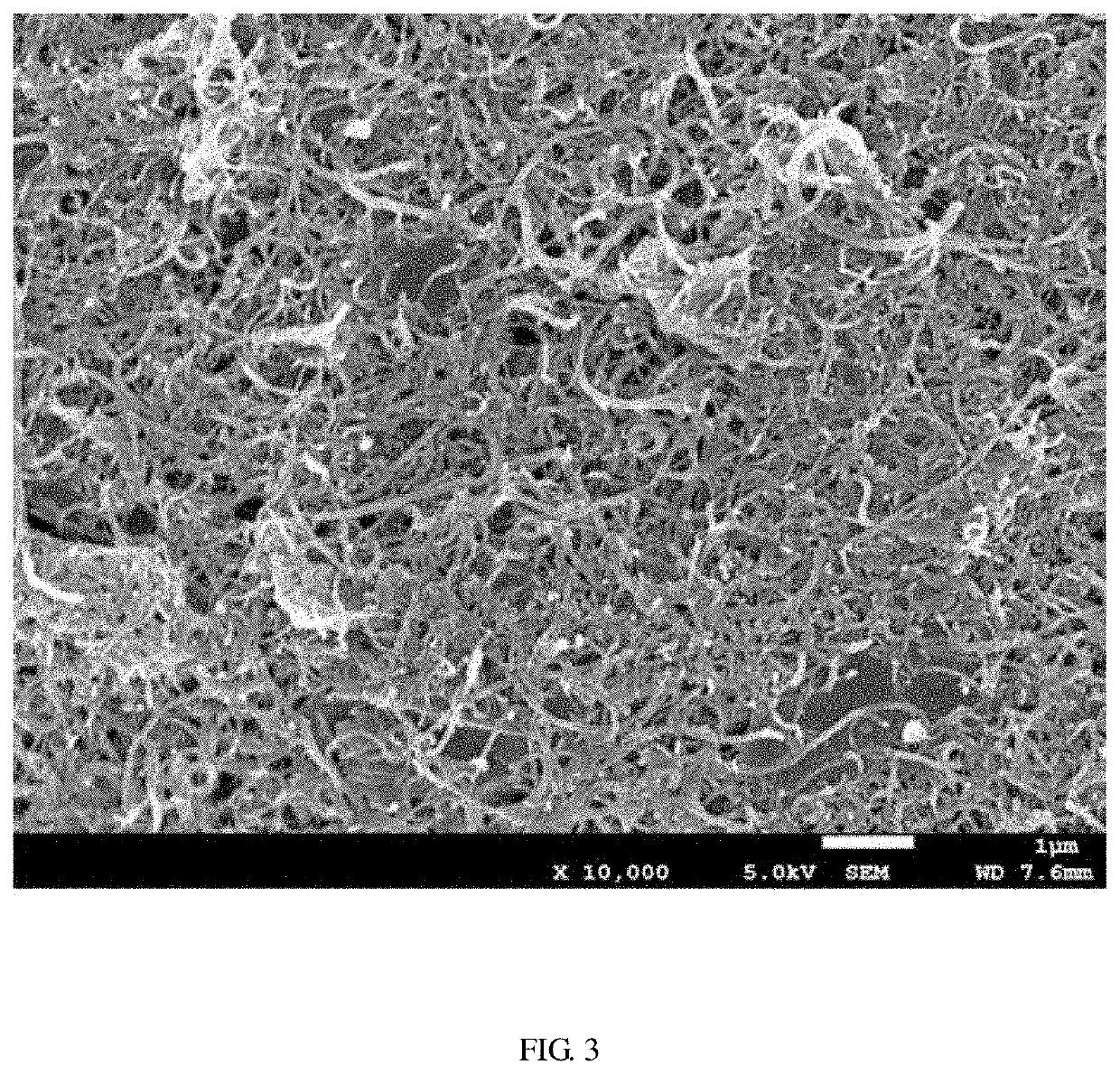

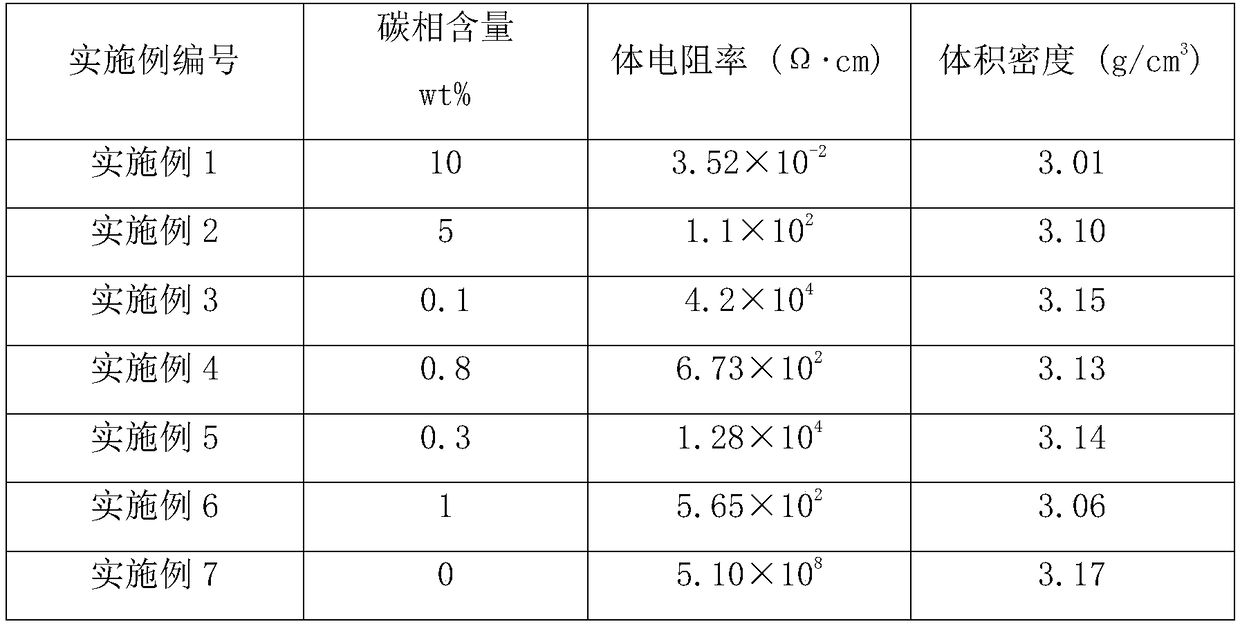

Silicon carbide ceramic with adjustable resistance and preparation method thereof

InactiveCN108911756ALower grain boundary resistanceLower bulk resistanceElectrical resistance and conductanceBoron carbide

The invention discloses silicon carbide ceramic with adjustable resistance and a preparation method thereof. The ceramic material mainly comprises a silicon carbide phase as a main phase, boron carbide as a sintering aid phase, and a carbon phase as a conductive phase, and the ceramic material can be prepared and has the bulk resistivity adjustable from 10<-2> to 10<8> Omega.cm. The silicon carbide ceramic has a density of 3.00 to 3.20 g / cm<3>. The core of the method is to coat the surface of silicon carbide raw material powder with a graphene-based material layer, and to adjust the content ofthe conductive phase in the silicon carbide ceramic to obtain the silicon carbide ceramic with adjustable bulk resistivity.

Owner:NINGBO VULCAN TECH CO LTD

Production method of large-size graphite electrode

The invention relates to a production method of a large-size graphite electrode which comprises the components in percentage by weight: 76-79 percent of calcined petroleum coke, 21-24 percent of medium-high temperature modified asphalt and the balance of filling material with the diameter of 0.075-2 mm, wherein the calcined petroleum coke comprises the following components in percentage by weight: not more than 4 percent of granules with the diameter of more than 12 mm, 6-10 percent of granules with the diameter of 8-13 mm, 13-17 percent of granules with the diameter of 4-8 mm, 9-13 percent of granules with the diameter of 2-4 mm and 30-32 percent of powder with the diameter of not more than 0.075 mm according to the particle size distribution; and the coking value of the modified asphalt is over 55 percent and the softening point is 95-100 DEG C. After the raw materials are mixed according to the proportion, the large-size graphite electrode is produced by adopting a conventional process, wherein the mixing temperature is 160-165 DEG C and the thicker lumpiness during the die-filling is less than 40 mm. A huge-size electrode with the diameter of over 960 mm can be produced by adopting the production method of the large-size graphite electrode; meanwhile, the electrode has low resistivity and good conduction property and can bear strong current, thereby enabling the unit consumption and the electricity consumption to be greatly lowered and saving the production cost.

Owner:JIEXIU JUYUAN & COALY

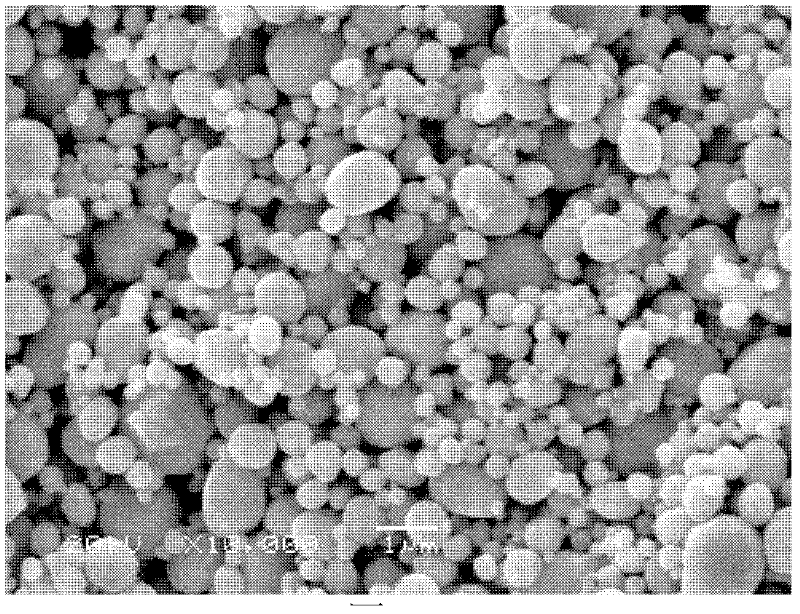

Preparation method of ITO (Indium Tin Oxide) powder and ITO sintering body

InactiveCN101830498AImprove sinterabilityLow maximum grain sizeGallium/indium/thallium compoundsTin oxidesIndiumMicrometer

The invention discloses a preparation method of ITO (Indium Tin Oxide) powder, comprising the following steps of: (a) adding an aqueous alkaline solution with the concentration of 10-30 percent by weight to an indium tin solution to obtain an indium tin hydroxide precipitation solution, and controlling the temperature of an initial precipitation solution between 18 DEG C and 30 DEG C in the process of adding the aqueous alkaline solution; (b) separating precipitations and liquid contained the indium tin hydroxide precipitation solution; (c) washing the separated precipitations; and (d) calcining the precipitations to obtain the ITO powder. The invention is beneficial to enhancing the sintering property of the ITO powder by selecting proper aqueous alkaline solution concentration and precipitation temperature according to that the aqueous alkaline solution concentration and the precipitation temperature have a great impact on the sintering property of the ITO powder when the indium tin solution is added to the aqueous alkaline solution; an ITO sintering body prepared by the ITO powder has at least 7.08 g / cm<3> of density, bulk resistivity lower than 1.90*10<-4> ohm.cm and maximum crystallite dimension of the sintering body, which is smaller than 10 micrometers.

Owner:西北稀有金属材料研究院宁夏有限公司 +1

Method and Apparatus for the Purification and Analytical Evaluation of Highly Purified Liquids

A method and apparatus for removing soluble and insoluble contaminants from highly purified and ultra-pure liquids having a bulk resistivity in excess of one megohm-centimeter by establishing laminar flow of the liquid in a cylindrical chamber through an electromagnetic field transverse to the direction of flow, to induce mobility of the constituents. The wall of the chamber forms a cathode and a central rod forms an anode in the chamber. The mobilized constituents are transported either to the anode or the cathode, where the material will adhere and agglomerate with other constituents. Systems are provided utilizing the method and apparatus for purifying and analytically evaluating highly purified and ultra-pure water.

Owner:MICROFIER

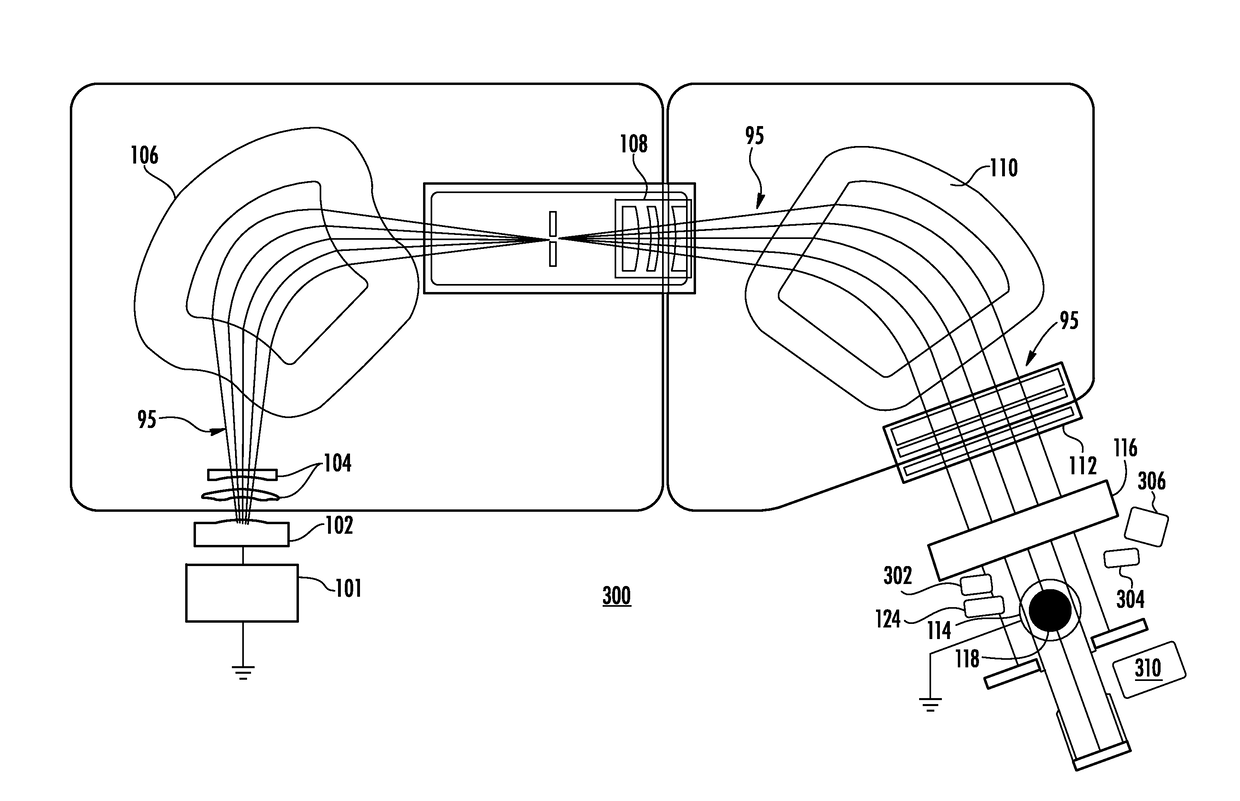

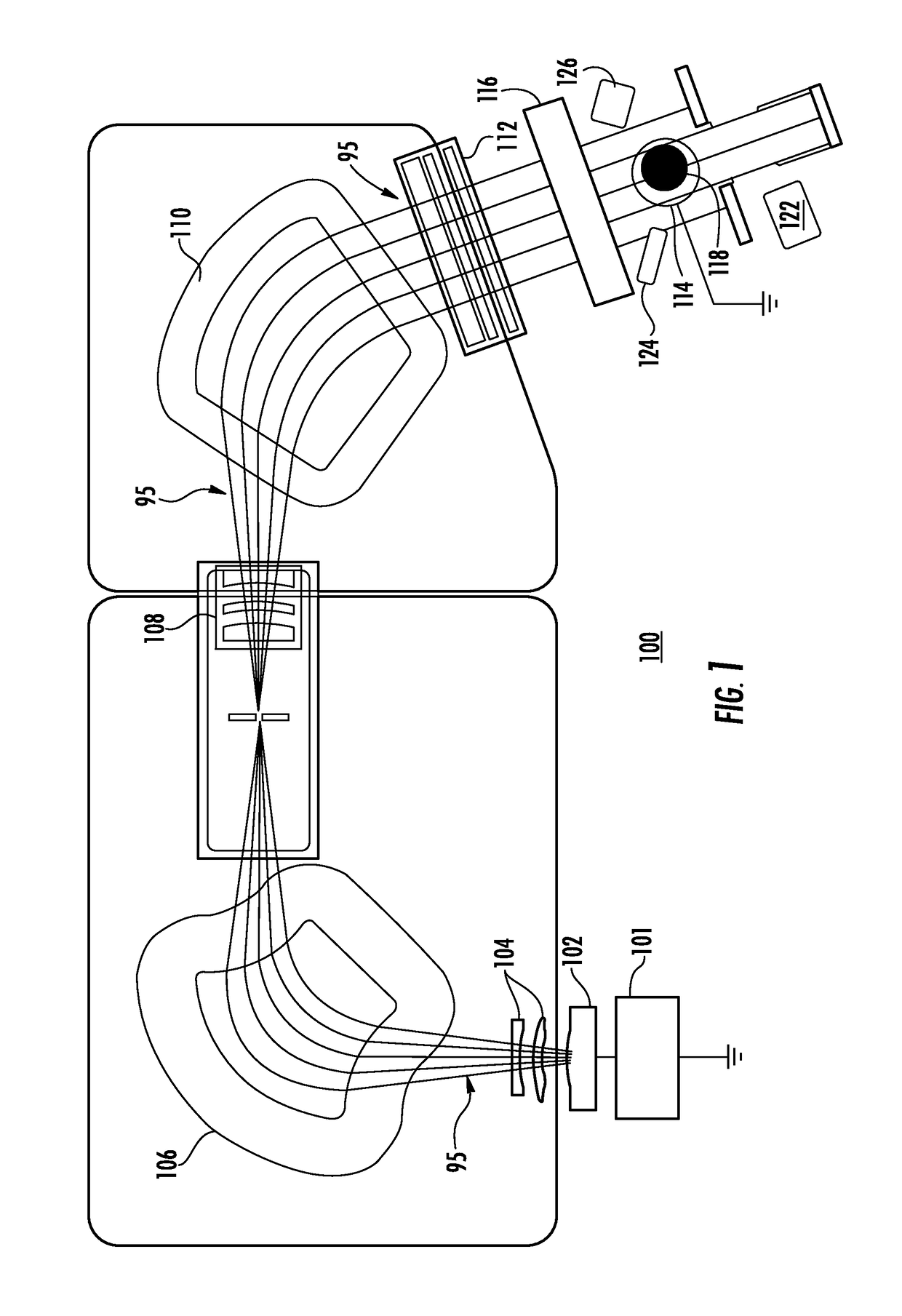

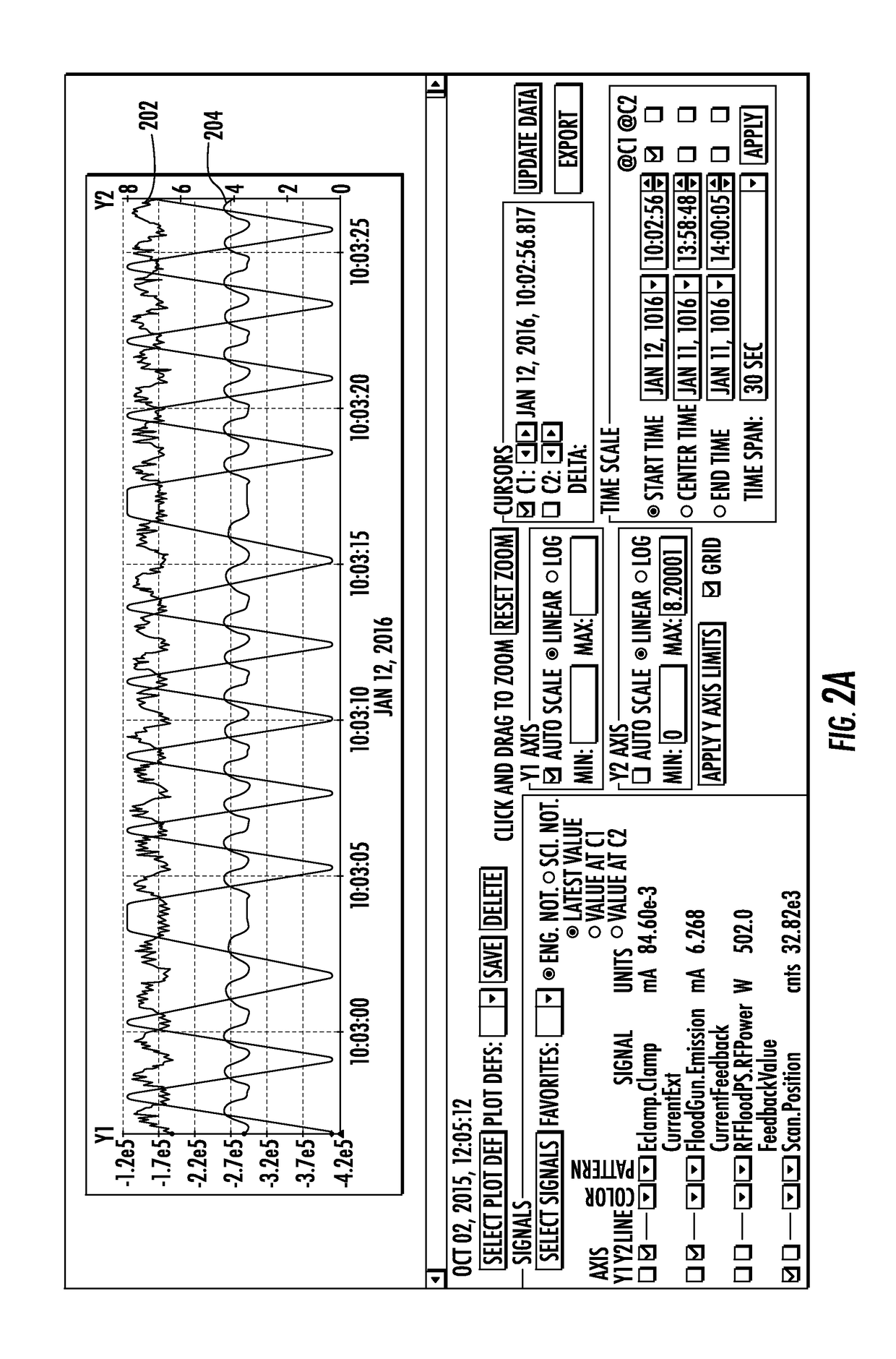

Method for implantation of semiconductor wafers having high bulk resistivity

ActiveUS20170207063A1Reduce variationHigh bulk resistivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingPower flowControl signal

An ion implanter may include an electrostatic clamp to hold a substrate; a plasma flood gun generating a flux of electrons impinging upon the substrate; and a controller coupled to the plasma flood gun and including a component generating a control signal responsive to a measurement signal, the control signal to adjust operation of the plasma flood gun to a target operating level. At the target operating level the flux of electrons may comprise a stabilizing dose of electrons, the stabilizing concentration of electrons, the stabilizing concentration reducing a clamp current variation in the electrostatic clamp to a target value, the target value being less than a second value of clamp current variation when the plasma flood gun is not operating.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Blackening method of lithium tantalate crystal substrate

ActiveCN106521633AImprove uniformityEasy accessPolycrystalline material growthAfter-treatment detailsTemperature differenceSurface acoustic wave

The invention discloses a blackening method of a lithium tantalate crystal substrate. The blackening method includes that in a chemical reductive atmosphere, a metal sheet and the lithium tantalate crystal substrate are alternately stacked by means of contacting after the surfaces of the same are roughened, and put in an environment lower than Curie temperature, the lithium tantalate crystal substrate is reduced to convert the same from white or faint yellow to colored and non-transparent, and original characteristics of the lithium tantalate crystal substrate as a piezoelectric material are still maintained. Bulk resistivity of the lithium tantalate crystal substrate after being reduced can be lowered, discharging generated by pyroelectric effect due to temperature difference in the manufacturing process of a surface acoustic wave filter (SAW filter) can be improved, accuracy of photoetching process of an interdigital electrode line is improved, and increasing of yield of SAW device manufacturing and lowering of production cost are facilitated.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

Method and apparatus for detecting liquid levels in liquid-storage containers

ActiveUS7275430B2Improve reliabilityDifferent typeMachines/enginesLubrication indication devicesElectrode pairBiomedical engineering

A method and apparatus for sensing different levels of liquids in their respective containers in a liquid-consuming and / or producing instrument system. According to a preferred embodiment, an elongated liquid-sensing probe having axially spaced electrodes adapted to sense liquid at multiple levels is arranged in each container of liquid. A controller, e.g. a suitably programmed microprocessor, operates to selectively poll different pairs of electrodes carried by the probe to determine whether or not the polled electrode pairs are immersed in the contained liquid. Preferably, the polling circuit comprises an electronically-controlled resistor that serves to normalize the level-sensing output signal for liquids of different bulk resistivity.

Owner:BECKMAN COULTER INC

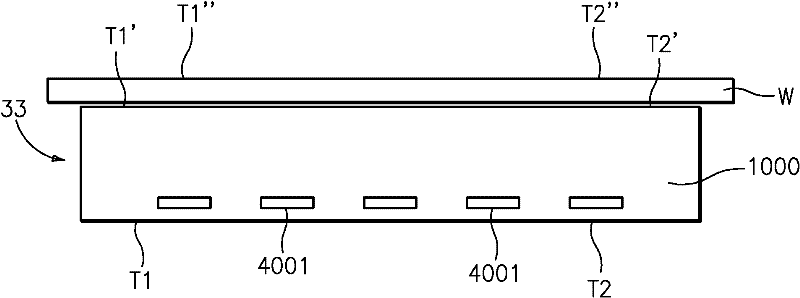

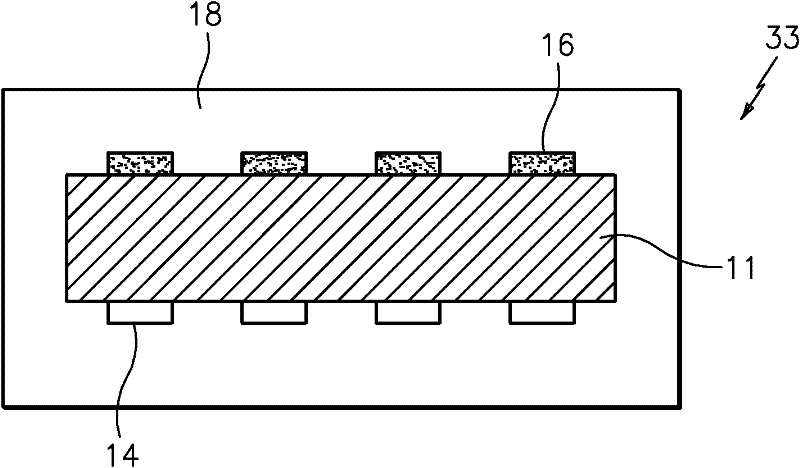

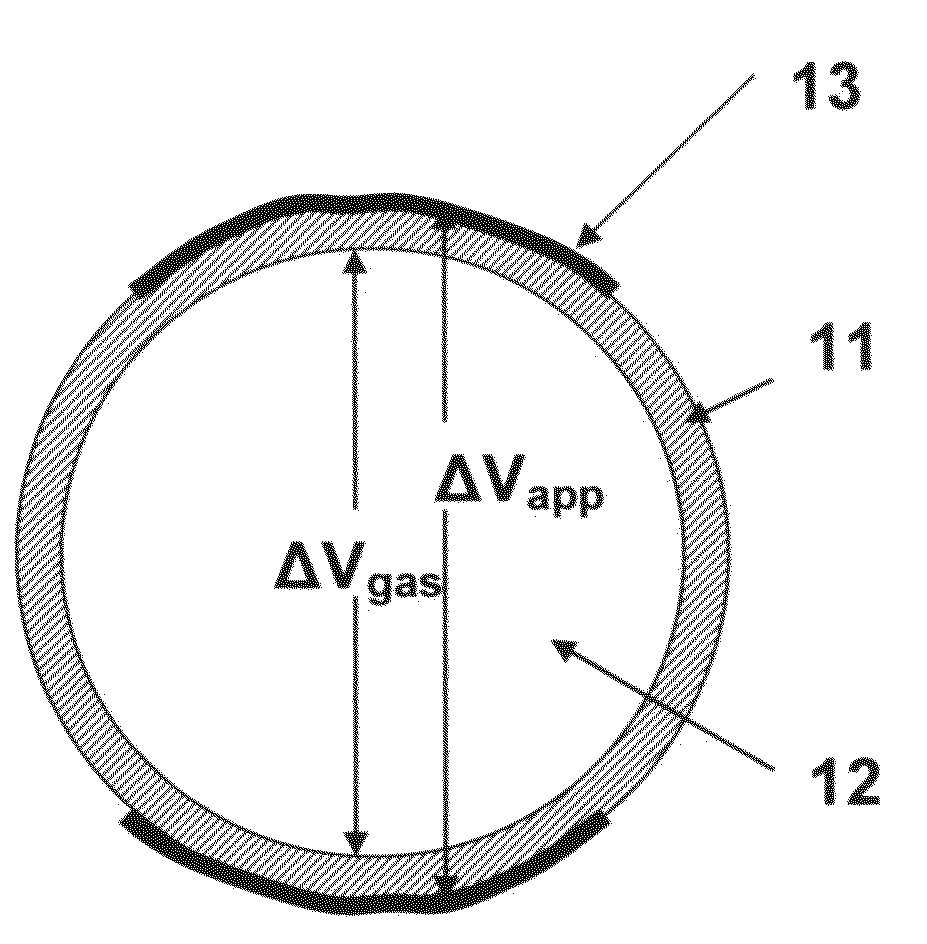

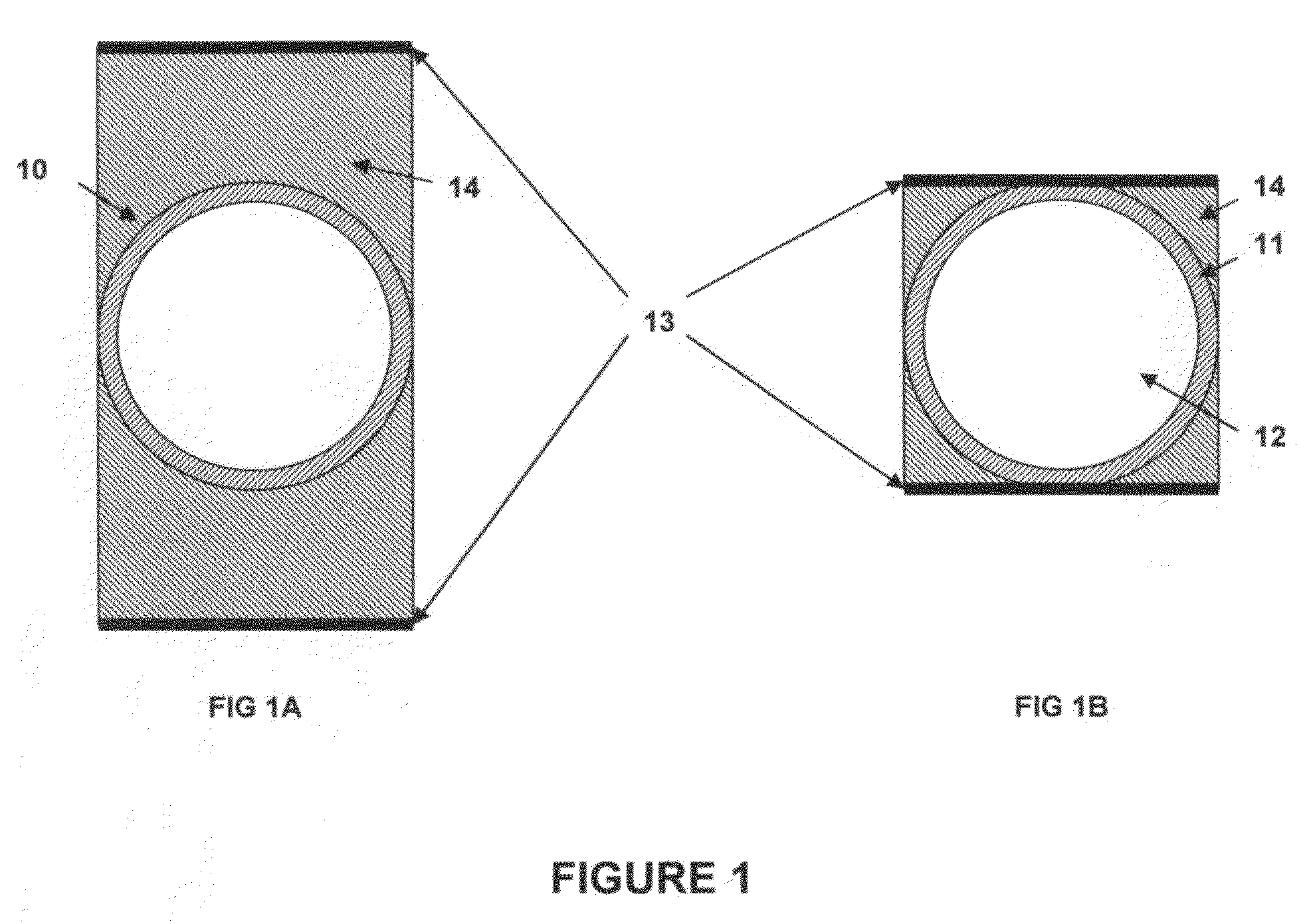

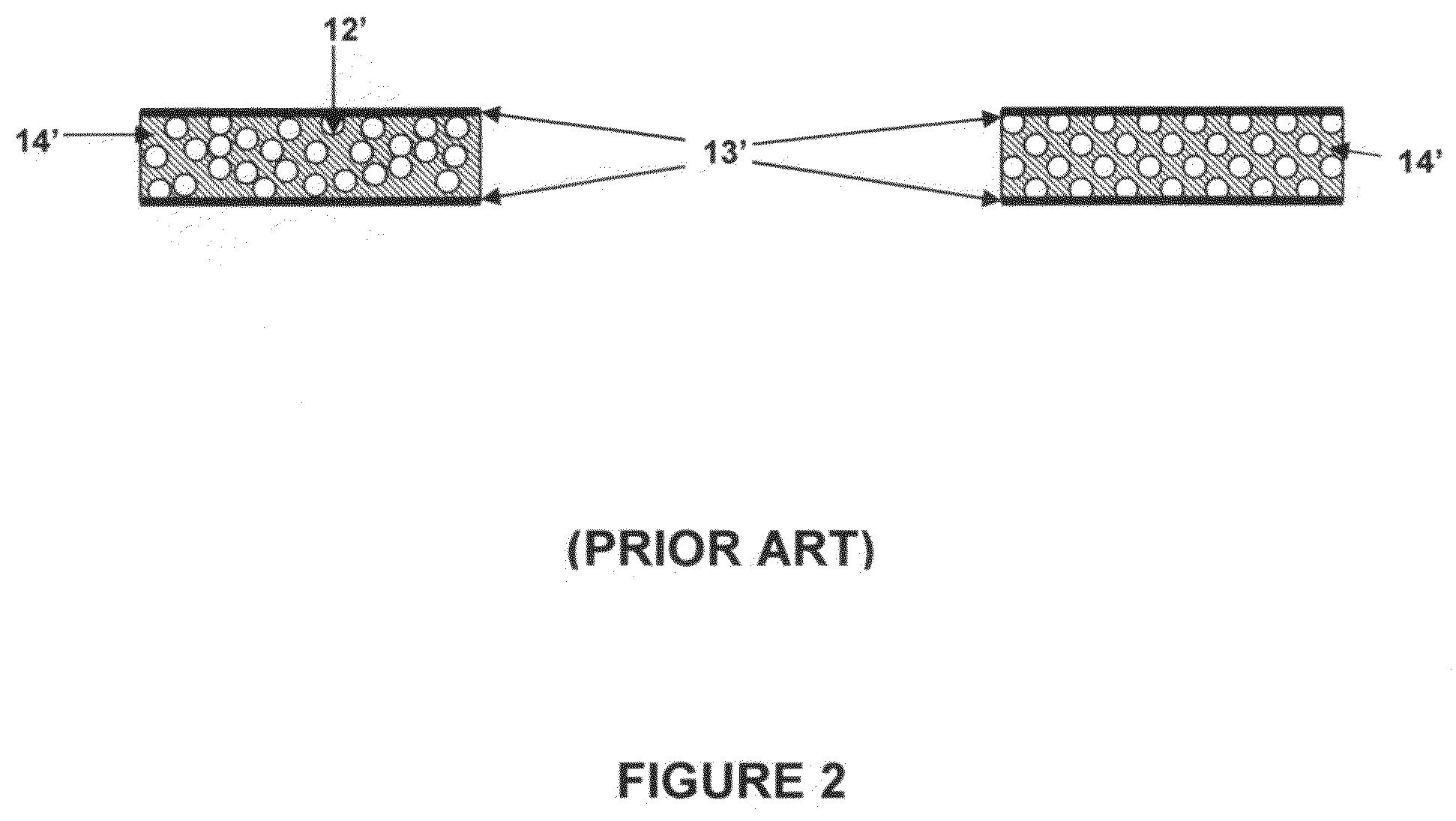

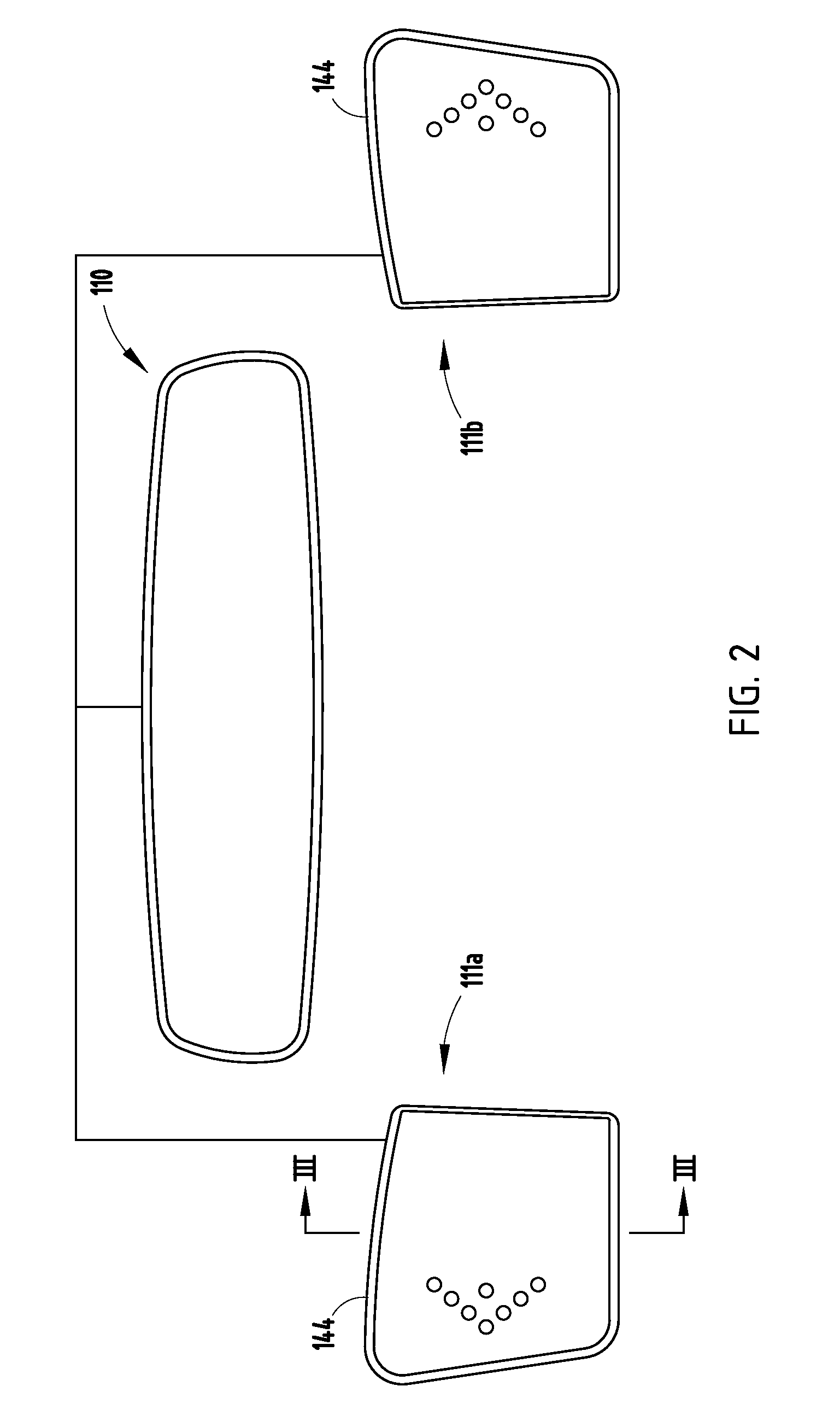

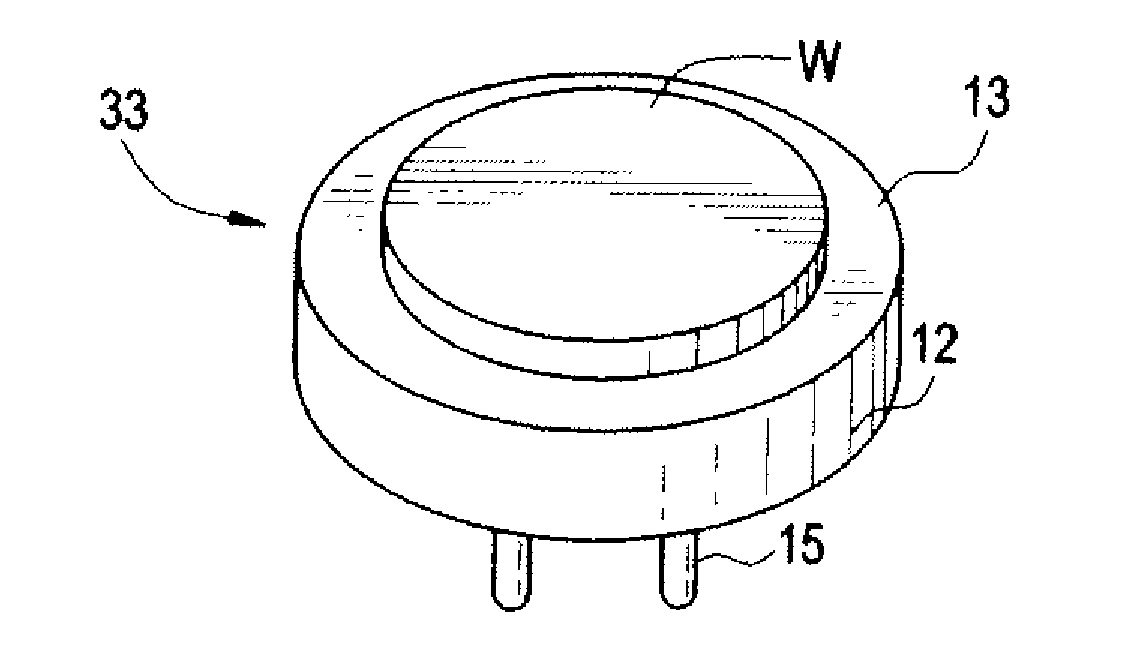

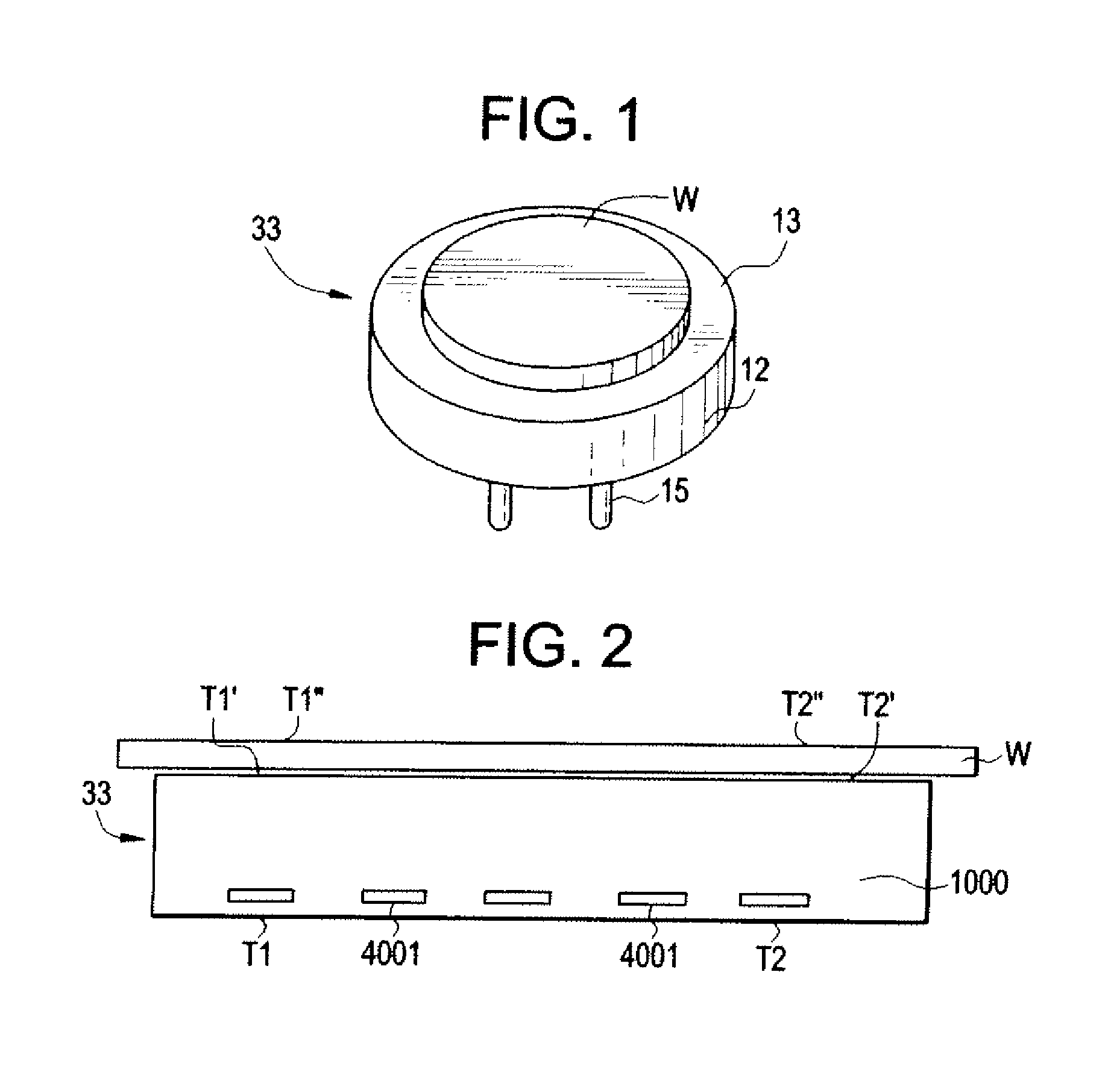

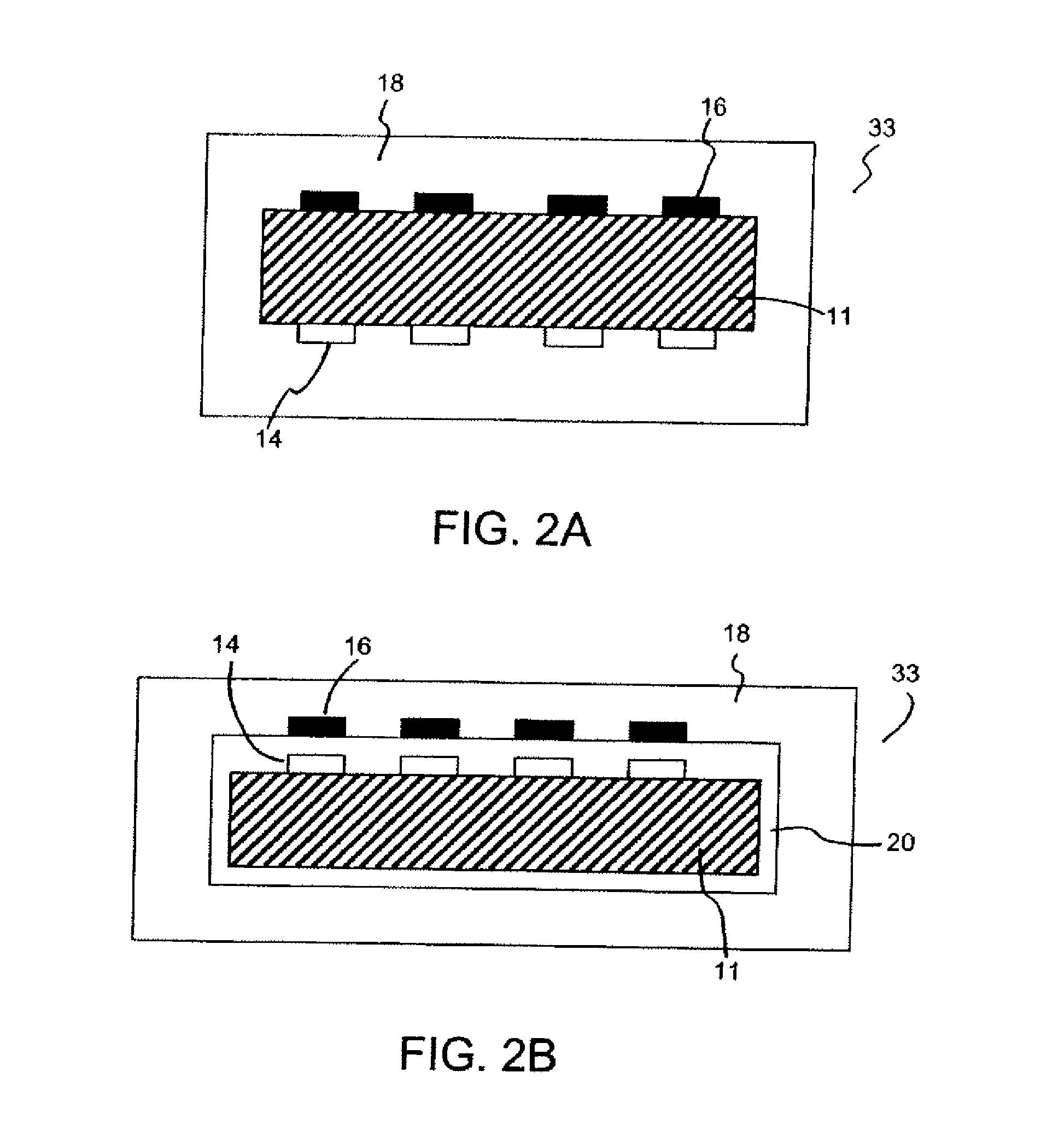

[methods and systems for resistivity anisotropy formation analysis]

ActiveUS20050114030A1Electric/magnetic detection for well-loggingSeismology for water-loggingPorositySlide window

Techniques for determining a formation property by simplifying various two-geological-layer or multi-geological-layer models into a multi-electrical-layer model. A volume fraction of a layer in a multi-electrical-layer model is determined for an anisotropic region (sliding window) of the formation. The multi-electrical-layer electrical model includes a relative-lower-resistivity layer and a relative-higher-resistivity layer. A high-resolution resistivity measurement is used in the determination and resistivities for the relative-lower-resistivity layer and for the relative-higher-resistivity layer based on the volume fraction and bulk resistivity measurements of the anisotropic region are determined. The formation property is based on the volume fraction, the resistivity of the relative-lower-resistivity layer, the resistivity of the relative-higher-resistivity layer, a total porosity of the anisotropic region, and bulk resistivity measurements of the region.

Owner:SCHLUMBERGER TECH CORP

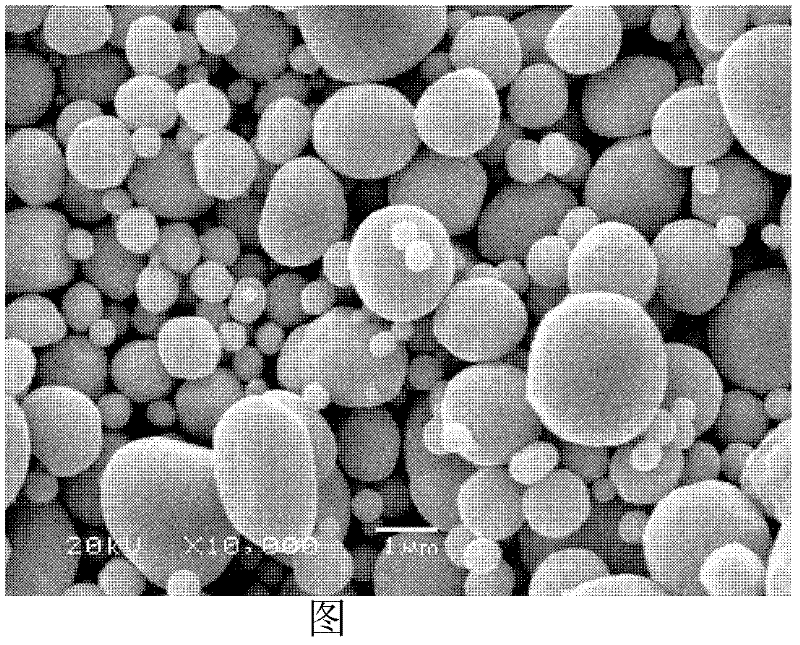

Preparation method for high-crystallinity silver powder

The invention relates to a preparation method for high-crystallinity silver powder. The preparation method is characterized by comprising the following steps of: firstly, synthesizing a silver carbonate precursor; uniformly coating the silver carbonate precursor by using a coating agent; and performing low-temperature crystal water removing, high-temperature thermal decomposition, densification sintering and washing on the coated silver carbonate precursor to obtain high-crystallinity silver powder. Due to the adoption of the method disclosed by the invention, high-crystallinity silver powder of which the particle diameter is 0.1-5 mu m and the tap density is 3.0-7.0 g / cm<3> can be finally obtained; the silver powder can be used for preparing silver slurry or silver paste for fine threads and high-accuracy printed galvanic circles; the silver powder has the advantages of high dispersity, high crystallinity, superior degree of sphericity, uniform particle size distribution, easiness for dispersing in silver slurry or silver paste and high filling characteristic, so that high-accuracy fine thread printing can be realized; and meanwhile, an obtained silver thick film has low sintering concentration rate and low bulk resistivity.

Owner:宁夏中色新材料有限公司

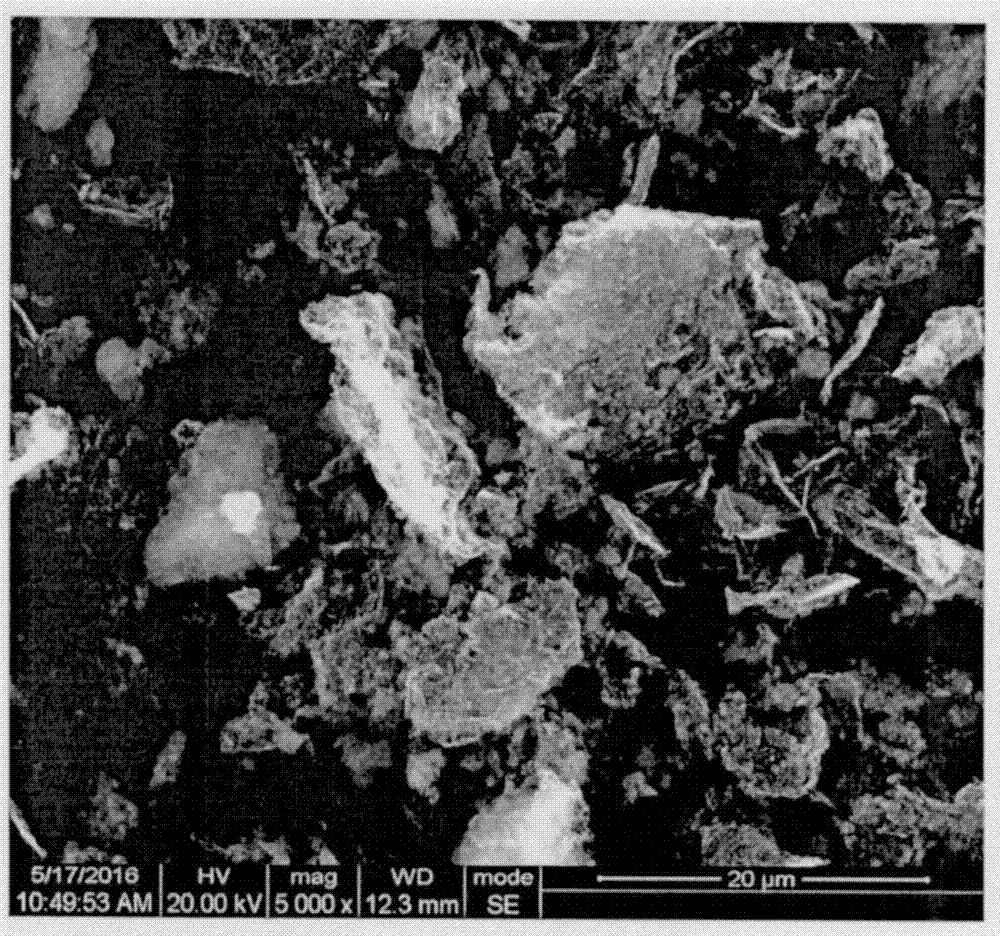

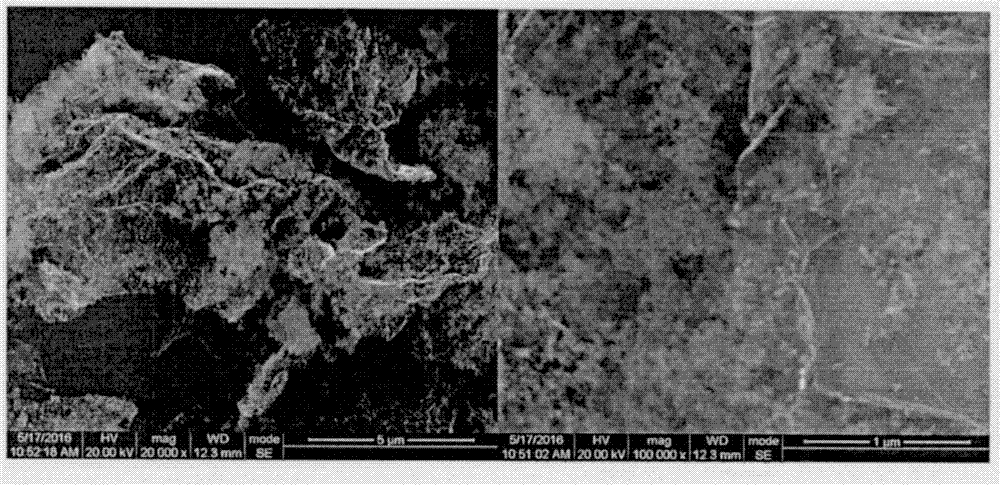

Graphene-white carbon black composite powder and preparation technology thereof

InactiveCN107541096AMaintain Monolayer DispersionImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersitySlurry

The invention relates to graphene-white carbon black composite powder and a preparation technology thereof. The preparation technology comprises dispersing a graphene oxide aqueous solution and whitecarbon black powder in water at a high speed to obtain uniform mixed aqueous slurry, adding a gelling agent and a surfactant into mixed aqueous slurry, adjusting pH of the solution so that graphene oxide-white carbon black hydrogel is obtained, filtering and drying the graphene oxide-white carbon black hydrogel to obtain graphene oxide-white carbon black aerogel and calcining the graphene oxide-white carbon black aerogel at a high temperature in the inert atmosphere to reduce the graphene oxide so that the graphene-white carbon black composite powder is obtained. The preparation technology issimple and reliable and realizes a low cost. The graphene-white carbon black composite powder has powder resistivity less than 100 omega. cm, graphene in the composite material has good single layer dispersity, rich pore structures are formed through layer enwinding, the white carbon black nano-particles are uniformly dispersed on the surface of the graphene layer, and the composite material has excellent electrical conductivity and thermal conductivity and can be widely used in the fields of coatings, rubber products and plastic.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

Preparation method of TZO semiconductor material for high-transmittance energy-saving glass

InactiveCN105272210AImprove transmittanceFast sputtering rateVacuum evaporation coatingSputtering coatingSputteringZinc tin oxide

The invention discloses a preparation method of a TZO semiconductor material for high-transmittance energy-saving glass and a preparation method thereof. ZnO and SnO2 powder is used as main materials; even mixing is carried out, a biscuit is manufactured, and drying, sintering and machining are carried out to obtain a zinc / tin oxide semiconductor material with the relative density larger than 95%; volume resistivity is smaller than or equal to 6*10<-2> omega.cm, the material is used as the magnetron sputtering target material for manufacturing Low-E glass with the transmittance larger than or equal to 85% and replaces zinc-tin alloy coating materials which are greatly used at present, the process of producing a zinc / tin oxide film through magnetron sputtering is more stable, the production technology is simpler, the sputtering speed is high, the production efficiency is improved by more than 5%, the large-area coating film layer has uniform ingredients and fine structure, the requirement of manufacturing double-silver three-silver Low-E glass for sputtering equipment is lowered, and the TZO semiconductor material has the advantages for preparing large-size high-transmittance glass.

Owner:NANJING TEMCH OPTOELECTRONICS MATERIAL CO LTD

Neutron detector

InactiveUS20080315108A1Efficient discriminationImproved signal characteristicTube/lamp screens manufactureElectric discharge tubesDielectricPulse height analyzer

A neutron detector comprises a gas-filled dielectric shell, preferably a glass balloon, having opposite electrodes. An electric field is established whereby ionizing particles may be detected via ionization and current flow in the gas, using a pulse height analyzer or other conventional means. The dielectric shell preferably has low gas permeability and a bulk resistivity in the range of 108 to 1017 Ω-m, and is preferably in the millimeter to centimeter size range. Multiple balloons may be arranged in parallel or may be individually addressable by the detector electronics.

Owner:MATERIALS INNOVATION INC +1

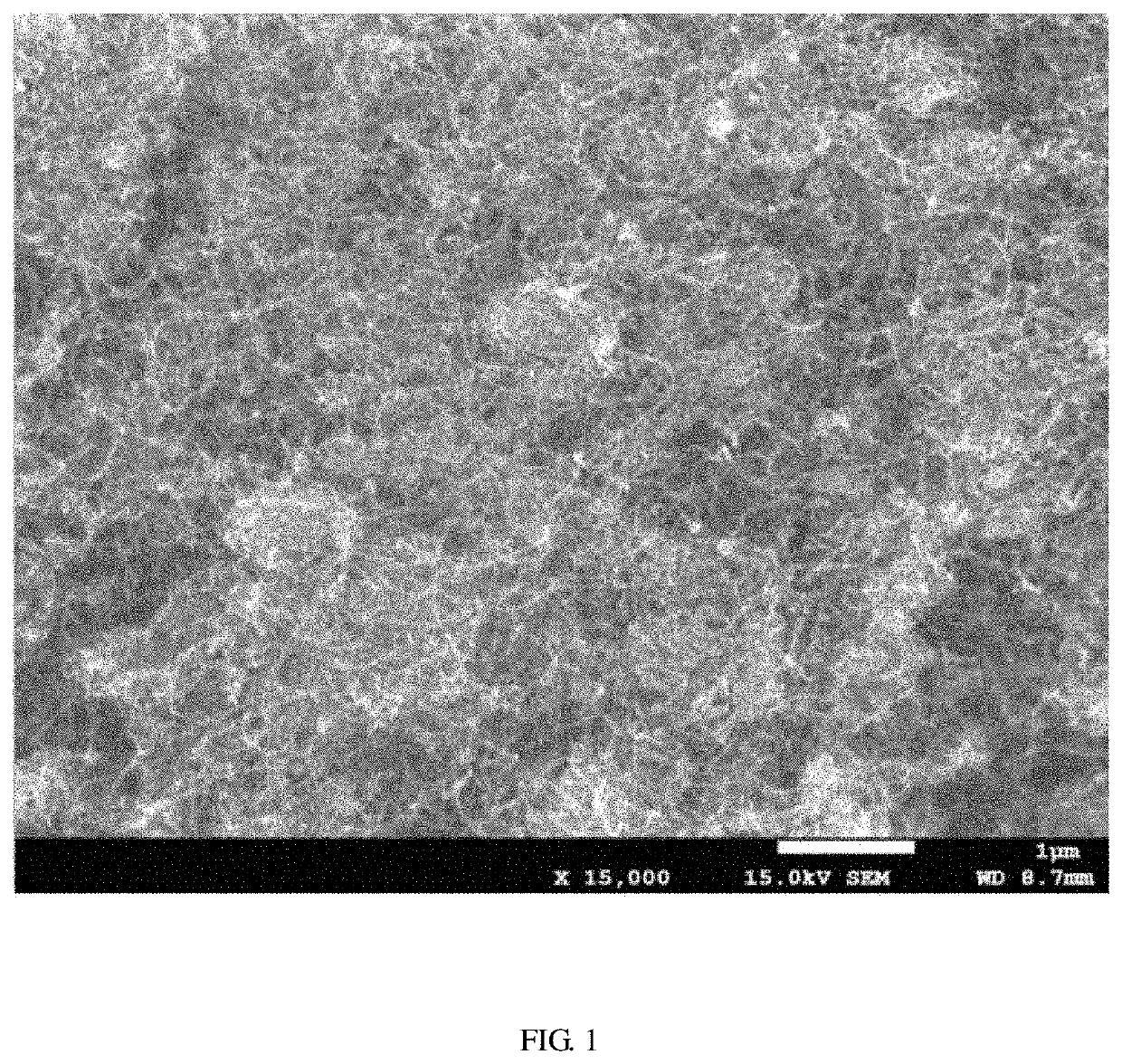

Electroless copper plating polydopamine nanoparticles

Aqueous dispersions of artificially synthesized, mussel-inspired polyopamine nanoparticles were inkjet printed on flexible polyethylene terephthalate (PET) substrates. Narrow line patterns (4 μm in width) of polydopamine resulted due to evaporatively driven transport (coffee ring effect). The printed patterns were metallized via a site-selective Cu electroless plating process at a controlled temperature (30° C.) for varied bath times. The lowest electrical resistivity value of the plated Cu lines was about 6 times greater than the bulk resistivity of Cu. This process presents an industrially viable way to fabricate Cu conductive fine patterns for flexible electronics at low temperature, and low cost.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Preparation method for coating material using conductive biomass charcoal as filling material

InactiveCN101096557AReduce manufacturing costImprove antistatic performancePolyurea/polyurethane coatingsElectrically-conductive paintsSolventBall mill

The invention discloses a paint making method based on conductive biological char as filler, which comprises the following steps: adopting conductive char as filler and phenol resin varnish as base; calcining broad-leaved tree species timber at 800 deg. c insulated by air for 20h to form char; grinding the char in the milling machine to form char particle with even grain size at 35um; measuring conductive property of char under sufficient compaction condition; controlling the bulk resistivity at 0.1-100 omega.cm; weighing 20-50% char to blend with residual phenol resin and solvent; adopting spray technique. The invention saves cost to increase antistatic property without breaking other properties, which can adjust surface resistivity.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

Wafer processing apparatus having a tunable electrical resistivity

InactiveCN102203931ASemiconductor/solid-state device manufacturingElectrical resistance and conductanceElectromagnetic shielding

An article with an etch resistant coating is disclosed. The article is a heating element, wafer carrier, or electrostatic chuck. The article has a base substrate made of a ceramic or other material, and further has one or more electrodes for resistance heating or electromagnetic chucking or both. The eth resistant coating has a plurality of regions made from materials having different electrical volume resistivities, such that the overall coating has a bulk resistivity that can be tailored by varying the relative size of each region.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Neutron detector

InactiveUS7923698B2Line/current collector detailsElectric discharge tubesDielectricPulse height analyzer

A neutron detector comprises a gas-filled dielectric shell, preferably a glass balloon, having opposite electrodes. An electric field is established whereby ionizing particles may be detected via ionization and current flow in the gas, using a pulse height analyzer or other conventional means. The dielectric shell preferably has low gas permeability and a bulk resistivity in the range of 108 to 1017 Ω-m, and is preferably in the millimeter to centimeter size range. Multiple balloons may be arranged in parallel or may be individually addressable by the detector electronics.

Owner:UT BATTELLE LLC +1

Broadband high-permeability high-impedance manganese-zinc ferrite and preparation method thereof

InactiveCN112142457AImprove permeabilityIncrease resistanceInorganic material magnetismSpray GranulationCompression molding

The invention provides a broadband high-permeability high-impedance manganese-zinc ferrite and a preparation method thereof, relates to the technical field of magnetic materials, and is used for solving the problems of low resistivity, high dielectric constant and in-applicability of a high-frequency manganese-zinc ferrite above 1 MHZ in the prior art, and high cost of a NiZn ferrite applicable atthe high frequency. An iron-poor formula is adopted, the annular magnetic core is obtained through the steps of mixing, pre-sintering, grinding, spray granulation, compression molding and sintering,and the ferrite has high impedance and high magnetic conductivity at 1-100 MH.

Owner:临沂春光磁业有限公司

Sputtering target and process for producing same

ActiveCN104024470AImprove power generation efficiencyIncrease concentrationElectric discharge tubesVacuum evaporation coatingHigh concentrationDensity ratio

Provided is a sputtering target which contains Na in a high concentration and, despite this, is inhibited from discoloring, generating spots, and causing abnormal discharge and which has high strength and rarely breaks. Also provided is a process for producing the sputtering target. The sputtering target has a composition which contains 10-40 at% Ga and 1.0-15 at% Na as metallic components other than F, S, and Se, with the remainder comprising Cu and unavoidable impurities, the Na being contained in the form of at least one Na compound selected from sodium fluoride, sodium sulfide, and sodium selenide. The sputtering target has a theoretical density ratio of 90% or higher, a folding strength of 100 N / mm2 or higher, and a bulk resistivity of 1 mOmegacm or less. The number of 0.05 mm2 or larger aggregates of the at least one of sodium fluoride, sodium sulfide, and sodium selenide present per cm2 of the target surface is 1 or less on average.

Owner:MITSUBISHI MATERIALS CORP

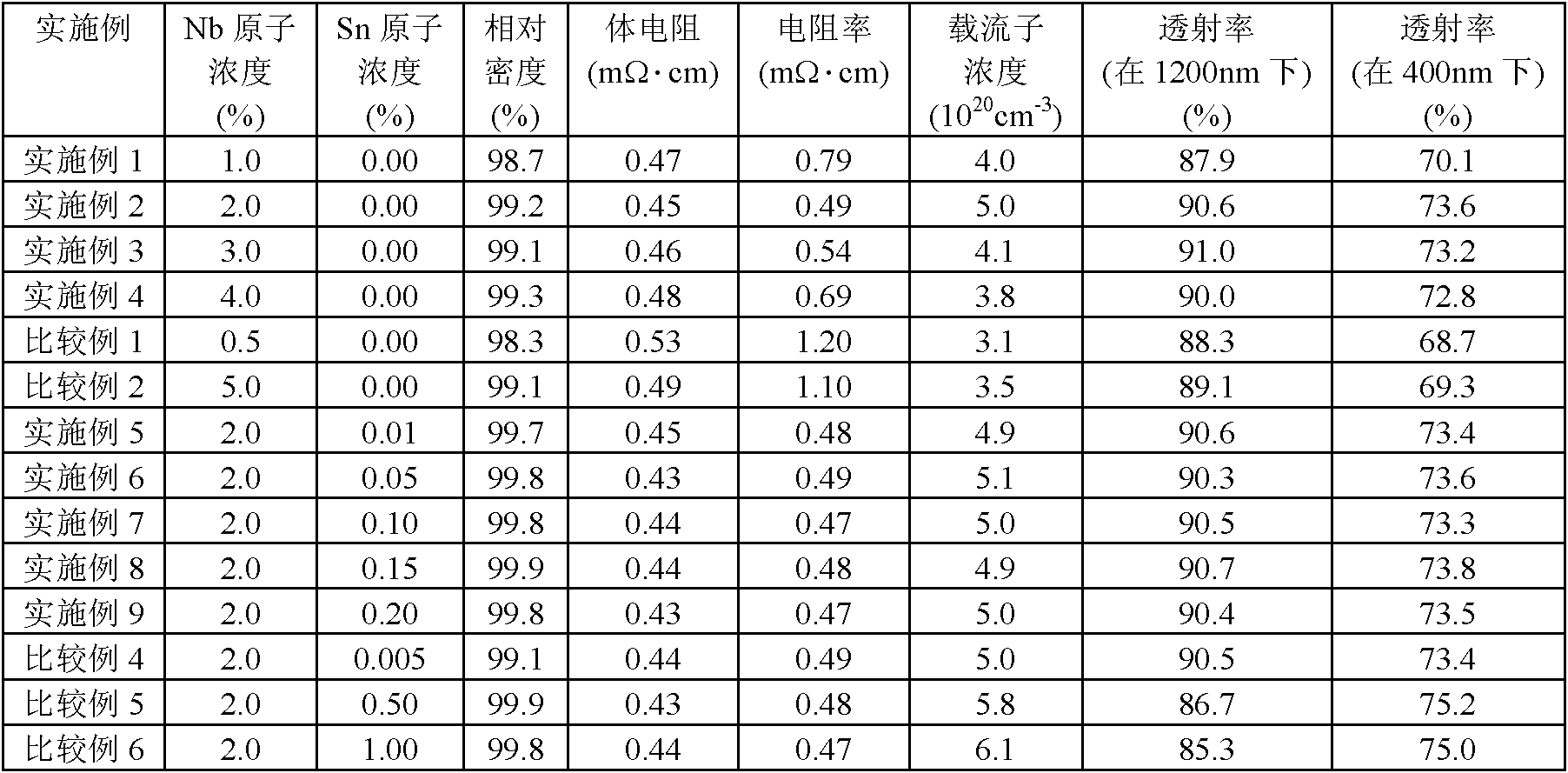

Indium oxide sintered body and indium oxide transparent conductive film

ActiveCN102666429AImprove transmittanceImprove conversion efficiencyConductive layers on insulating-supportsVacuum evaporation coatingIndiumNiobium

Disclosed is an indium oxide sintered body which contains niobium as an additive. The indium oxide sintered body is characterized in that: the ratio of the number of niobium atoms relative to the total number of atoms of all the metal elements contained in the sintered body is within the range of 1-4%; the relative density thereof is not less than 98%; and the bulk resistivity thereof is not more than 0.9 m[omega]cm. The indium oxide sintered body has high transmittances in short wavelength and long wavelength ranges, since the carrier concentration thereof is not too high although the resistivity thereof is low. Also disclosed is an indium oxide transparent conductive film.

Owner:JX NIPPON MINING & METALS CORP

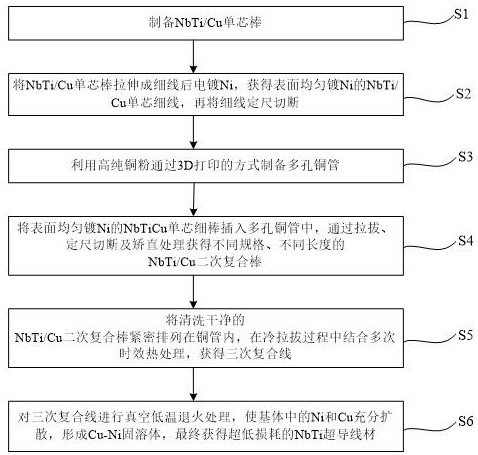

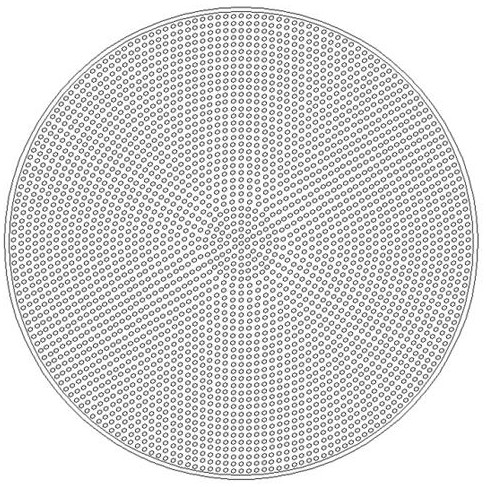

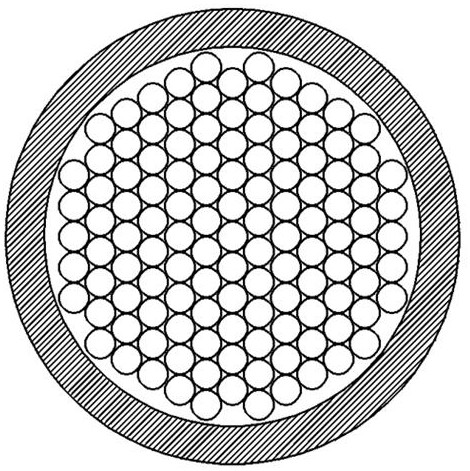

Preparation method of ultralow-loss NbTi superconducting wire

ActiveCN114783681AHigh resistivityEasy to processSuperconductors/hyperconductorsSuperconductor devicesWire rodElectric resistivity

The invention belongs to the technical field of superconducting wire preparation processes, and relates to a preparation method of an ultralow-loss NbTi superconducting wire, an NbTi / Cu single-core rod is prepared by a casting method, the single-core rod is cold-drawn into a fine wire, then the surface of the fine wire is uniformly plated with Ni, finally annealing heat treatment is carried out to improve the resistivity of a wire matrix, and the resistivity of the matrix is regulated and controlled by adjusting the thickness of a Ni plating layer, so that the ultra-low-loss NbTi superconducting wire is obtained. And the superfine core wire rod has excellent processing performance and ultralow loss. A multi-core secondary composite rod is prepared through 3D printing of a porous copper pipe, and finally, the 100,000-core-level NbTi superconducting wire with high critical current density and ultralow loss is successfully prepared through combination of pipe penetrating three-time composite and multiple times of aging heat treatment, and a traditional hot extrusion process is omitted in preparation of a single-core thin wire and the secondary composite rod. And the problems of high loss of the superfine core wire, poor deformation of the core wire, low yield and the like are thoroughly solved.

Owner:西部超导材料科技股份有限公司

Wafer processing apparatus having a tunable electrical resistivity

InactiveUS7929269B2Semiconductor/solid-state device manufacturingElectrical resistance and conductanceElectromagnetic shielding

An article with an etch resistant coating is disclosed. The article is a heating element, wafer carrier, or electrostatic chuck. The article has a base substrate made of a ceramic or other material, and further has one or more electrodes for resistance heating or electromagnetic chucking or both. The eth resistant coating has a plurality of regions made from materials having different electrical volume resistivities, such that the overall coating has a bulk resistivity that can be tailored by varying the relative size of each region.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[methods and systems for resistivity anisotropy formation analysis] [methods and systems for resistivity anisotropy formation analysis]](https://images-eureka.patsnap.com/patent_img/1637366f-8bee-41ff-aeed-3928ec84bf92/US20050114030A1-20050526-D00000.png)

![[methods and systems for resistivity anisotropy formation analysis] [methods and systems for resistivity anisotropy formation analysis]](https://images-eureka.patsnap.com/patent_img/1637366f-8bee-41ff-aeed-3928ec84bf92/US20050114030A1-20050526-D00001.png)

![[methods and systems for resistivity anisotropy formation analysis] [methods and systems for resistivity anisotropy formation analysis]](https://images-eureka.patsnap.com/patent_img/1637366f-8bee-41ff-aeed-3928ec84bf92/US20050114030A1-20050526-D00002.png)