Silicon carbide ceramic with adjustable resistance and preparation method thereof

A technology for silicon carbide ceramics and silicon carbide slurry is applied in the field of silicon carbide ceramics and their preparation, and can solve the problems of affecting the electrical properties of silicon carbide ceramics, decreasing the density of silicon carbide ceramics, affecting the strength and toughness of silicon carbide ceramics, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

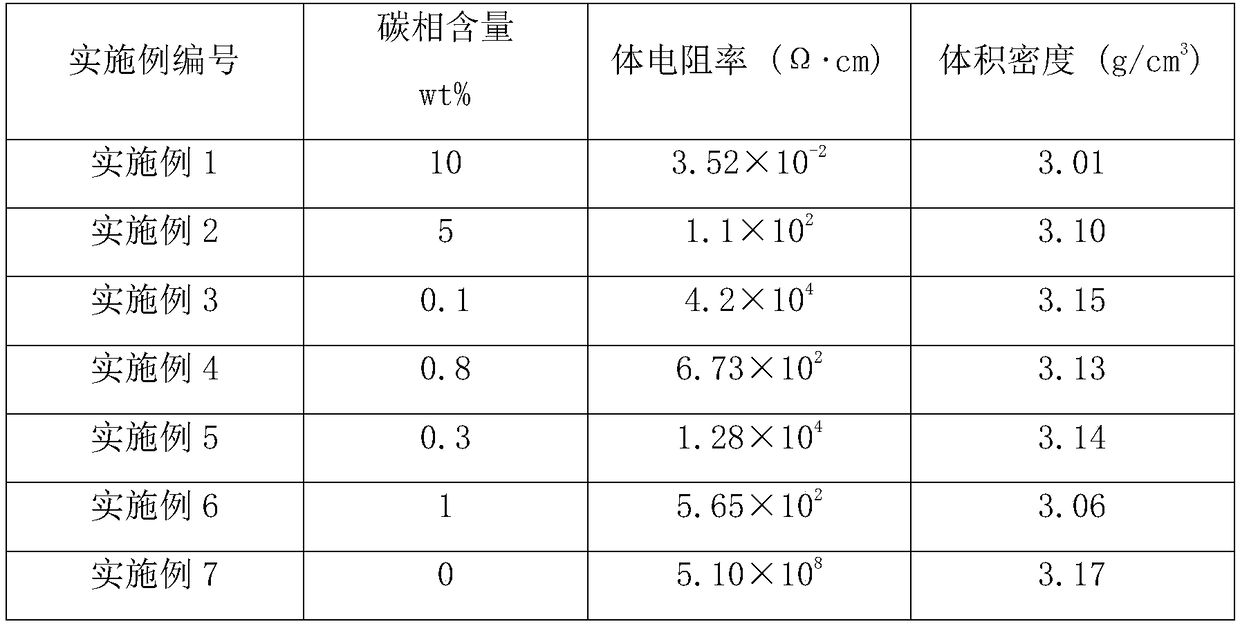

[0038] A silicon carbide ceramic with adjustable resistance, wherein, the content of silicon carbide phase is 90wt%, the content of boron carbide phase is 0.1%, the content of carbon phase is 9.8wt%, and the content of impurities is 0.1%. The prepared silicon carbide ceramics have a density of 3.01g / cm 3 , the resistivity is 3.52×10 -2 Ω·cm.

[0039] It is prepared as follows:

[0040] 89.9g of silicon carbide, 0.1g of boron carbide micropowder, 10.0g of graphene powder and other raw materials were fully ball milled and mixed for 24 hours in an ethanol solution containing 1g of dispersant PVP. The prepared slurry was dried in an oven at 70 °C for 24 h. After grinding and pulverizing, pass through a 120-mesh sieve, press molding at 15 MPa, and isostatic pressing at 200 MPa to obtain a silicon carbide ceramic green body. The green body is subjected to degreasing treatment under nitrogen at 1200°C, and then pressureless sintered at 1900°C for 24 hours to obtain the finished p...

Embodiment 2

[0042] A silicon carbide ceramic with adjustable resistance, wherein, the content of silicon carbide phase is 95% by weight; the content of boron carbide phase is 0.45%; the content of carbon phase is 4.5% by weight; and the content of impurities is 0.05%. The prepared silicon carbide ceramics have good density, with a density of 3.10g / cm 3 , the resistivity is 1.1×10 2 Ω·cm.

[0043] It is prepared as follows:

[0044] 94.5g of silicon carbide, 0.5g of boron carbide micropowder, 5.0g of graphene powder, etc. were used as raw materials in a methanol solution containing 1.0g of dispersant CMC and fully ball milled and mixed for 12 hours, and the raw material powder was prepared by spray granulation. Silicon carbide ceramic green bodies were prepared by dry pressing at 15 MPa and isostatic pressing at 200 MPa. The prepared green body was degreased at 1300°C under argon gas, and then the green body was kept at 2150°C for 24 hours for pressureless sintering.

Embodiment 3

[0046] A silicon carbide ceramic with adjustable resistance, wherein the content of silicon carbide phase is 99.35% by weight; the content of boron carbide phase is 0.45%; the content of carbon phase is 0.15% by weight; and the content of impurities is 0.05%. The prepared silicon carbide ceramics have good density, with a density of 3.15g / cm 3 , the resistivity is 4.2×10 4 Ω·cm.

[0047] It is prepared as follows:

[0048] 99.4g of silicon carbide, 0.5g of boron carbide micropowder, 0.1g of graphene powder, etc. were used as raw materials in a methanol solution containing 0.5g of dispersant CMC for 48 hours, and the raw material powder was prepared by spray granulation. Silicon carbide ceramic green bodies were prepared by dry pressing at 10MPa and isostatic pressing at 200MPa. The prepared green body was degreased at 1000° C. under nitrogen condition, and then the green body was kept at 2000° C. for 48 hours for pressureless sintering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com