High-density super-hard material manufacturing method

A technology of superhard materials and production methods, which is applied in transportation and packaging, metal processing equipment, etc., can solve the problems of unstable product quality, low density, uneven product density, etc., and achieve good density and sintering shrinkage The effect of small size and high product dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

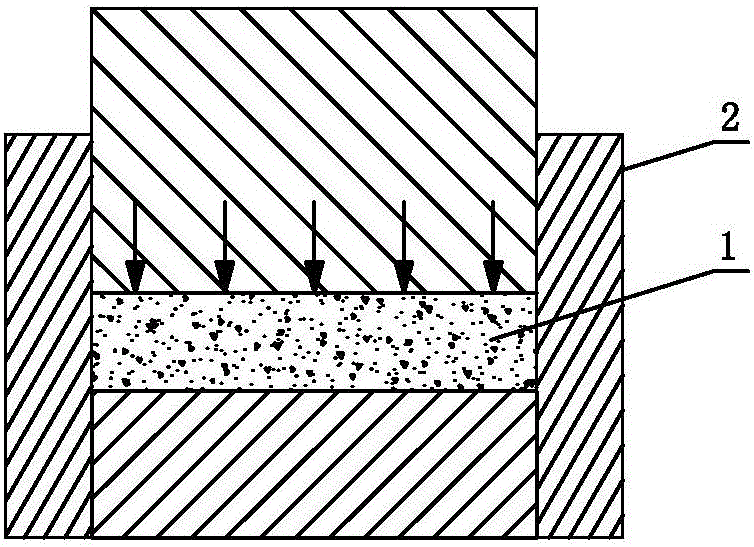

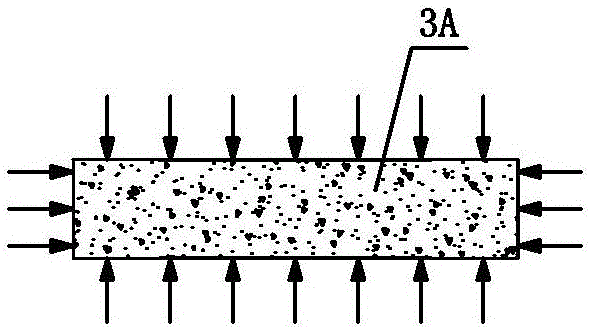

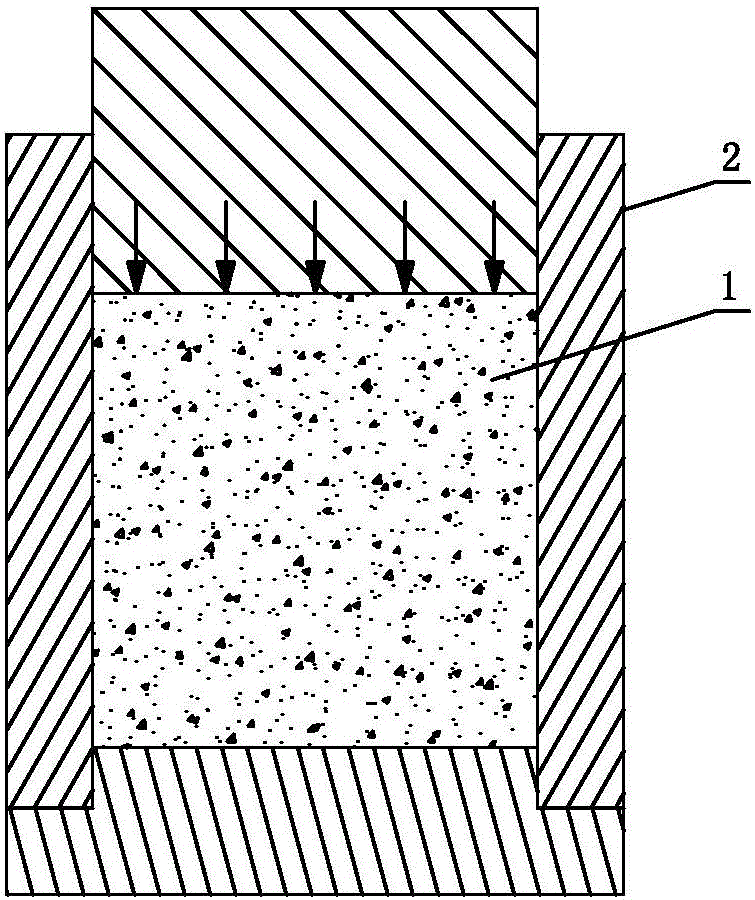

[0058] see Figure 1-Figure 4 , Figure 9 , Figure 10 with Figure 13 (Arrow in the figure is the stressed direction of superhard material product), the manufacture method of this high-density superhard material product, comprises the following steps:

[0059] ①. Prepare the formula raw materials required for the corresponding superhard material products in proportion, then select and process them into the required particle size range, and mix them evenly in the three-dimensional mixer for use;

[0060] 2. Put the uniformly mixed formula raw material 1 into the mold 2, prefabricate the cuboid product body 3A and the cylindrical product body 3B by a hydraulic forming machine, and dry it for use;

[0061] ③. Put the prefabricated product body into a flexible film bag, and then vacuumize the air in the flexible film bag containing the product body and seal it;

[0062]④. Carry out isostatic pressing and secondary pressure setting on the product green body sealed with flexibl...

no. 2 example

[0074] see Figure 5-Figure 8 , Figure 11 , Figure 12 with Figure 13 (Arrows in the figure are the direction of force of the superhard material product), the manufacturing method of this high-density superhard material product is different from the first embodiment in that: the superhard material product is in the shape of a torus, a tube, etc. Shape with lumen structure. In the production process, it is prefabricated into a circular product body 3C and a tubular product body 3D by a hydraulic forming machine. In the isostatic pressing secondary pressure setting treatment, the pressurized medium 4 is a liquid, and the liquid can carry out this process. The inner cavity of the product green body 3 is subjected to isostatic pressure for secondary pressure setting at the same time, so that the density is uniform and the size is accurate.

[0075] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com