Preparation method of large-size zirconia-based heat insulation material

A zirconia-based, heat-insulating material technology, applied in the field of ceramic materials, can solve the problems of unfavorable high porosity maintenance, small drying shrinkage, and high uniformity, and achieve the effects of facilitating preparation, reducing sintering shrinkage, and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

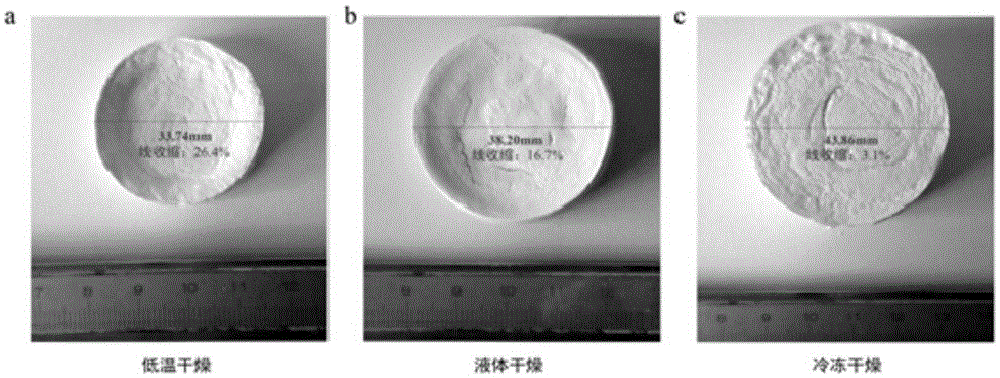

[0053] The screening of embodiment 1 drying method of the present invention

[0054] During the drying and dehydration process of the gel, with the continuous loss of water filled between the raw material particles, voids appear between the raw material particles that were originally uniformly dispersed in the water slurry. In order to reduce the surface energy, the particles fixed in it will approach each other to form a relatively tight accumulation, and the macroscopic performance is that the green body shrinks and deforms. If the drying process is not properly controlled, problems such as curling, deformation, or even cracking and scrapping of the green body will occur, which will have an important impact on the final performance of the ceramic.

[0055] Commonly used drying methods for gel injection molding are low temperature drying and solution displacement drying:

[0056] Low-temperature drying: put the wet billet into a constant temperature and humidity box, and d...

Embodiment 2

[0061] Embodiment 2 The formulation test screening of the thermal insulation material of the present invention

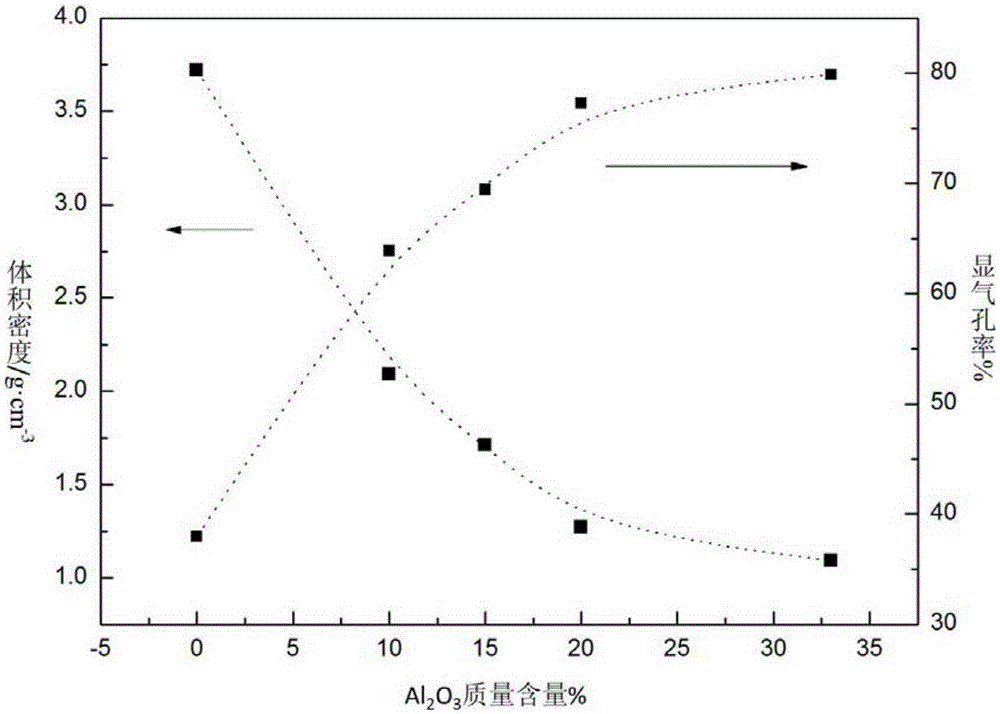

[0062] In order to ensure the thermal insulation performance of the ceramic material, it is required that the thermal insulation material has a relatively high porosity. However, ZrO 2 The sintering of the ceramic green body will produce a large volume shrinkage, which will densify the material, which is not conducive to maintaining the porous structure of the green body, resulting in an increase in the density of porous ceramics. while ZrO 2 and α-Al 2 o 3 No solid solution is formed between them at high temperature, by adding to ZrO 2 Add α-Al to the powder 2 o 3 powder, using α-Al 2 o 3 powder to ZrO 2 sintering hindrance, thereby reducing the ZrO 2 The sintering shrinkage can effectively maintain the porosity of porous ceramics after sintering.

[0063] At 1500°C, to ZrO 2 Add different content of α-Al to the powder 2 o 3 The shrinkage results of...

Embodiment 3

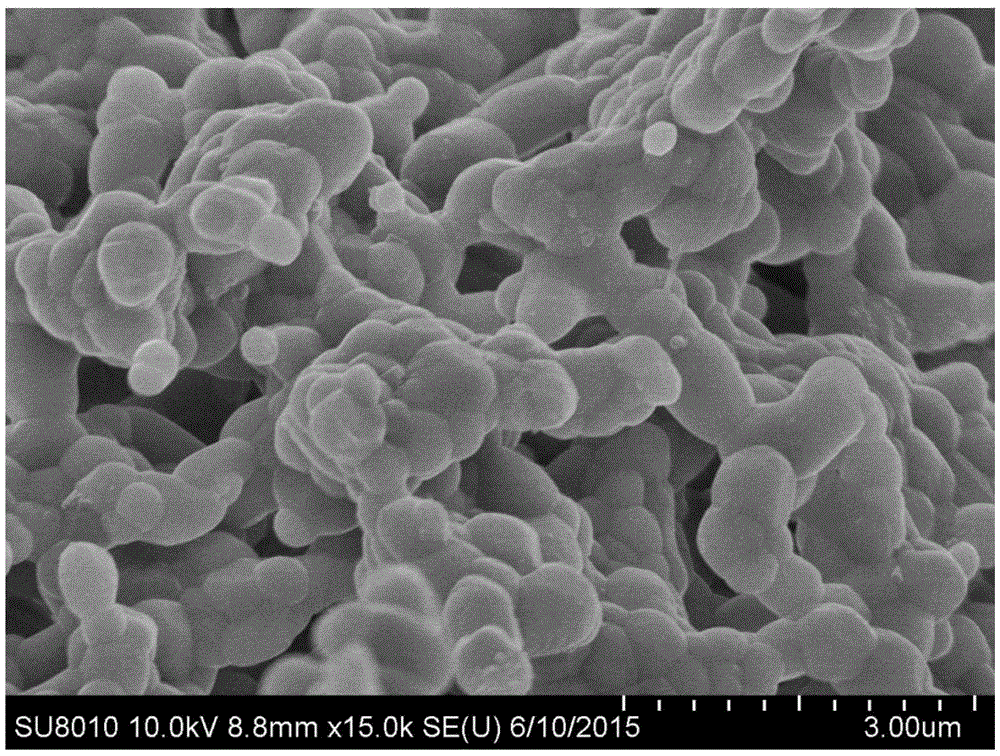

[0069] In this example, the organic monomer is acrylamide, the crosslinking agent is N,N'-methylenebisacrylamide, the dispersant is ammonium polyacrylate, and the catalyst is N',N'-tetramethylethylenediamine. The initiator is ammonium persulfate.

[0070] The preparation process proceeds as follows:

[0071] Mix 279g of deionized water, 27.9g of acrylamide, and 2.7g of N,N'-methylenebisacrylamide and stir until a clear and transparent solution (premix); mix the premix, 86.7g of ZrO 2 Powder, 28.9gα-Al 2 o 3 Put the powder, 3ml of ammonium polyacrylate, and 400g of zirconia ball milling balls into an alumina ball milling tank, and mill for 12 hours;

[0072] Add 13.5g of 20% ammonium persulfate aqueous solution and 1.3g of N,N,N',N'-tetramethylethylenediamine to the obtained slurry, and pour it into a silicone oil-coated polypropylene mold quickly after stirring fully. The size is 135mm×135mm×70mm, and the thickness of the injection mold is 30mm; the mold is placed in a wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com