Silicon oxide-based ceramic core for large-size directional hollow blade of heavy-duty gas turbine and preparation of silicon oxide-based ceramic core

A technology of hollow blades and ceramic cores, applied in cores, casting molding equipment, casting molds, etc., can solve problems such as poor creep resistance, large firing shrinkage, and slow core removal speed, so as to improve high temperature performance, The effect of reducing sintering shrinkage and increasing the rate of core removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

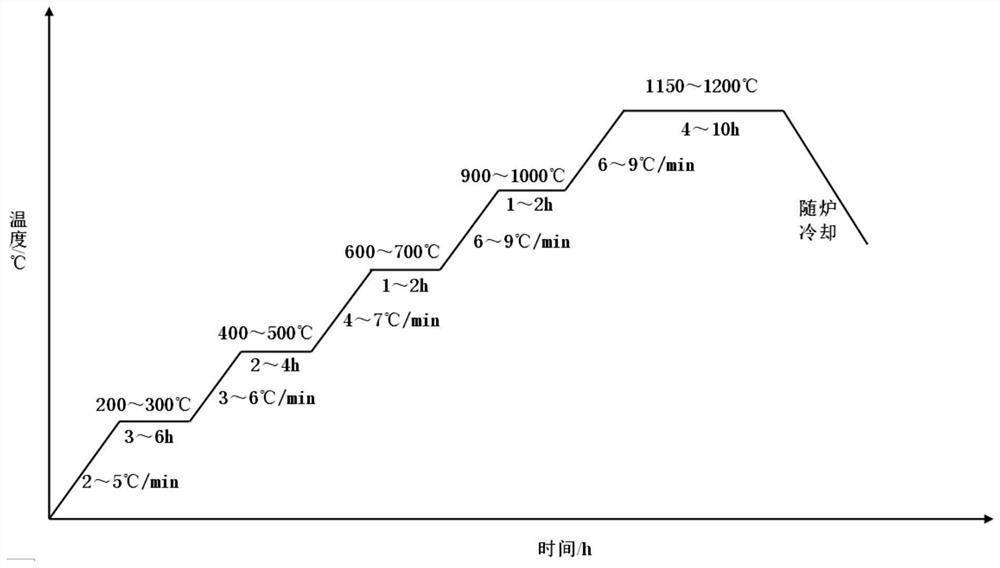

Image

Examples

Embodiment 1

[0034] A method for preparing a silicon oxide-based ceramic core for a large-size directional hollow blade of a heavy-duty gas turbine, comprising the following process steps:

[0035] 1. Weigh the powder: Weigh a certain weight of quartz glass powder (SiO 2 Content is 99.9%), zircon powder, aluminum oxide powder and calcium carbonate powder are put into ball mill jar. In the powder, take by weight percentage 20% 200 mesh quartz glass powder, 20% 400 mesh quartz glass powder, 20% 600 mesh quartz glass powder, 30% zircon powder, 5% alumina powder, 5% % calcium carbonate powder.

[0036] 2. Ball mixing: Add 0.5% of oleic acid by weight of the powder, add alumina ceramic balls and mix according to the ball-to-material ratio of 2:1, and the ball mixing time is 4 hours to obtain the mixed powder.

[0037] 3, mix plasticizer: take by weighing the plasticizer that accounts for 16% of mixed powder weight described in step 2, the composition of plasticizer is 90% paraffin, 5% beeswax...

Embodiment 2

[0044] A method for preparing a silicon oxide-based ceramic core for a large-size directional hollow blade of a heavy-duty gas turbine, comprising the following process steps:

[0045] 1. Weigh the powder: Weigh a certain weight of quartz glass powder (SiO 2 Content is 99.95%), zircon powder, aluminum oxide powder and calcium carbonate powder are put into ball mill jar. In the powder, take by weight percentage 25% of 200 mesh quartz glass powder, 35% of 400 mesh quartz glass powder, 30% of 600 mesh quartz glass powder, 6% of zircon powder, 3% of alumina powder, 1 % calcium carbonate powder.

[0046] 2. Ball mixing: Add 0.2% of oleic acid by weight of the powder, add alumina ceramic balls and mix according to the ball-to-material ratio of 2:1, and the ball mixing time is 6 hours to obtain the mixed powder.

[0047] 3, mix plasticizer: take by weighing the plasticizer that accounts for 18% of mixed powder weight described in step 2, the composition of plasticizer is 93% paraff...

Embodiment 3

[0065] A method for preparing a silicon oxide-based ceramic core for a large-size directional hollow blade of a heavy-duty gas turbine, comprising the following process steps:

[0066] 1. Weigh the powder: Weigh a certain weight of quartz glass powder (SiO 2 Content is 99.99%), zircon powder, aluminum oxide powder and calcium carbonate powder are put into ball mill jar. In the powder, take by weight percentage 30% of 200 mesh quartz glass powder, 40% of 400 mesh quartz glass powder, 25% of 600 mesh quartz glass powder, 4% of zircon powder, 0.5% of alumina powder, 0.5 % calcium carbonate powder.

[0067] 2. Ball mixing: Add 0.1% of oleic acid by weight of the powder, add alumina ceramic balls and mix according to the ball-to-material ratio of 2:1, and the ball mixing time is 10 hours to obtain the mixed powder.

[0068] 3, mix plasticizer: take by weighing the plasticizer that accounts for 20% of mixed powder weight described in step 2, plasticizer is composed of 94.5% paraff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com