Fabric structure and manufacturing method thereof

A production method and fabric technology, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve problems such as comfort that cannot be compared with direct contact with fabrics, and cannot achieve cooling effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

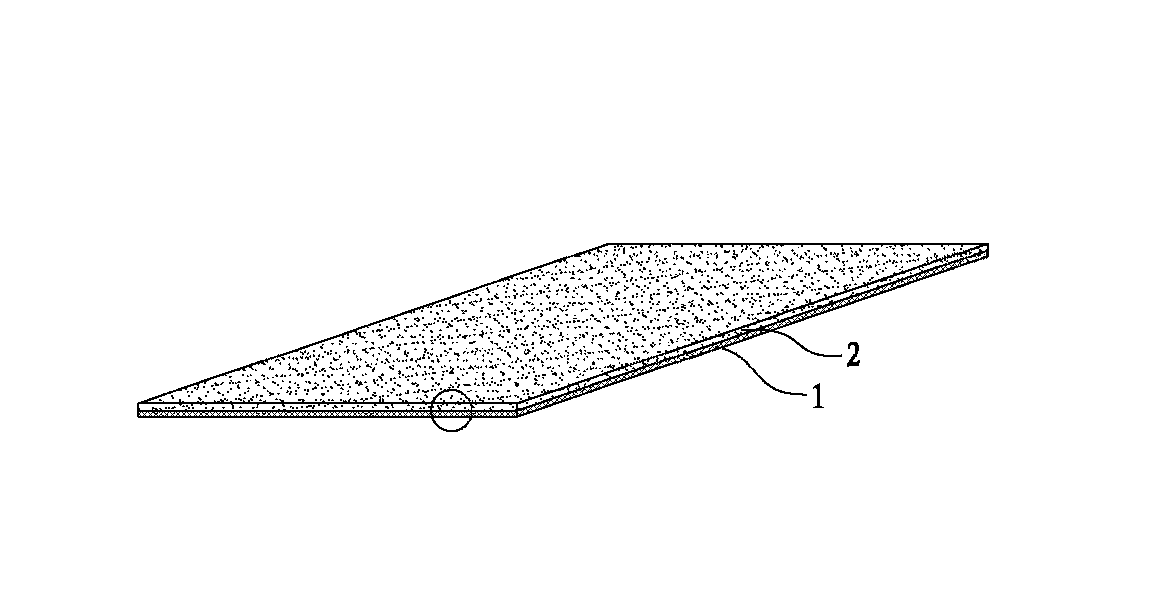

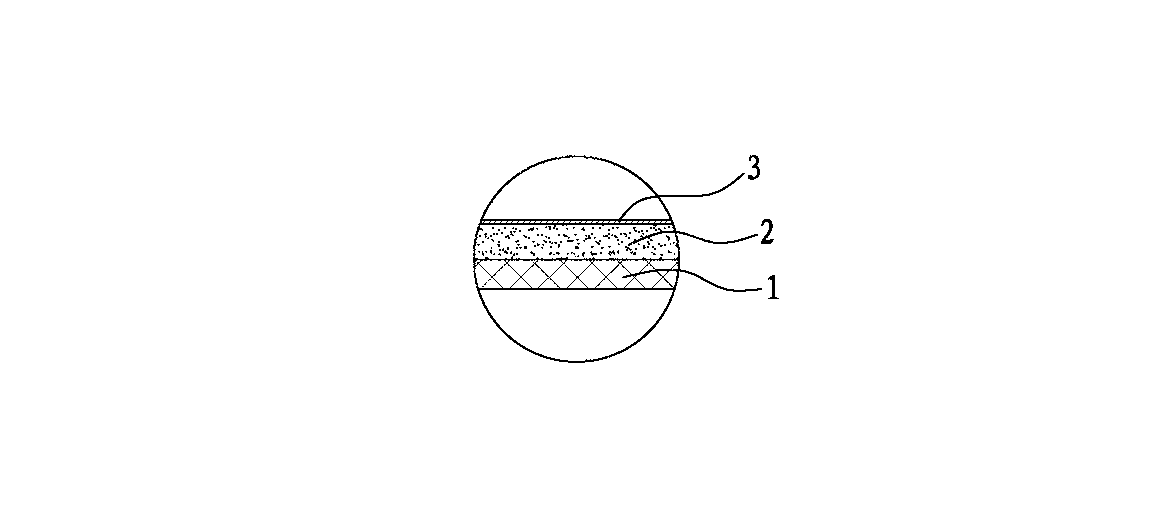

[0022] like Figure 1 to Figure 3 As shown, the present invention discloses a cloth structure and a manufacturing method thereof, the specific steps of which are:

[0023] Step 1, forming the cloth layer 1;

[0024] Step 2, composite a gel (GEL) layer 2 on one surface of the cloth layer 1; the gel layer 2 can be bonded to the surface of the cloth layer 1 by spraying, roller coating or scraper coating;

[0025] Step 3, compound a layer of protective layer 3 on the gel layer 2 after step 2, this protective layer 3 can adopt film, chemical coating or cloth layer, and chemical coating is PU (polyurethane) , PVE (polyvinyl ether) or EVA (ethylene vinyl acetate), etc.; and the cloth layer can be woven or non-woven, and its function is to make the surface of the gel solidify.

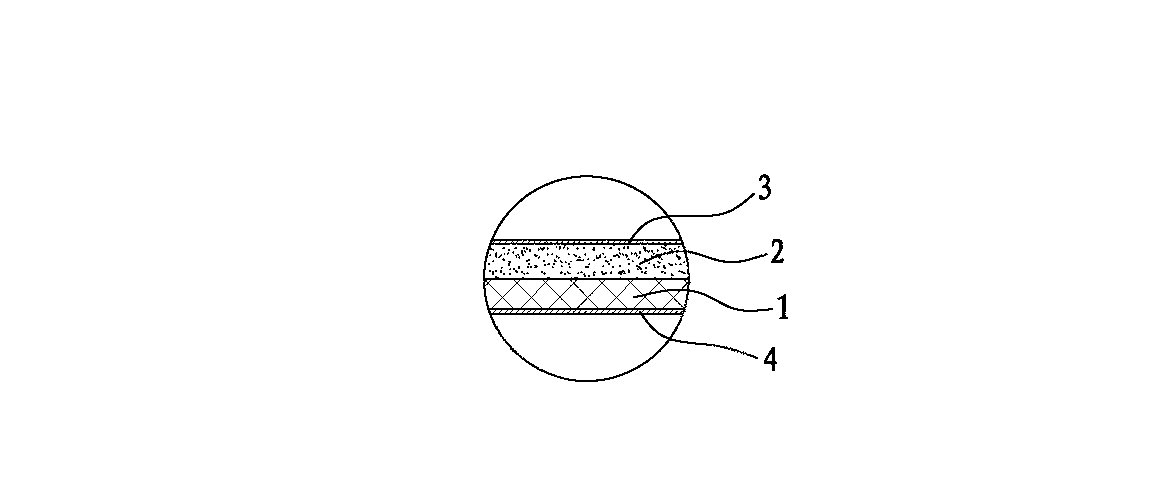

[0026] like image 3 As shown, for a thinner cloth layer 1, in order to prevent gel leakage, a layer of film 4 is compounded on the other side of the cloth layer 1 that is not compounded with the gel layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com