A kind of mixing type polyurethane foam material and preparation method thereof

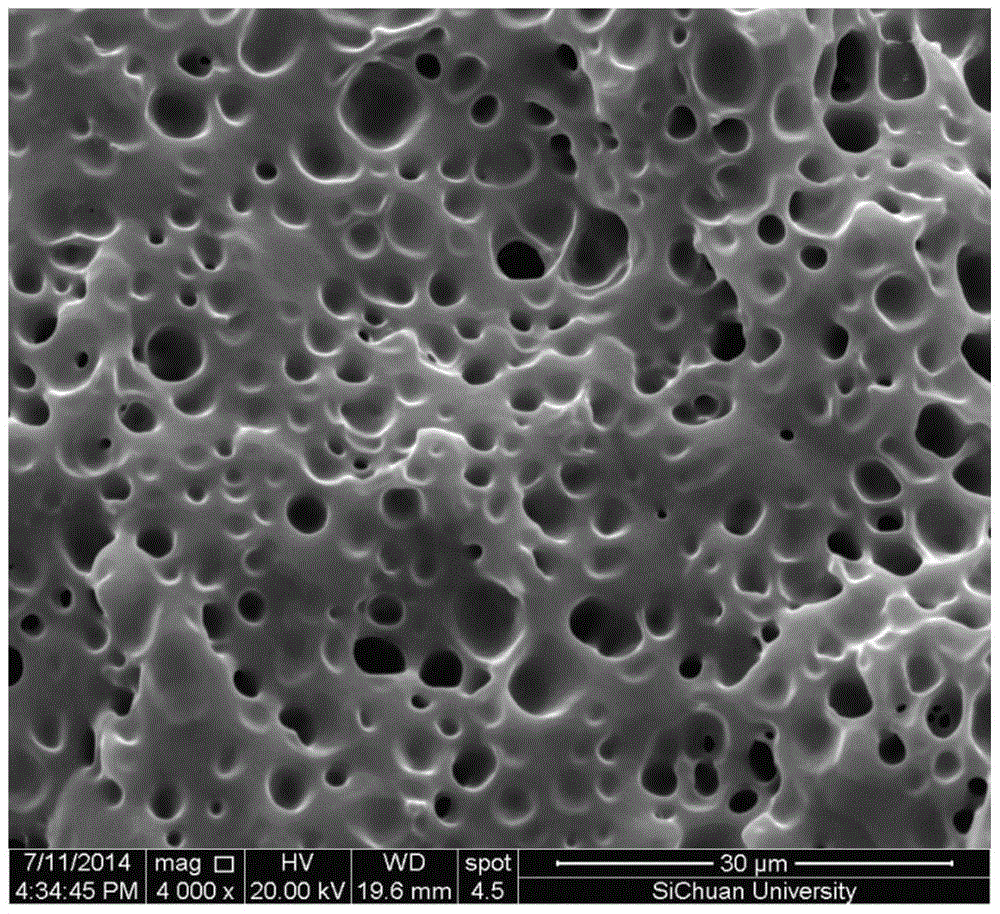

A technology of mixing polyurethane and foam materials, which is applied in the field of polyurethane foam materials. It can solve the problems of difficult control of cell size, uneven distribution of cells, burning and yellowing of polyurethane foam materials, etc., and achieves excellent impact resistance, size The effect of narrow distribution range and uniform cell distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the present embodiment, the preparation method of mixing type polyurethane foam material is as follows:

[0029] (1) Pre-vulcanization of mixing polyurethane

[0030] Mix 3.2 g of vulcanizing agent dicumyl peroxide and 4.8 g of basic filler nano-silica to obtain a mixture, add 100 g of polyether polyurethane raw rubber into an internal mixer, and masticate at 80 ° C for 1 min. Soften the raw ether-type polyurethane rubber, then add the mixture into the internal mixer, knead at 80°C for 5 minutes, mix the above three materials evenly to obtain a kneaded product, and carry out the kneaded product in the open mixer in different temperature sections Pre-vulcanization, the specific operation is: vulcanize the kneaded material at 115°C for 15 minutes, then raise the temperature of the mill to 125°C and vulcanize at this temperature for 5 minutes to obtain a sheet-shaped pre-sulfide with a thickness of 2mm.

[0031] (2) Foaming

[0032] After the presulfide obtained in st...

Embodiment 2

[0037] In the present embodiment, the preparation method of mixing type polyurethane foam material is as follows:

[0038] (1) Pre-vulcanization of mixing polyurethane

[0039]Mix 1.6 g of vulcanizing agent dicumyl peroxide and 2.4 g of basic filler nano-silica uniformly to obtain a mixture, add 100 g of polyether polyurethane raw rubber into an internal mixer, and masticate at 100 ° C for 1 min. Soften the ether type polyurethane raw rubber, then add the mixture into the internal mixer, knead at 100°C for 5 minutes, mix the above three materials evenly to obtain a kneaded product, and carry out the kneaded product in the open mixer for temperature division Pre-vulcanization, the specific operation is: vulcanize the kneaded material at 120°C for 5 minutes, then increase the temperature of the mill to 135°C and vulcanize at this temperature for 3 minutes to obtain a sheet-shaped pre-sulfide compound with a thickness of about 2mm.

[0040] (2) Foaming

[0041] After the presul...

Embodiment 3

[0045] In the present embodiment, the preparation method of mixing type polyurethane foam material is as follows:

[0046] (1) Pre-vulcanization of mixing polyurethane

[0047] Mix 3.2 g of vulcanizing agent cumyl tert-butyl peroxide and 4.8 g of basic filler nano-calcium carbonate to obtain a mixture, add 100 g of polyether polyurethane raw rubber into an internal mixer, and masticate at 90 ° C for 1 min. The polyether polyurethane raw rubber is softened, and then the mixture is added to the internal mixer, and mixed at 90°C for 5 minutes. The above three materials are mixed uniformly to obtain a kneaded product, and the kneaded product is carried out in an open mixer. Pre-vulcanization by temperature section, the specific operation is: vulcanize the kneaded material at 115°C for 30 minutes, then increase the temperature of the mill to 125°C and vulcanize at this temperature for 15 minutes to obtain a sheet-shaped pre-vulcanized compound with a thickness of 4mm.

[0048] (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com