Architectural ceramic prepared from industrial solid waste through dry method and process for preparing architectural ceramic

A technology for building ceramics and solid waste residues, which is applied in the production, application, and clay products of ceramic materials, etc., can solve the problems of poor product function, low efficiency, and difficult control of the production process, so as to reduce the cost of slurry degumming and reduce Firing shrinkage, the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

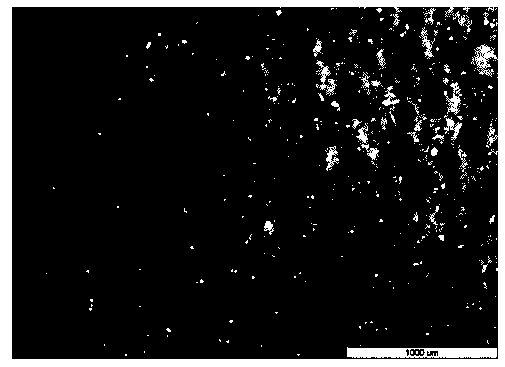

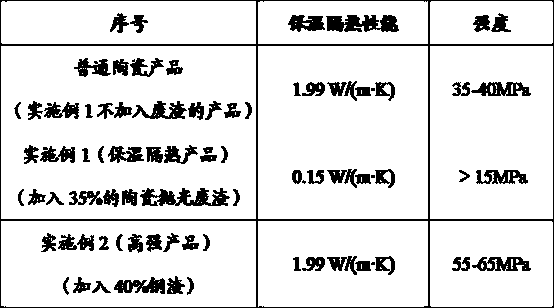

[0051] In terms of mass percentage, 35% of ceramic polishing waste is pretreated, dried and passed through a 100-mesh sieve. Mix 63% ceramic raw materials and 3% hydroxymethyl cellulose together, and wet ball mill until the slurry particle size is 250 mesh sieve and 0.8~1.2%; the composition of ceramic raw materials is 20% kaolin, 10% Yili Stone, 5% bentonite, 5% talc, 60% potassium albite feldspar. The ball-milled slurry is sieved to remove iron; the slurry is spray-dried. The spray-dried powder and ceramic polishing waste enter the mixer for dry mixing, and pass through a 20-mesh sieve after mixing. The sieved powder is conveyed to the press for molding, the pressed bricks enter the drying kiln for drying, and the dried bricks enter the roller kiln for firing at 1200 °C. The bulk density of the fired product is less than 900kg / m 3 , the compressive strength is greater than 15MPa, it has the function of light heat preservation and heat insulation, the thermal conductivity ...

Embodiment 2

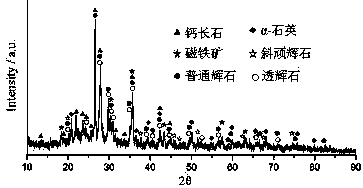

[0053] In terms of mass percentage, 40% steel slag is pretreated and passed through a 100-mesh sieve after drying. Mix 59% ceramic raw materials and 1% sodium silicate together, and wet ball mill until the slurry particle size is 250 mesh sieve and 0.8~1.2%; the composition of ceramic raw materials is 22% Bailaiyang soil, 14% red Laiyang soil, 13% high density soil, 16% Mengyin feldspar, 28% Laiwu feldspar and 7% talc. The ball-milled slurry is sieved to remove iron; the slurry is spray-dried. The spray-dried powder and ceramic polishing waste are sent to a powder mill for dry mixing, and then passed through a 20-mesh sieve after mixing. The sieved powder is conveyed to the press for molding, the pressed bricks enter the drying kiln for drying, and the dried bricks enter the roller kiln for firing at 1185 °C. The main crystal phase of the fired product is quartz, anorthite and diopside. The product has high strength and wear resistance, and the flexural strength can reach 55...

Embodiment 3

[0055] In terms of mass percentage, 20% of ceramic polishing waste slag, 20% of steel slag, and 10% of aluminum slag are pretreated, and passed through a 100-mesh sieve after drying. Mix 48% of ceramic raw materials and 2% gum arabic together, and wet ball mill until the slurry particle size is 0.8~1.2% of the 250 mesh sieve; wherein the ceramic raw materials are composed of 18% pyrophyllite, 20 % kaolin, 43% potassium feldspar, 4% nepheline, 10% Guangdong white clay, 5% talc. The ball-milled slurry is sieved to remove iron; the slurry is spray-dried. The spray-dried powder is dry-mixed with ceramic polishing waste slag and steel slag, and is pulverized and mixed by a pulverizer, and passed through a 20-mesh sieve after mixing. The sieved powder is conveyed to the press for molding, the pressed bricks enter the drying kiln for drying, and the dried bricks enter the roller kiln for firing at 1220 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com