Method for forming a film of sensing material in a deep trench

A technology for inductive materials and deep grooves, applied in metal material coating technology, technology for producing decorative surface effects, decorative art, etc., can solve the problem that the semiconductor process steps cannot be carried out, the photoresist cannot be removed cleanly, and the cost is relatively high. Long time and other problems, to achieve the effect of reducing reflectivity, reducing damage to devices, and reducing optical impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the accompanying drawings, the present invention is described in detail as follows:

[0038] The method for forming an inductive material film in a deep groove of the present invention has a specific process flow as follows:

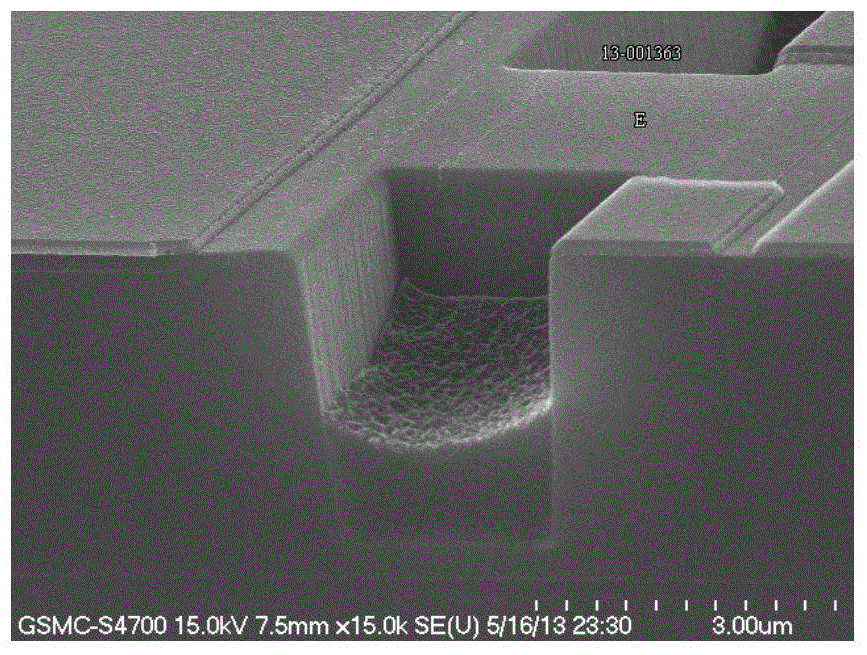

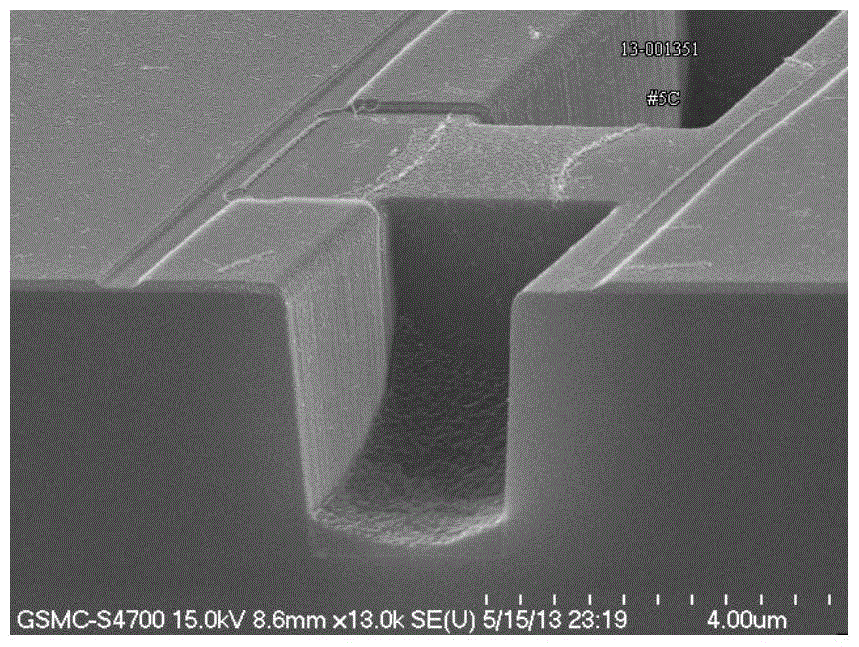

[0039] Step 1, grow a layer of hard mask 102 on the silicon substrate 101, such as image 3 shown. The material of the hard mask 102 may be silicon oxide or silicon nitride.

[0040] Step 2, coating a layer of photoresist 103, and forming a deep trench photolithographic window, such as Figure 4 shown.

[0041] The photoresist 103 can be positive or negative, and the photoresist used in this embodiment is TOK P6159. A typical baking temperature is 90°C for 60 seconds. The lithography machine can use any type of lithography machine, and the typical lithography machine is Nikon I-14.

[0042] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com