Refractory brick and preparation method thereof

A technology of refractory bricks and bauxite, which is applied in the field of refractory materials, can solve problems such as rotation, loose refractory bricks, unplanned maintenance of rotary kilns, etc., and achieve the effect of small sintering shrinkage and good refractory performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

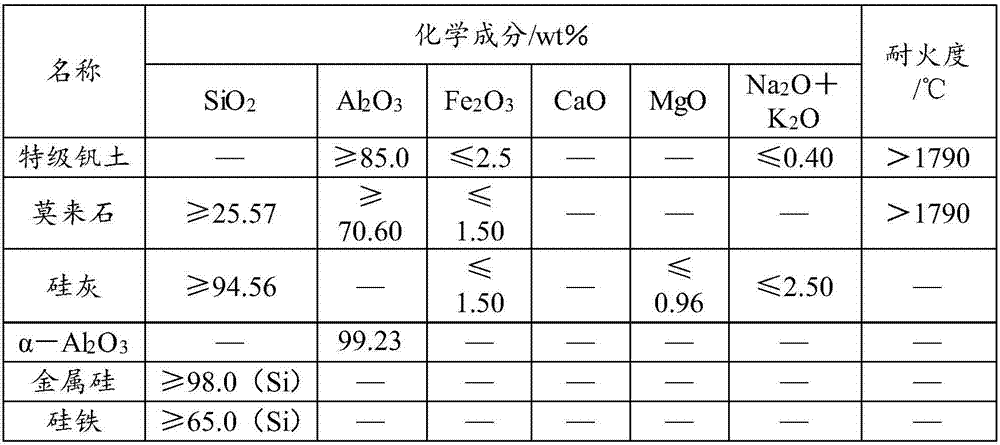

[0030] The present invention provides a kind of preparation method of the refractory brick described in the above technical solution, comprising:

[0031] Alumina, mullite, silica powder, metal silicon, ferrosilicon, Al 2 o 3 , sodium phosphate and water are mixed to obtain a mixture;

[0032] The mixture is made into bricks and then dried to obtain refractory bricks.

[0033] In the present invention, the alumina, mullite, silicon micropowder, metal silicon, ferrosilicon, Al 2 o 3 , sodium phosphate and their consumption are consistent with the above-mentioned technical scheme, no longer repeat them here.

[0034] In the present invention, the preparation method of the mixture is preferably:

[0035] Mullite, silica powder, metal silicon, ferrosilicon, Al 2 o 3 mixed with sodium phosphate to obtain a mixture;

[0036] Alumina is mixed with water to obtain aggregate;

[0037] The mixture is mixed with aggregate to obtain a mixture.

[0038] In the present invention, ...

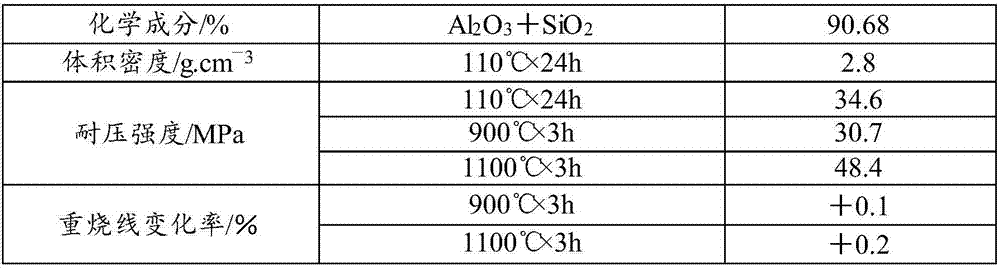

Embodiment 1

[0045] The raw material composition and dosage of refractory bricks are: bauxite 6-2mm 30wt%, bauxite 2-0mm 35wt%, bauxite particle size ≤ 200 mesh (indicating that it can pass through the 200 mesh mesh, that is, the particle size is less than 74 microns) fine powder 15wt %; Mullite ≤ 200 mesh (indicating that it can pass through the 200 mesh mesh, that is, the particle size is less than 74 microns) fine powder 5wt%, silica fume 1wt%, ferrosilicon powder 5wt%, α-Al 2 o 3 Micropowder 6wt%, metal silicon 1wt%, sodium hexametaphosphate 2wt%, the total amount of the above raw materials is 100%.

[0046] Mullite, silica fume, ferrosilicon powder, α-Al 2 o 3 Micropowder, metal silicon and sodium hexametaphosphate are put into the pre-mixer and mixed for 10-15 minutes, and the mixed powder is discharged for use, and then the super-grade bauxite granular aggregate is poured into the mud mill in proportion, and mixed for 2-3 minutes. Minutes later, add bauxite mass of 3-4wt% water t...

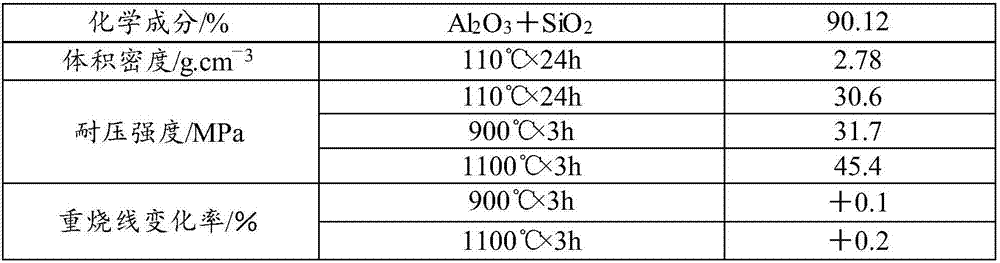

Embodiment 2

[0051] The raw material composition and dosage of refractory bricks are: bauxite 6-2mm 30wt%, bauxite 2-0mm 35wt%, bauxite particle size ≤ 200 mesh (indicating that it can pass through the 200 mesh mesh, that is, the particle size is less than 74 microns) fine powder 10wt %; 10wt% of fine powder of mullite≤200 mesh (indicating that it can pass through the 200 mesh, that is, the particle size is less than 74 microns), 1wt% of silica fume, 5wt% of ferrosilicon powder, α-Al 2 o 3 Micropowder 6wt%, metal silicon 1wt%, sodium tripolyphosphate 2wt%, the total amount of the above raw materials is 100%.

[0052] Mullite, silica fume, ferrosilicon powder, α-Al 2 o 3 Micropowder, metal silicon and sodium tripolyphosphate are put into the pre-mixer in proportion and mixed for 10-15 minutes, and then the mixed powder is discharged for use, and then the super-grade bauxite granular aggregate is poured into the mud mill in proportion, and mixed for 2-3 minutes. Minutes later, add bauxite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com