A low sintering temperature power type piezoelectric ceramic material and its preparation method

A technology of low sintering temperature and piezoelectric ceramics, applied in the field of piezoelectric ceramics, can solve the problems of deteriorating electrical properties of piezoelectric materials and lowering insulation resistivity, and achieve the effects of low cost, reduced sintering shrinkage, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

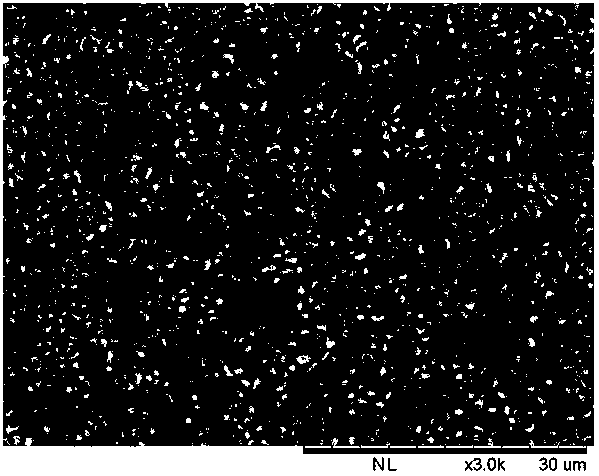

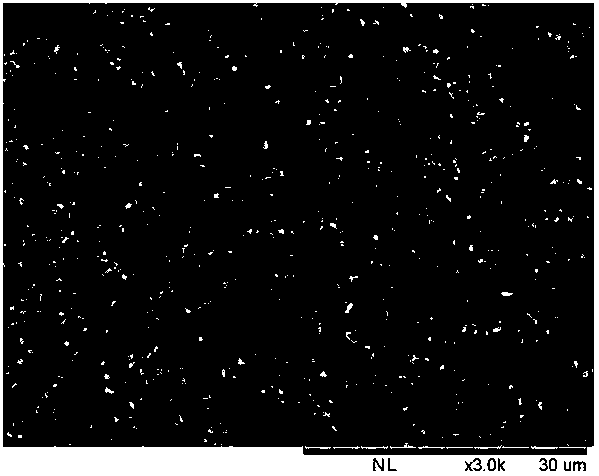

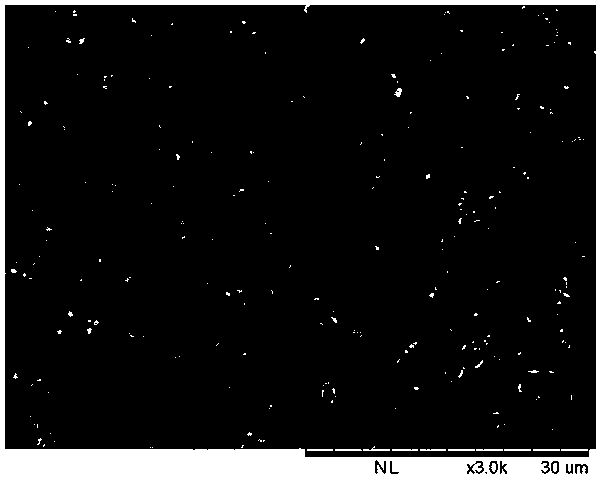

Image

Examples

preparation example Construction

[0050] 2. In the preparation method of the present invention, the method of spray granulation is adopted to improve the fluidity of the powder, increase the molding density, and reduce the sintering shrinkage. Adding CuO as a sintering aid after spray granulation can play a better role in the sintering aid;

[0051] 3. The preparation method of the present invention has the advantages of simple process, no need for special equipment, low cost, etc., is suitable for large-scale production, and meets the requirements of industrial production.

Embodiment 1

[0054] Pb 0.93 Sr 0.02 Ba 0.05 (Ni 1 / 2 W 1 / 2 ) 0.01 (Mn 1 / 3 Sb 2 / 3 ) 0.02 (Zr 0.527 Ti 0.473 ) 0.97 o 3 +0.01wt% Fe 2 o 3 +0.07wt%Sm 2 o 3 +0.1wt%MnO 2 +0.1wt% CuO piezoelectric ceramic material

[0055] Weigh out the stoichiometric ratio of Pb 3 o 4 , ZrO 2 、TiO 2 , SrCO 3 、BaCO 3 , MnCO 3 、Sm 2 o 3 , Sb 2 o 3 , Fe 2 o 3 , NiO, WO 3 For the raw material powder, use wet ball milling process to mix all the powders evenly; the ball milling conditions are: ball milling material, agate balls and deionized water are mixed at a mass ratio of 1:1.2:1.0, and ball milled for 24 hours. The obtained mixed powder is compacted and synthesized under atmospheric atmosphere. The synthesis temperature is 850°C and the synthesis time is 2 hours. Ionized water was mixed at a mass ratio of 1:1.2:1.0, and ball milled for 48 hours. Dry the finely ground powder, add polyvinyl alcohol (PVA) aqueous solution with a mass fraction of 7% of the powder mass and 5% as a bind...

Embodiment 2

[0057] Pb 0.93 Sr 0.02 Ba 0.05 (Ni 1 / 2 W 1 / 2 ) 0.01 (Mn 1 / 3 Sb 2 / 3 ) 0.02 (Zr 0.527 Ti 0.473 ) 0.97 o 3 +0.01wt% Fe 2 o 3 +0.07wt%Sm 2 o 3 +0.1wt%MnO 2 +0.2wt% CuO piezoelectric ceramic material

[0058] The only difference between this embodiment and embodiment 1 is: the mass of CuO powder added is 0.2wt% powder;

[0059] The rest of the content of this embodiment is the same as that described in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com