Patents

Literature

96results about How to "High mechanical quality factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

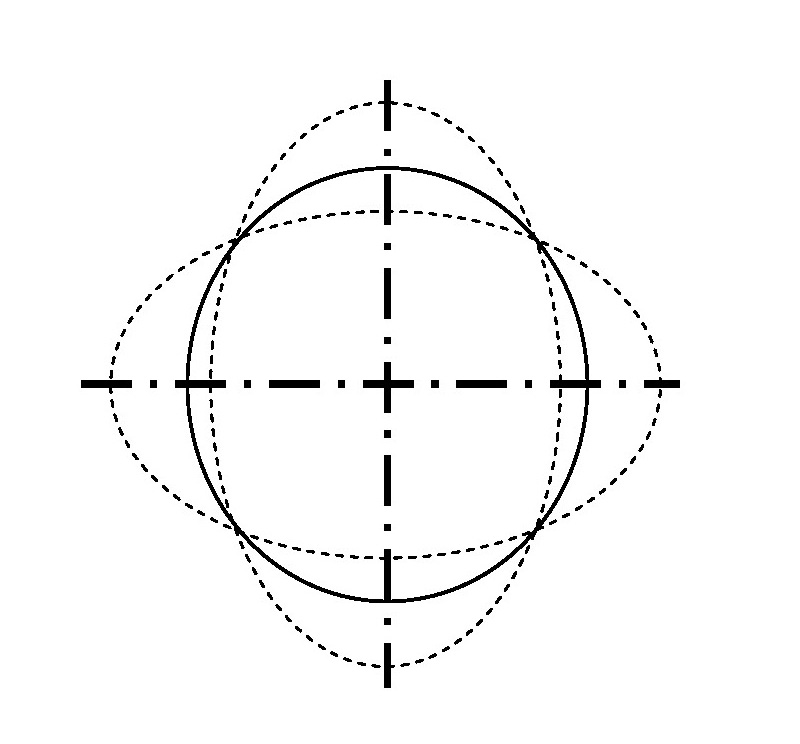

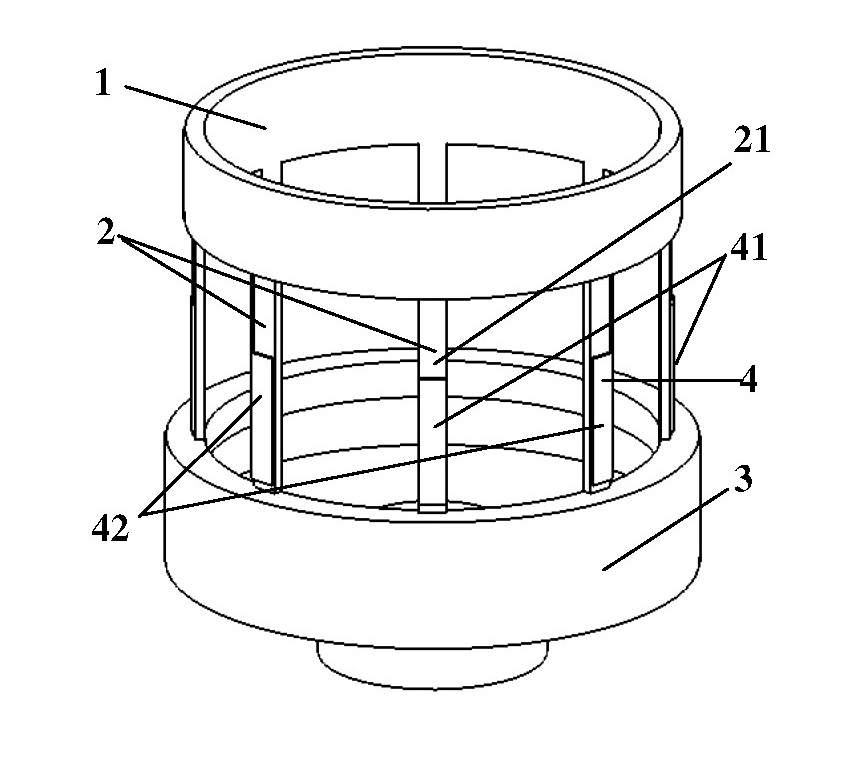

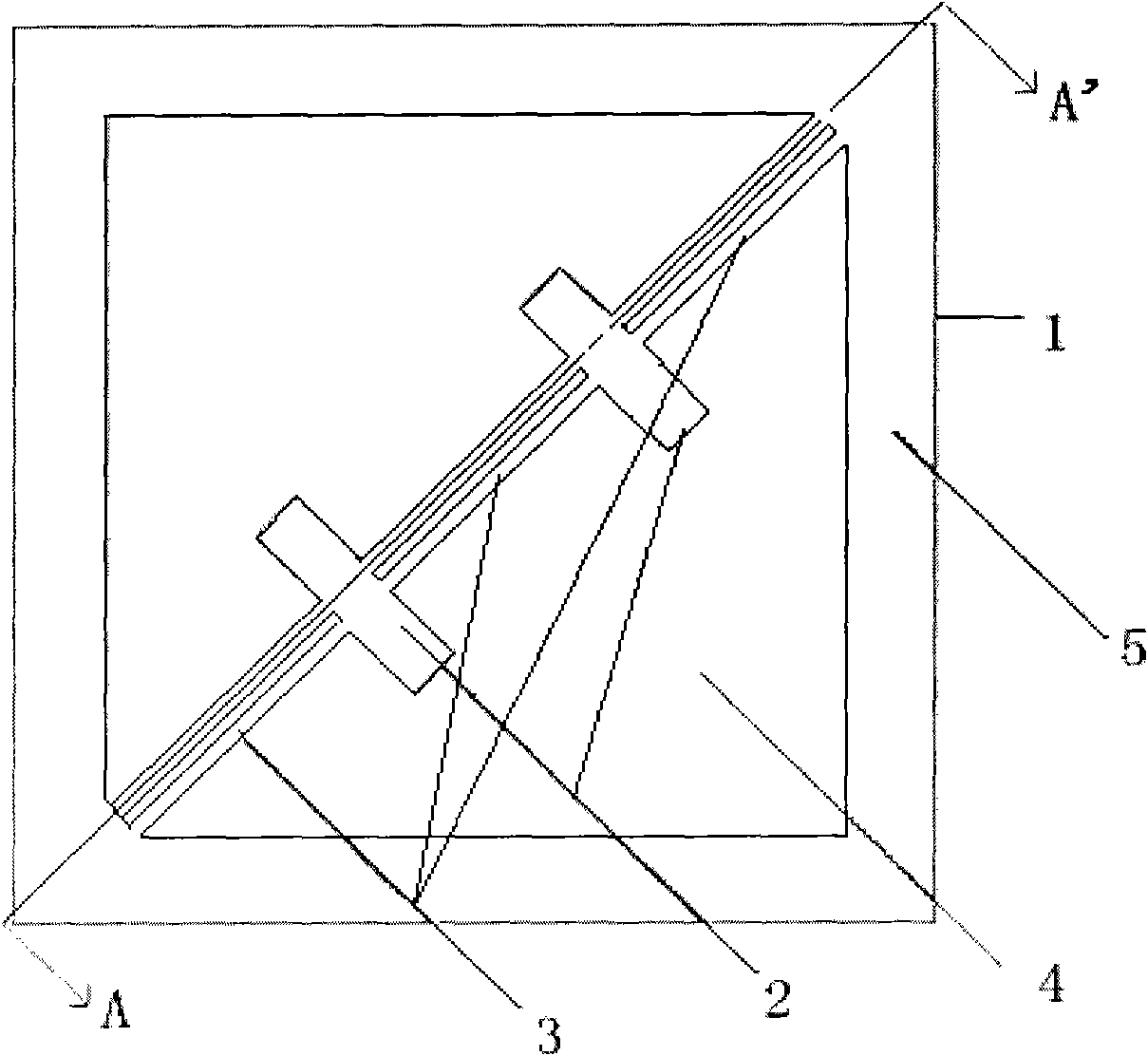

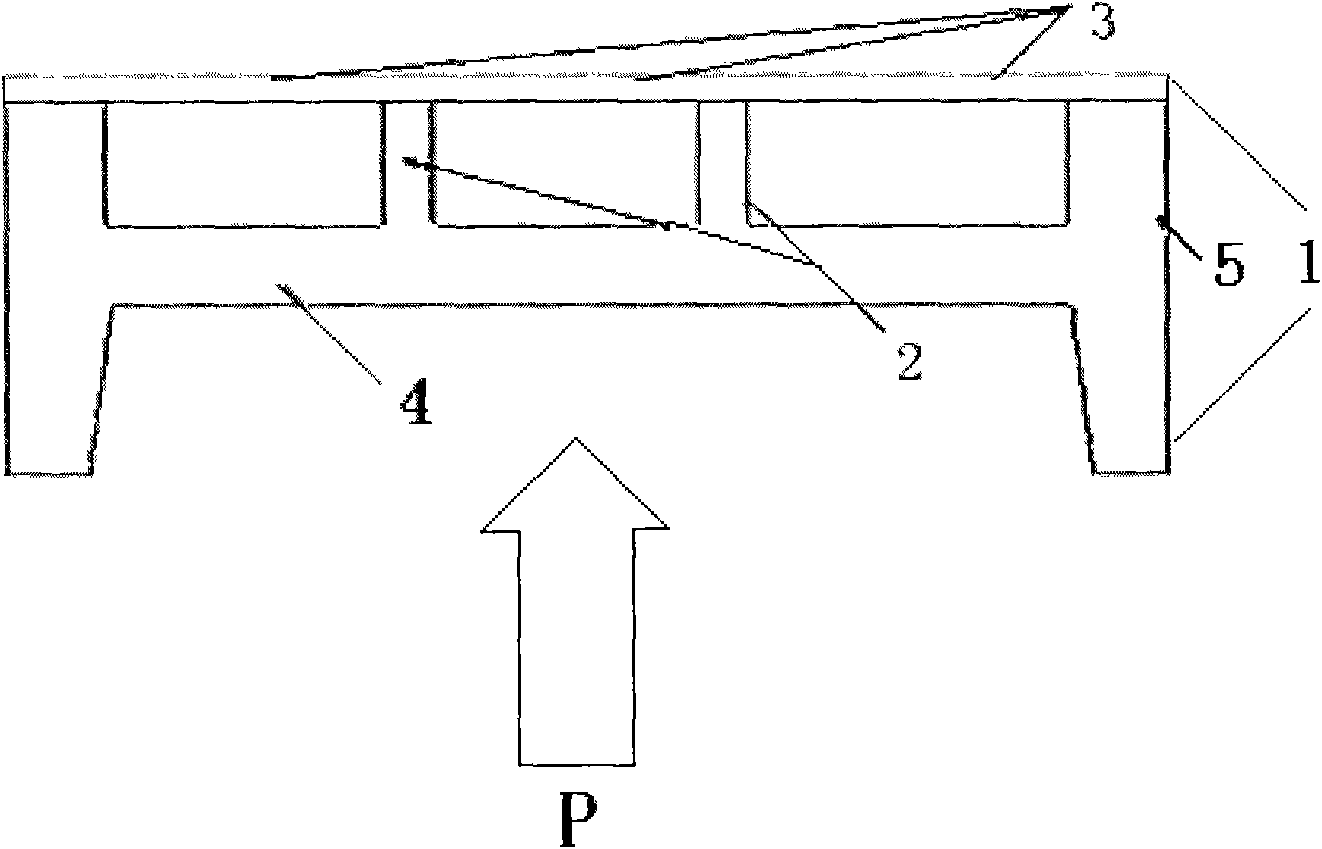

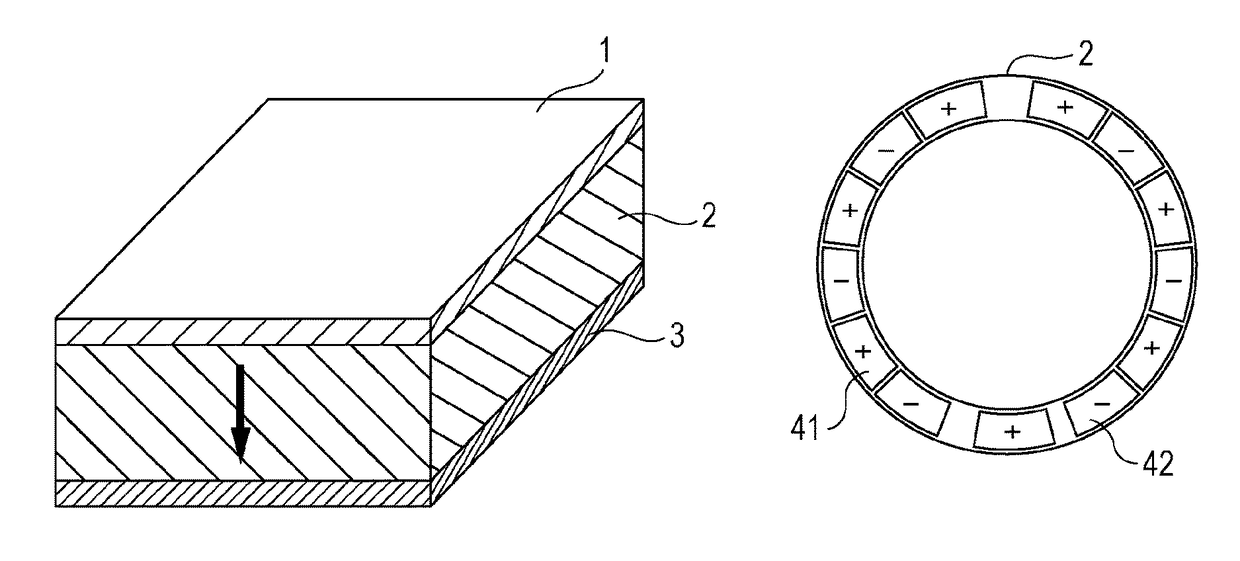

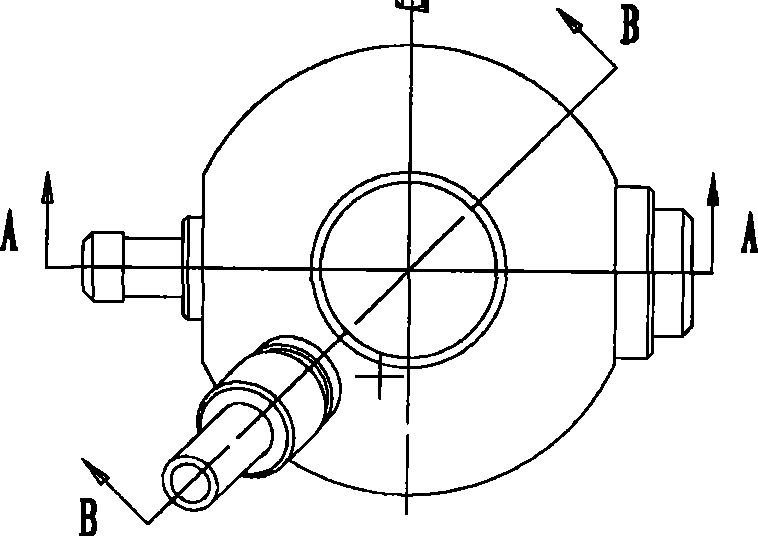

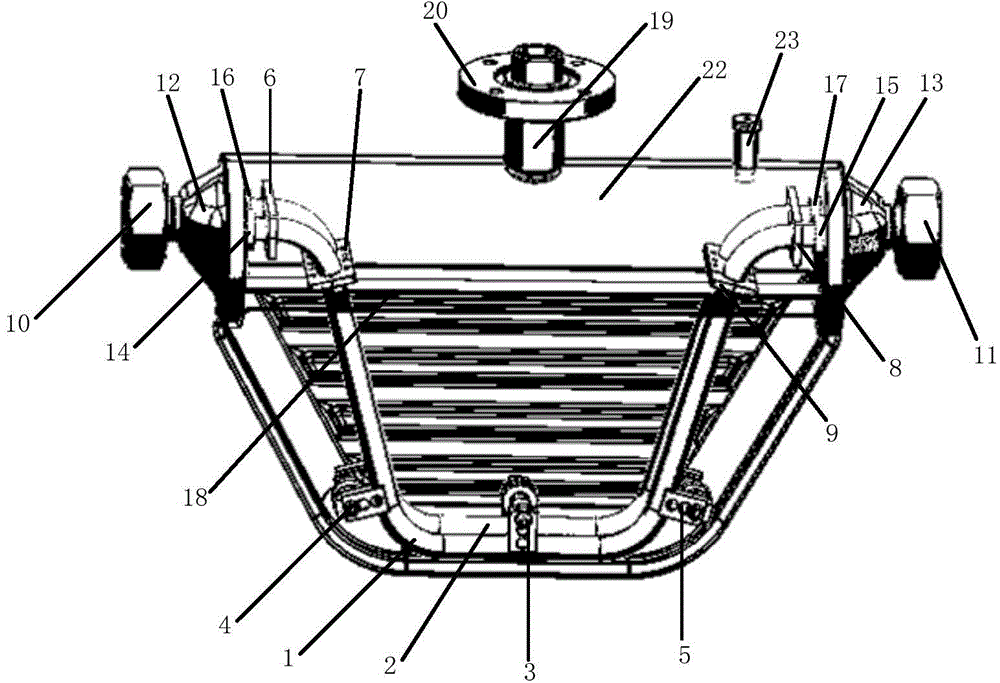

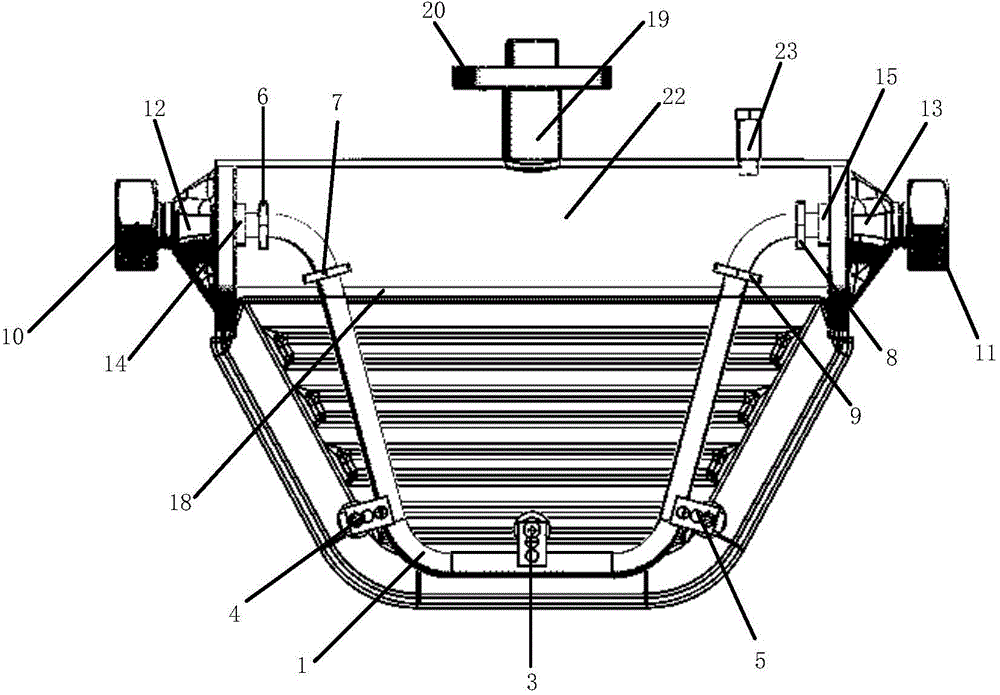

Harmonic oscillator of solid fluctuation gyro and solid fluctuation gyro

ActiveCN101936734ALean structureReduce air dampingSpeed measurement using gyroscopic effectsTurn-sensitive devicesElectricityResonance

The invention discloses a harmonic oscillator of a solid fluctuation gyro, which comprises a resonance ring (1), a resonance transmission part (2), a chassis (3) and a piezoelectric element (4), wherein, the resonance ring (1) is connected with the chassis (3) through the resonance transmission part (2), the resonance transmission part (2) is composed of support beams (21) which are uniformly distributed in the circumferential direction, and the piezoelectric element (4) is arranged on the support beams (21). The invention further discloses the solid fluctuation gyro provided with the harmonic oscillator. The solid fluctuation gyro and the harmonic oscillator of the invention have the advantages of high sensitivity, good sensing effect, convenient machining, low machining cost, simple mechanical balance procedure and the like.

Owner:NAT UNIV OF DEFENSE TECH

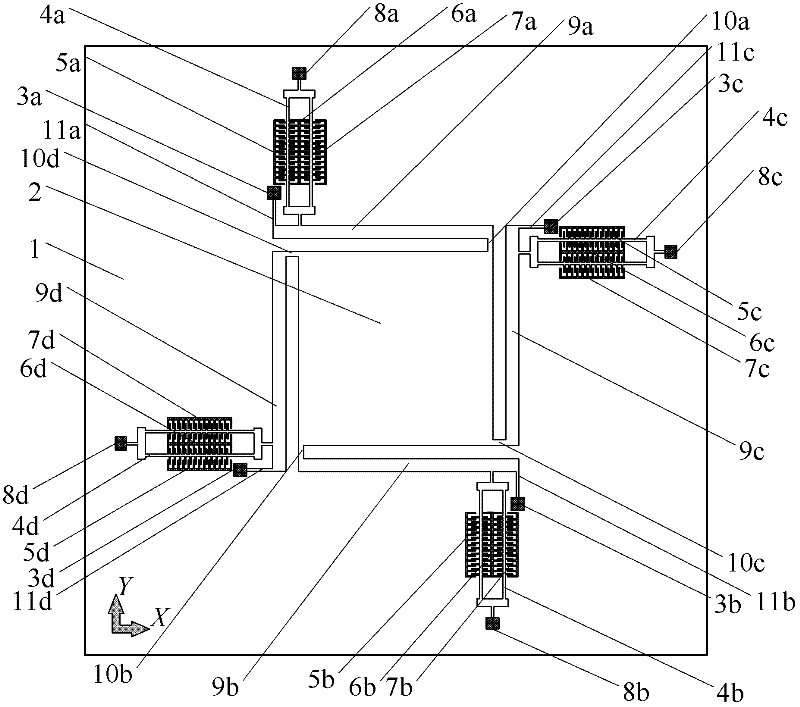

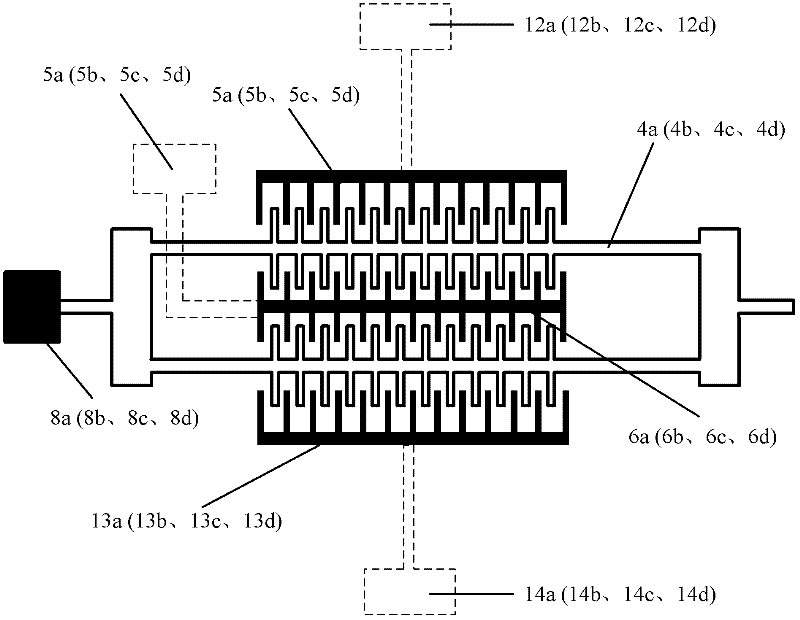

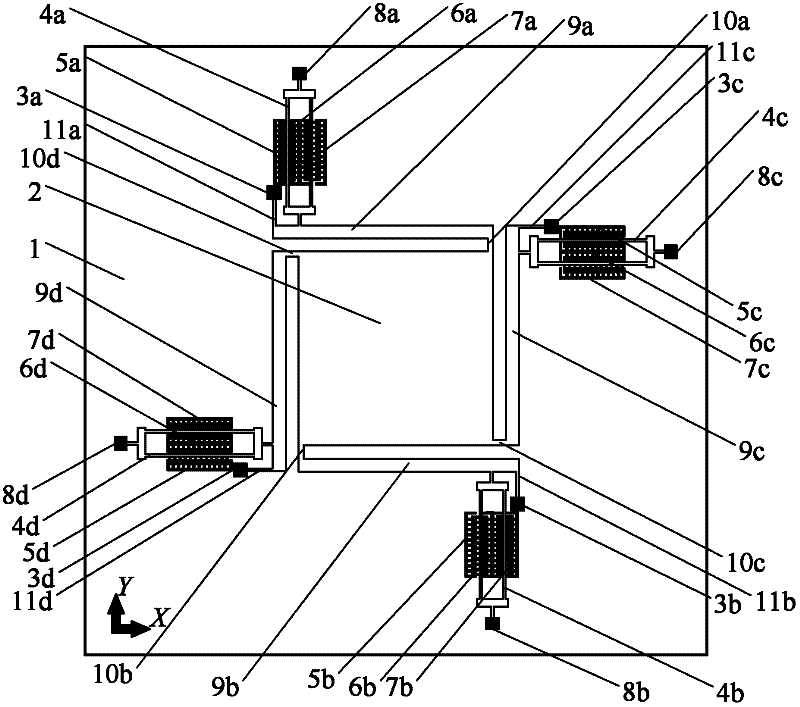

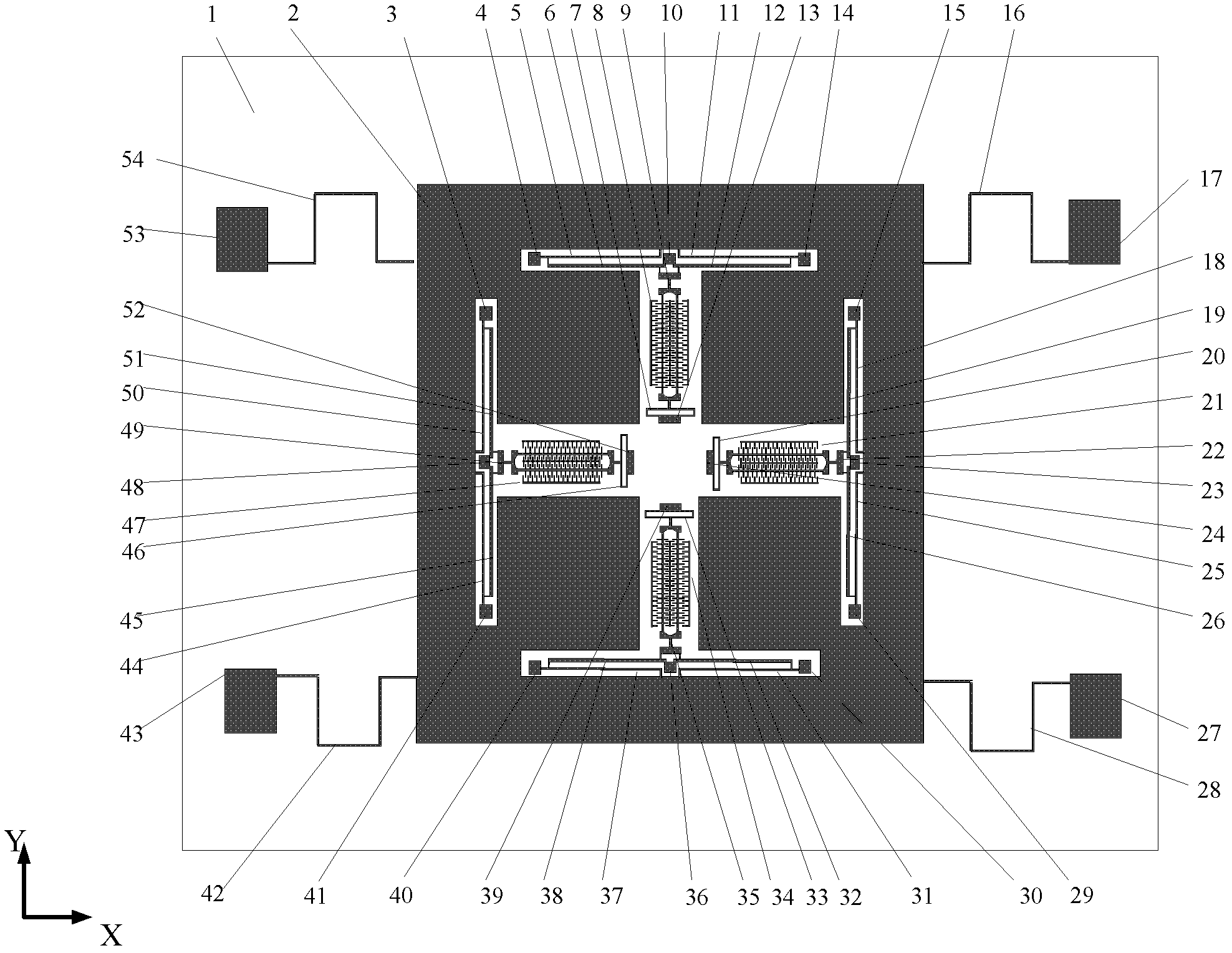

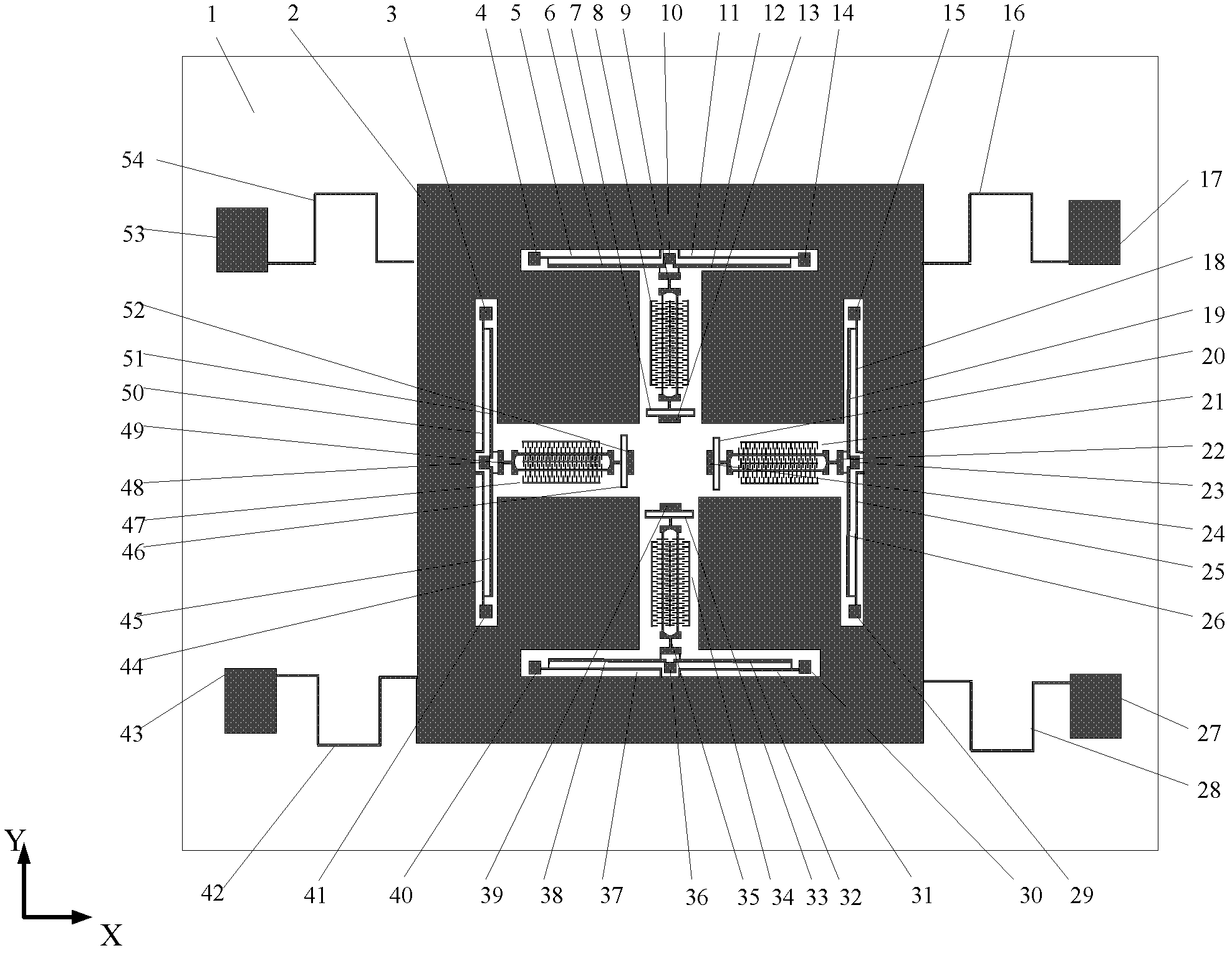

High-sensitivity dual-axis silicon-micro resonance accelerometer

InactiveCN102495236AHigh sensitivityHigh resolutionAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceAccelerometer

The invention relates to a high-sensitivity dual-axis silicon-micro resonance accelerometer which consists of an upper mechanical part and a lower part, wherein the upper mechanical part comprises a mass block, a micro lever amplification mechanism, tuning fork resonators, an electrostatic comb actuator and a comb tooth capacitor detector; the lower part comprises a signal wire and an electrode; the upper part in the structure of the accelerometer is made on a monocrystalline silicon wafer; the lower part is made on a glass substrate; in an upper mechanical mechanism, one square mass block is adopted to sense accelerated speeds in two orthogonal directions; one ends of four resonators with the same structural parameters are fixed on a substrate through anchor points and the other ends of the resonators are connected with the mass block through a micro lever mechanism; four primary micro levers which are totally same are respectively connected at four vertex angles of the mass block; and the upper mechanical mechanism is suspended above the lower glass substrate through the anchor points at one ends of the resonators and anchor points of a fulcrum of the micro lever mechanism. The high-sensitivity dual-axis silicon-micro resonance accelerometer has the advantages of high sensitivity, strong decoupling capability, large range, high stability, small volume, simple structure and the like and is suitable for the fields of the automobile industry, the aerospace, seismic monitoring and the like.

Owner:BEIHANG UNIV

Micromachine-based electromagnetic excitation resonant pressure sensor

InactiveCN102374909AAvoid introducingAvoid bonding processForce measurement by measuring frquency variationsFluid pressure measurement by electric/magnetic elementsThermal expansionAnchor point

The invention discloses a micromachine-based electromagnetic excitation resonant pressure sensor, and relates to a micromachine sensing technology. The sensor is provided with three groups of resonators which are clamped by anchor points on a pressure membrane, arranged on a diagonal line of a frame, and provided with electrodes. The resonators applied with excitation signals are excited by magnetic field force under the action of an external magnetic field; and when pressure to be tested is present outside, the pressure membrane generates strain, and the strain is transmitted to the resonators through the anchor points to change the rigidity of the resonators, so that the natural frequency of the resonators is changed, and the pressure to be tested outside can be measured by detecting the frequency of output signals of vibration pickup electrodes. The sensor has two packaging modes, and is subjected to stress isolation through a ceramic ring of which the coefficient of thermal expansion is basically same as monocrystalline silicon. The resonators of the sensor work in a horizontal vibration mode; the shift caused by external factors such as temperature and the like is inhibited through differential output, and the sensitivity is improved; and the resonators are released by a heavy boron-diffusion self-stop corrosion technology, a process is simple and the consistency is high.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

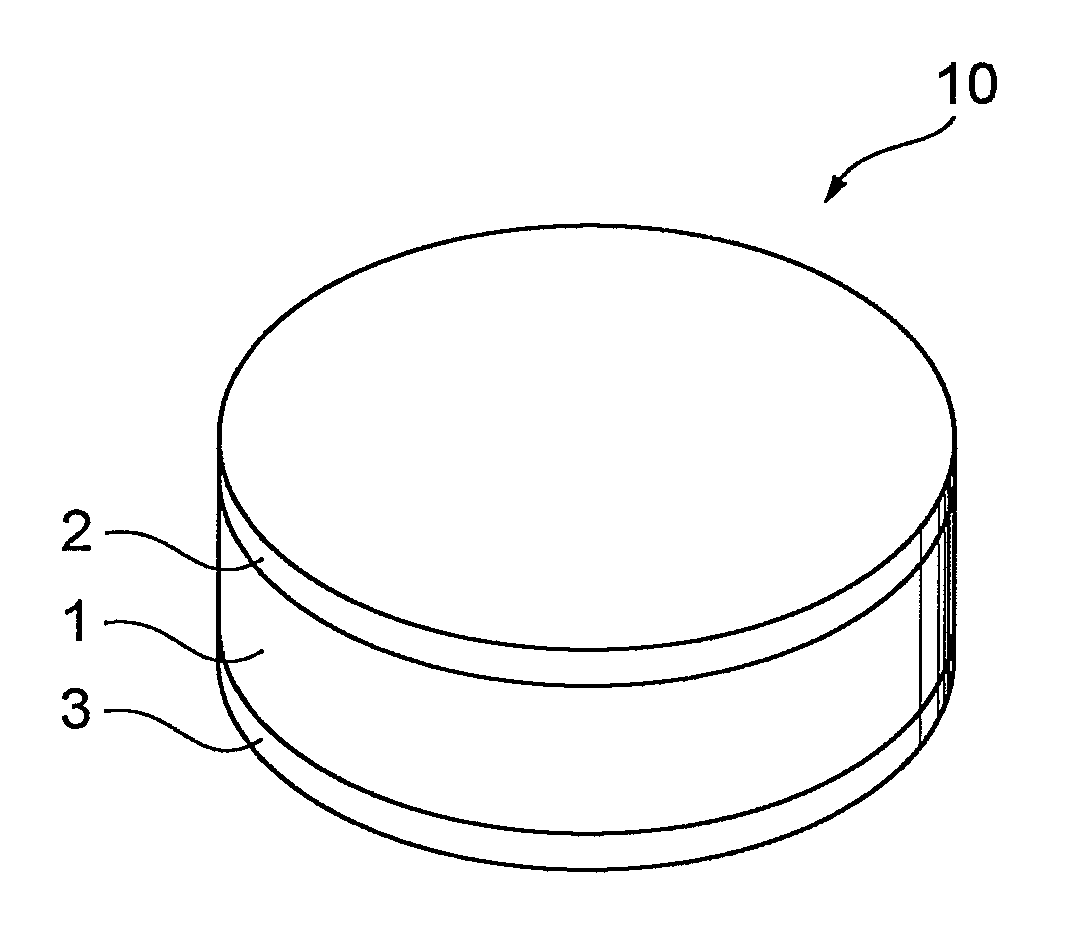

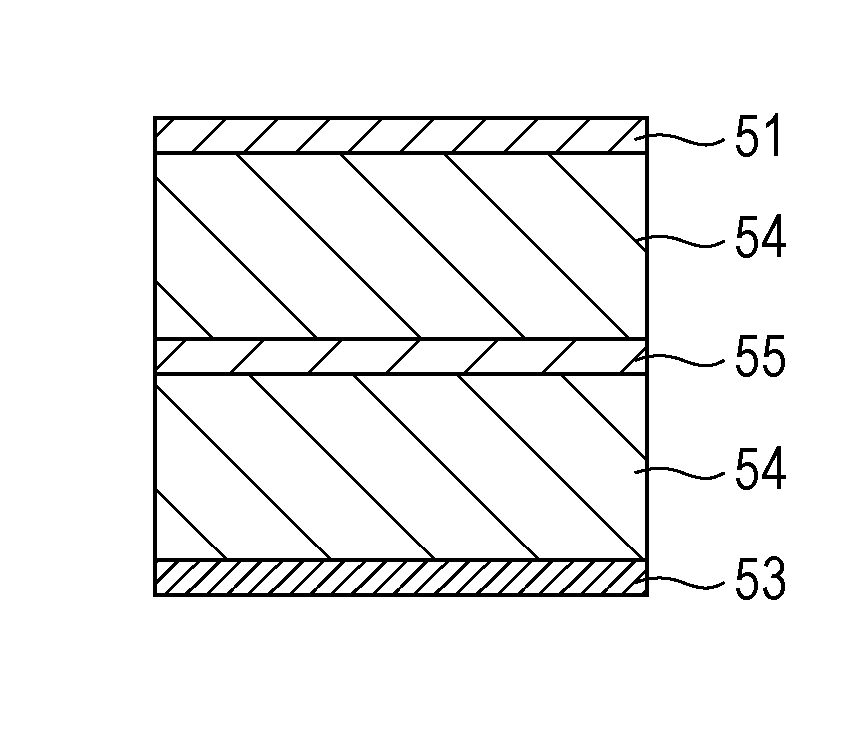

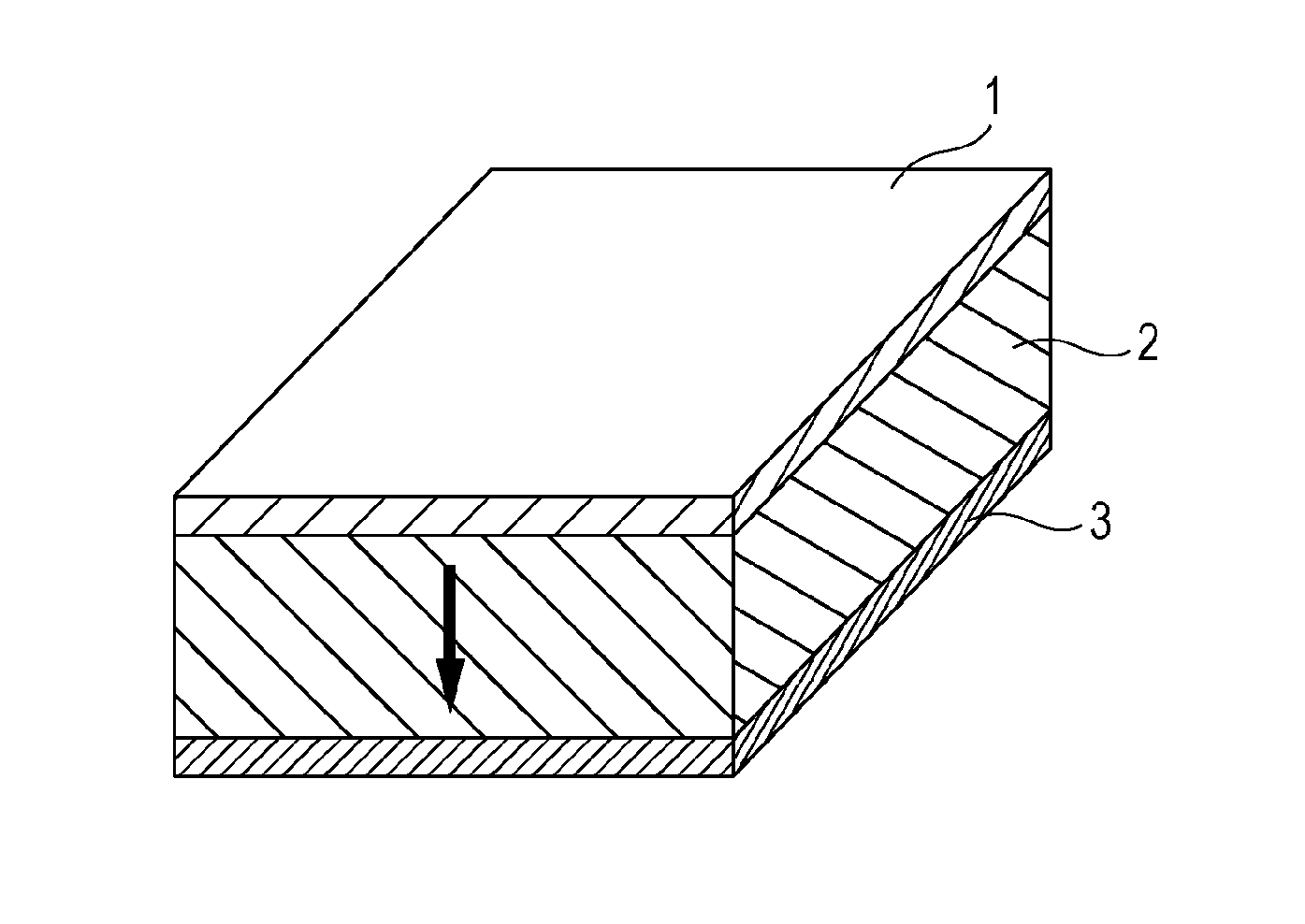

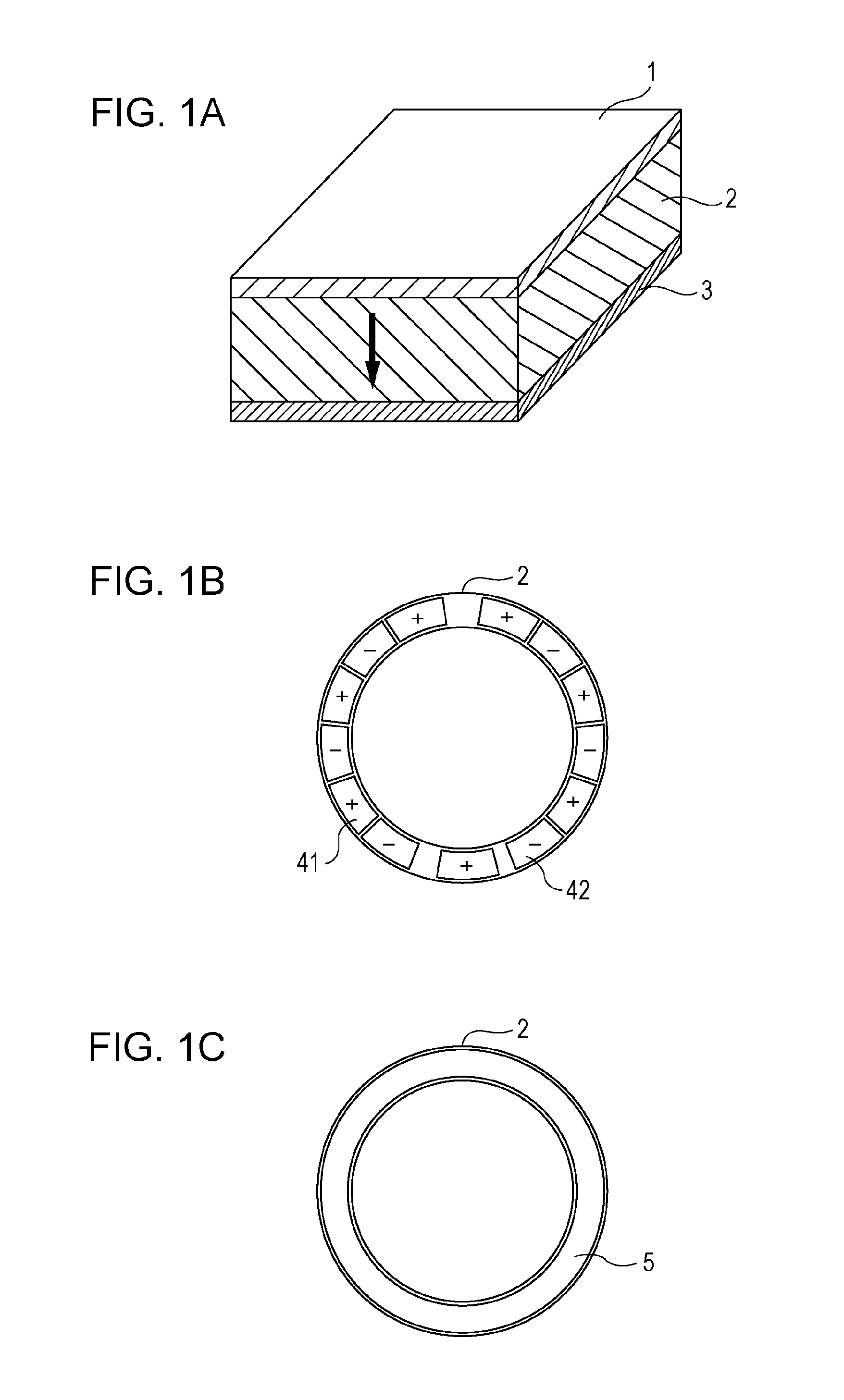

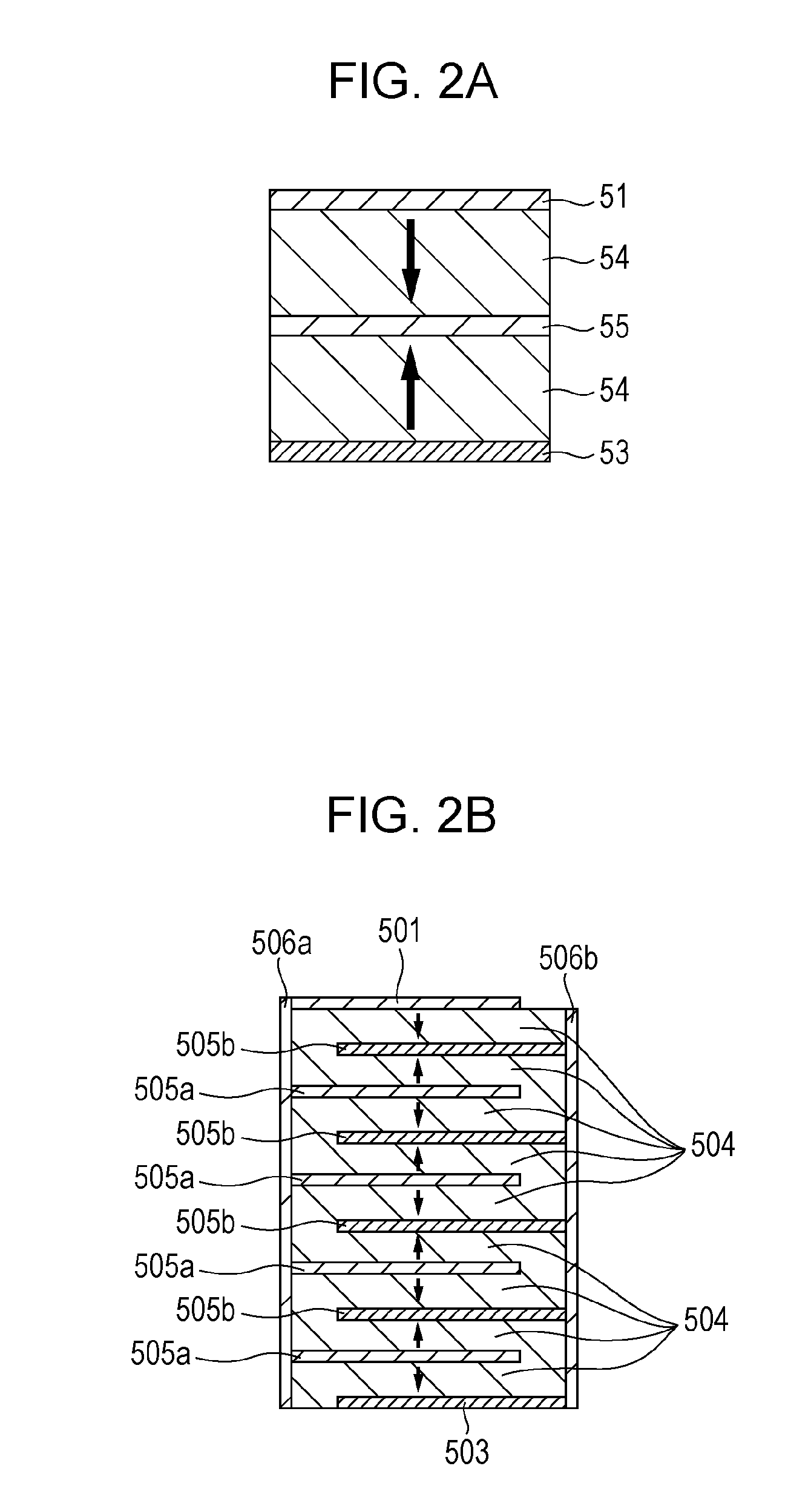

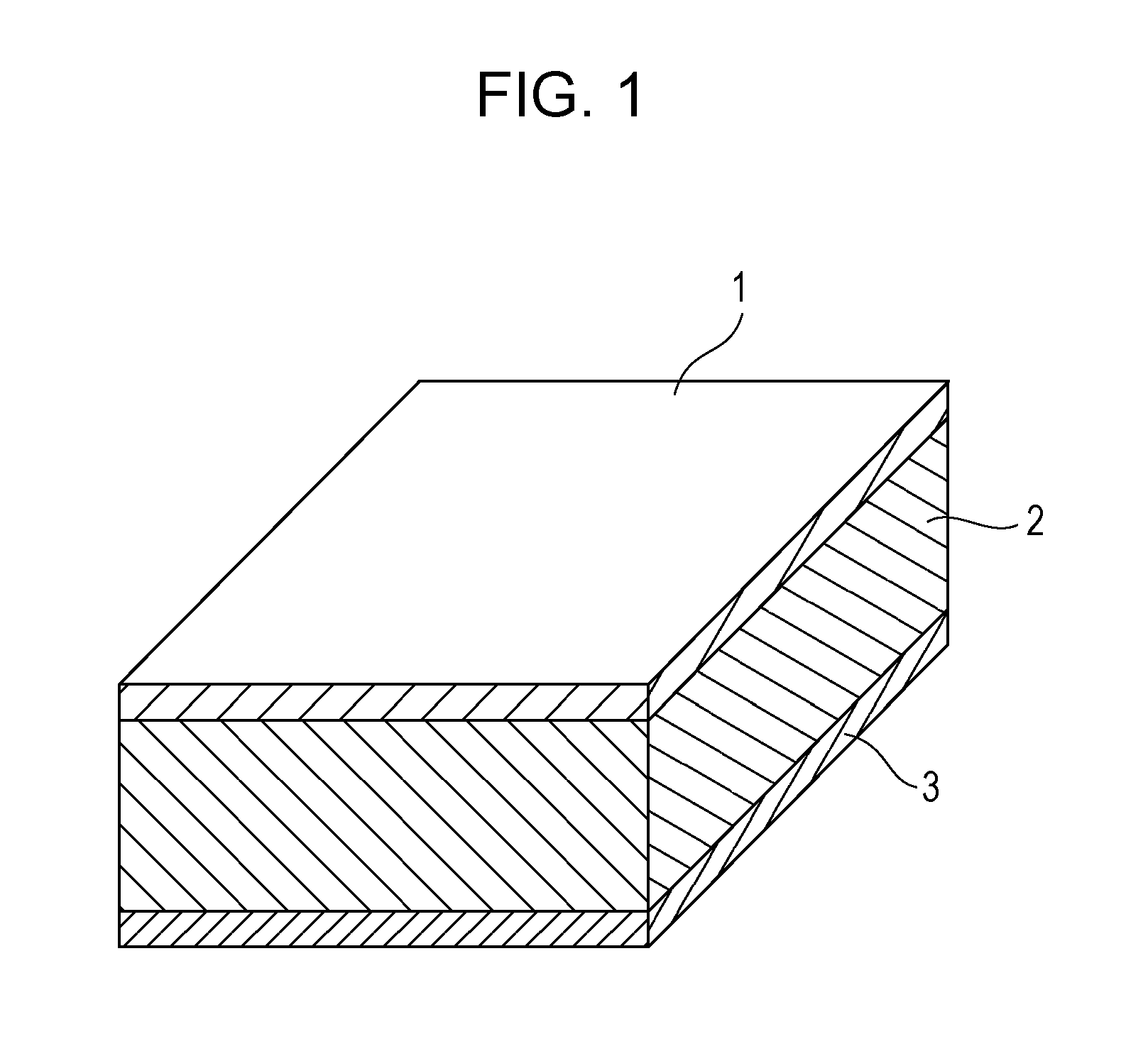

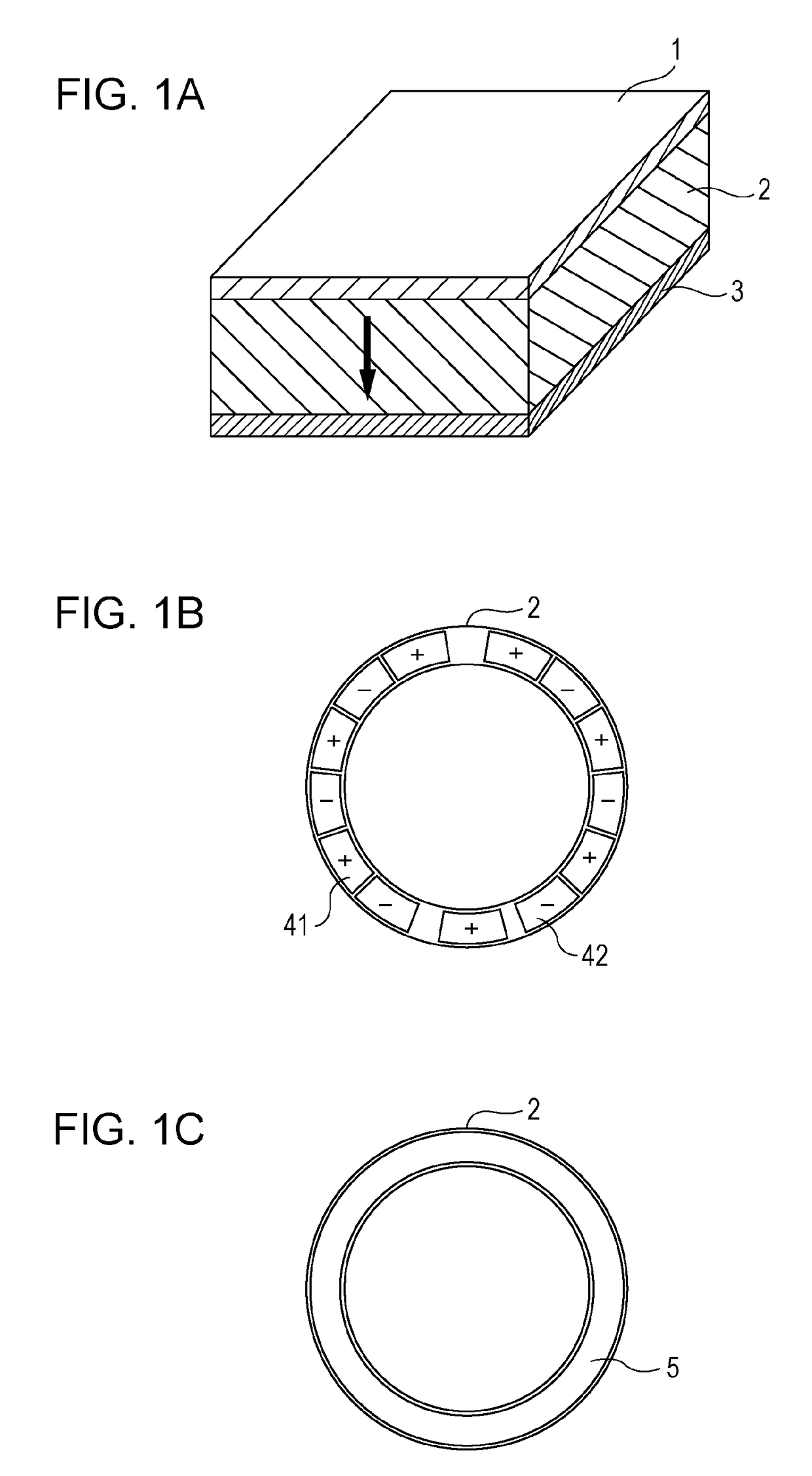

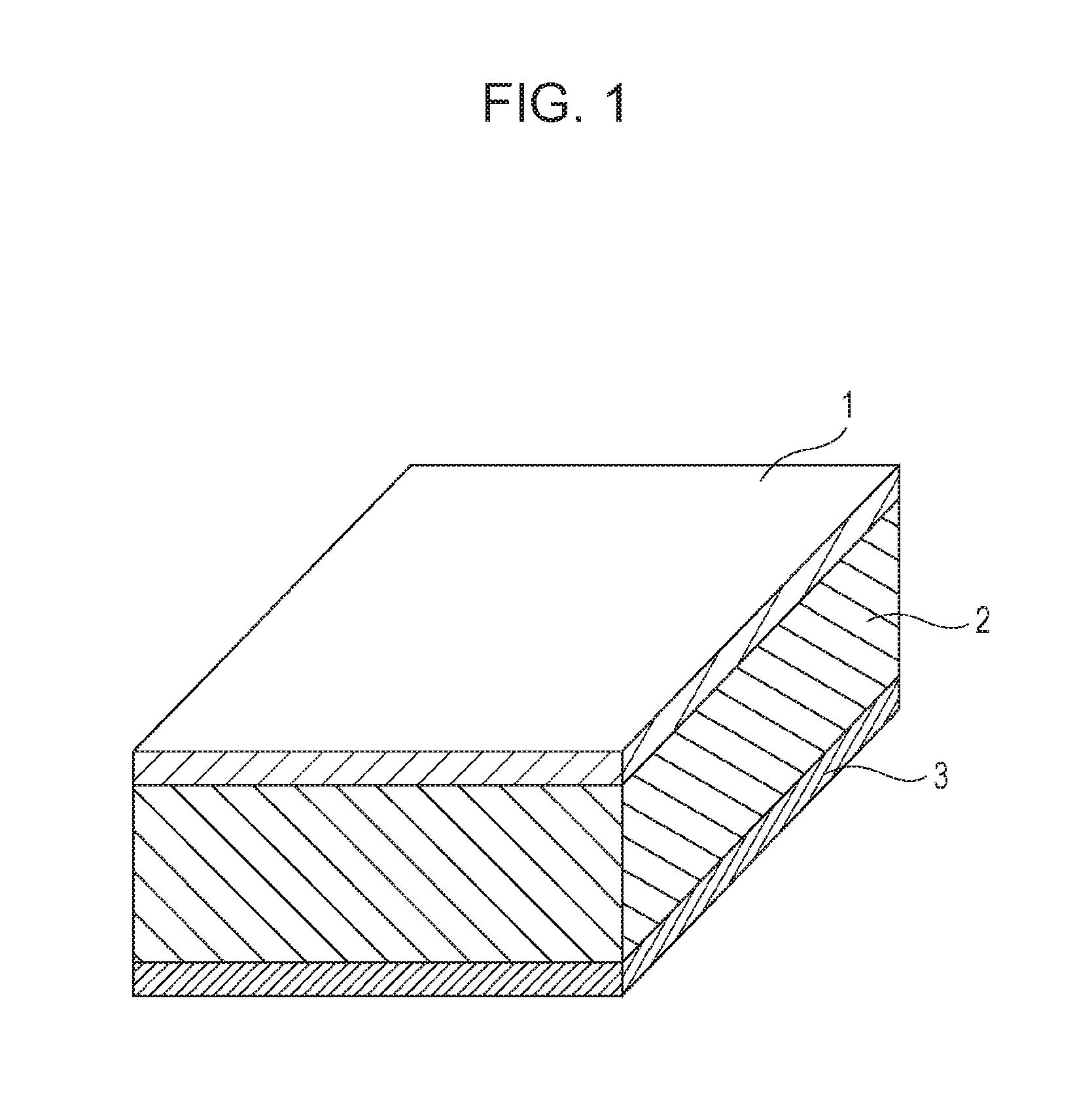

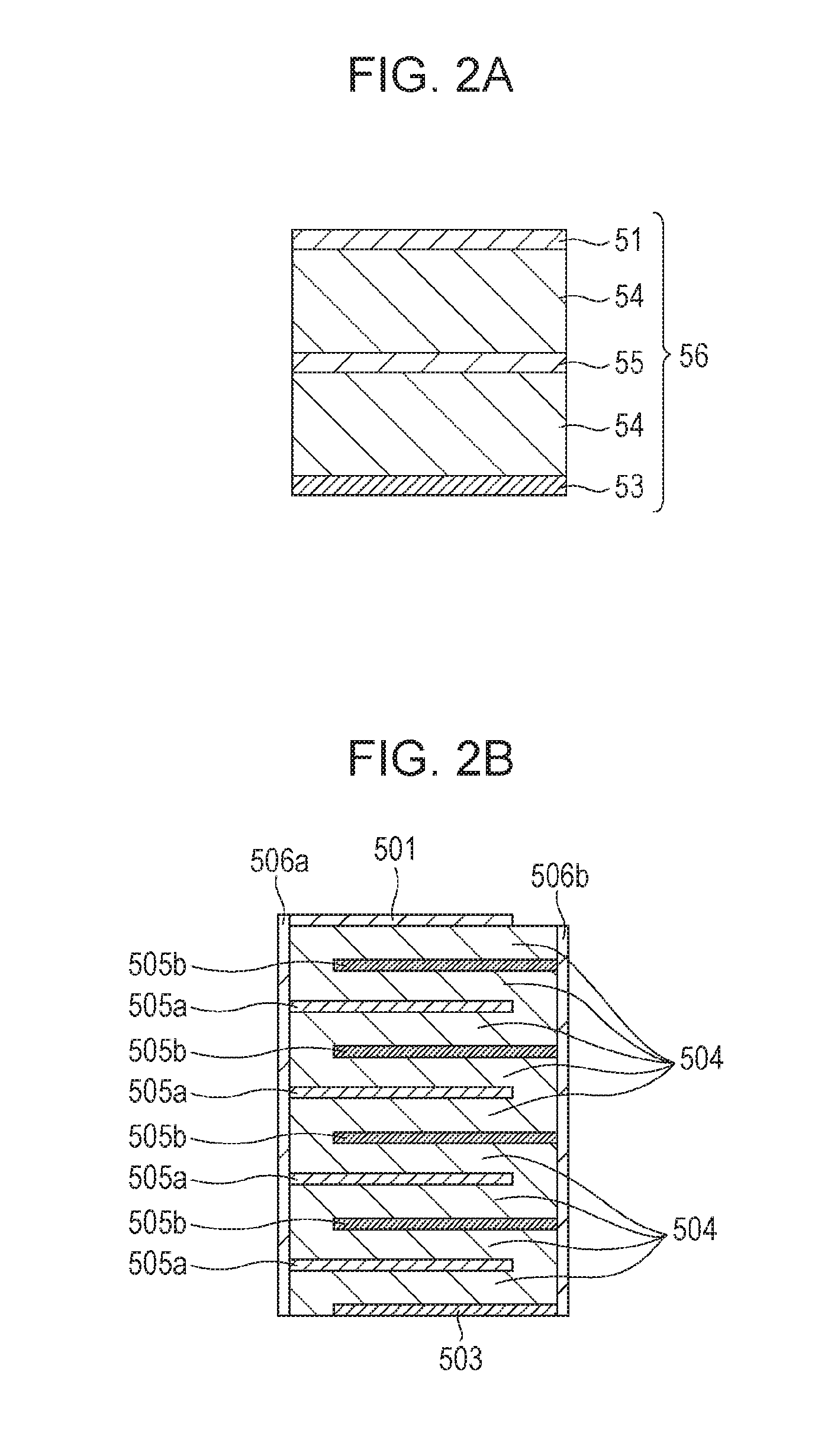

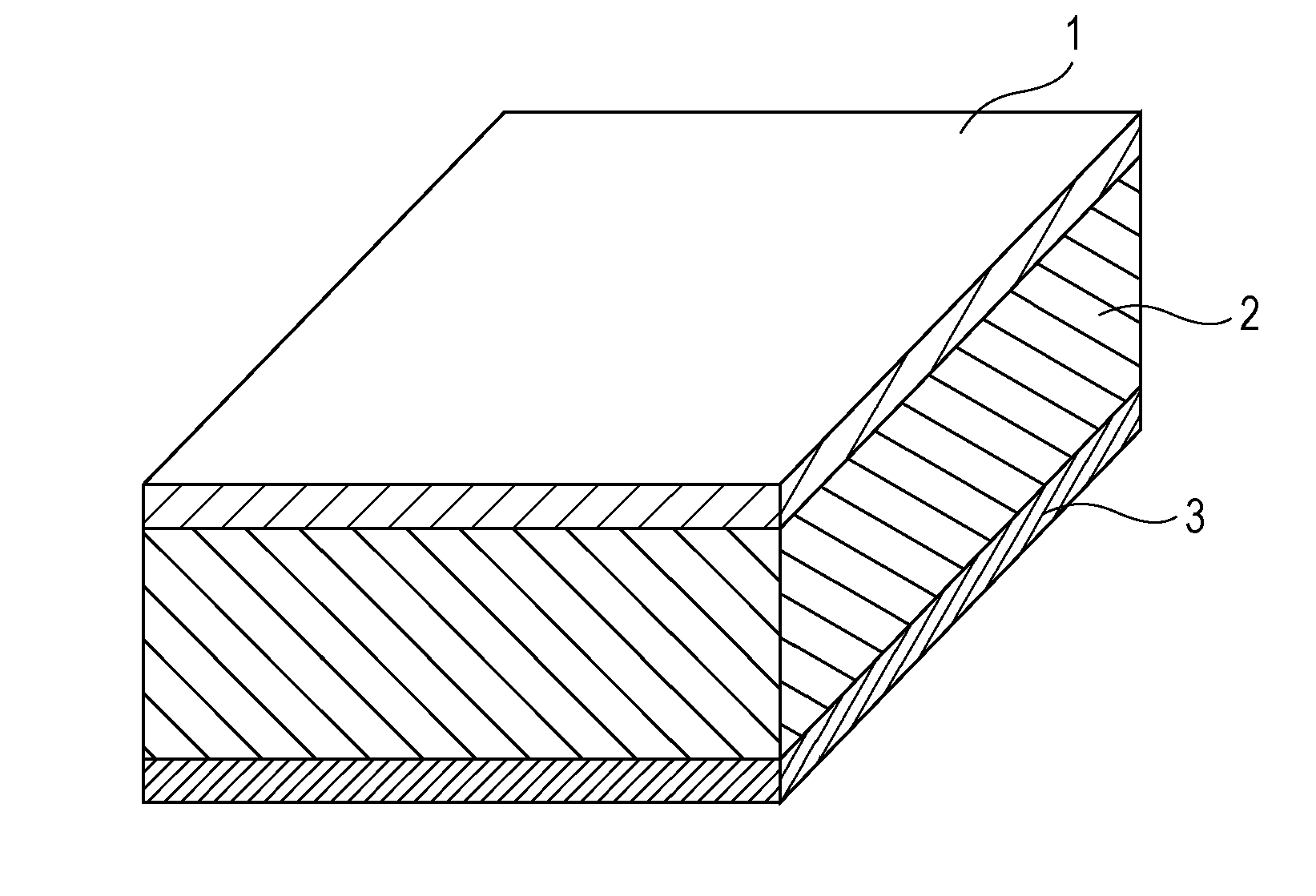

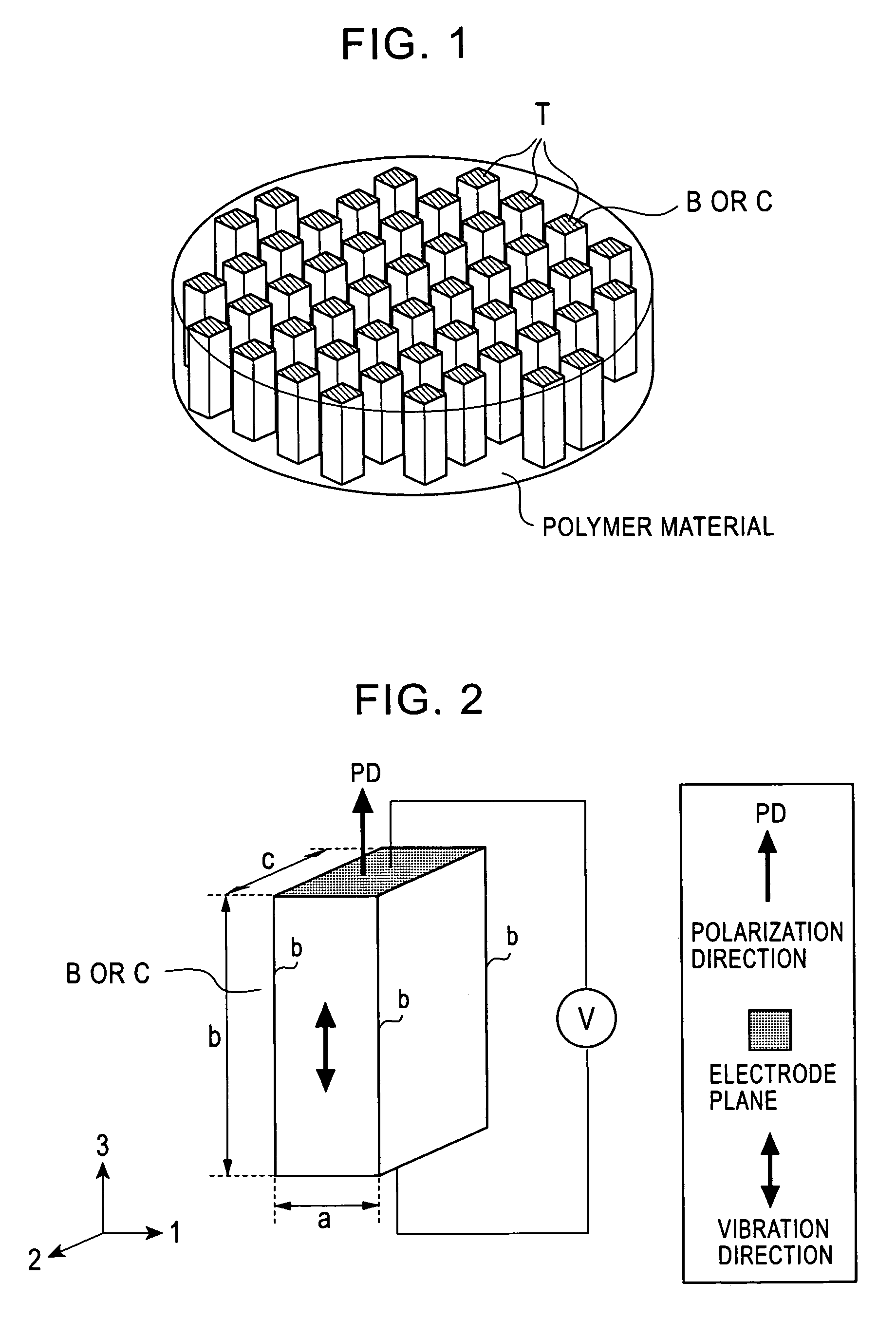

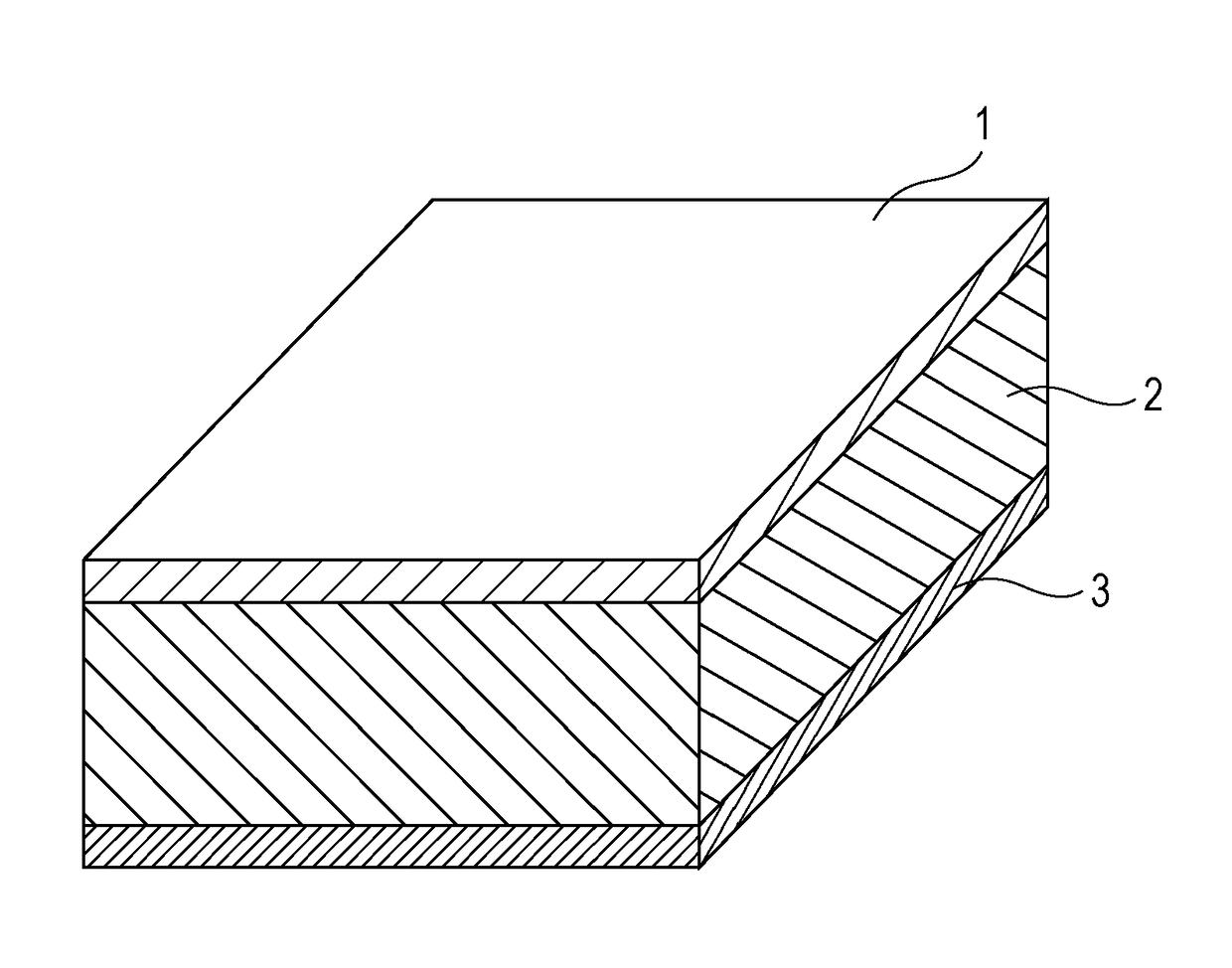

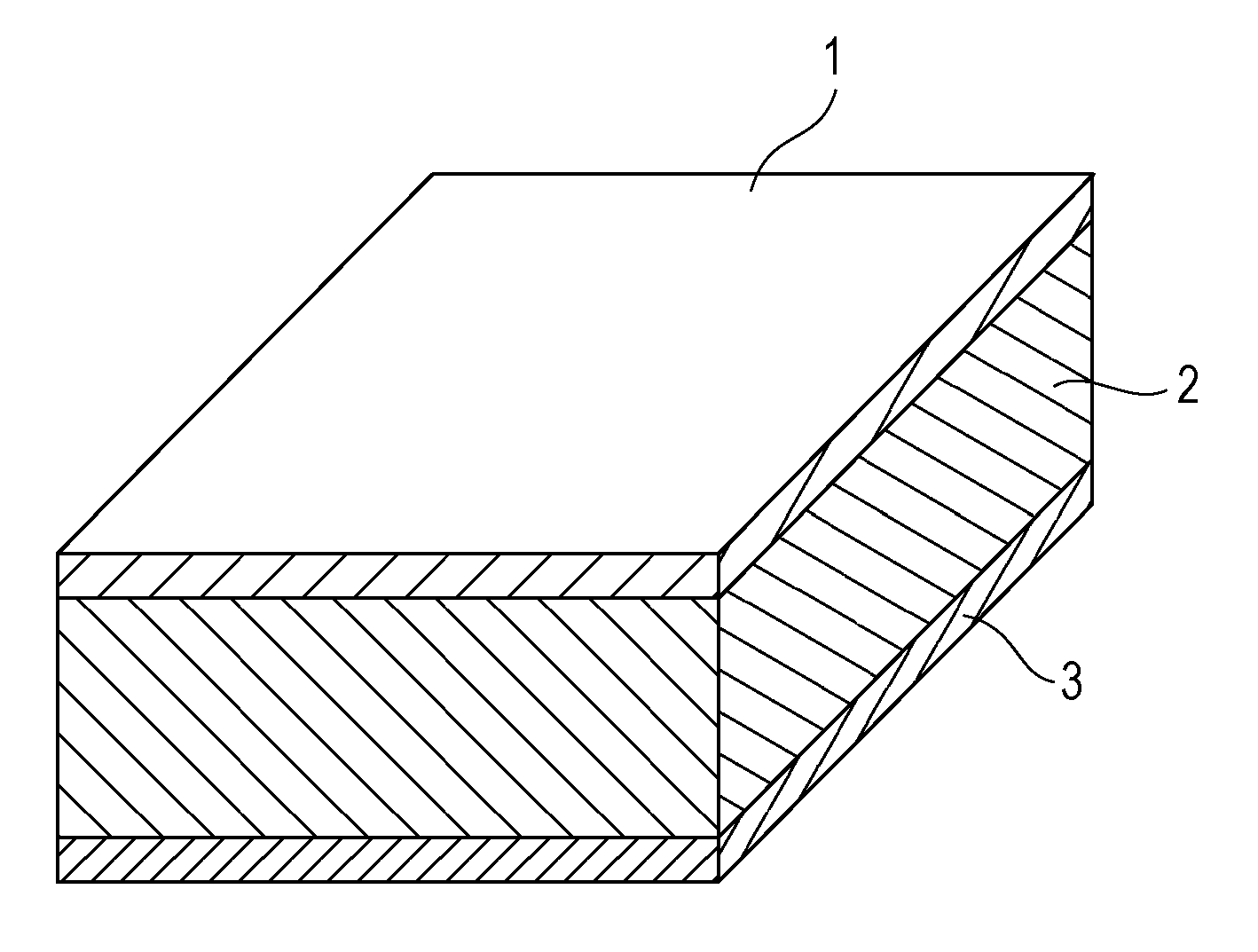

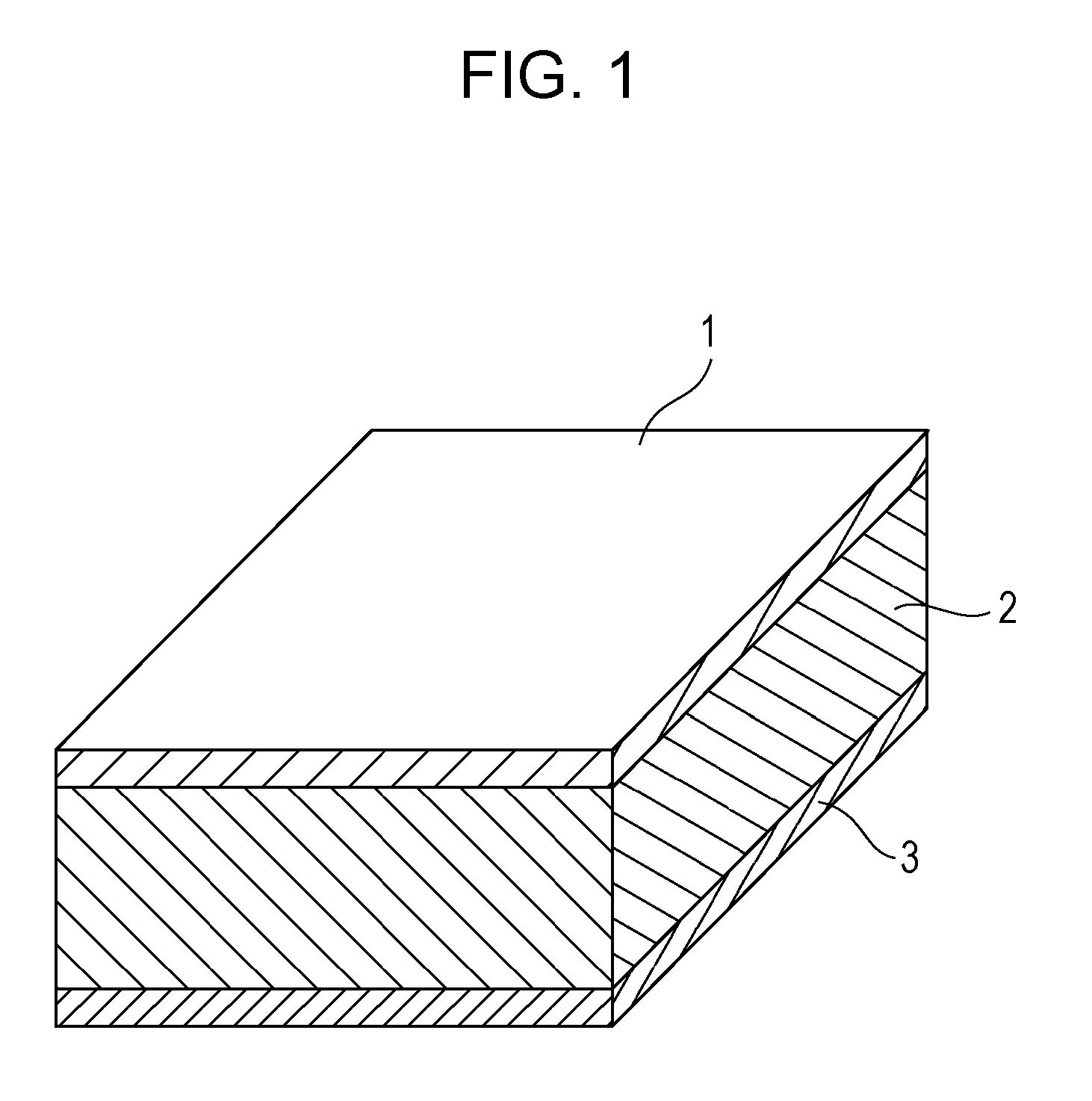

Piezoelectric ceramic, vibrator and ultrasonic motor

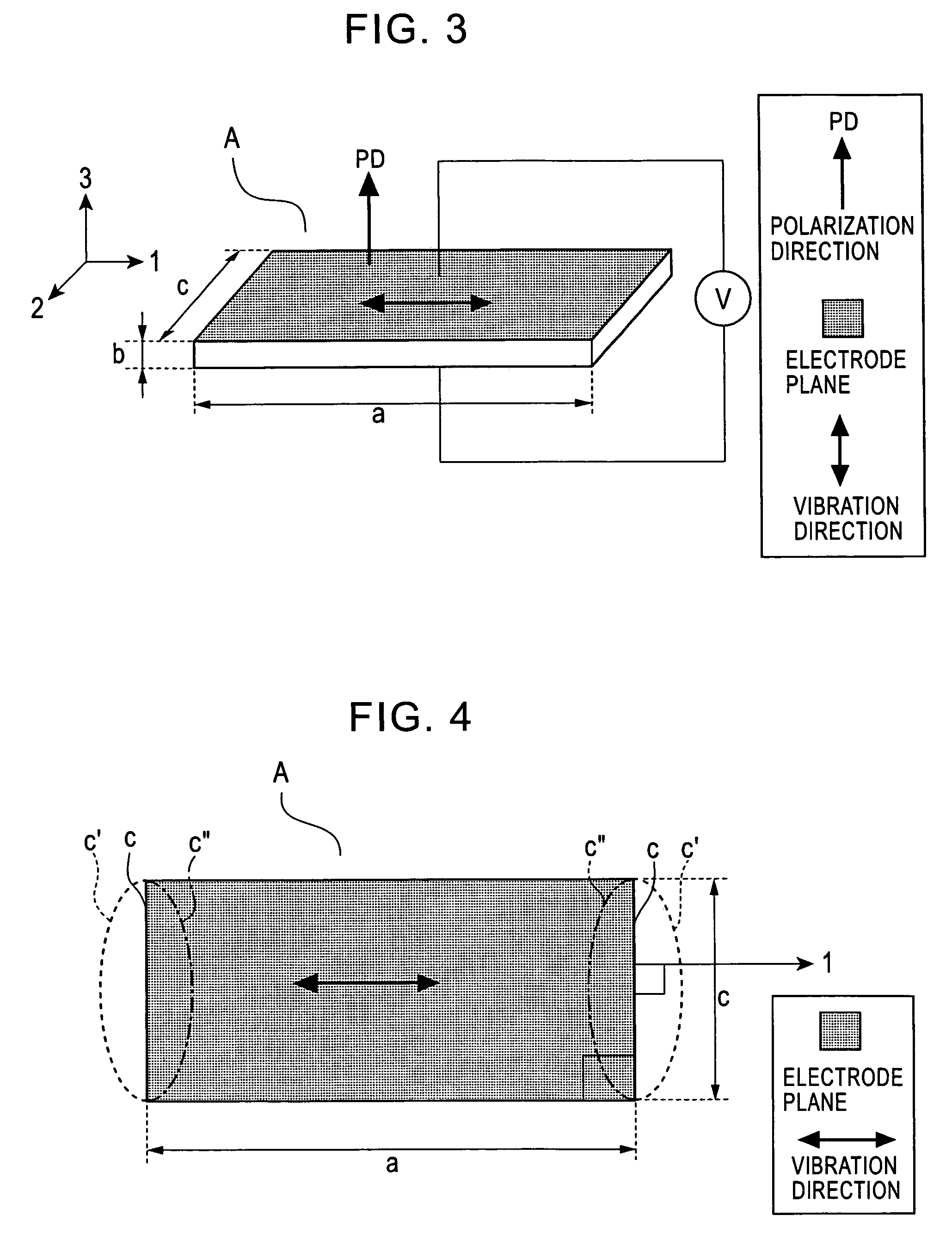

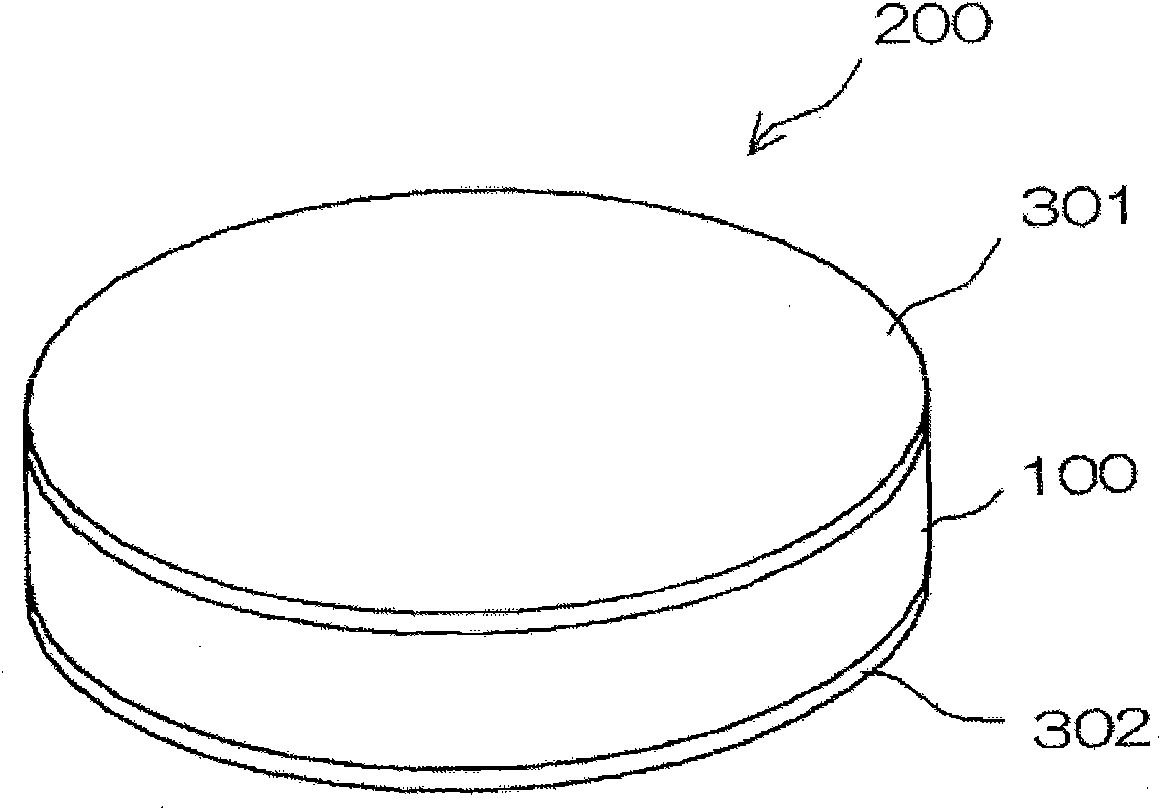

ActiveUS7944126B2Reduced Pb contentHigh mechanical quality factorPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesUltrasonic motorCeramic

Provided is a piezoelectric ceramic 1 containing a compound represented by the following general formula (1), as a main component and at least one element selected from Mn, Fe and Cu in an amount of 0.04 to 0.6% by mass based on the main component, and a vibrator 10 having the piezoelectric ceramic 1 and electrodes 2, 3. CaxBa1−xTiO3 (1)where, x satisfies 0.05≦x≦0.20.

Owner:TDK CORPARATION

Doped and modified lead zirconate-titanate piezoelectric ceramic and preparation method thereof

ActiveCN107986782ALower sintering temperatureHigh electromechanical coupling coefficientPiezoelectric/electrostrictive device manufacture/assemblyLead zirconate titanateElectromechanical coupling coefficient

The invention discloses a doped and modified lead zirconate-titanate piezoelectric ceramic and a preparation method thereof. The doped and modified lead zirconate-titanate piezoelectric ceramic is shown in a following chemical formula I, namely xPb(Mg1 / 3Nb2 / 3)O3-yPb(Ni1 / 3Nb2 / 3)O3-(1-x-y)Pb(Ti1 / 2Zr1 / 2)O3+lSrCO3+mZnO+nQ, wherein Q is at least selected from Li2CO3 (lithium carbonate), CuO (copper oxide), SiO2 (silicon dioxide), MnO2 (manganese dioxide), Bi2O3 (bismuth oxide) and La2O3 (lanthanum oxide); l, m and n are respectively the mass percentages of SrCO3 (strontium carbonate), ZnO (zinc oxide) and Q in the compound Pb(Mg1 / 3Nb2 / 3)O3-Pb(Ni1 / 3Nb2 / 3)O3-Pb(Ti1 / 2Zr1 / 2)O3; x is greater than or equal to 0.10 and is smaller than or equal to 0.70, y is greater than or equal to 0.08 and is smallerthan or equal to 0.38, l is greater than 0 and is smaller than or equal to 0.5, m is greater than 0 and is smaller than or equal to 0.50, and n is greater than or equal to 0 and is smaller than or equal to 0.5. The doped and modified lead zirconate-titanate piezoelectric ceramic has the excellent properties of low sintering temperature, high electromechanical coupling coefficient, high piezoelectric strain coefficient, small dielectric loss and the like.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

Sodium niobate barium-bismuth-potassium titanate lead-free piezoelectric ceramic composition

InactiveCN102515762AExcellent piezoelectric ferroelectric propertiesImprove ferroelectric propertiesOxygenSodium niobate

The invention provides a novel sodium niobate barium-bismuth-potassium titanate lead-free piezoelectric ceramic composition. The composition comprises perovskite antiferroelectric NaNbO3 and strong ferroelectric Ba1-y(Bi0.5K0.5)yTiO3. A general formula of the composition is (1-x)NaNbO3-xBa1-y(Bi0.5K0.5)yTiO3, wherein x and y in the formula satisfy the following equations: 0.025<=x<=0.25 and 0

Owner:SICHUAN NORMAL UNIVERSITY

Piezoelectric material, piezoelectric element, and electronic equipment

ActiveUS20150368161A1High mechanical quality factorProcess stabilityTelevision system detailsInking apparatusPotassiumCurie temperature

There are provided a lead- and potassium-free piezoelectric material that has a high Curie temperature and a high mechanical quality factor and is stable in long-term driving and a piezoelectric element including the lead- and potassium-free piezoelectric material. A piezoelectric material containing a perovskite-type metal oxide having the general formula (1): NaxBa1-yNbyZr1-yO3 wherein x satisfies 0.85≦x≦0.96 and y satisfies 0.90≦y≦0.96 and a piezoelectric element including the piezoelectric material. The piezoelectric material may include the perovskite-type metal oxide and Cu, and the Cu content corresponds to 2.00 mol % or less of the amount of the perovskite-type metal oxide.

Owner:CANON KK

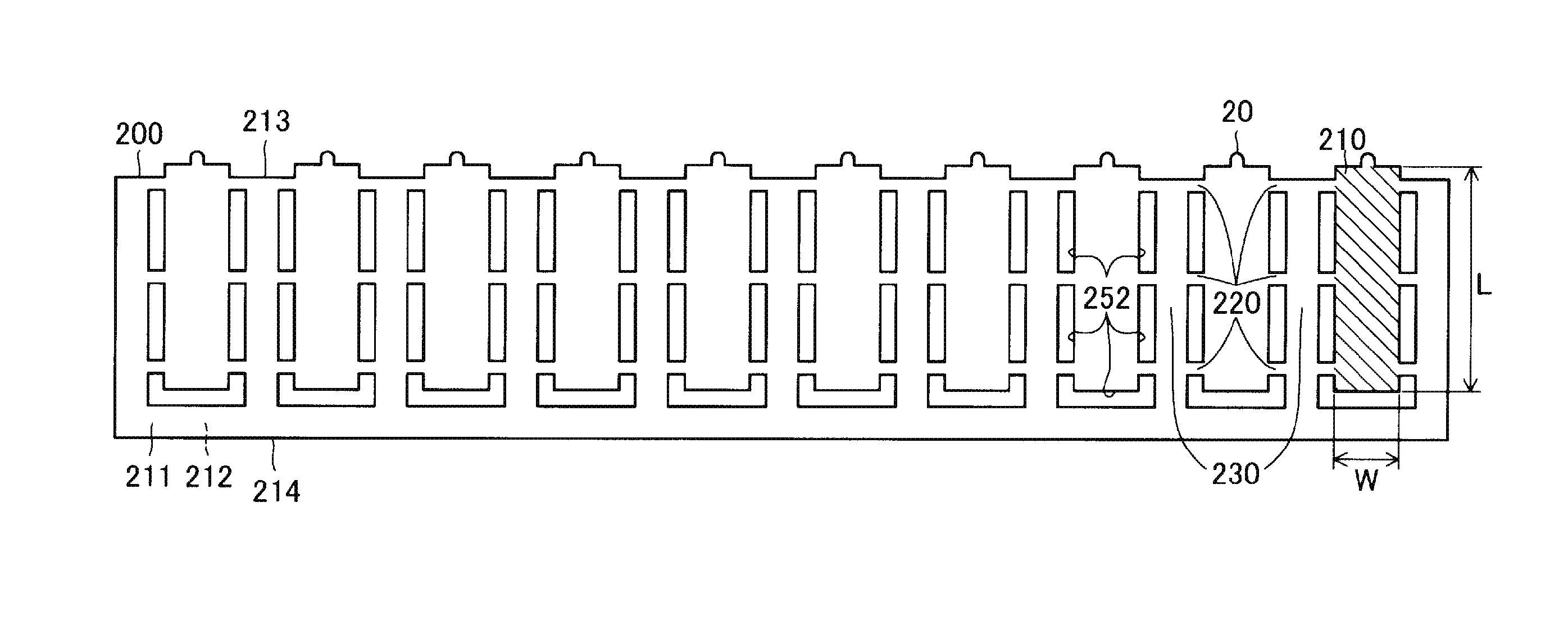

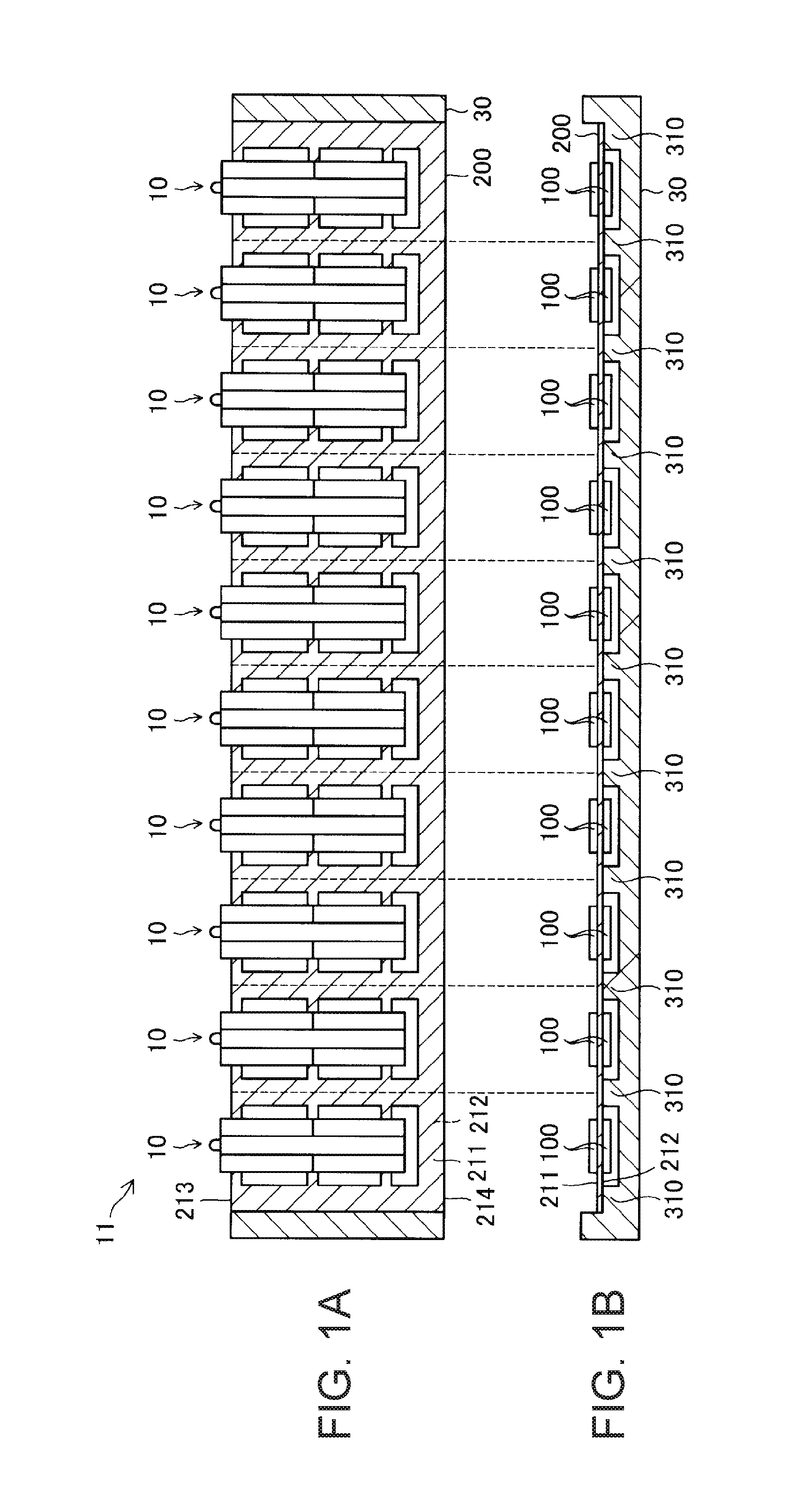

Piezoelectric drive device, robot, and drive method thereof

ActiveUS20160241165A1Increase output powerIncrease valueProgramme-controlled manipulatorPiezoelectric/electrostriction/magnetostriction machinesEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

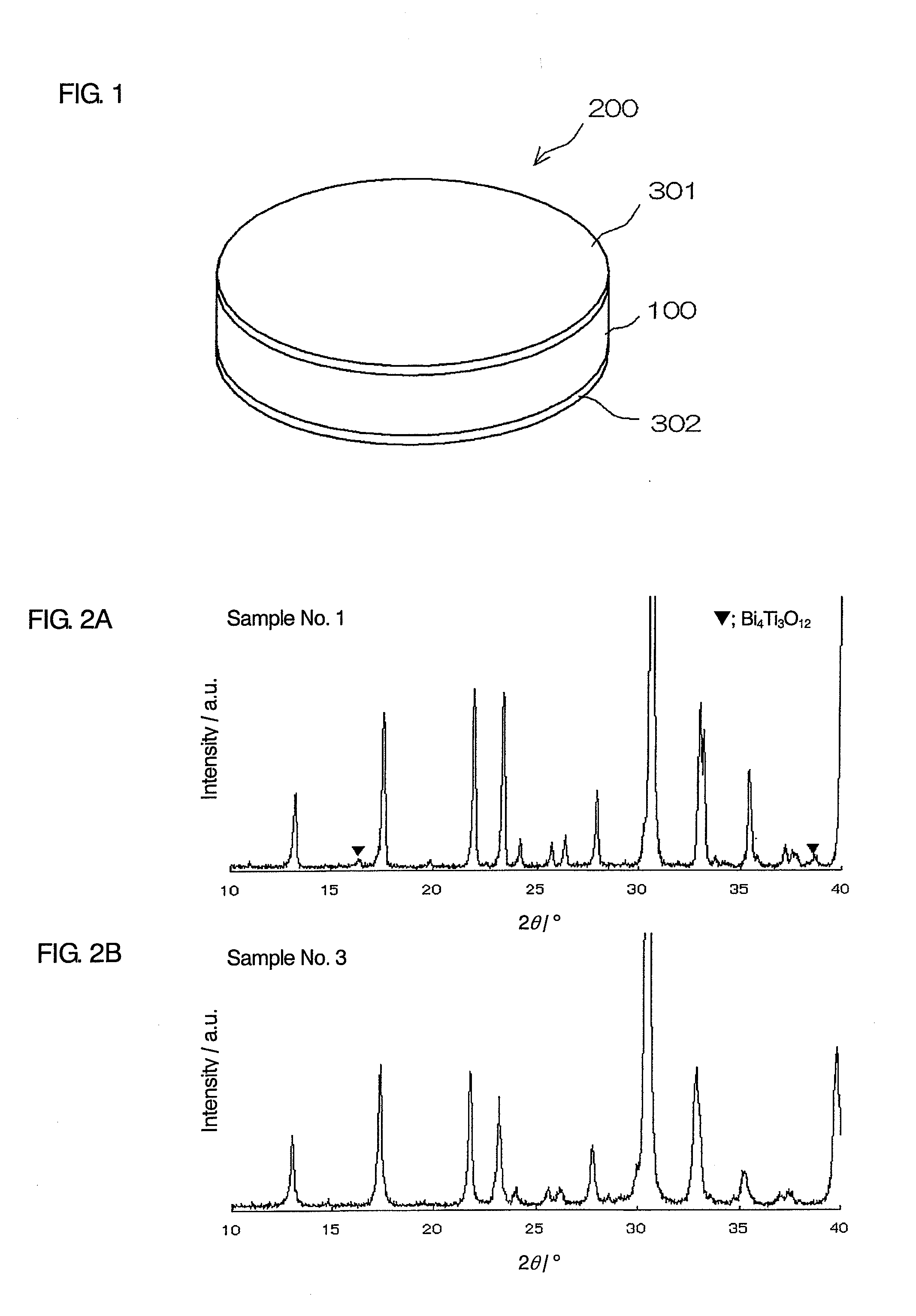

Piezoelectric ceramic composition and piezoelectric device

ActiveUS20100133959A1Excellent piezoelectric propertiesHigh constantPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCrystal structureLanthanide

There are provided a piezoelectric ceramic composition that includes a bismuth layer-structured compound, which contains Na, Bi, Co and Ln (lanthanoide), as a main component and a piezoelectric ceramic composition that includes a compound, which contains Na, Bi, Ti, Co and Ln (lanthanoide) and has a Na0.5Bi4.5Ti4O15 type crystal structure, as a main component, wherein the piezoelectric ceramic composition has an atomic ratio of 0<Ln / (Na+Bi+Ln)≦0.04.

Owner:NGK SPARK PLUG CO LTD

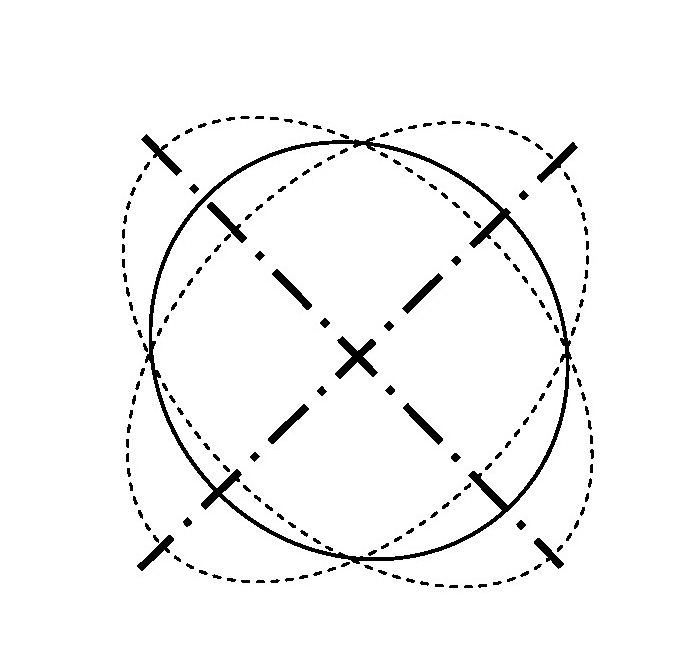

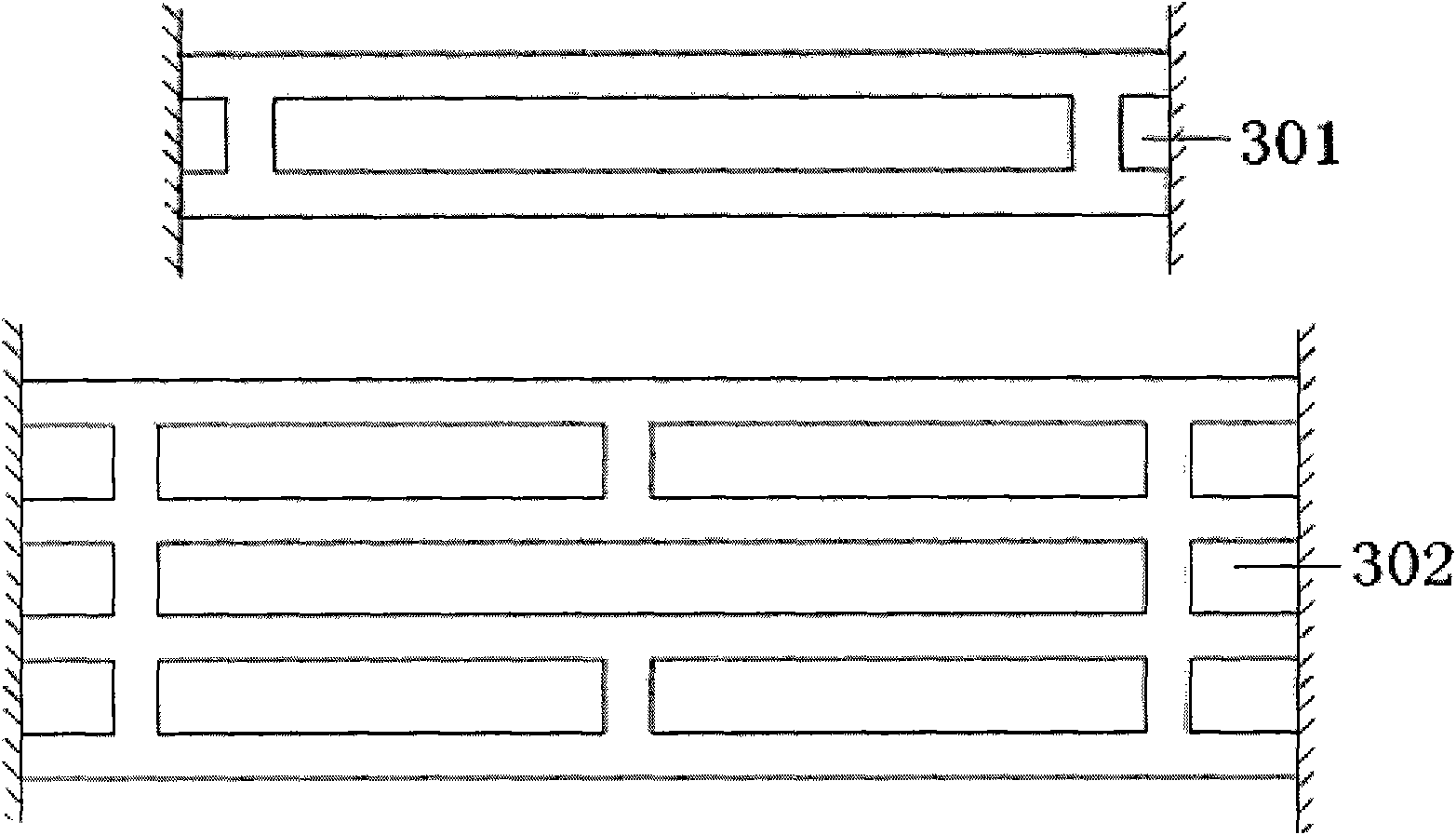

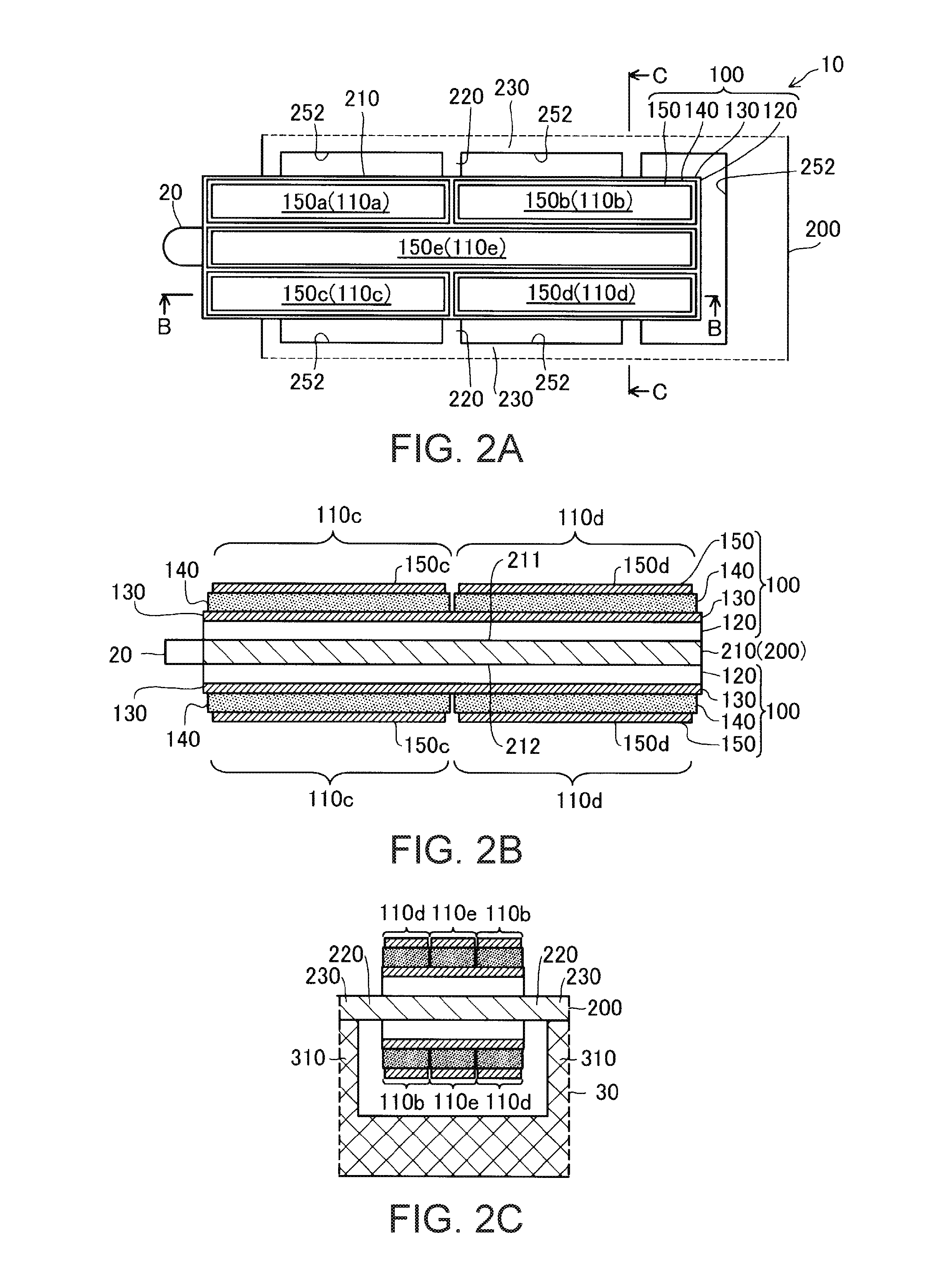

Biaxially-resonant silicon-micromachined accelerometer structure in shape of Chinese character 'tian'

InactiveCN102539832AIncrease in sizeGood anti-noiseAcceleration measurement using interia forcesSolid-state devicesAccelerometerClosed loop

The invention discloses a biaxially resonant silicon-micromachined accelerometer in the shape of a Chinese character 'tian' and aims at designing and manufacturing a high-sensitivity and high-resolution biaxially-resonant silicon-micromachined accelerometer. The structure is characterized in that (1) because a mass block structure in the shape of a Chinese character 'tian' is adopted, the volume of a mass block is maximized, and the acceleration can be converted into an inertial force more effectively; and the whole structure is symmetrically distributed, which is favorable for resisting noises and inhibiting temperature drift; (2) a support beam (in the shape of a Chinese character 'ji') arranged at the periphery of the structure facilitates the release of the residual stress and temperature stress of the structure, thereby reducing the support stiffness of the structure in a sensitive direction; (3) due to the application of a spring-like beam (in the shape of a Chinese character 'kou') at one end of a resonator, the influence of external shocks on the beam is reduced, and the spring-like beam plays a role in releasing the residual stress of the structure; and (4) an arc structure at the root part of a tuning fork in the resonator can be used for effectively reducing the energy coupling and improving the mechanical quality factor of the resonator, and is easy for realizationof closed-loop control.

Owner:BEIHANG UNIV

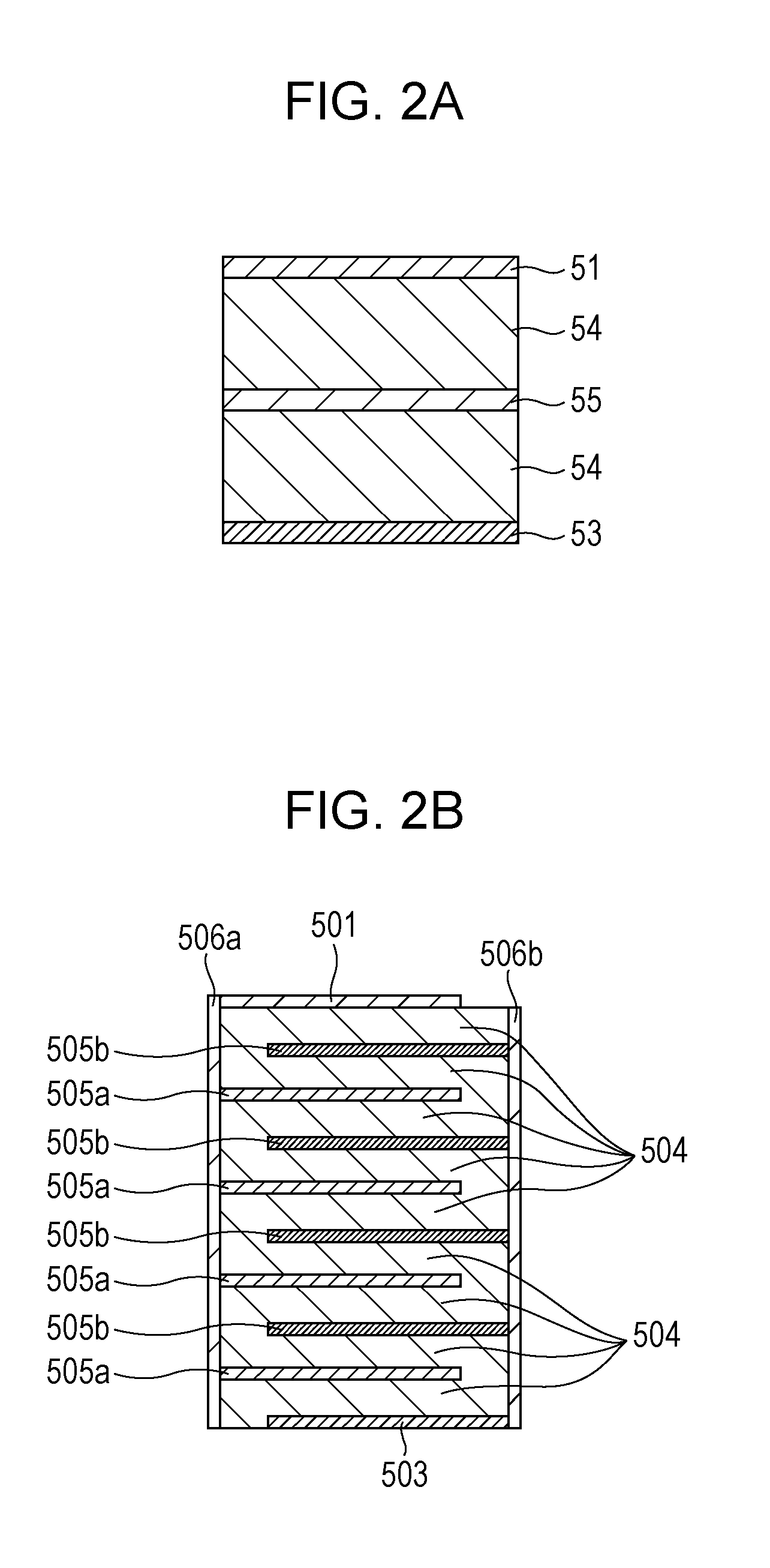

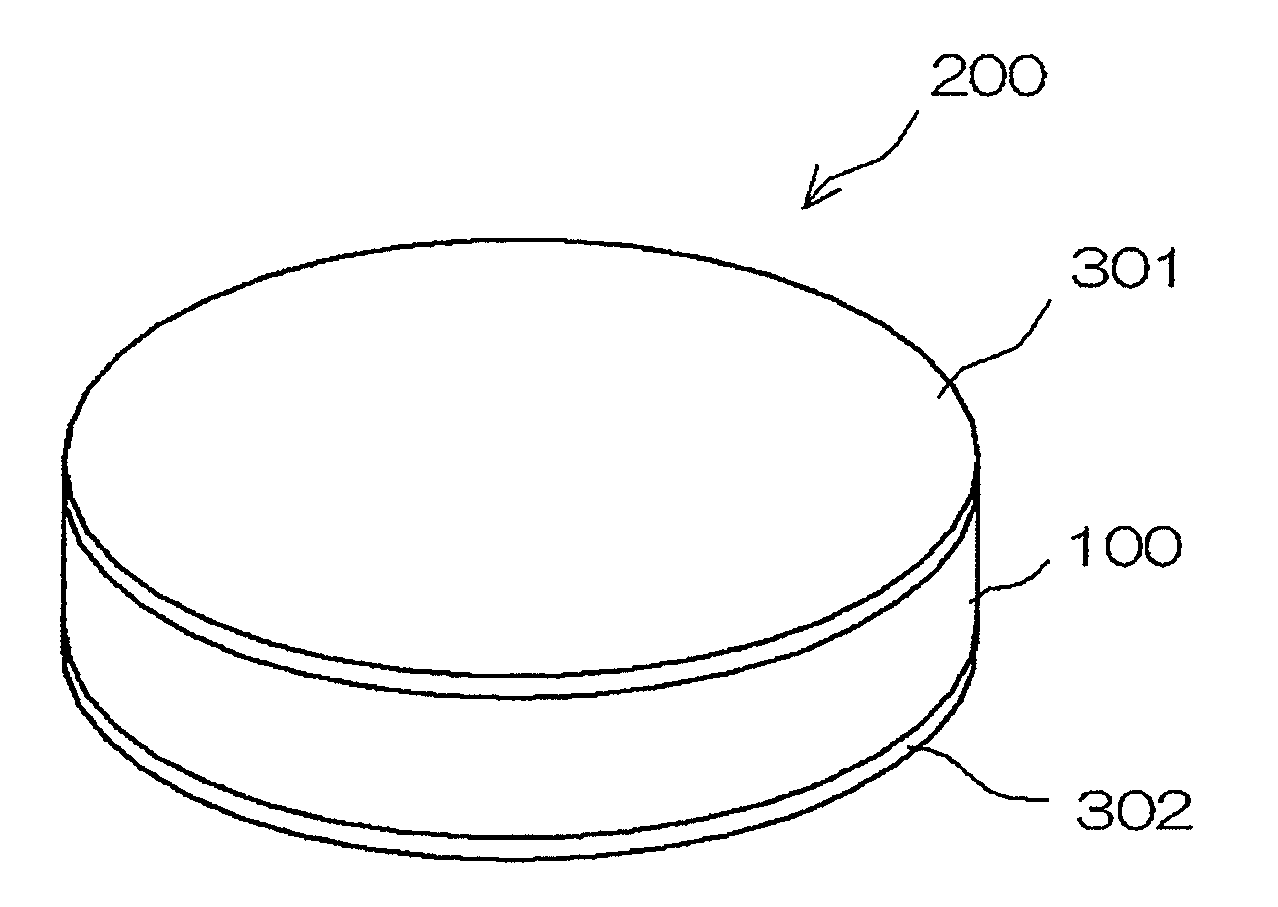

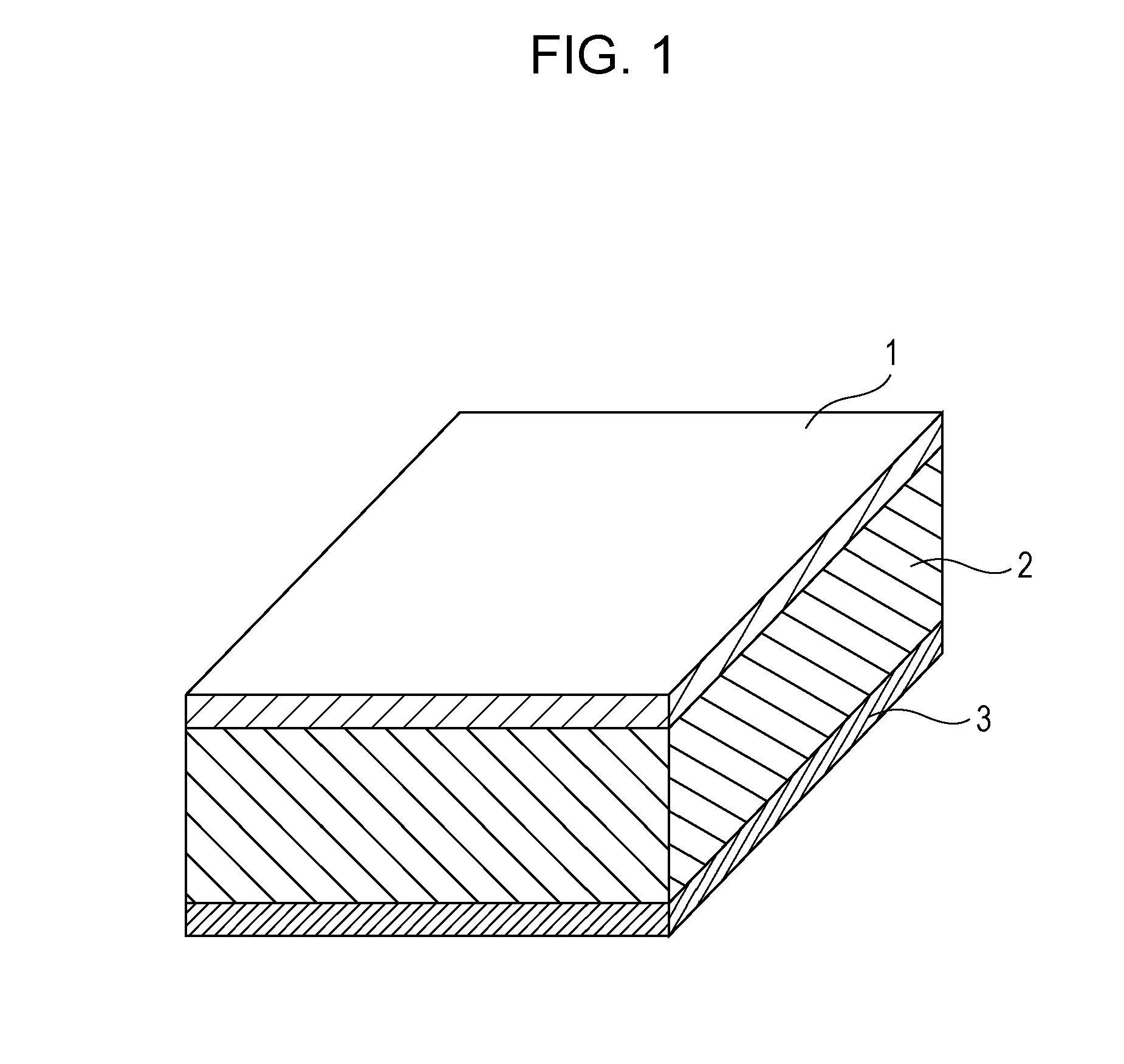

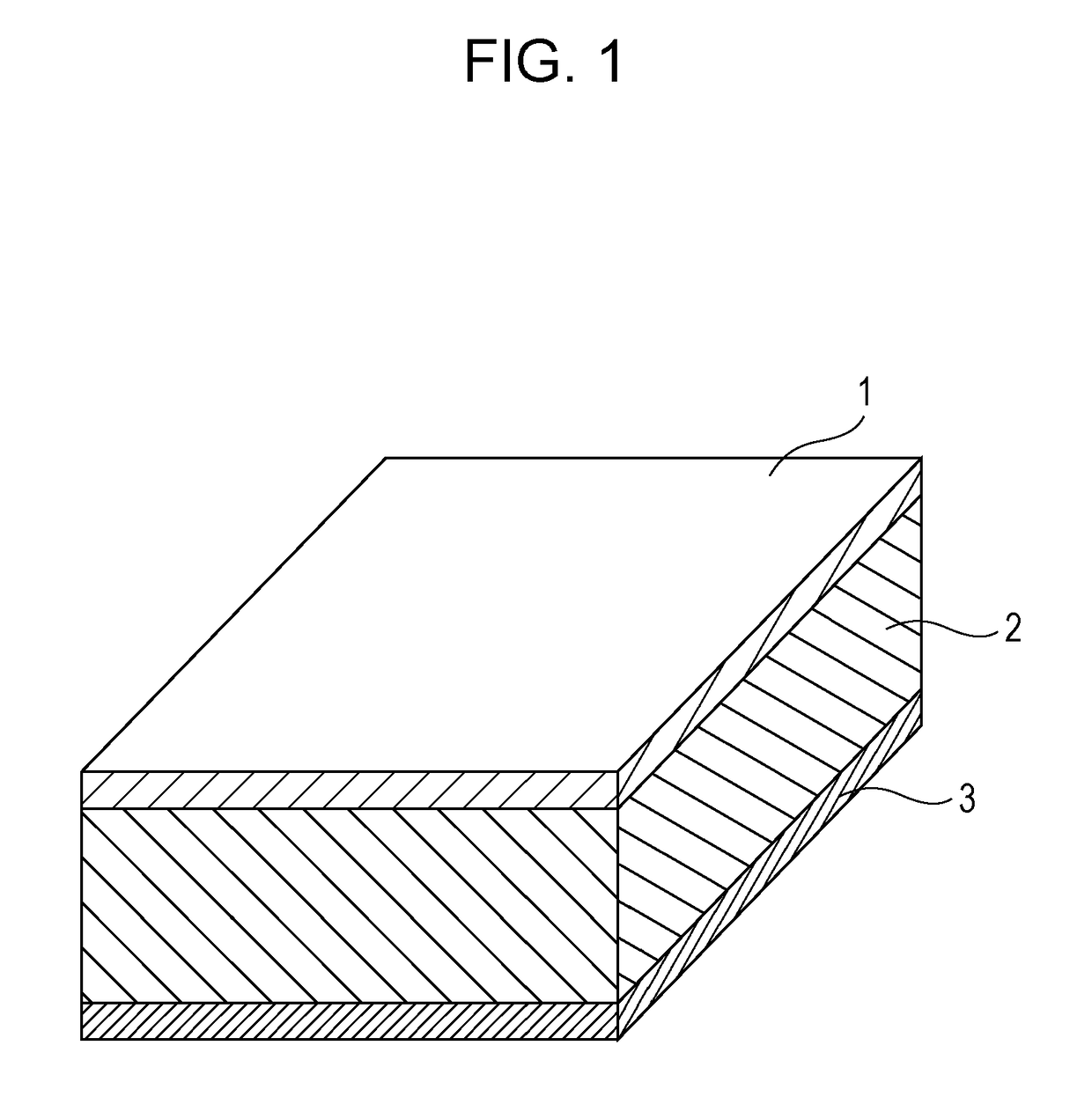

Ceramic powder, piezoelectric ceramic, piezoelectric element, and electronic equipment

ActiveUS20150255703A1High constantHigh mechanical quality factorTelevision system detailsInking apparatusPerovskiteZirconium

A ceramic powder contains a metal oxide represented by the following general formula (1). The ceramic powder has a single perovskite-type crystal phase. The ceramic powder is composed of particles having an average equivalent circular diameter in the range of 100 nm or more and less than 1000 nm and has a ratio c1 / a1 in the range of 1.000≦c1 / a1≦1.010, wherein c1 and a1 denote the c-axis length and a-axis length, respectively, of unit cells of the perovskite-type metal oxide, c1 being greater than or equal to a1.(Ba1-xCax)α(Ti1-y-zZryMnz)O3(0.9900≦α≦1.0100, 0.125≦x≦0.300, 0.020≦y≦0.095, 0.003≦z≦0.016)

Owner:CANON KK

Ca2+ doped bismuth laminated piezoceramic material and preparation method thereof

InactiveCN101982441ALow dielectric constantImprove performancePiezoelectric/electrostrictive/magnetostrictive devicesEngineeringMechanical engineering

The invention relates to a Ca2+ doped bismuth laminated piezoceramic material and a preparation method thereof, belonging to the field of piezoceramic material. The invention adopts SrBI2NbTaO9 system piezoceramic material as basal body, Ca is doped at Sr site in certain mol ratio (Ca / Sr is more than 0 and less than 1), solid phase synthesis process is utilized to carry out heat preservation sintering for 0.1-6h at the temperature of 1300 DEG C, thus obtaining the novel piezoceramic material, and composition thereof is CaxSr1-xBi2NbTaO9 (x is more than 0 and less than 1). The main properties of the material include: epsilon33T / epsilon 0 is 150 minus or plus 20, d33 is 20pC / N, the material can be used for preparing piezoceramic elements in various shapes, the material can be assembled into various piezoceramic sensors, and the material can be widely applied in measuring, detecting and automation under high temperature condition.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Mechanical resonators fabricated out of bulk-solidifying amorphous metal alloys

InactiveUS20080118759A1Superior elastic limitImprove corrosion resistanceMechanical apparatusResonant frequencyVibrating structure gyroscopeMeasuring instrument

The use of bulk-solidifying amorphous metal alloys, frequently called “liquid metals”, are disclosed as a preferred material of construction for the manufacture of mechanical resonators, such as mechanical resonators utilized in the following: systems using tuning forks and variants of tuning forks, inertial microbalances, vibrating level detectors, vibrating viscosity and rheology measuring instruments, vibrating tube meters, such as Coriolis mass flow meters, vibrating structure gyroscopes, vortex flow meters, sonotrodes for various applications such as welding and medical applications, and piezoelectric activated mechanical resonators. A method of attaining high mechanical Q factors, sensitivity, elasticity, hardness, and high specific strength properties offered by the use of bulk-solidifying amorphous metal alloys in the manufacture of mechanical resonators is disclosed.

Owner:SIERRA INSTR

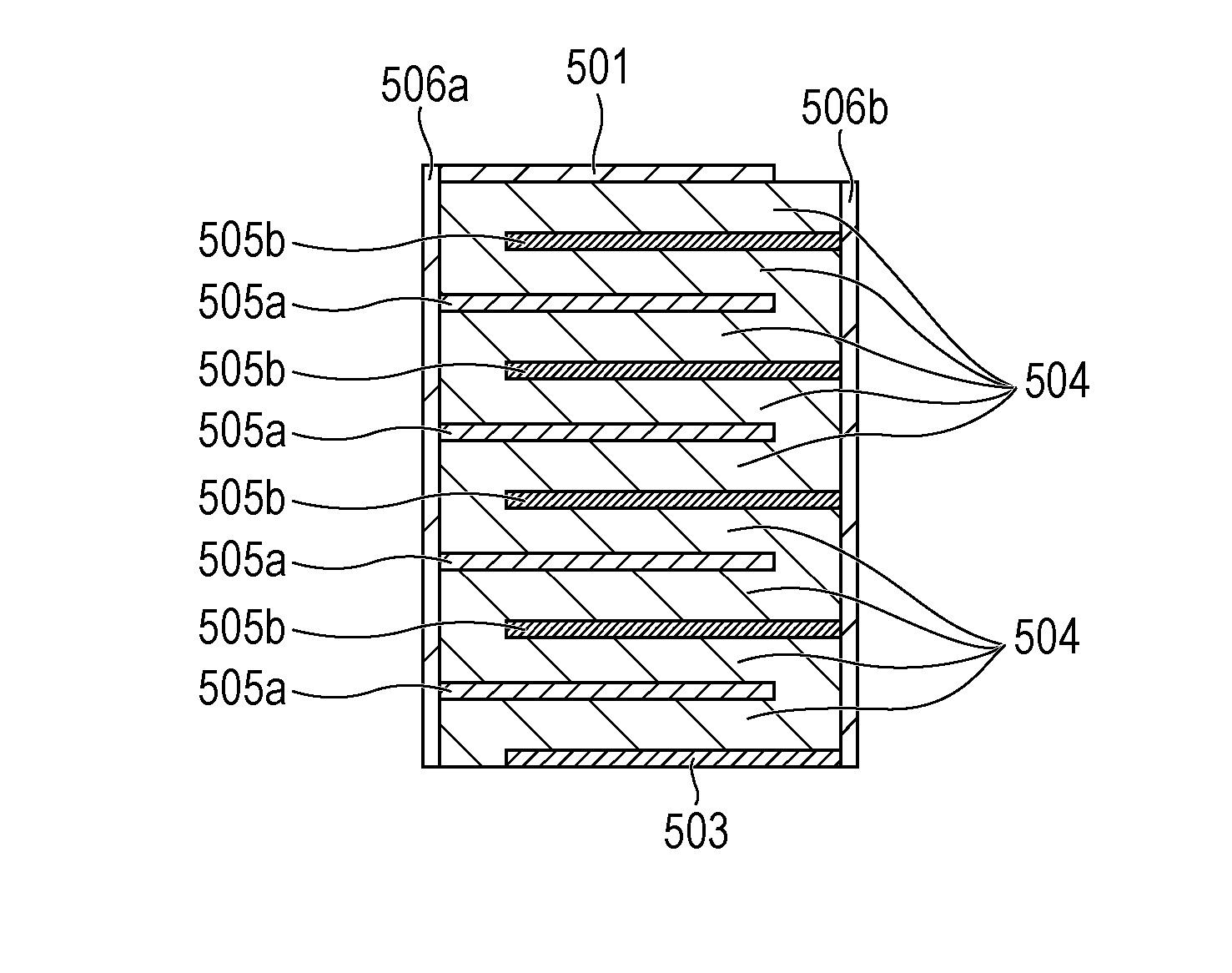

Piezoelectric ceramic, method for producing the same, piezoelectric element, multilayer piezoelectric element, liquid ejection head, liquid ejecting apparatus, ultrasonic motor, optical device, vibrating apparatus, dust-removing apparatus, imaging apparatus, and electronic device

InactiveUS20160351789A1High mechanical quality factorExcellent piezoelectric propertiesTelevision system detailsInking apparatusPotassiumCurie temperature

Provided is a piezoelectric ceramic that does not contain any of lead, potassium, and cobalt and has a high Curie temperature, a good mechanical quality factor, and good piezoelectric properties. The piezoelectric ceramic includes a perovskite-type metal oxide represented by General Formula (1), CuO, and MgO. In the piezoelectric ceramic, the content of CuO is 0.1 mol % or more and 1 mol % or less and the content of MgO is 0.1 mol % or more and 2 mol % or less of the content of the perovskite-type metal oxide.(NaxBa1-y)(NbyTi1-y)O3, where 0.85≦x≦0.92, 0.85≦y≦0.92, 0.95≦x / y≦1.05. General Formula (1):

Owner:CANON KK

Piezoelectric material, piezoelectric element, and electronic equipment

ActiveUS20150295160A1High and stable constantHigh mechanical quality factorPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesOperating temperature rangeMetal

To provide a lead-free piezoelectric material having a high and stable piezoelectric constant in a wide operating temperature range. The piezoelectric material contains a perovskite type metal oxide having the general formula (1), Mn, Mg,(Ba1-xCax)a(Ti1-y-zSnyZrz)O3 (1)(wherein x is in the range of 0.050≦x≦0.200, y is in the range of 0.010≦y≦0.040, and z is in the range of 0≦z≦0.040, provided that x≧0.375(y+z)+0.050, and a is in the range of 0.9925+b≦a≦1.0025+b)wherein the amount b (mol) of Mn on a metal basis per mole of the metal oxide is in the range of 0.0048≦b≦0.0400, and the Mg content on a metal basis per 100 parts by weight of the metal oxide is 0.100 parts by weight or less.

Owner:CANON KK

Piezoelectric material, piezoelectric element, and electronic apparatus

ActiveUS9806251B2Good constantHigh mechanical quality factorInking apparatusPiezoelectric/electrostriction/magnetostriction machinesMetalPerovskite

A piezoelectric material contains a main component containing a perovskite-type metal oxide represented by general formula (1), a first sub-component containing Mn, and a second sub-component containing Bi or Bi and Li. A Mn content relative to 100 parts by weight of the metal oxide is 0.500 parts by weight or less (including 0 parts by weight) in terms of metal, a Bi content relative to 100 parts by weight of the metal oxide is 0.042 parts by weight or more and 0.850 parts by weight or less in terms of metal, and a Li content relative to 100 parts by weight of the metal oxide is 0.028 parts by weight or less (including 0 parts by weight) in terms of metal:(Ba1−x−yCaxSny)α(Ti1−zZrz)O3 (where 0.020≦x≦0.200, 0.020≦y≦0.200, 0≦z≦0.085, 0.986≦α≦1.100) General formula (1).

Owner:CANON KK

Piezoelectric material, piezoelectric element, and electronic apparatus

ActiveUS20160365502A1Satisfactory constantSatisfactory mechanical quality factorTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesOperating temperature rangeOperating temperature

There is provided a lead-free piezoelectric material having a satisfactory piezoelectric constant and mechanical quality factor in the range of device operating temperatures (from −30° C. to 50° C.). The piezoelectric material contains a main constituent containing a perovskite-type metal oxide expressed by the general formula (Ba1-xCax)a(Ti1-yZry)O3, where x, y and a satisfy the 0.030≦x<0.090, 0.030≦y≦0.080, and 0.9860≦a≦1.0200. The material also contains 0.040 to 0.500 part by weight of Mn, 0.042 to 0.850 part by weight of Bi, 0 to 0.028 part by weight of Li, 0.001 to 4.000 part by weight of a third sub-constituent including at least one of Si and B, and 0.001 to 4.000 parts by weight of Cu, each in terms of element relative to 100 parts by weight of the metal oxide.

Owner:CANON KK

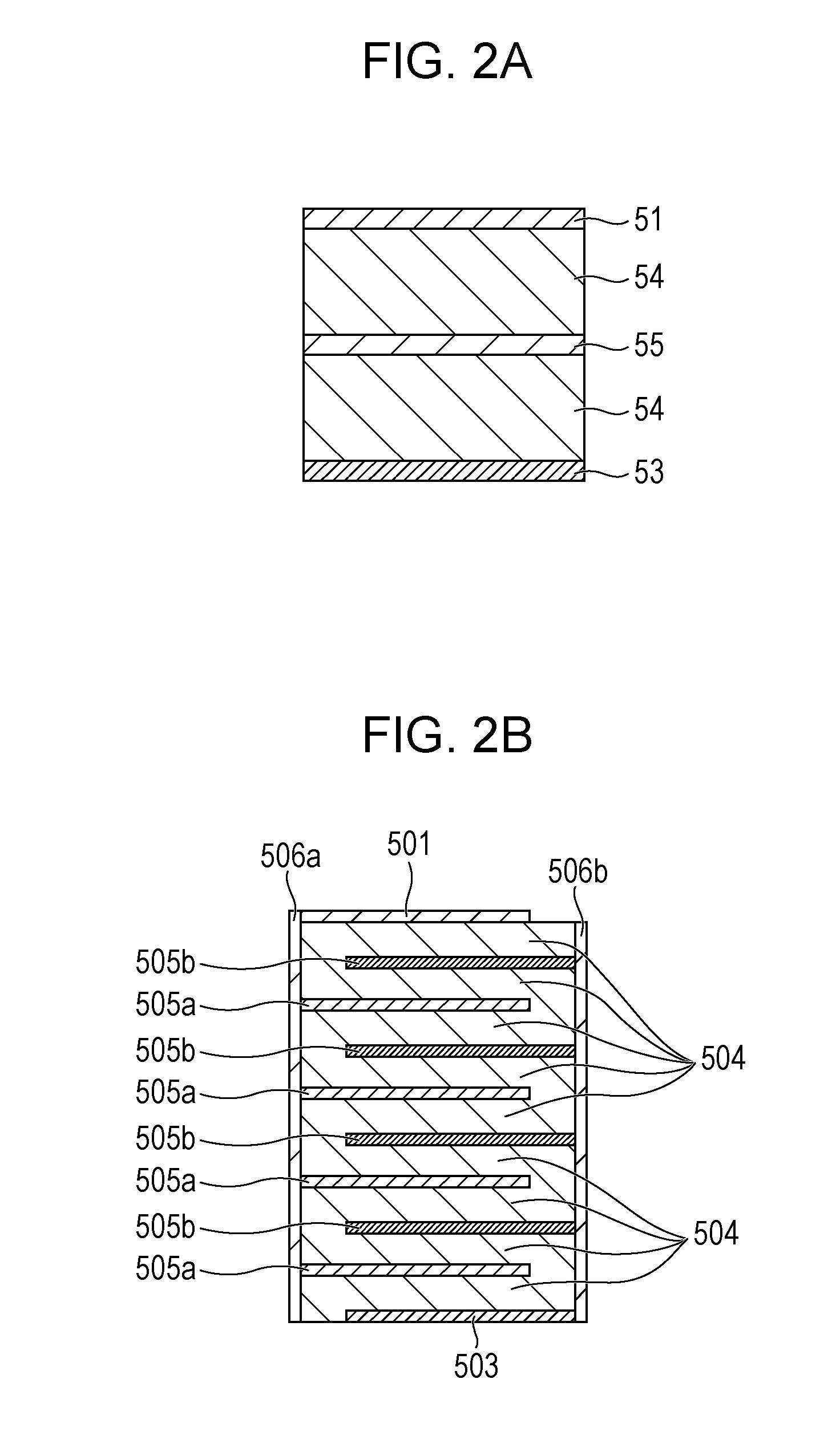

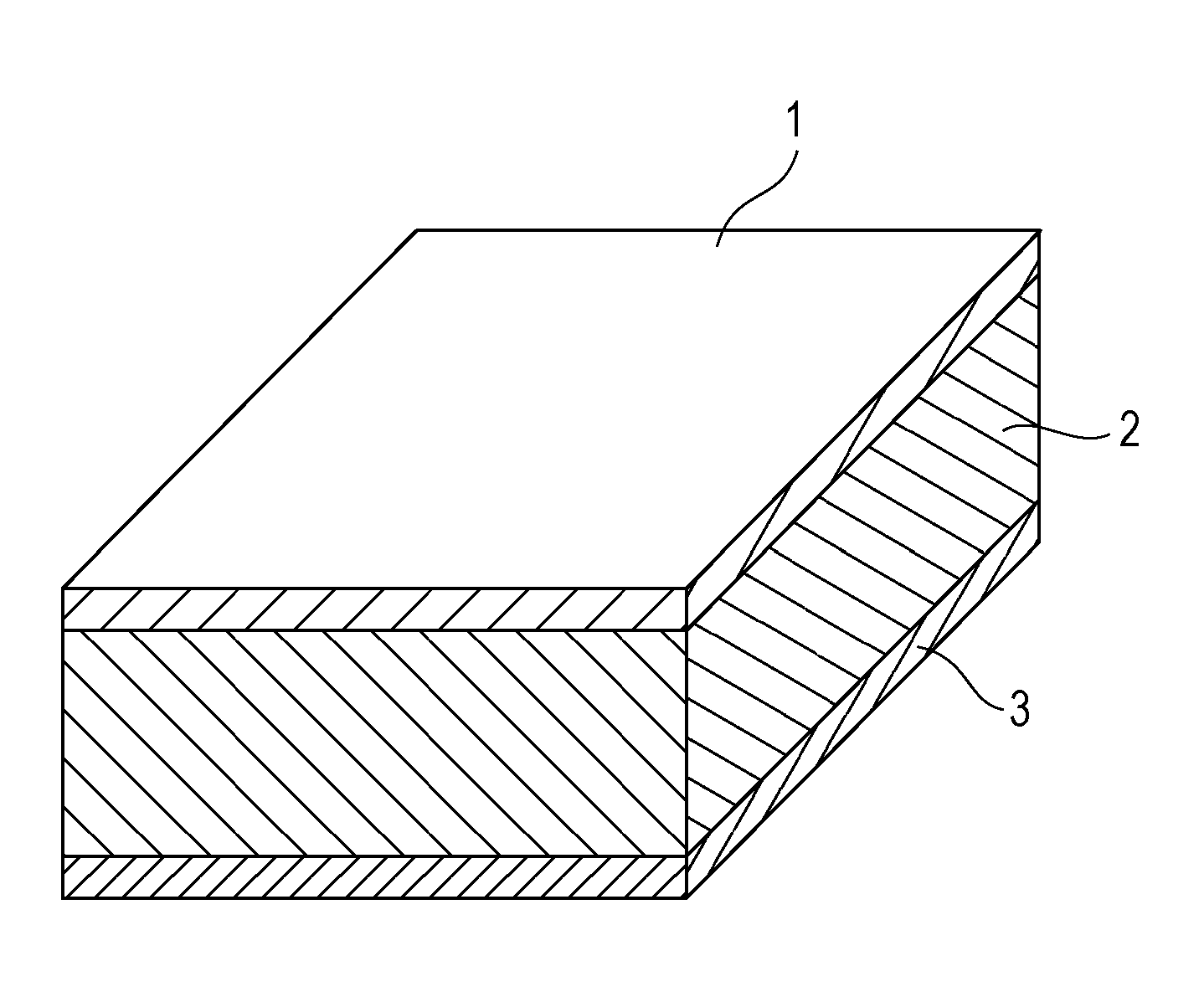

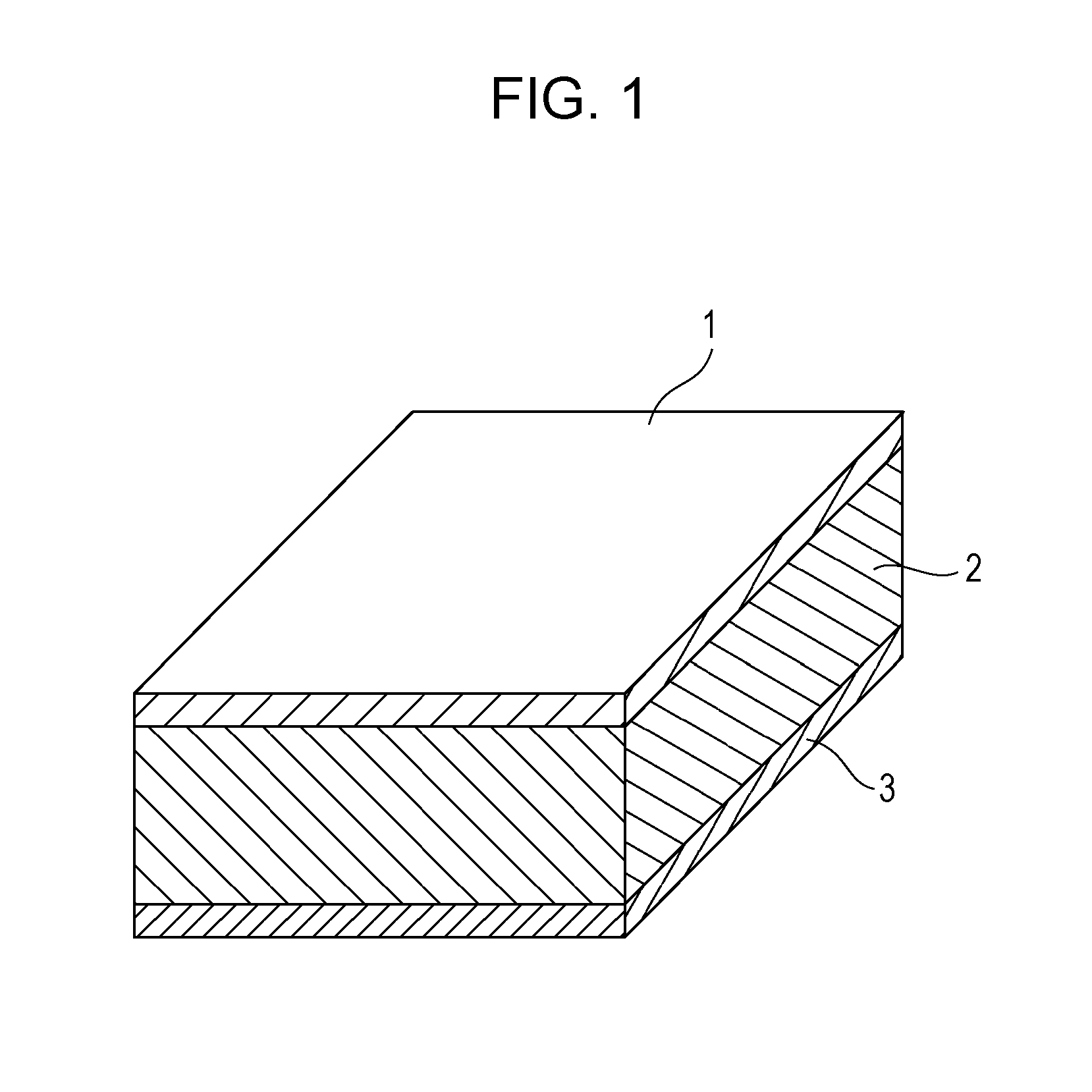

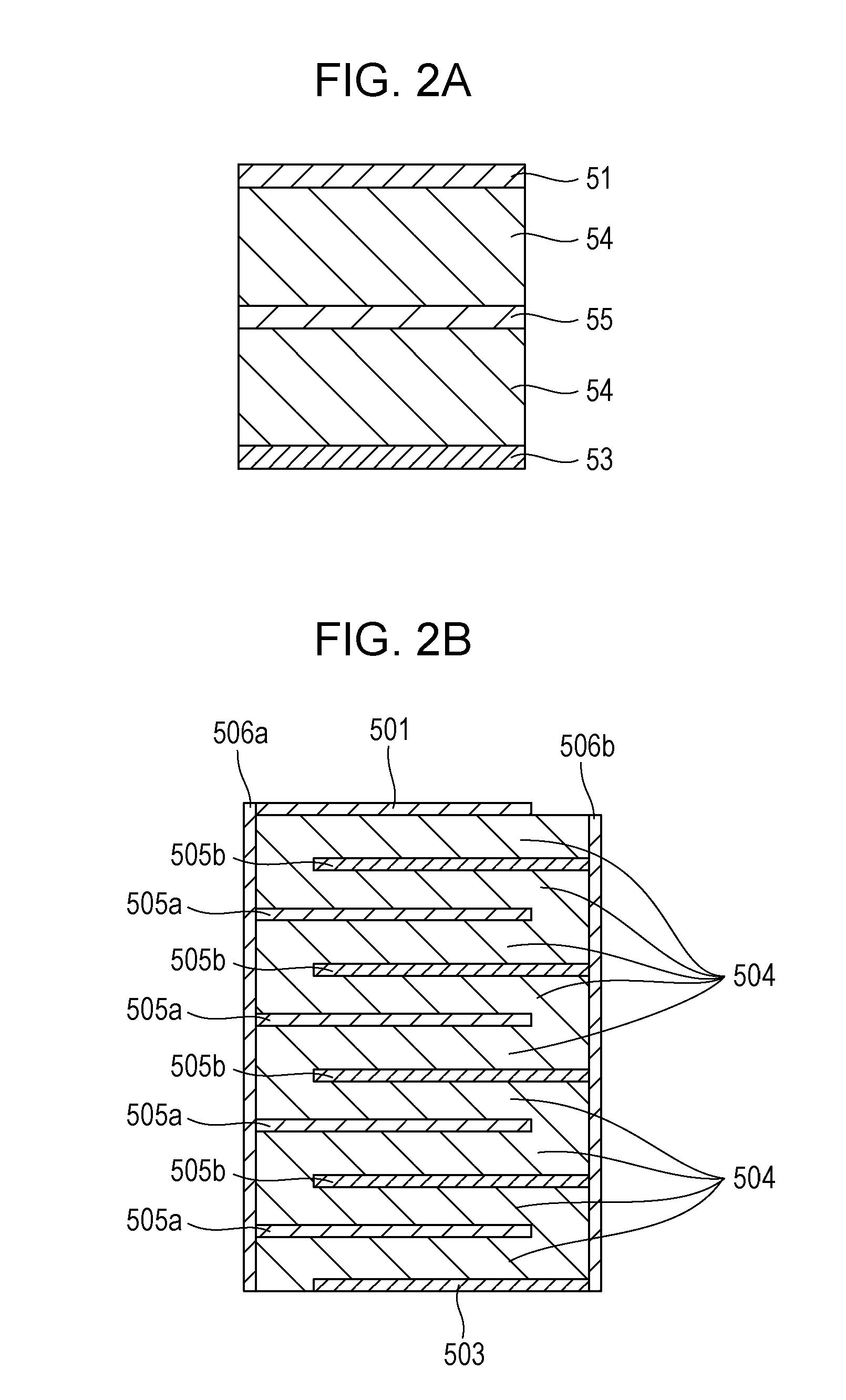

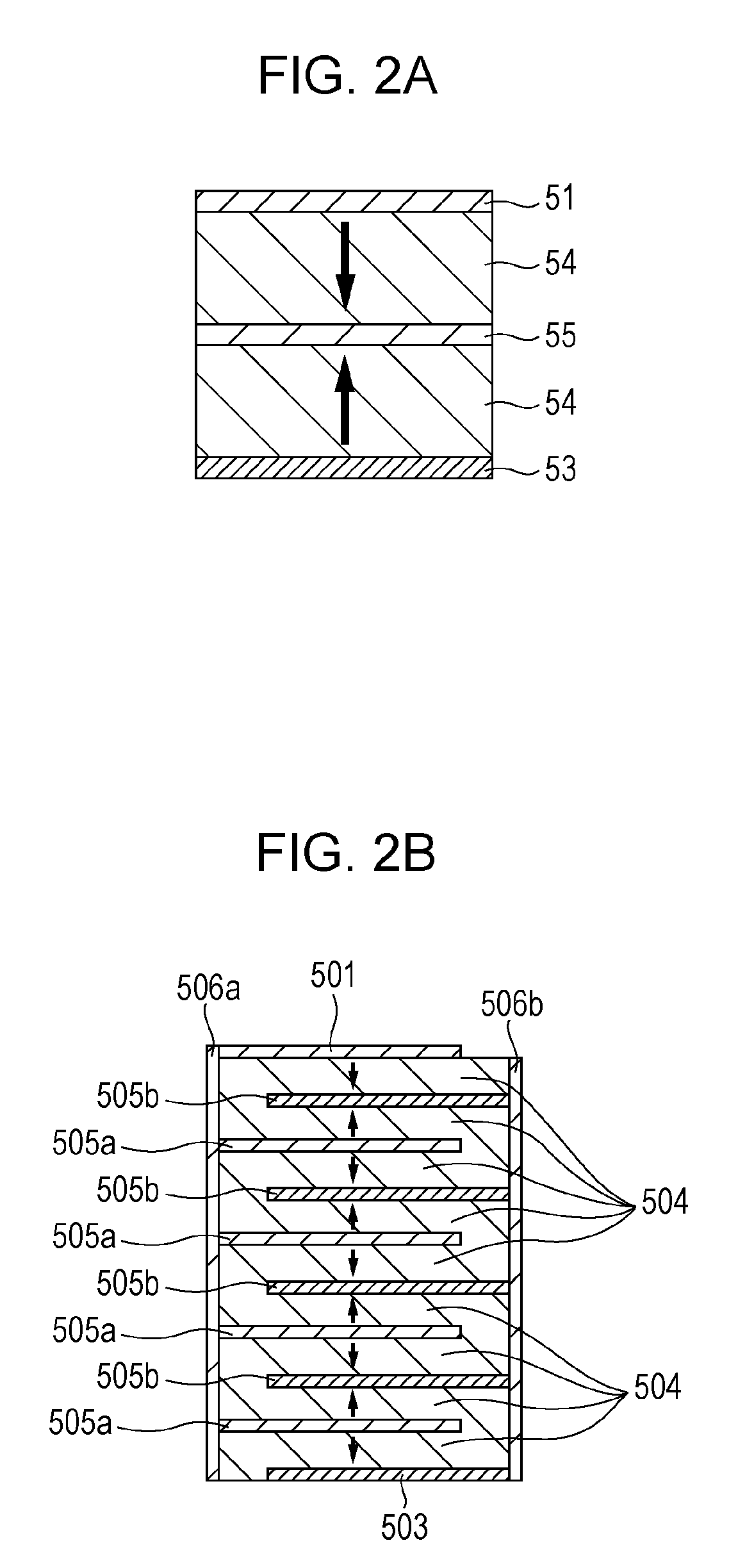

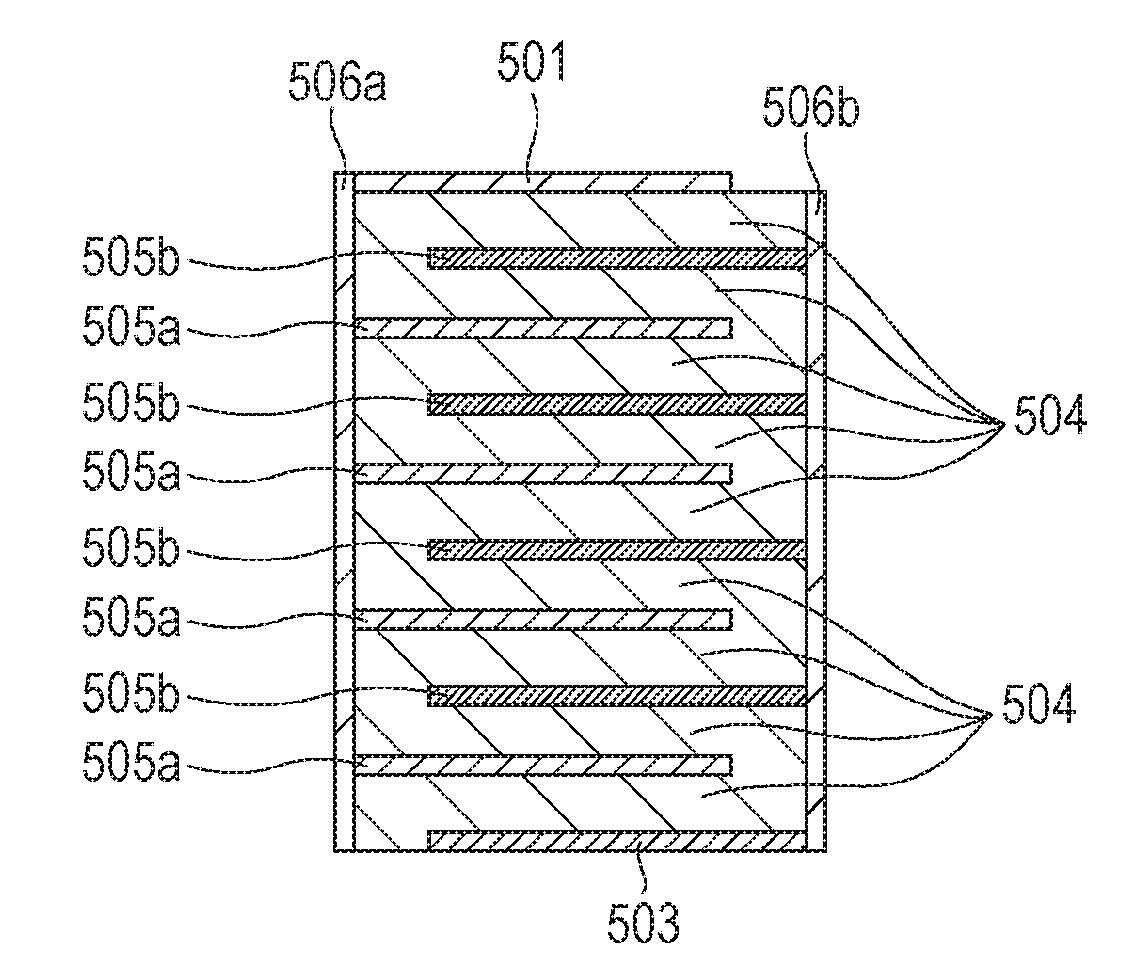

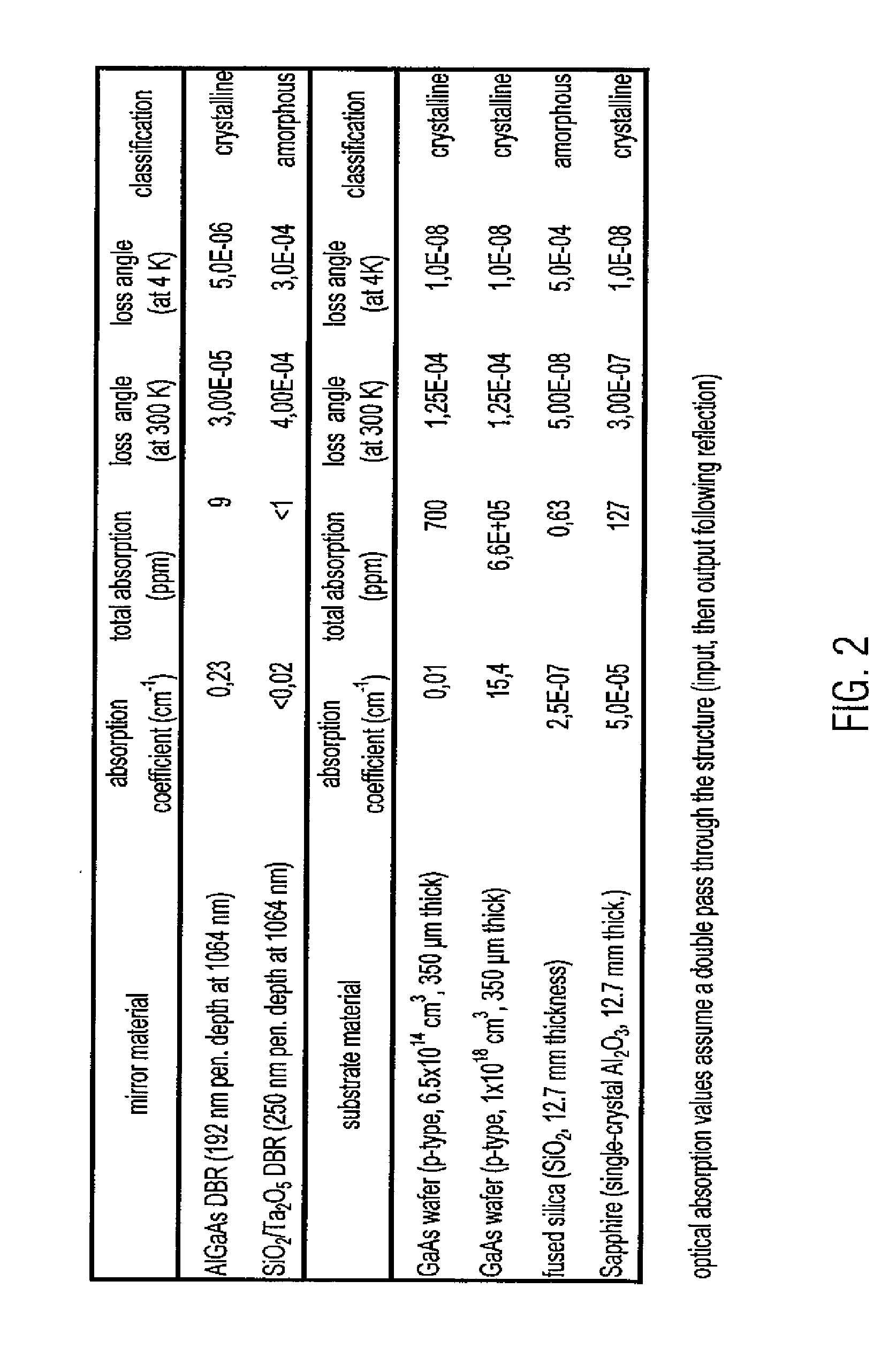

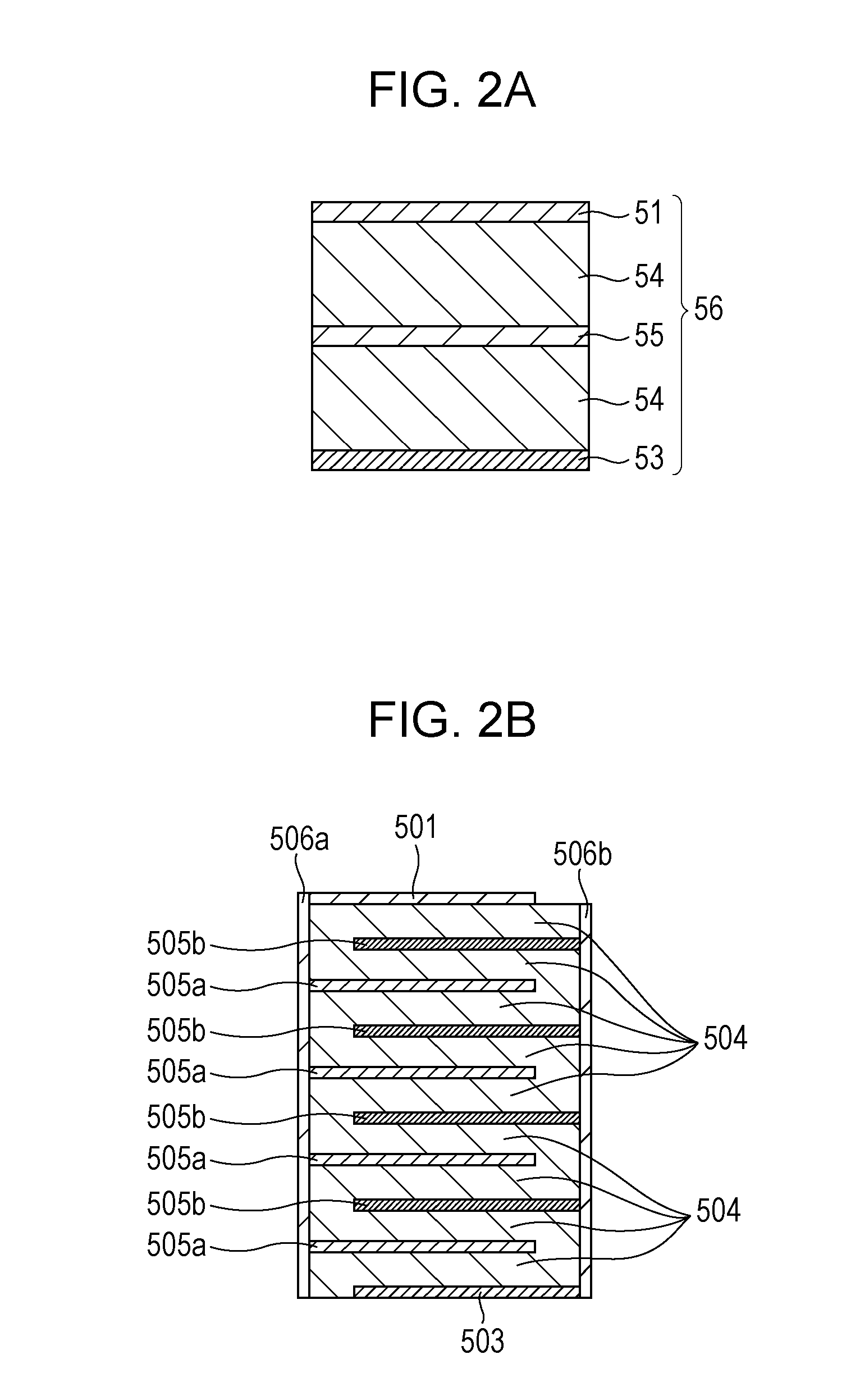

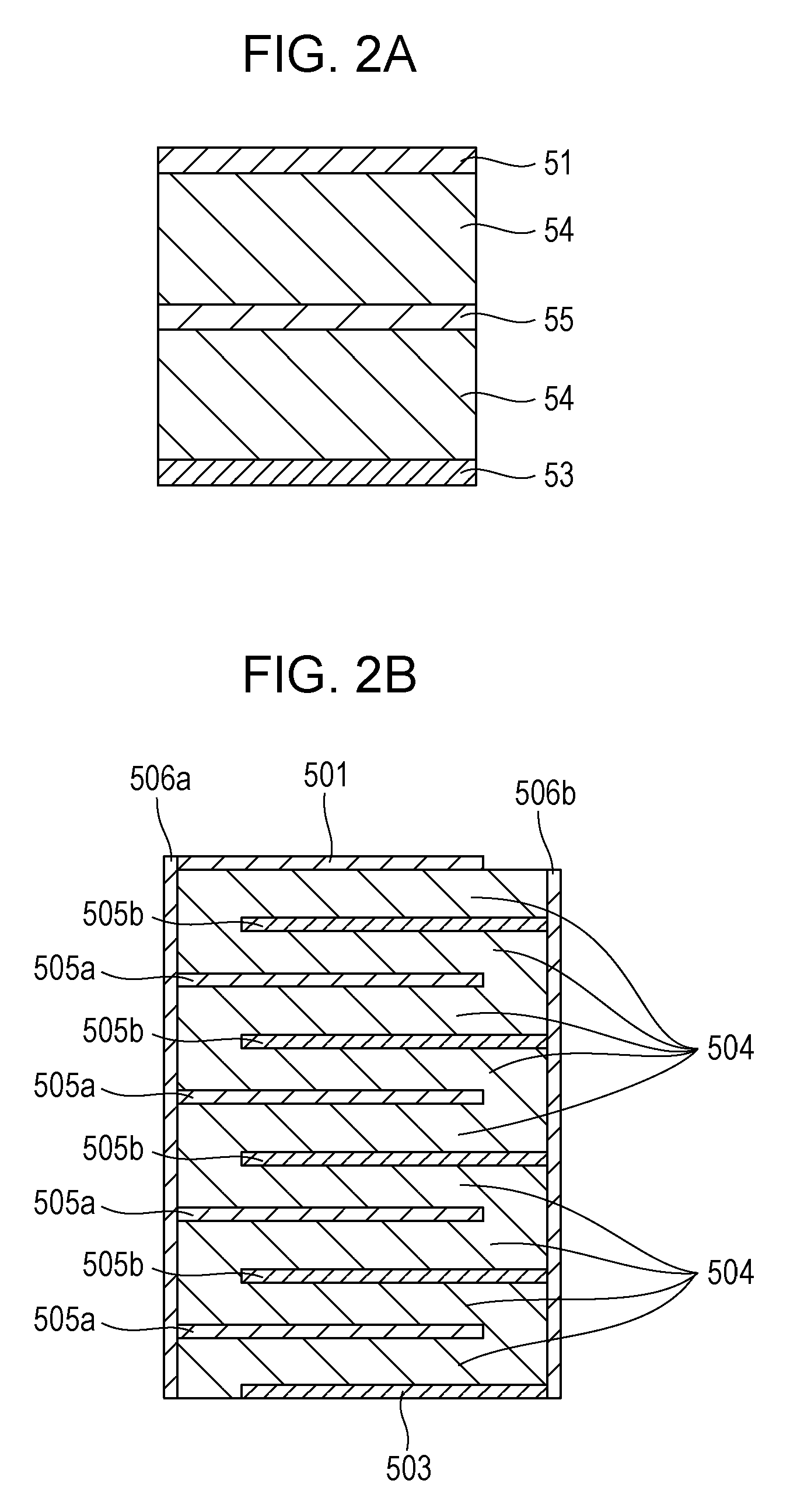

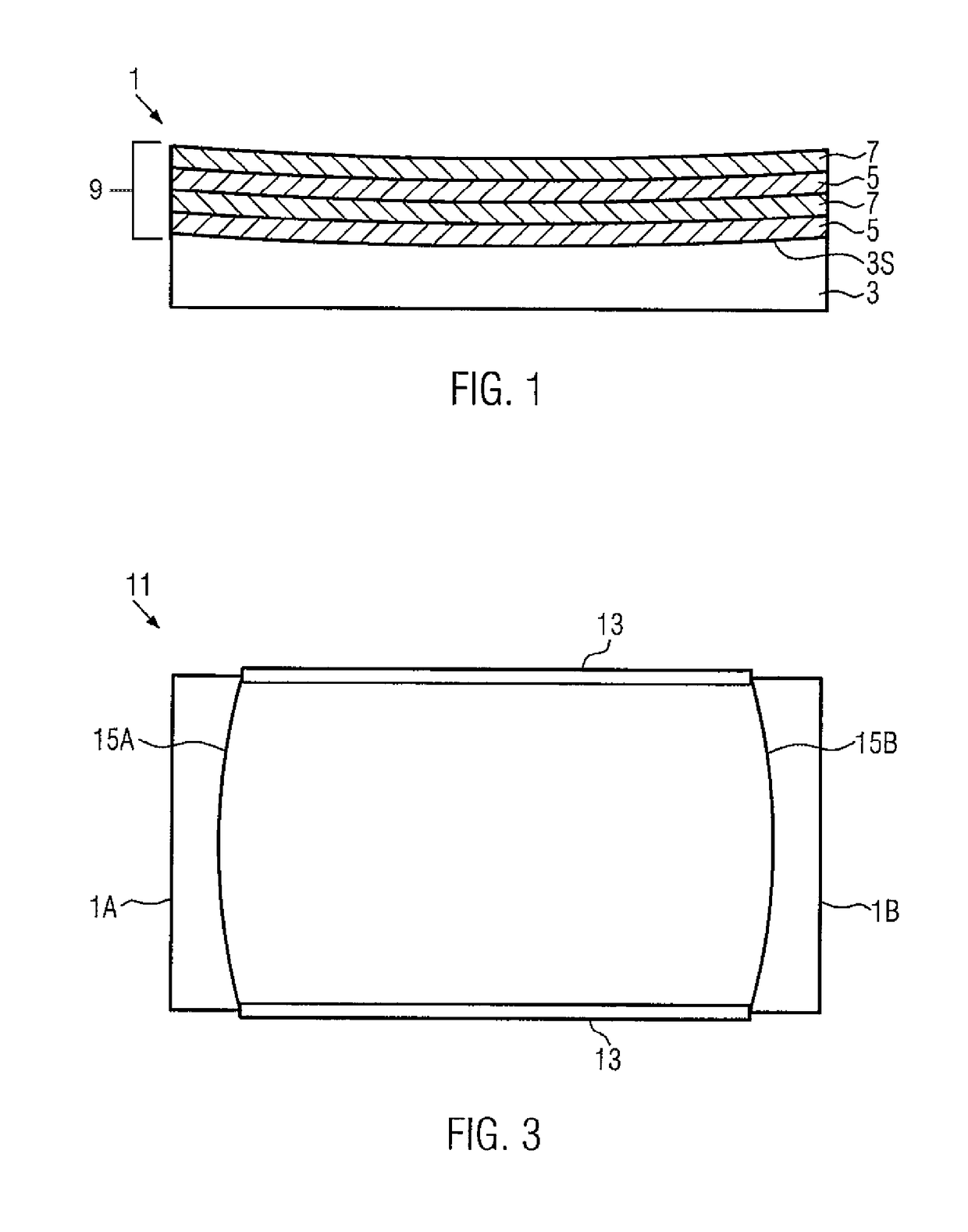

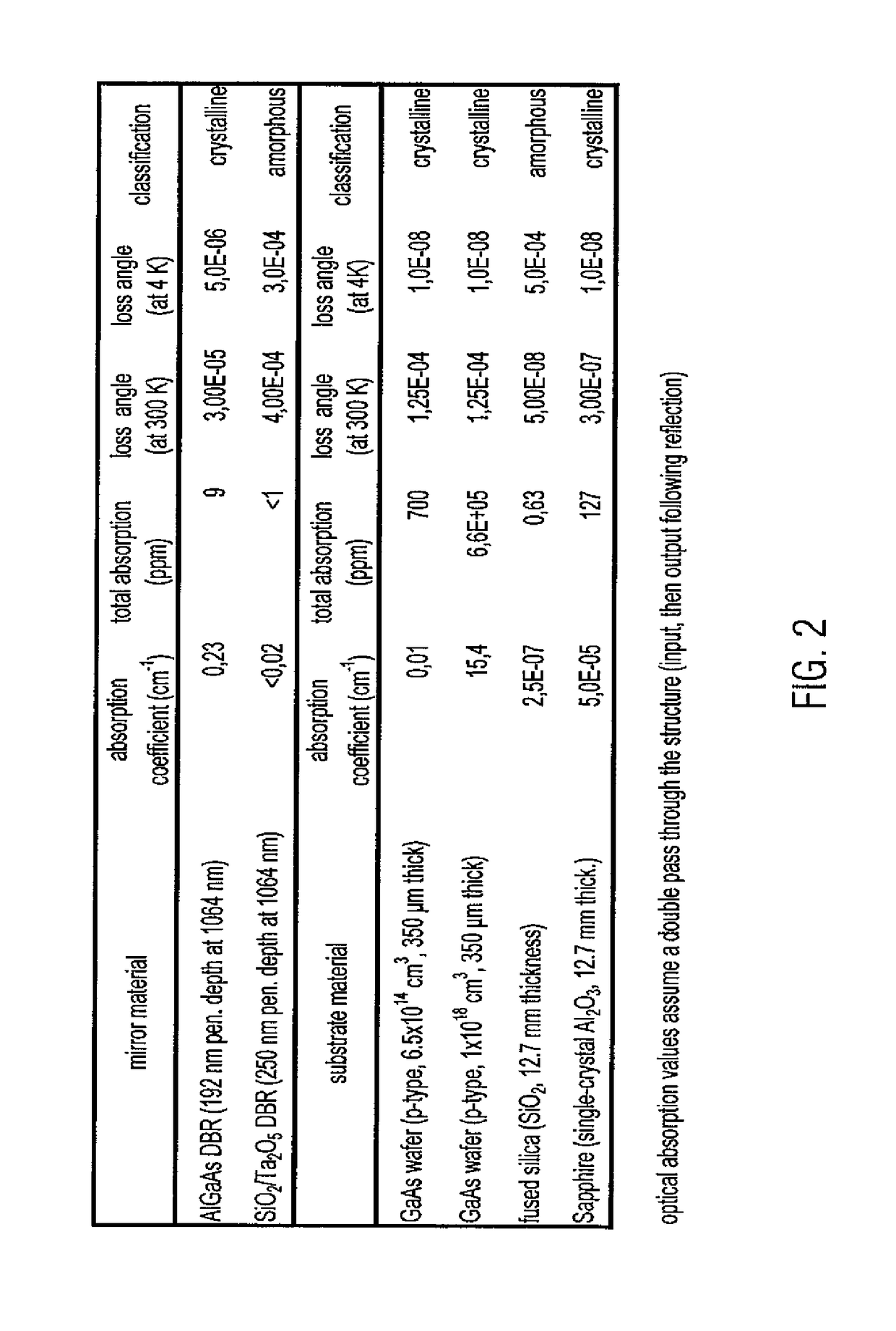

Substrate Transferred Monocrystalline Bragg Mirrors

ActiveUS20140063606A1Reduce mechanical dampingReduce absorptionMirrorsSemiconductor/solid-state device manufacturingRefractive indexSingle crystal

A mirror assembly comprising a carrier substrate; a stack comprising a plurality of alternating monocrystalline semiconductor layers of a first and a second type, wherein the layers of the first type have an index of refraction higher than the layers of the second type thereby forming a Bragg mirror; wherein the carrier substrate is curved having a radius of curvature between 0.1 m and 10 km; wherein the stack is attached to the curved carrier substrate.

Owner:THORLABS INC

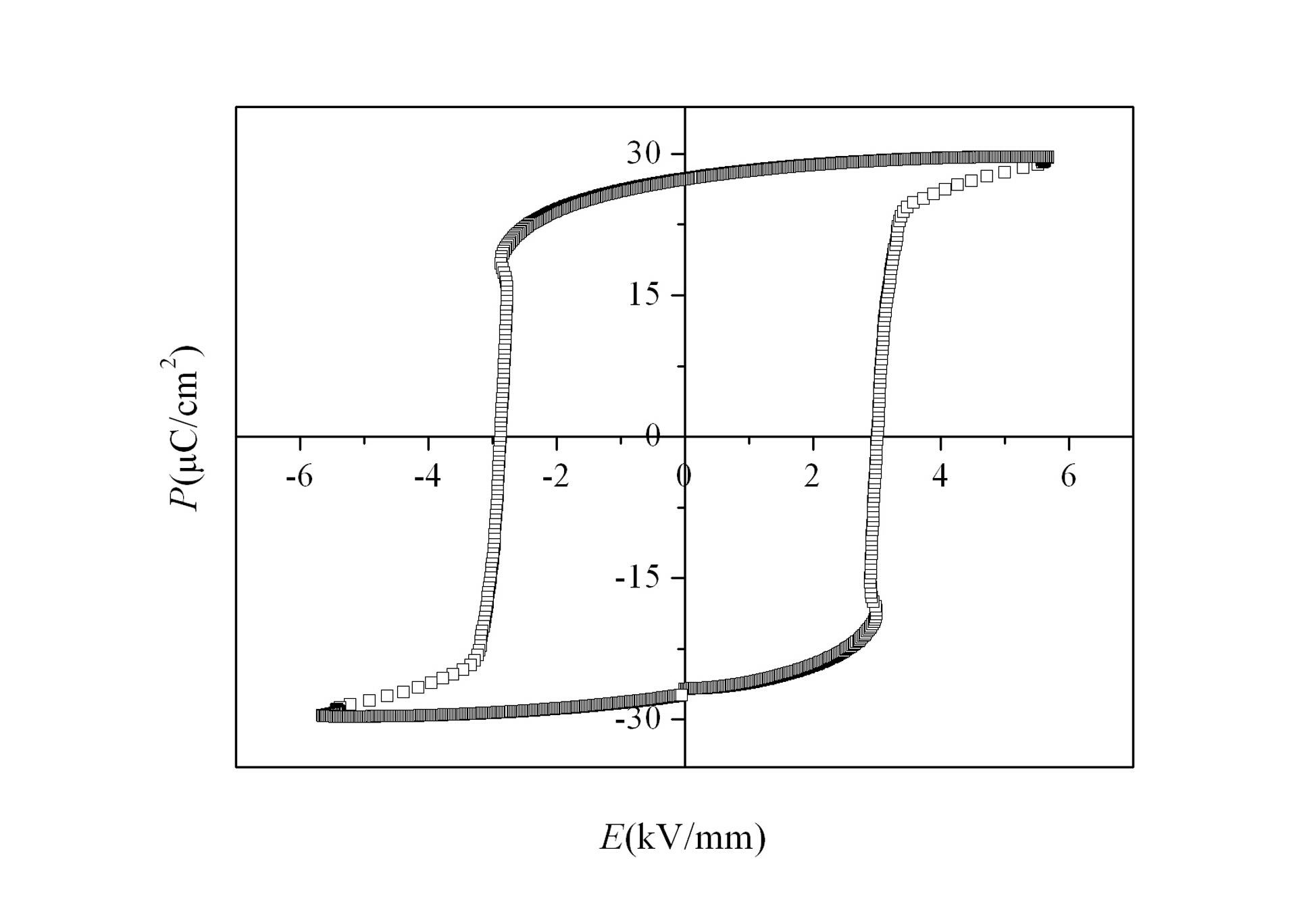

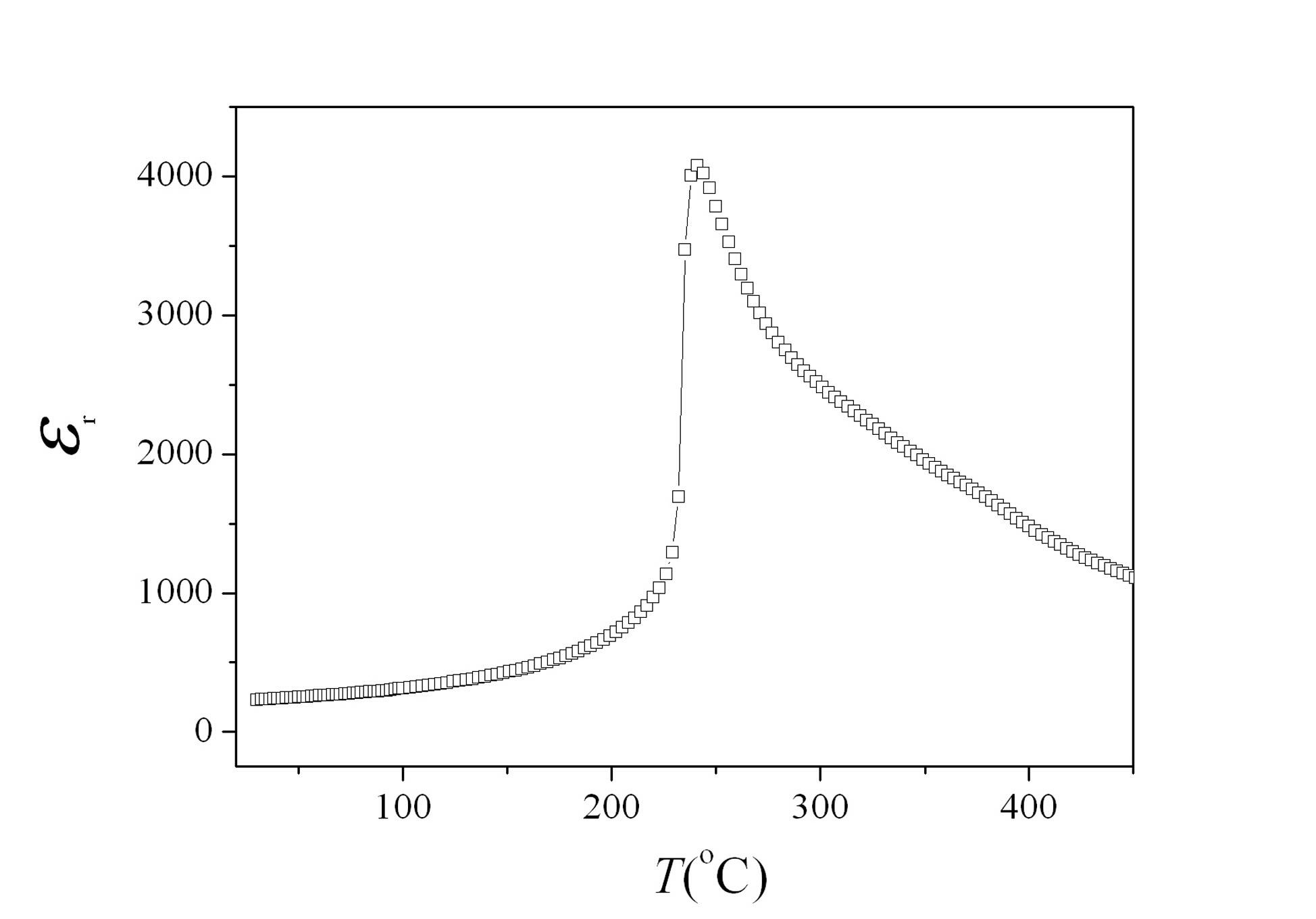

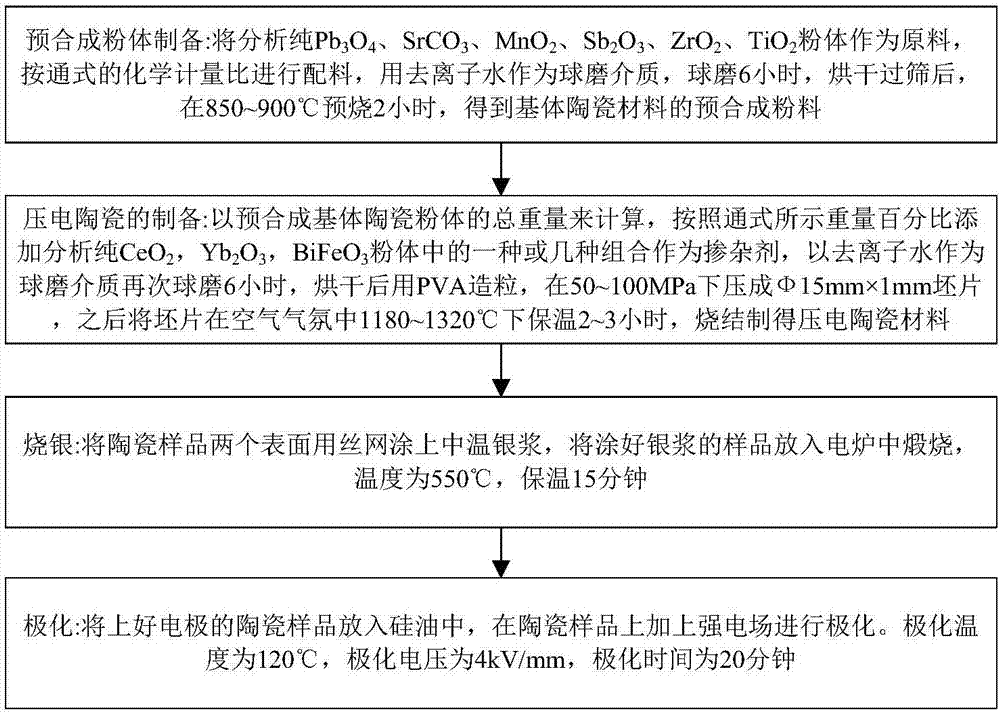

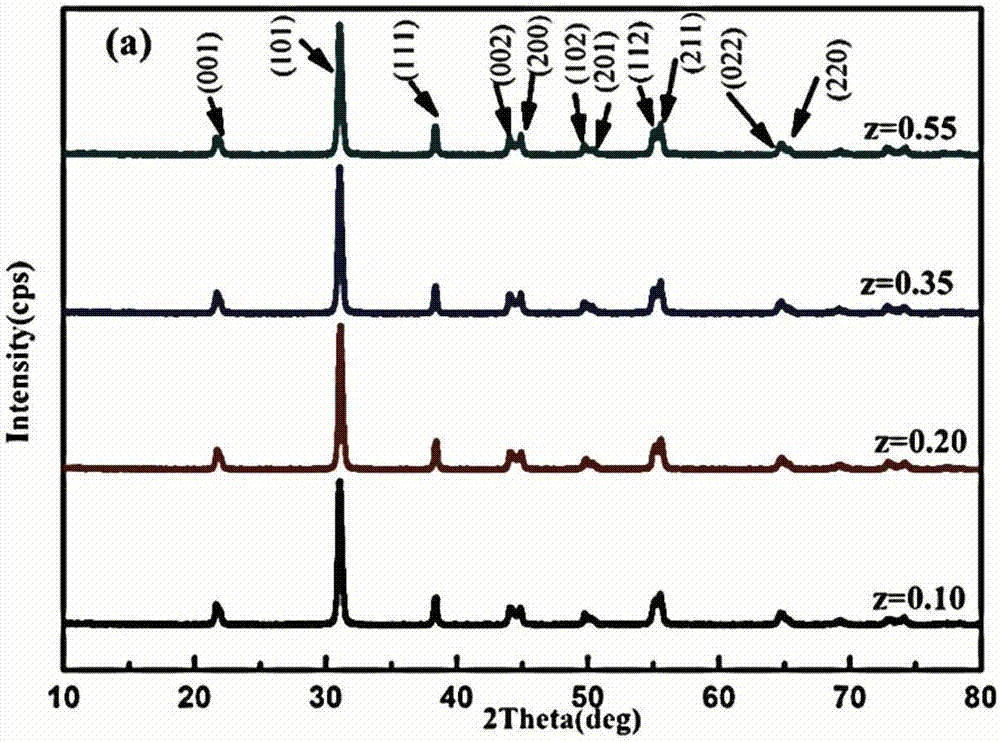

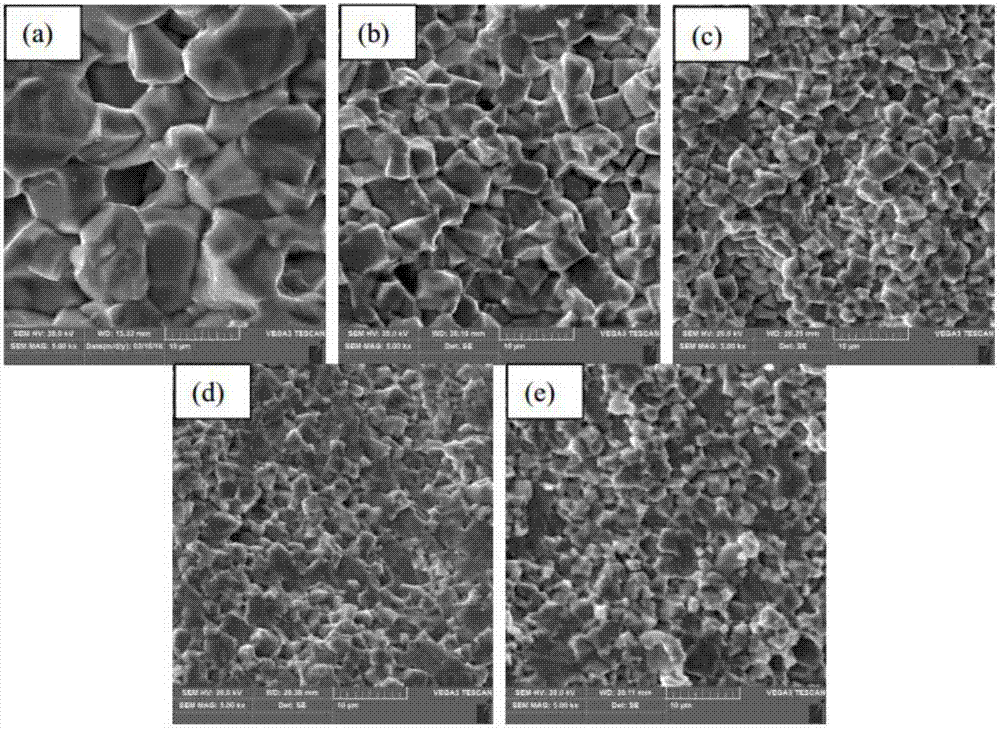

Piezoelectric ceramic material for underwater acoustic transducer and preparation method thereof

InactiveCN107226698AExcellent small signal characteristicsHigh mechanical quality factorPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionElectricityElectromechanical coupling coefficient

The invention discloses a piezoelectric ceramic material for an underwater acoustic transducer and a preparation method thereof. The chemical general formula of the piezoelectric ceramic material is Pb0.98Sr0.02(Mn1 / 3Sb2 / 3)0.08Zr0.47Ti0.45O3+xwt%CeO2+ywt%Yb2O3+zwt%BiFeO3, and in the formula, Pb0.98Sr0.02(Mn1 / 3Sb2 / 3)0.08Zr0.47Ti0.45O3 is base ceramic powder, xwt% represents the weight percentage of CeO2 in the base ceramic powder, ywt% represents the weight percentage of Yb2O3 in the base ceramic powder and zwt% represents the weight percentage of BiFeO3 in the base ceramic powder. The piezoelectric ceramic material has a piezoelectric constant greater than or equal to 300p C / N, an electromechanical coupling factor greater than or equal to 0.56, the minimum dielectric loss of 2.74% in a strong alternating electric field of 5 kV / cm and a mechanical quality factor greater than or equal to 1301. The piezoelectric ceramic material has piezoelectric properties and loss properties satisfying high power underwater acoustic transducer demands and has a wide application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

Piezoelectric material, piezoelectric element, and electronic apparatus

ActiveUS20150041701A1Satisfactory constantSatisfactory mechanical quality factorInking apparatusPiezoelectric/electrostriction/magnetostriction machinesMetalPerovskite

Provided is a lead-free piezoelectric material having satisfactory piezoelectric constant and mechanical quality factor in a device driving temperature range (−30° C. to 50° C.) The piezoelectric material includes a main component containing a perovskite-type metal oxide represented by Formula 1, a first auxiliary component composed of Mn, and a second auxiliary component composed of Bi or Bi and Li. The content of Mn is 0.040 parts by weight or more and 0.500 parts by weight or less based on 100 parts by weight of the metal oxide on a metal basis. The content of Bi is 0.042 parts by weight or more and 0.850 parts by weight or less and the content of Li is 0.028 parts by weight or less (including 0 parts by weight) based on 100 parts by weight of the metal oxide on a metal basis.(Ba1-xCax)a(Ti1-yZry)O3 . . . (1), wherein, 0.030≦x<0.090, 0.030≦y≦0.080, and 0.9860≦a≦1.0200.

Owner:CANON KK

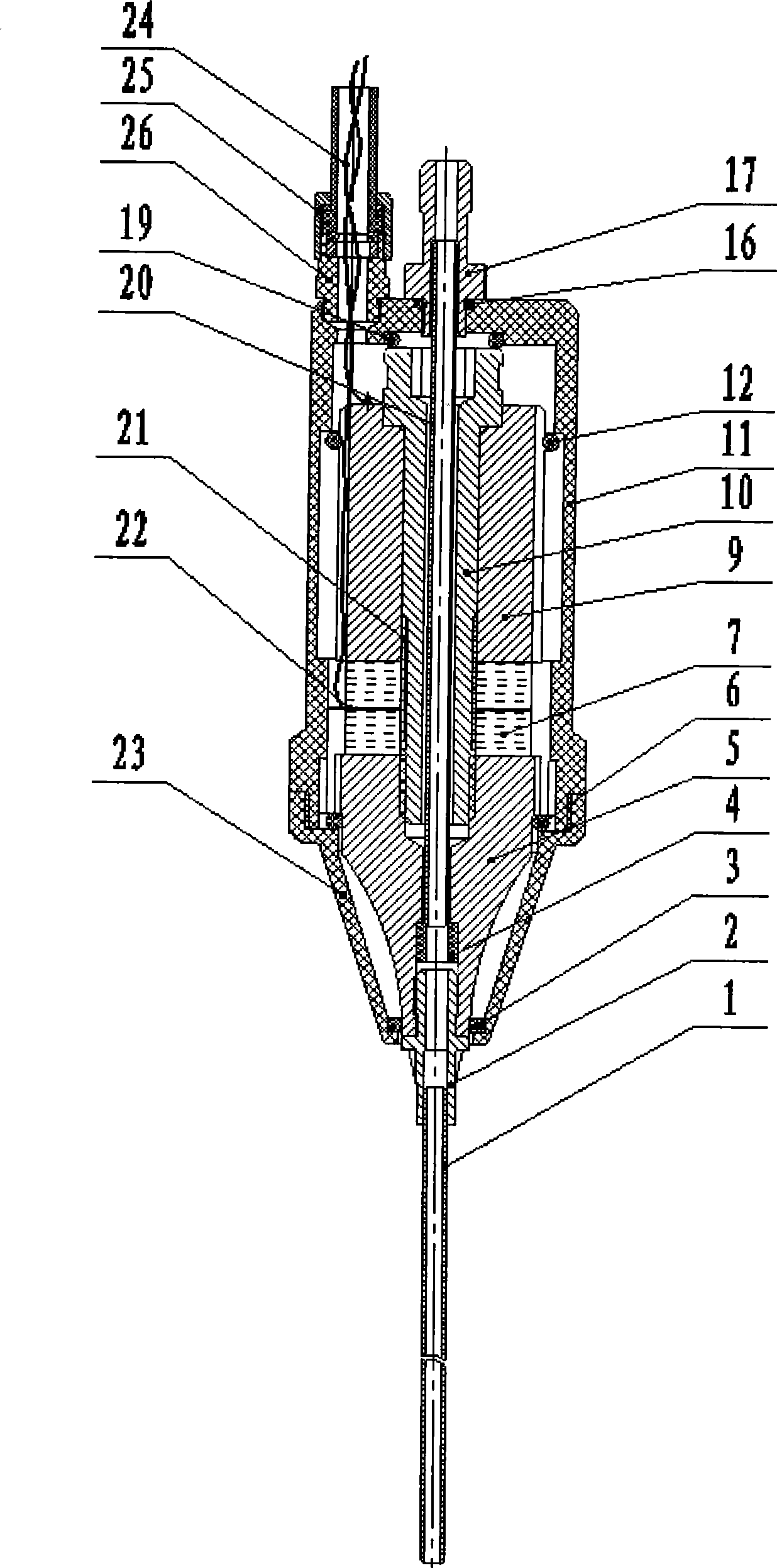

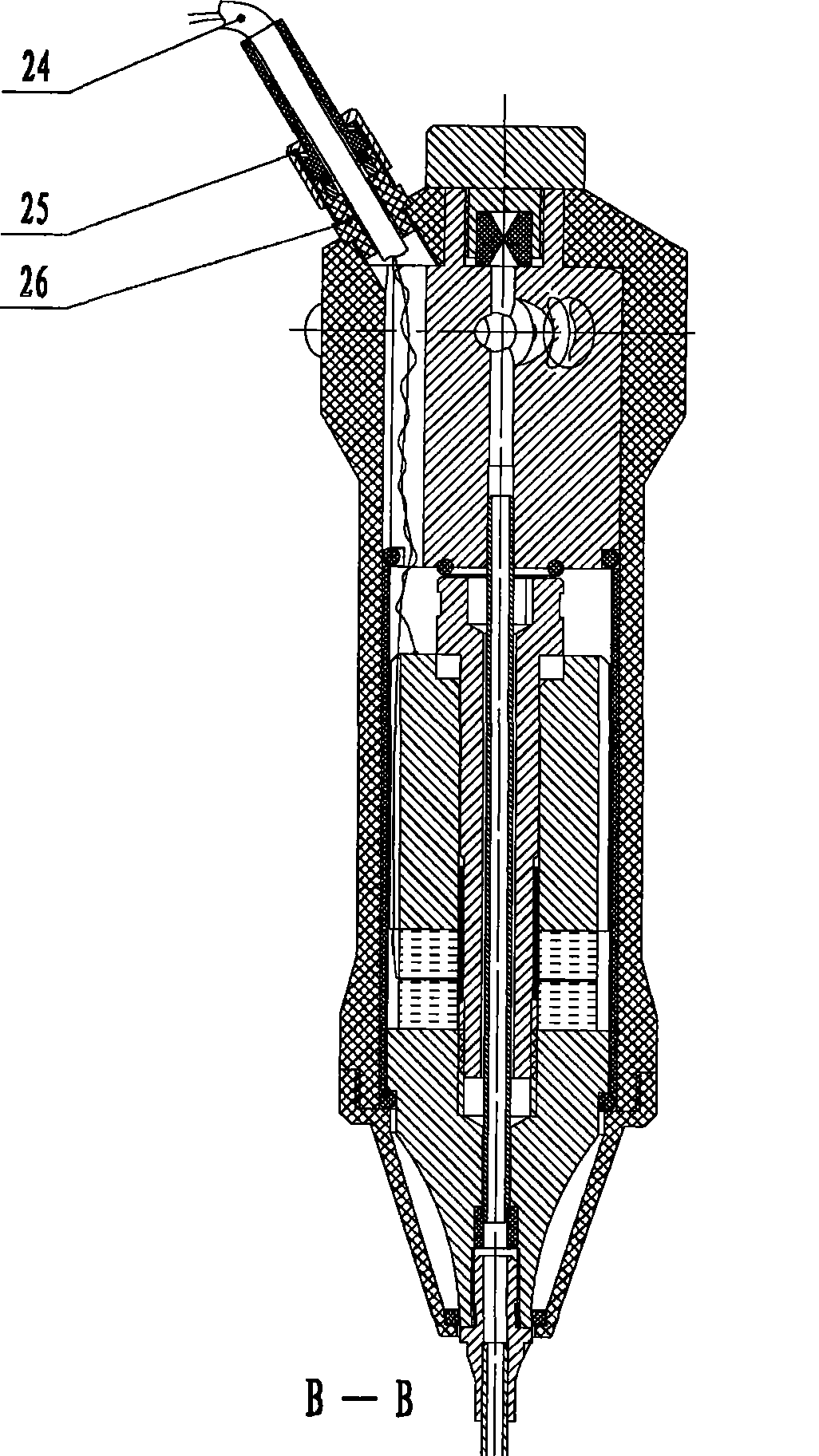

In vivo ultrasound lithotripter

ActiveCN101467910ALower impedanceLow calorific valueOrgan movement/changes detectionSurgical instrument detailsUltrasonic sensorTransformer

The invention relates to an intracorporal ultrasonic lithotripter consisting of an ultrasonic transducer and an automatic frequency tracking system, wherein, the ultrasonic transducer comprises more than two groups of piezoelectric ceramic pieces, a counterweight, the piezoelectric ceramic pieces and an amplitude transformer are connected together through hollow bolts, and the ultrasonic transducer is installed in the housing handle made of fire-resistant resin materials. A broken stone probe is connected with the front end of the amplitude transformer, a back cover is connected with the back end of the housing handle by screw threads, a pneumatic stone breaking device or a laser stone breaking device can be connected after the back cover is took down, an air regulation device which can regulate the adsorptive pressure in the operation process conveniently is installed on the side of the back end of the housing handle. The whole transducer can be fumigated in 125 DEG C. The automatic frequency tracking system adopts DDS and large-scale programmable devices, a direct digital frequency synthesizer to generate driving signals of the ultrasonic transducer and a strategy of autotracking after scanning search, thus, the automatic frequency tracking system adapts to the discreteness of the transducer and overcomes effects of a variety of causes on the resonance points.

Owner:BEIJING ANHEJIALIER TECH CO LTD

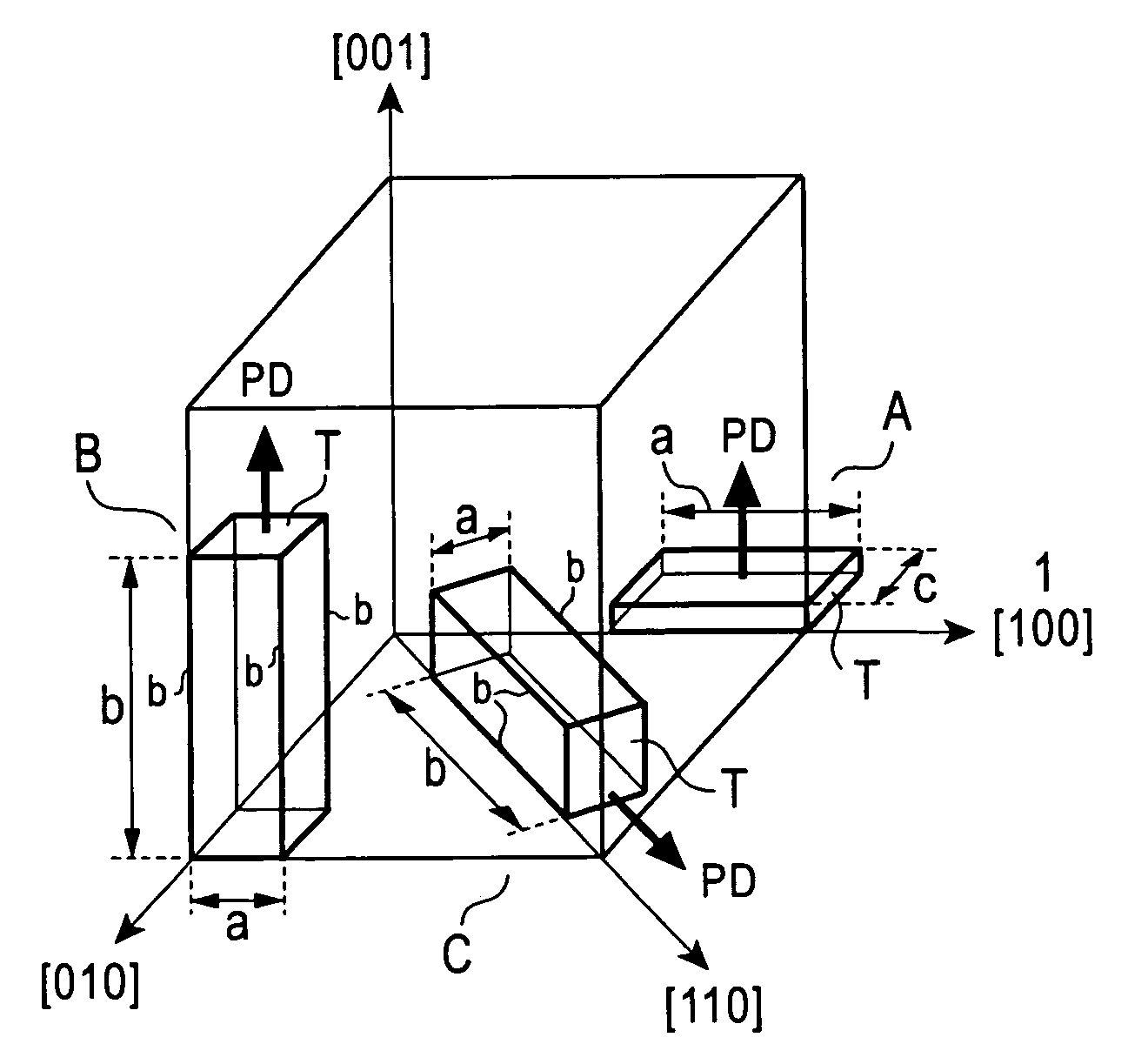

Piezoelectric single crystal and piezoelectric single-crystal device and method for manufacturing the same

InactiveUS7518292B2Stable growthHigh mechanical quality factorPiezoelectric/electrostrictive device manufacture/assemblyPolycrystalline material growthIndiumSingle crystal

An inexpensive piezoelectric single-crystal device being excellent in the piezoelectric characteristics and having a complex perovskite structure can be provided by adding a specific additive to a lead magnesium niobate-lead titanate (PMN-PT) single crystal or a lead zinc niobate-lead titanate (PZN-PT or PZNT) single crystal. Specifically, the piezoelectric single crystal has a complex perovskite structure and is formed of a composition containing 35 to 98 mol % lead magnesium niobate [Pb(Mg1 / 3Nb2 / 3)O3] or lead zinc niobate [Pb(Zn1 / 3Nb2 / 3)O3], 0.1 to 64.9 mol % lead titanate [PbTiO3], and 0.05 to 30 mol % lead indium niobate [Pb(In1 / 2Nb1 / 2)O3] wherein calcium is substituted for 0.05 to 10 mol % lead in the composition.

Owner:KAWATETABU MINING

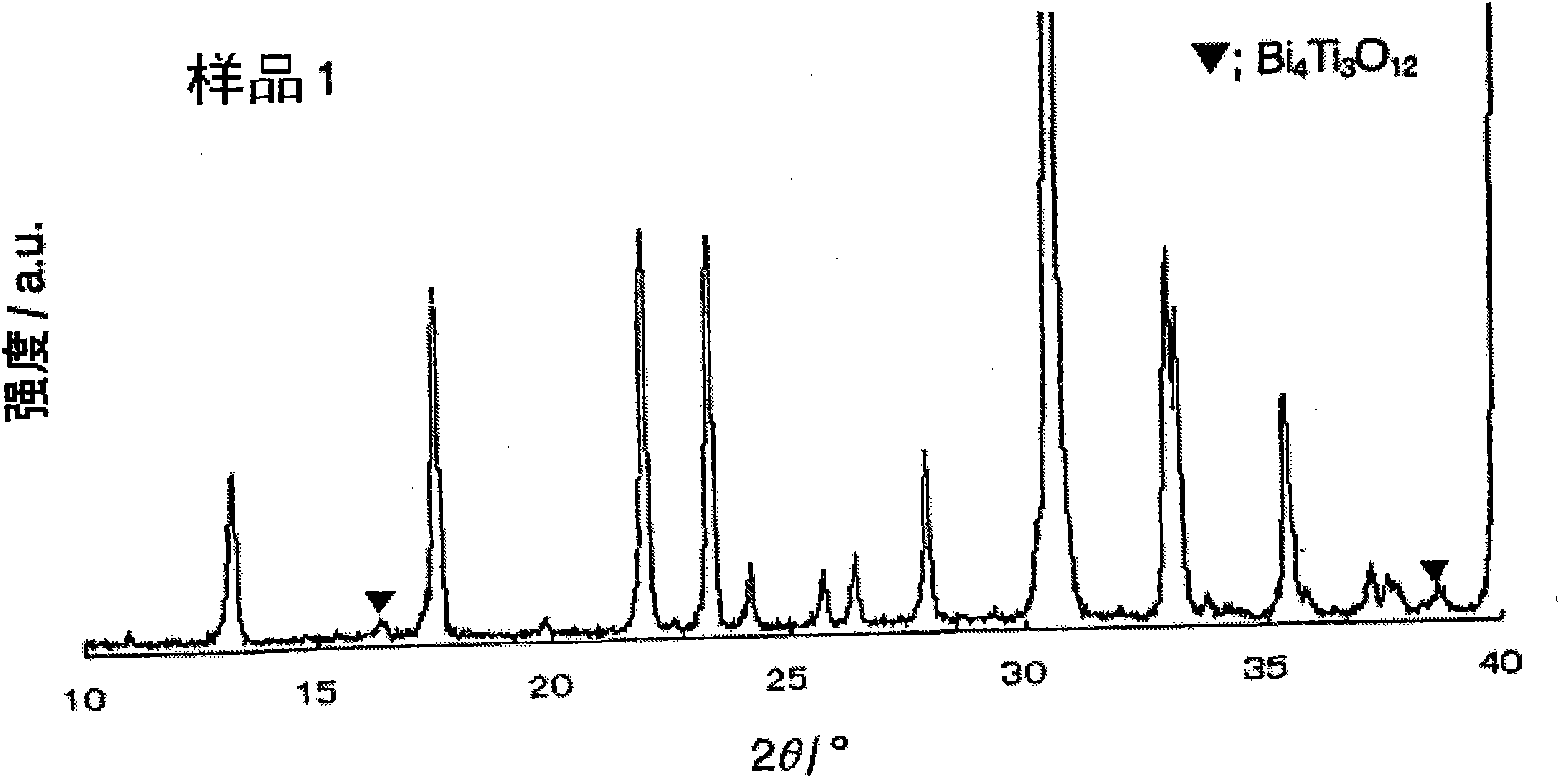

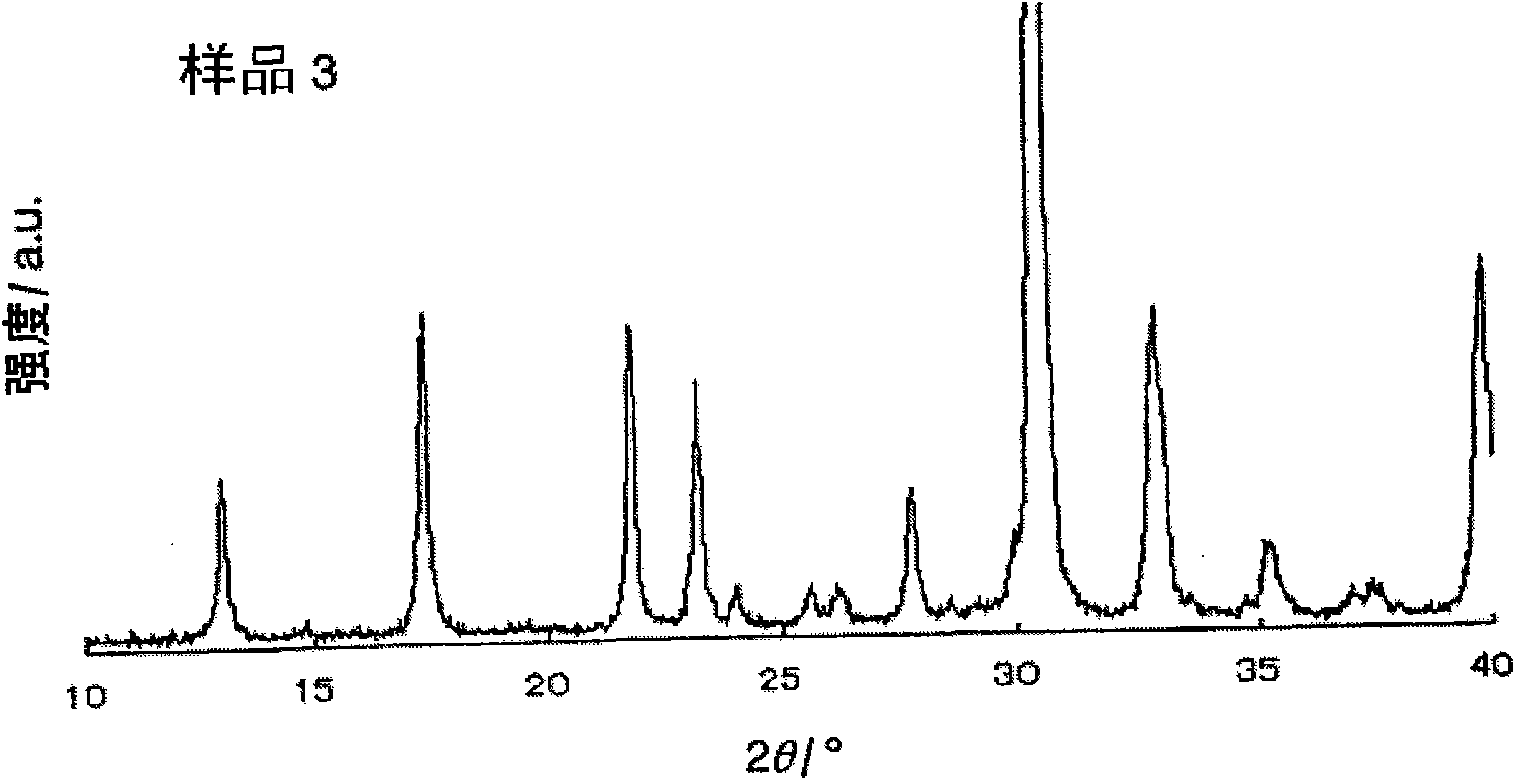

Piezoelectric ceramic composition and piezoelectric device

InactiveCN101657393AExcellent piezoelectric propertiesHigh mechanical quality factorPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksLanthanideBismuth

Disclosed is a piezoelectric ceramic composition mainly composed of a bismuth lamellar compound containing Na, Bi, Co and an Ln (lanthanoid). Also disclosed is a piezoelectric ceramic composition mainly composed of a compound containing Na, Bi, Ti, Co and an Ln (lanthanoid) and having a crystal phase represented by Na0.5Bi4.5Ti4O15. The piezoelectric ceramic compositions are characterized in thatthe atomic ratio satisfies the following relation: 0 < Ln / (Na + Bi + Ln) = 0.04.

Owner:NGK SPARK PLUG CO LTD

High-quality-factor leadless piezoelectric ceramic

The invention provides potassium-sodium niobate based leadless piezoelectric ceramic which has high mechanical quality factor and a preparation process of the piezoelectric ceramic. The chemical general formula of the piezoelectric ceramic is 0.956(0.988-x)(K<0.37>Na<0.63>)<0.86>Ca<0.04>Li<0.02>Nb<0.85>O<3>-0.044(0.988-x)K<0.85>Ti<0.85>Nb<1.15>O<5>-xBaSnO3-yMnO-zCeO, wherein 0.024 <= x <= 0.073, 0.005 <= y <= 0.09, 0.005 <= z <= 0.08, x, y and z being molar weight. The ceramic system is higher than 240 pC / N in piezoelectric constant, is more than 0.3 in planar electromechanical coupling factor, is not less than 2100 in dielectric constant, is lower than 0.02 in dielectric loss at room temperature under 1 kHz, and is not lower than 110 in mechanical quality factor.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Piezoelectric material, piezoelectric element, and electronic apparatus

ActiveUS9761788B2Satisfactory piezoelectric constantHigh mechanical quality factorInking apparatusPiezoelectric/electrostriction/magnetostriction machinesElectronMetal

Provided is a lead-free piezoelectric material having satisfactory piezoelectric constant and mechanical quality factor in a device driving temperature range (−30° C. to 50° C.) The piezoelectric material includes a main component containing a perovskite-type metal oxide represented by Formula 1, a first auxiliary component composed of Mn, and a second auxiliary component composed of Bi or Bi and Li. The content of Mn is 0.040 parts by weight or more and 0.500 parts by weight or less based on 100 parts by weight of the metal oxide on a metal basis. The content of Bi is 0.042 parts by weight or more and 0.850 parts by weight or less and the content of Li is 0.028 parts by weight or less (including 0 parts by weight) based on 100 parts by weight of the metal oxide on a metal basis.(Ba1-xCax)a(Ti1-yZry)O3 . . . (1), wherein, 0.030≦x<0.090, 0.030≦y≦0.080, and 0.9860≦a≦1.0200.

Owner:CANON KK

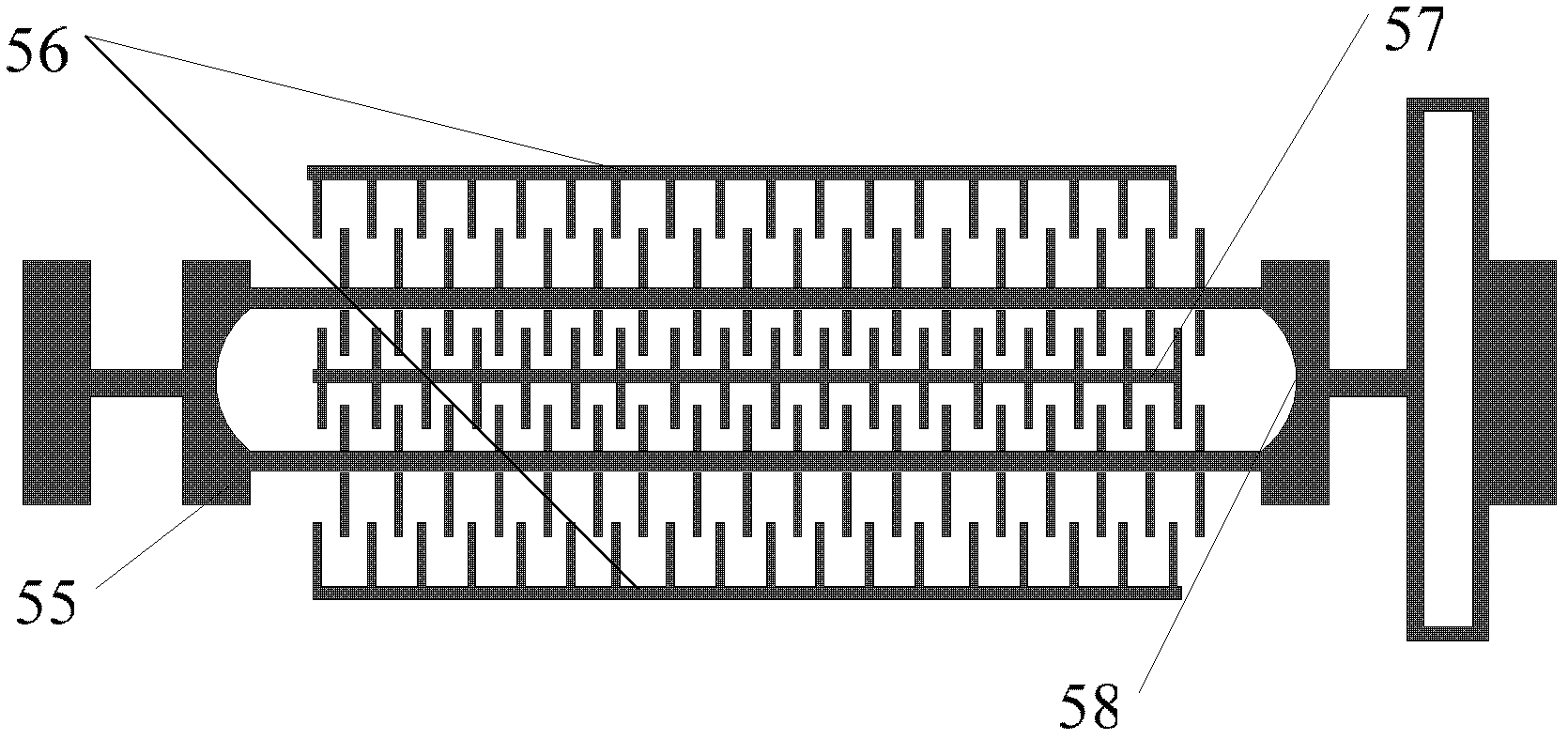

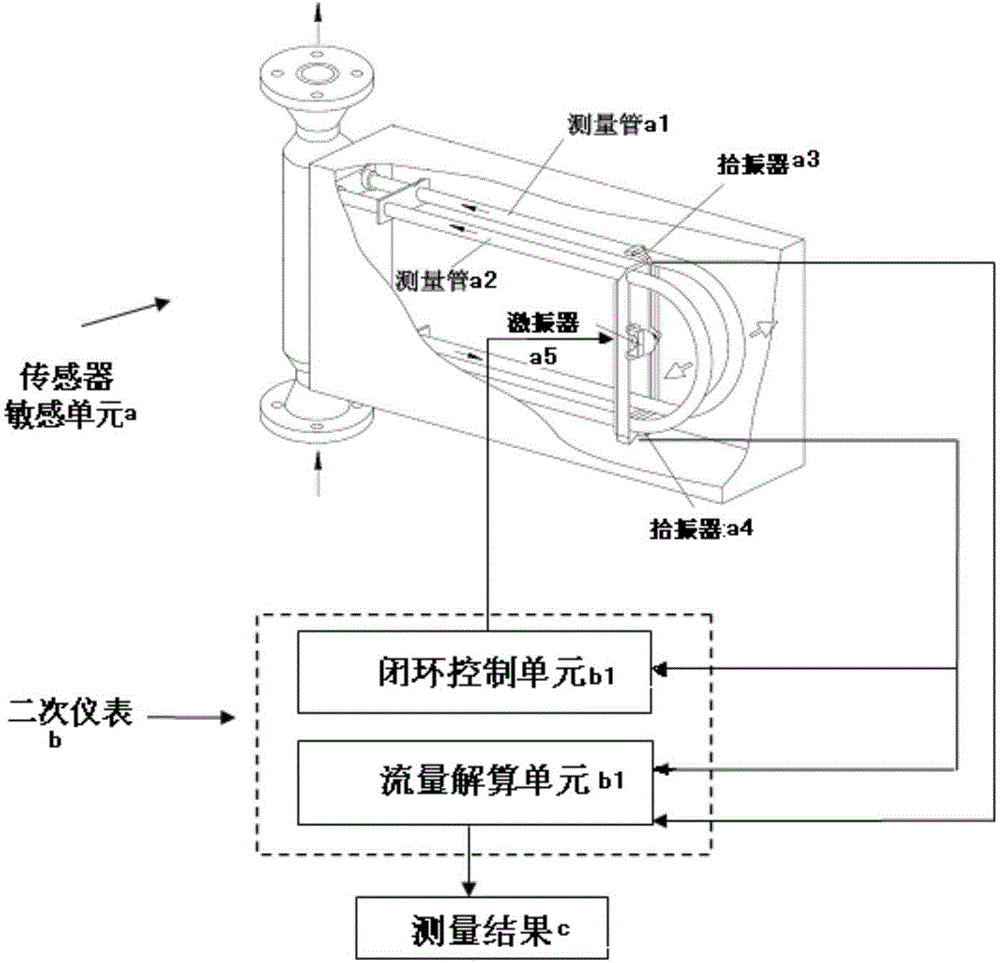

Mass flow sensor

InactiveCN104406645AReduce resistanceHigh mechanical quality factorDirect mass flowmetersCompressed natural gasClassical mechanics

The invention relates to a mass flow sensor. The mass flow sensor comprises a first measuring pipe and a second measuring pipe, wherein the two measuring pipes are identical in structure and size and are arranged in a shell in parallel, an angle formed between the axis of a straight pipe section of each measuring pipe and the axis of a first oblique pipe section and an angle formed between the axis of the first oblique pipe section and the axis of a first port section are respectively of an obtuse angle, and an angle formed between the axis of the straight pipe section and the axis of a second oblique pipe section and an angle formed between the axis of the second oblique pipe section and the axis of a second port section are respectively of an obtuse angle. By adopting the technical scheme, when the mass flow of compressed natural gas is measured, the resistance to the compressed natural gas can be reduced; moreover, the distance can be firmly controlled, and a compressed natural gas circulation measuring pipe is enabled to have a high mechanical quality factor, good stability and high shock resistance.

Owner:孙晓君 +1

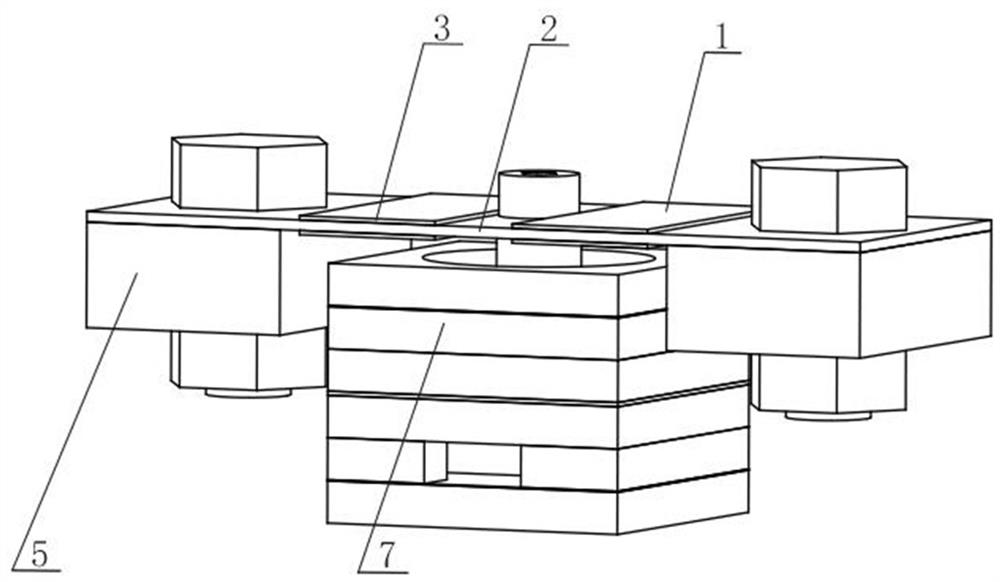

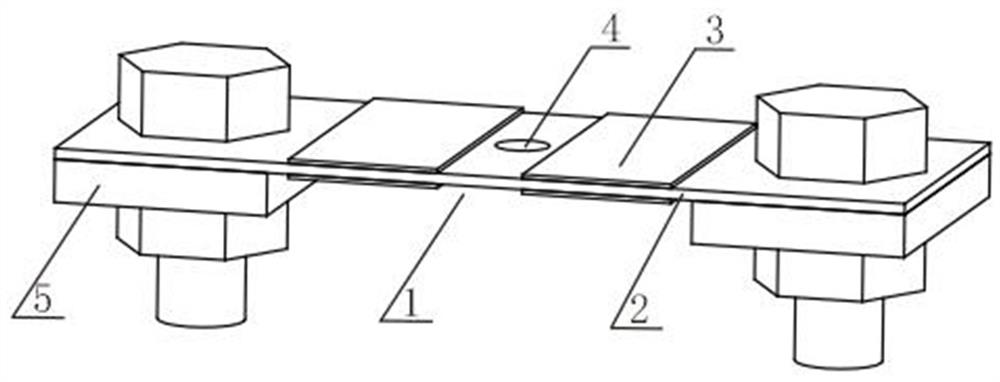

Piezoelectric pump driven by piezoelectric composite beam with adjustable resonant frequency

PendingCN113162462AImprove workabilityImprove working conditionPiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsWaferingEngineering

The invention relates to a piezoelectric pump driven by a piezoelectric composite beam with an adjustable resonant frequency, and belongs to the technical field of piezoelectric pumps. The piezoelectric pump comprises a driving mechanism and a single diaphragm pump; the driving mechanism comprises a piezoelectric composite beam mechanism with the adjustable resonant frequency; the piezoelectric composite beam mechanism comprises an elastic straight beam, two pairs of piezoelectric patches and a pair of mass blocks; one pair of piezoelectric patches are arranged on the upper and lower surfaces of the left side of the center of the elastic straight beam, and the other pair of piezoelectric patches are arranged on the upper and lower surfaces of the right side of the center of the elastic straight beam to form a piezoelectric bimorph structure and are symmetrically positioned on the elastic straight beam; all the piezoelectric patches are connected in series or in parallel through wires; and the diaphragm pump is fixedly connected to a central mounting hole of the elastic straight beam through a bolt. According to the piezoelectric pump, the resonant frequency of the piezoelectric composite beam mechanism can be adjusted by changing the size of the mass blocks so that the resonant frequency can be matched with the optimal working frequency of the one-way valve, both the piezoelectric composite beam mechanism and the one-way valve are ensured to work in the optimal state, and therefore the output performance and the working efficiency of the piezoelectric pump are improved.

Owner:HEFEI UNIV OF TECH

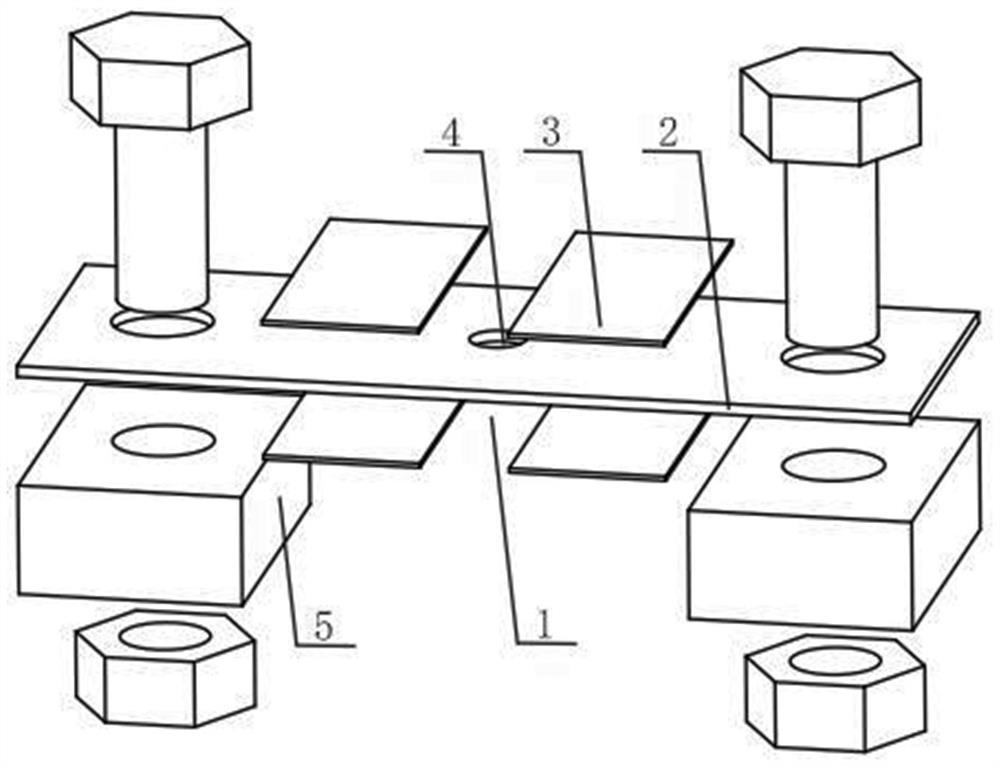

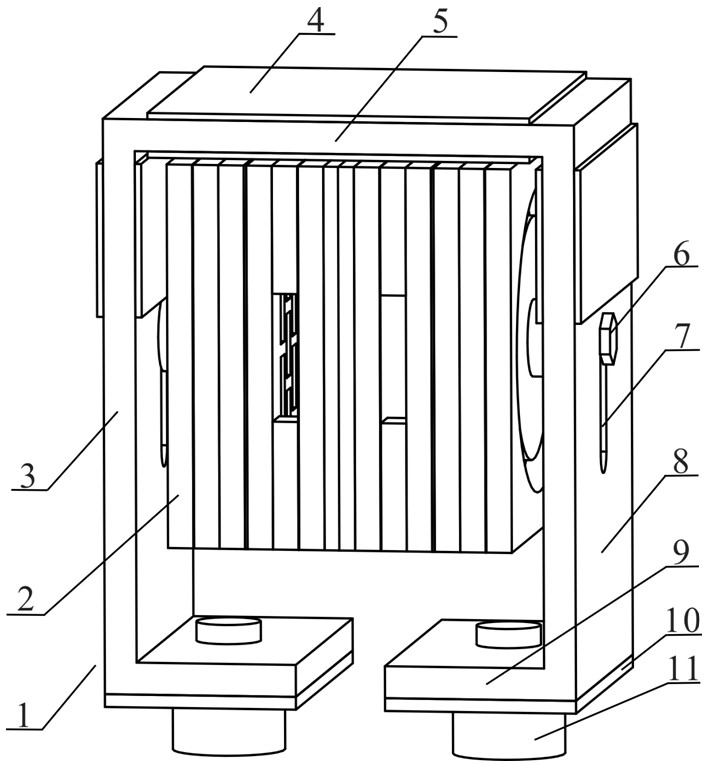

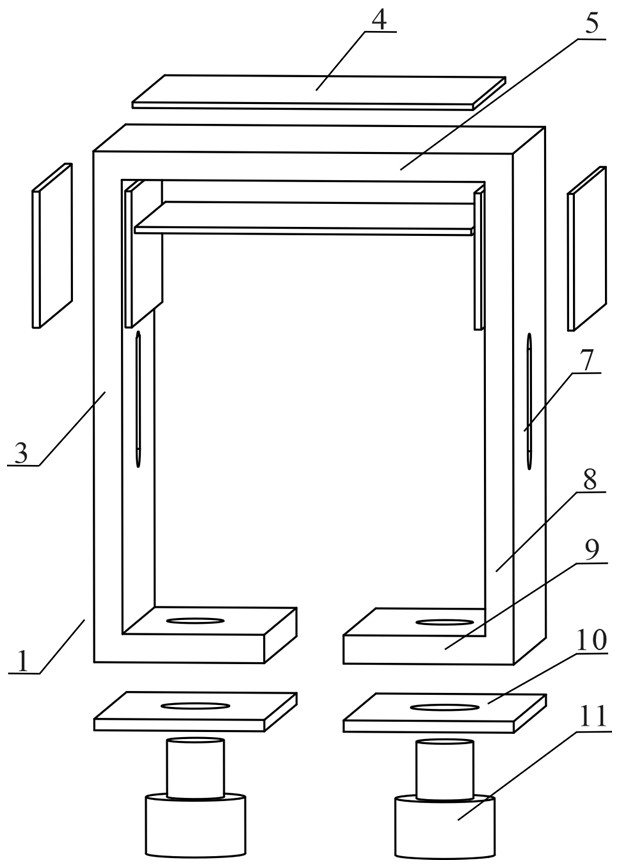

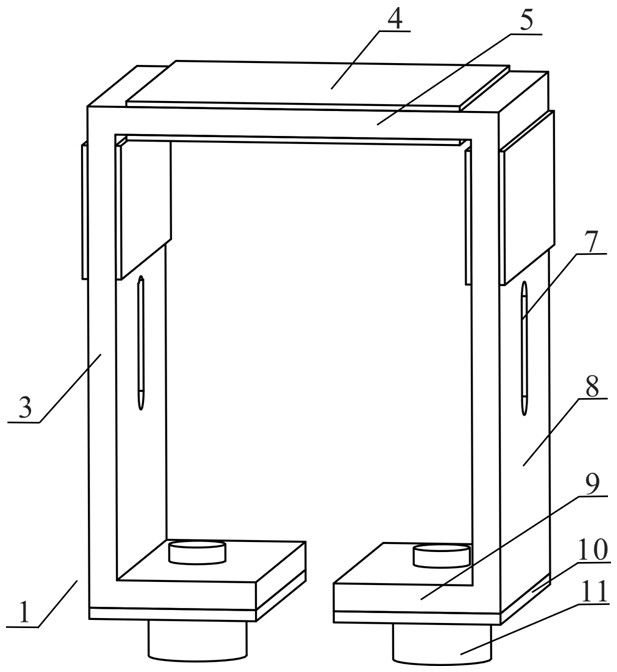

Piezoelectric pump driven by tuning fork type actuator with adjustable resonant frequency

ActiveCN113482891AImprove working conditionImprove workabilityPiezoelectric/electrostriction/magnetostriction machinesPositive displacement pump componentsDiaphragm pumpWafering

The invention relates to a piezoelectric pump driven by a tuning fork type actuator with adjustable resonant frequency, and belongs to the technical field of piezoelectric pumps. The piezoelectric pump comprises the tuning fork type piezoelectric actuator with adjustable resonant frequency and a pair of diaphragm pumps, and the tuning fork type piezoelectric actuator comprises an inverted U-shaped tuning fork type body and piezoelectric plates which are bonded and fixed on the surface of the tuning fork type body; and the tuning fork type body is composed of a cross beam, a pair of driving arms, a mass block at the lower ends of the driving arms and an additional mass block fixedly connected to the bottom of the mass block through bolts. The piezoelectric plates are respectively arranged on the top surface and the bottom surface of the cross beam and the inner side surfaces and the outer side surfaces of the pair of driving arms to form three pairs of piezoelectric bimorph structures; and the pair of diaphragm pumps comprises two diaphragm pumps which are fixedly connected together in a back-to-back mode and are fixedly arranged between the pair of driving arms of the tuning fork type body through kidney-shaped holes and bolts. According to the piezoelectric pump, the resonant frequency of the tuning fork type piezoelectric actuator can be adjusted in a large range by changing the size of the additional mass block, so that the resonant frequency is matched with the optimal working frequency of a one-way valve, and the output performance of the piezoelectric pump is improved.

Owner:HEFEI UNIV OF TECH

Piezoelectric material, piezoelectric element, multilayered piezoelectric element, liquid discharge head, liquid discharge apparatus, ultrasonic motor, optical apparatus, vibratory apparatus, dust removing device, image pickup apparatus, and electronic equipment

ActiveUS9537081B2High and stable constantHigh mechanical quality factorPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesOperating temperature rangeUltrasonic motor

To provide a lead-free piezoelectric material having a high and stable piezoelectric constant in a wide operating temperature range. The piezoelectric material contains a perovskite type metal oxide having the general formula (1), Mn, Mg,(Ba1-xCax)a(Ti1-y-zSnyZrz)O3 (1)(wherein x is in the range of 0.050≦x≦0.200, y is in the range of 0.010≦y≦0.040, and z is in the range of 0≦z≦0.040, provided that x≧0.375(y+z)+0.050, and a is in the range of 0.9925+b≦a≦1.0025+b)wherein the amount b (mol) of Mn on a metal basis per mole of the metal oxide is in the range of 0.0048≦b≦0.0400, and the Mg content on a metal basis per 100 parts by weight of the metal oxide is 0.100 parts by weight or less.

Owner:CANON KK

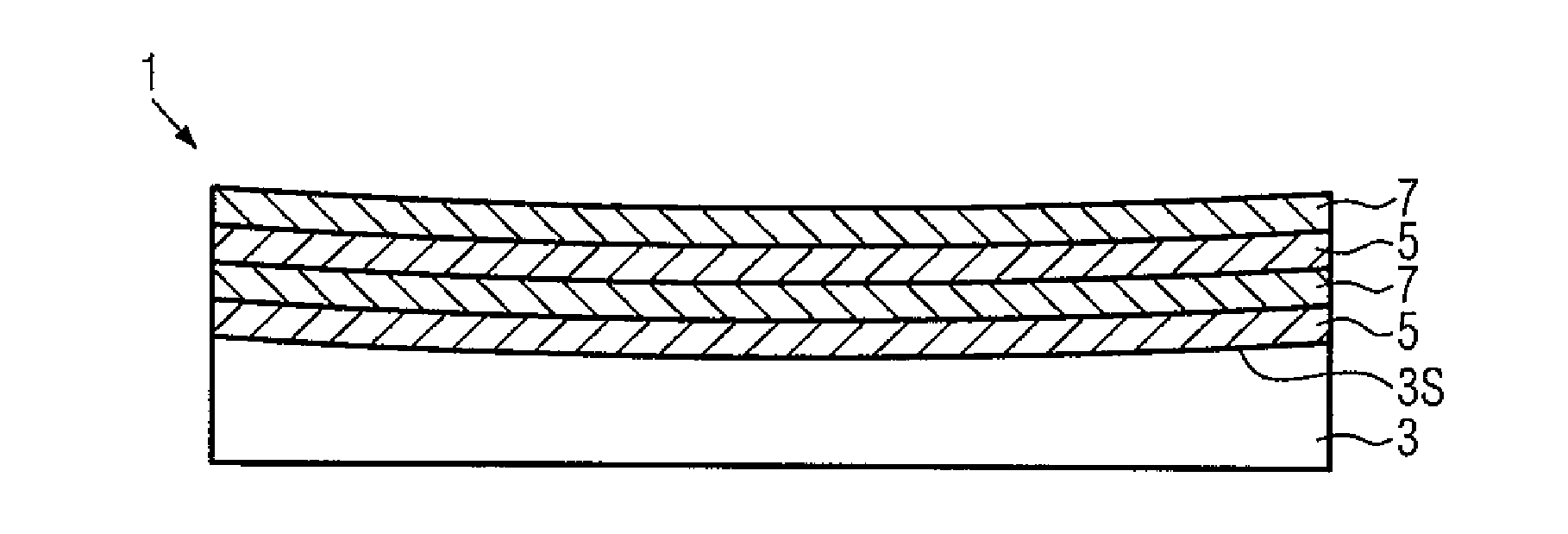

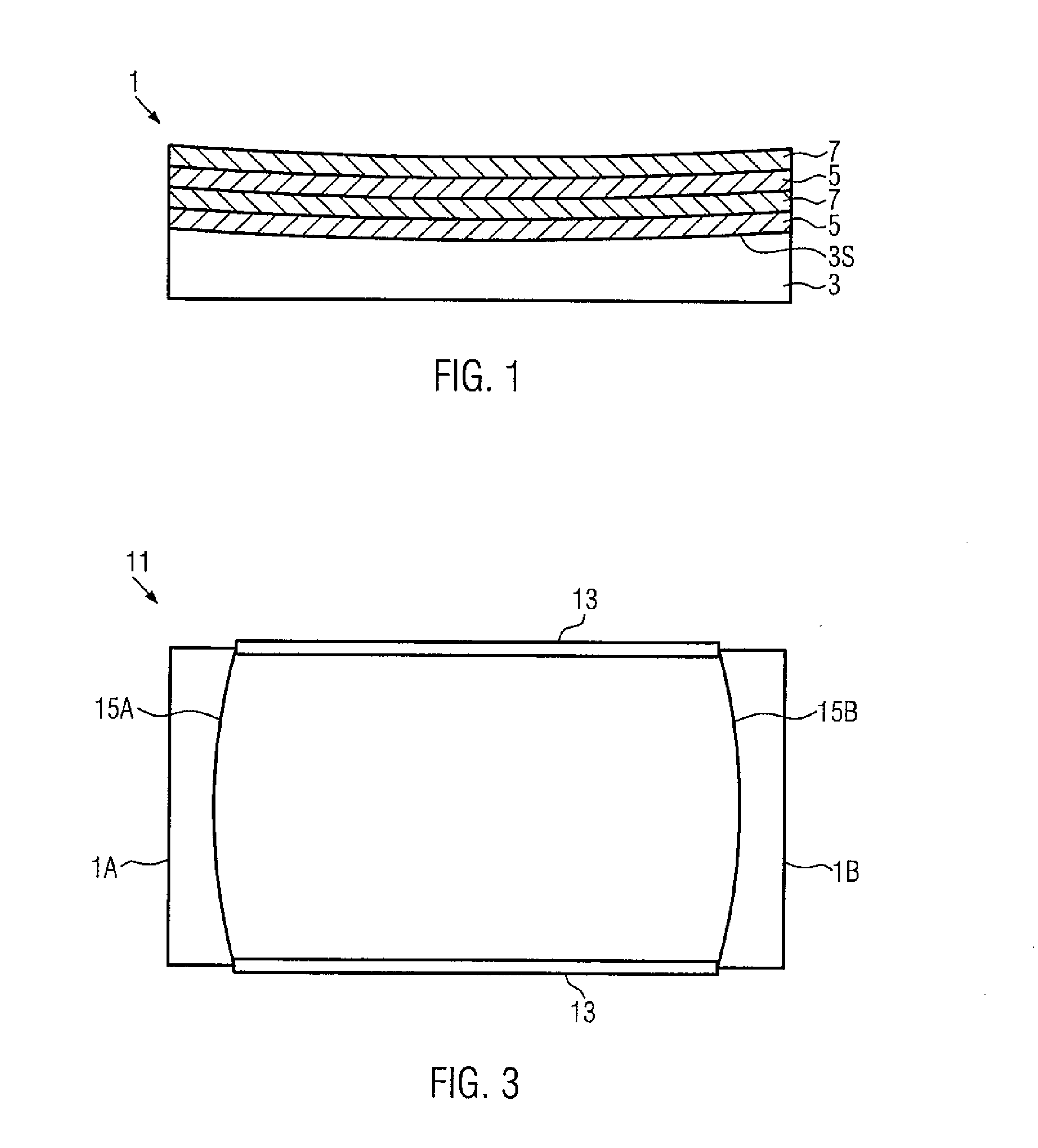

Substrate transferred monocrystalline bragg mirrors

ActiveUS9945996B2Reduce mechanical dampingReduce absorptionMirrorsColor/spectral properties measurementsRefractive indexSingle crystal

A mirror assembly comprising a carrier substrate; a stack comprising a plurality of alternating monocrystalline semiconductor layers of a first and a second type, wherein the layers of the first type have an index of refraction higher than the layers of the second type thereby forming a Bragg mirror; wherein the carrier substrate is curved having a radius of curvature between 0.1 m and 10 km; wherein the stack is attached to the curved carrier substrate.

Owner:THORLABS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com