Patents

Literature

41results about How to "No machining required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

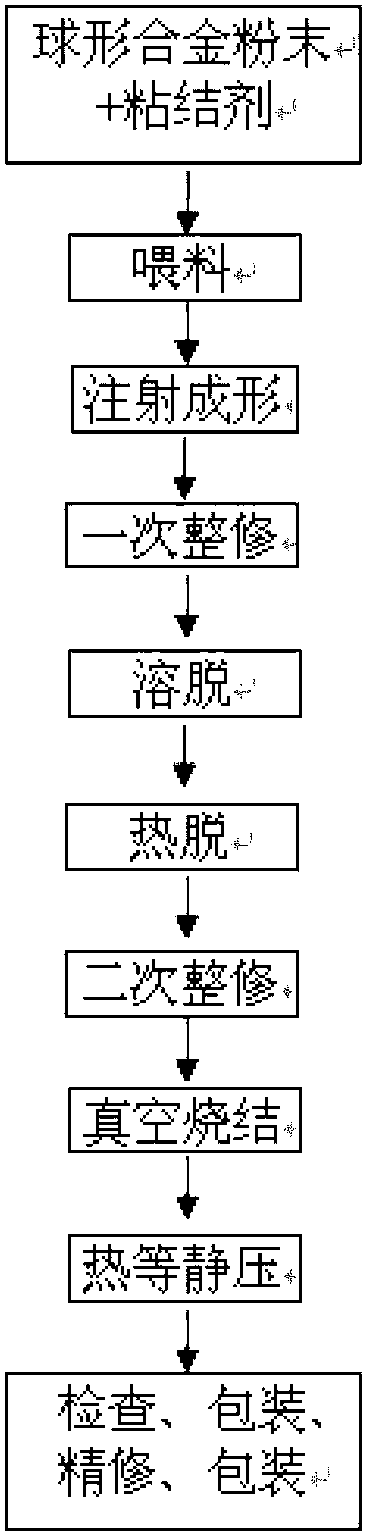

Method for preparing specially-shaped porous tungsten product with uniform pores

ActiveCN105499574AIncrease profitLow costTransportation and packagingMetal-working apparatusPore distributionAlloy

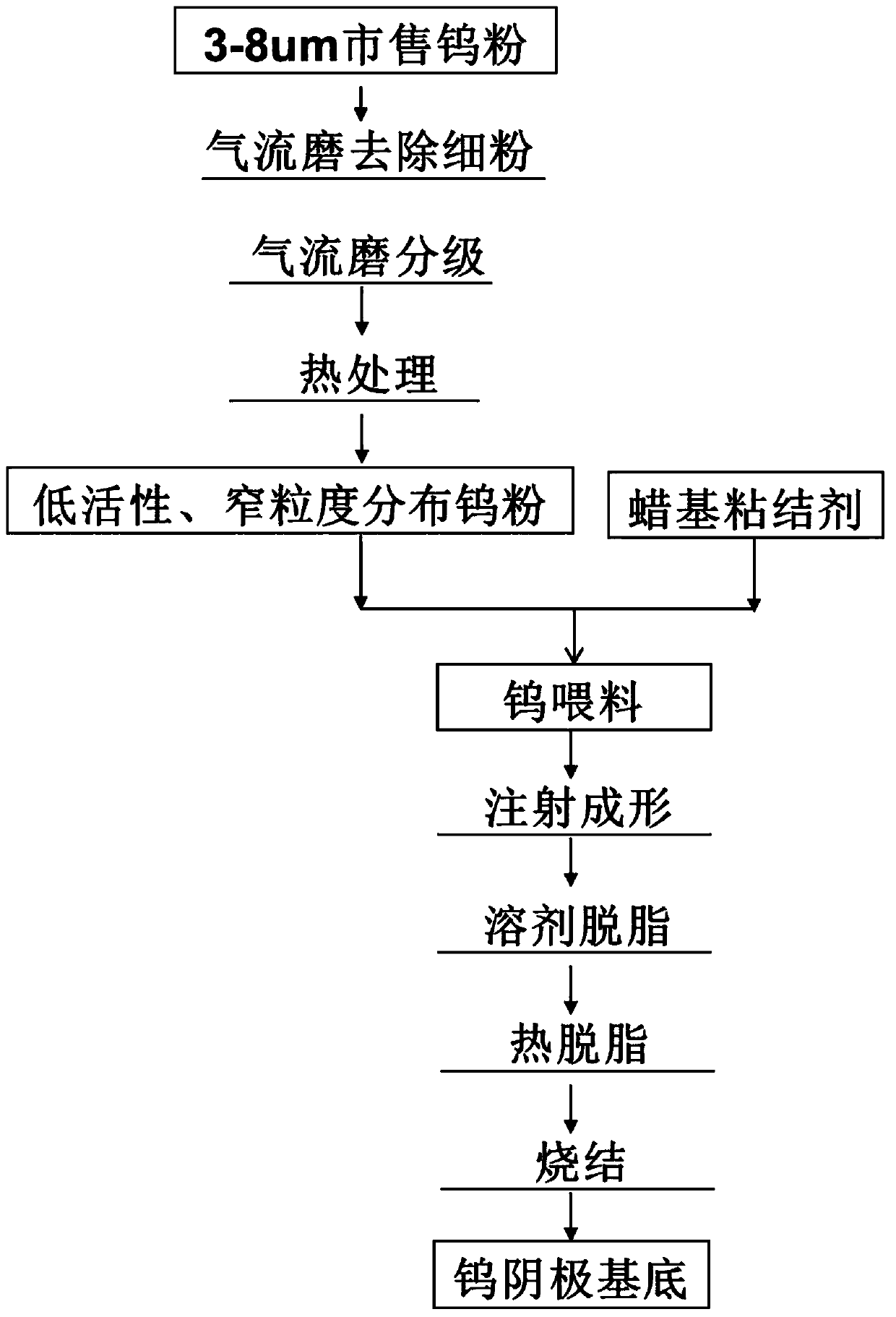

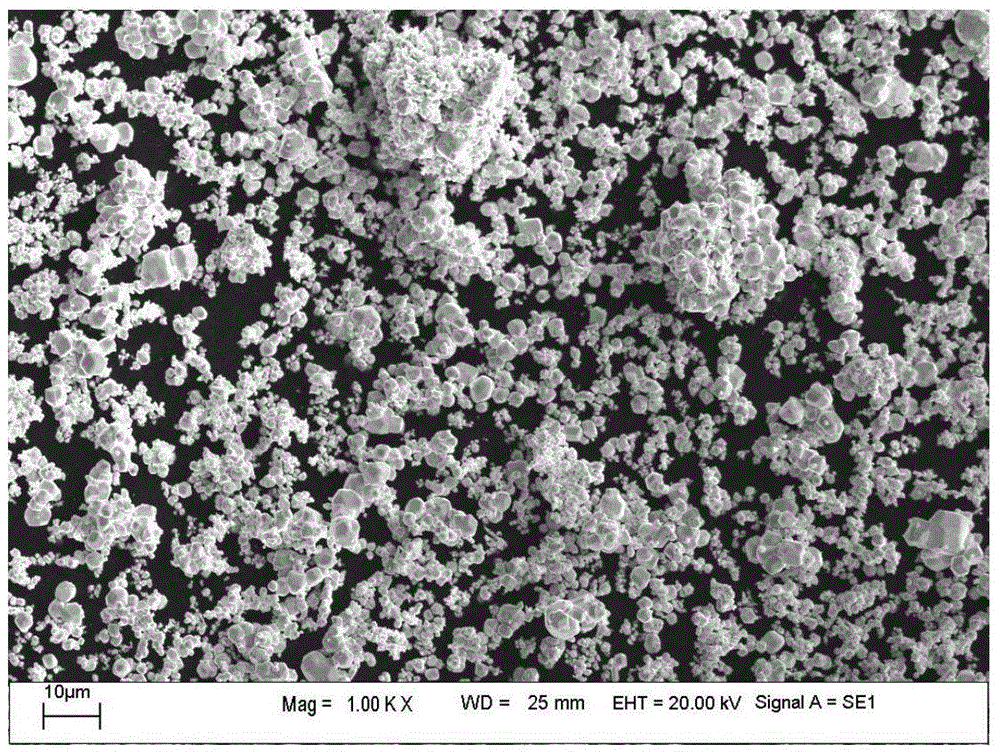

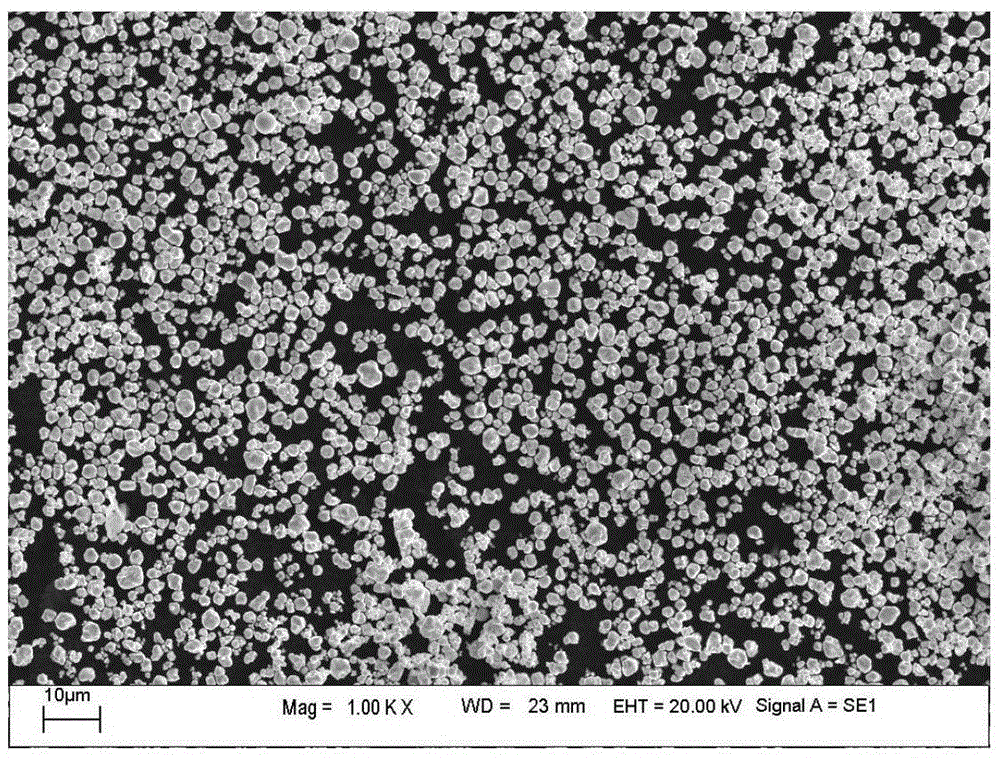

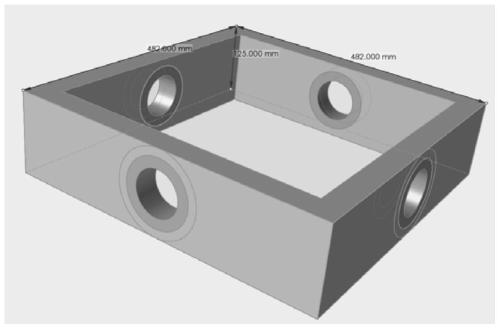

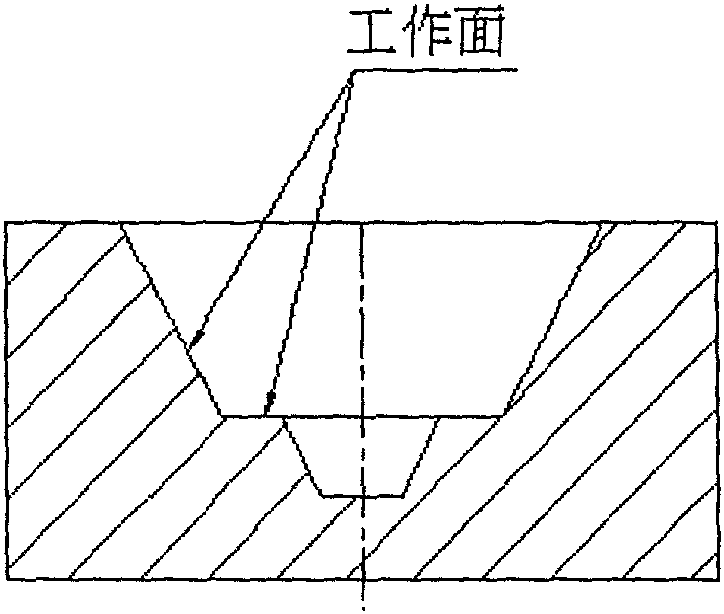

The invention provides a method for preparing a specially-shaped porous tungsten product with uniform pores, and belongs to the technical field of preparation of porous high-temperature alloy. After high-purity tungsten powder is dispersed, aggregates of the tungsten can be opened, and ultrafine particles (particle size being smaller than 2 mum) in original tungsten powder are collected and removed; after stage treatment is carried out, tungsten powder with narrow size distribution can be obtained; after thermal treatment is carried out, the tungsten powder can be purified, and the activity of the tungsten powder can be reduced to obtain nearly spherical powder with narrow size distribution, so that liquidity and tap density of the powder are improved, the loading amount of injection-molded powder is correspondingly improved, shrinkage deformation of a product in a sintering process is reduced, and a porous cathode substrate with high dimension precision is obtained; and the powder size distribution is narrow, and ultrafine powder is absent, so that the obtained cathode substrate is uniform in pore distribution. The porous tungsten product with a complex shape and high dimension precision can be directly prepared by combining jet-milling multi-time treatment with an injection molding process.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing high-density pure tungsten product through low-temperature sintering

ActiveCN105478776ALower sintering densification temperatureHigh tap densityHigh densityHydrogen atmosphere

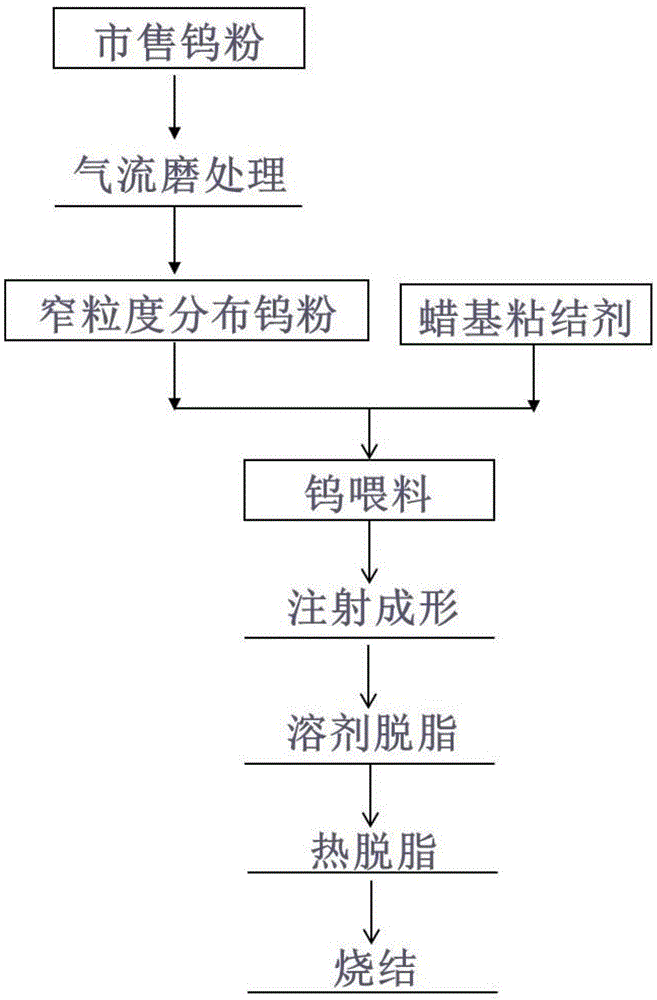

The invention provides a method for preparing a high-density special-shaped pure tungsten product through low-temperature sintering, and belongs to the technical field of powder injection molding. The method comprises the technological processes that an air flow mill is adopted for carrying out dispersing and staging treatment on commercially available high-purity tungsten powder, the treated powder and a bonding agent are evenly mixed for mixing, and even feed is obtained; the feed is subjected to injection molding to form a blank in a certain shape; and the formed blank is subjected to solvent degreasing and hot degreasing and then is sintered, and the tungsten product is obtained. Powder is subjected to dispersing and staging treatment through the air flow mill under the protective atmosphere, the powder is driven by gas to collide with each other and can be treated on a large scale, and no impurity is introduced; the particle size distribution of the treated powder becomes narrow, and the shape of particles becomes regular and is similar to a spherical shape; and loose-fitting tap density is increased, the loading amount of the injection-molded powder is correspondingly improved to 55%-70%, and the density of the pure tungsten product manufactured after sintering of the hydrogen atmosphere of 1,900 DEG C is higher than 96%.

Owner:UNIV OF SCI & TECH BEIJING

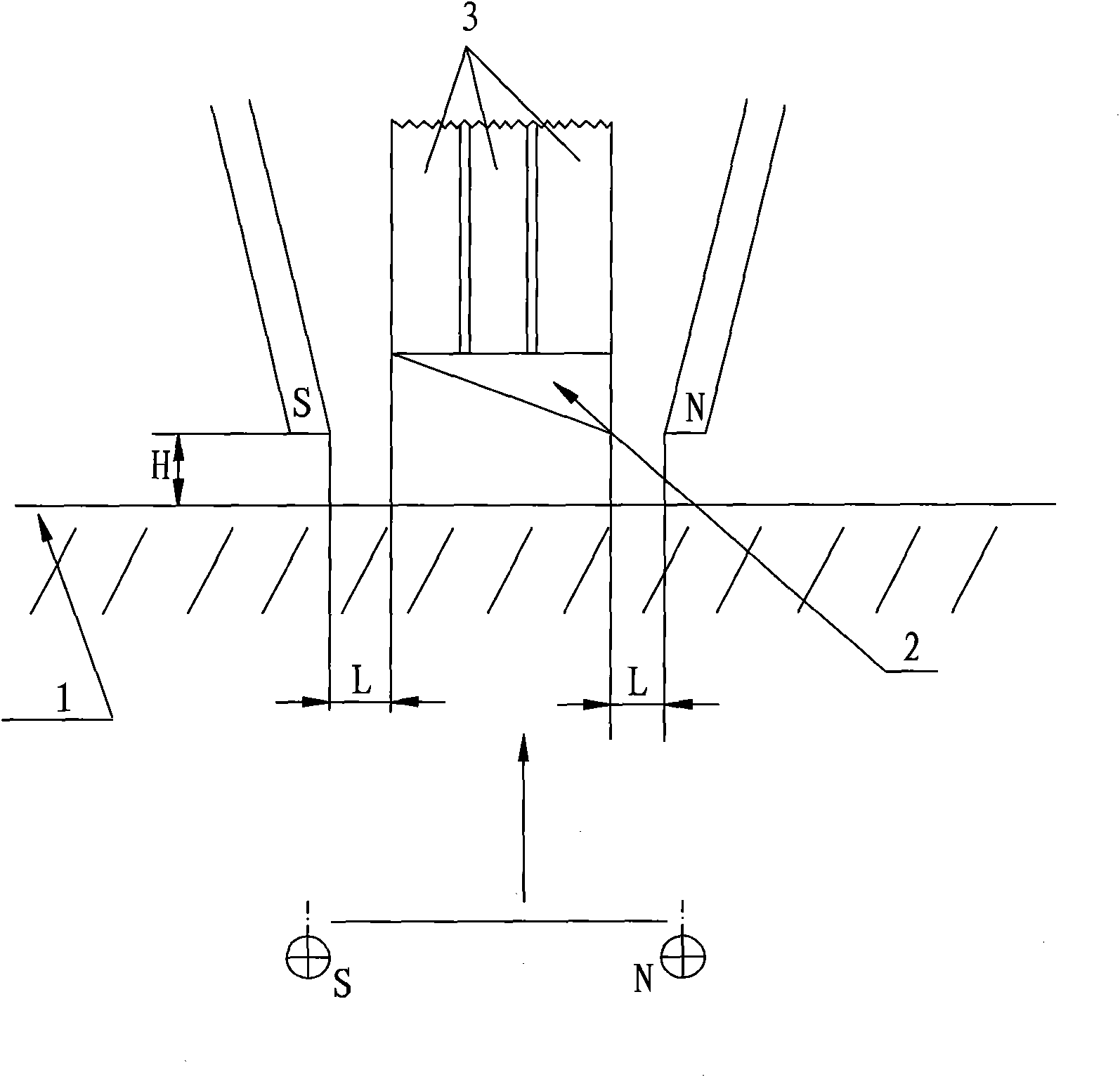

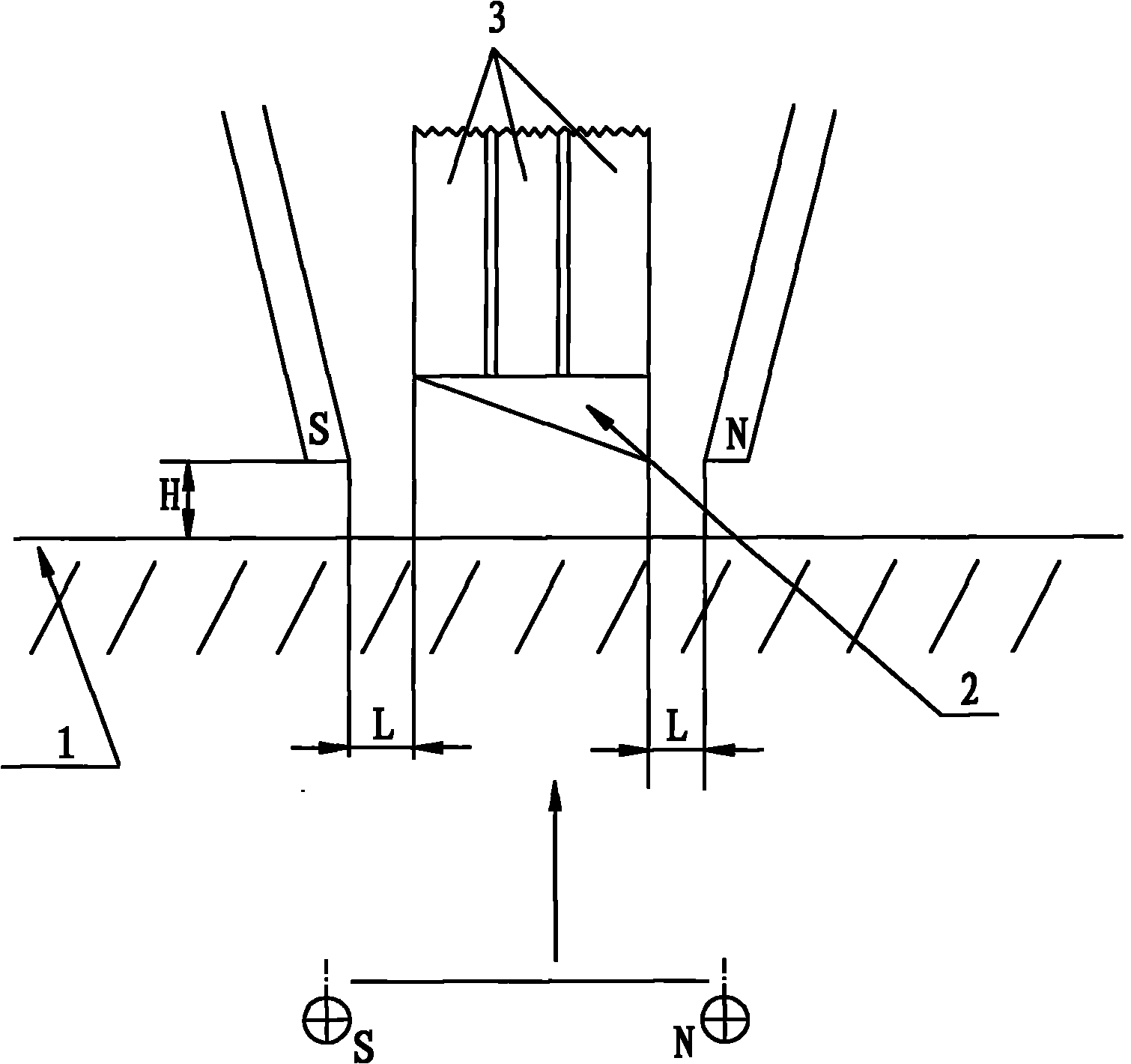

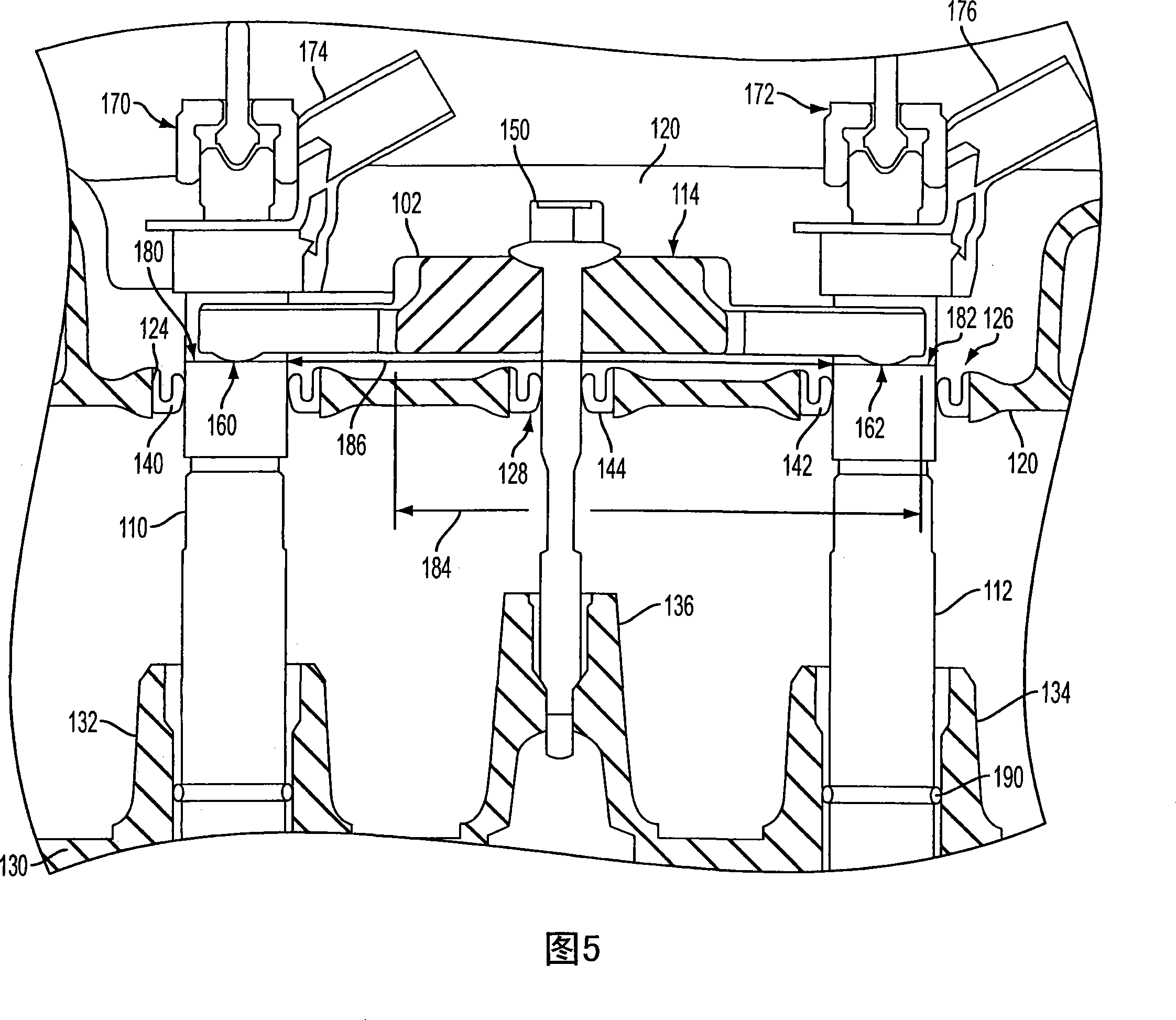

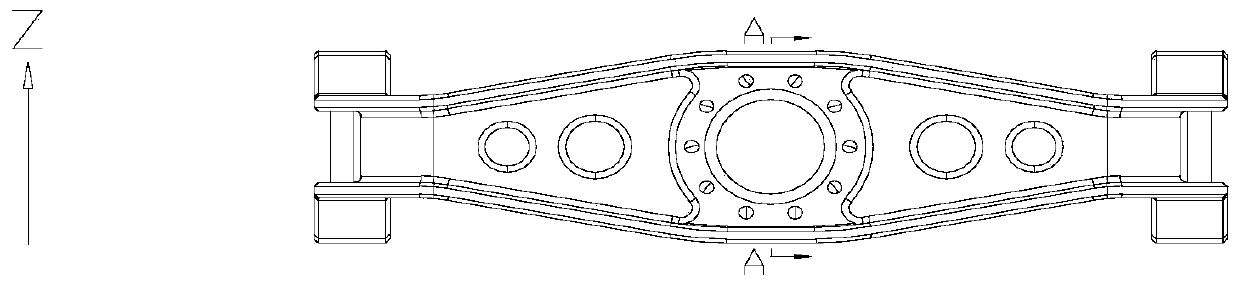

Drive device for vehicle

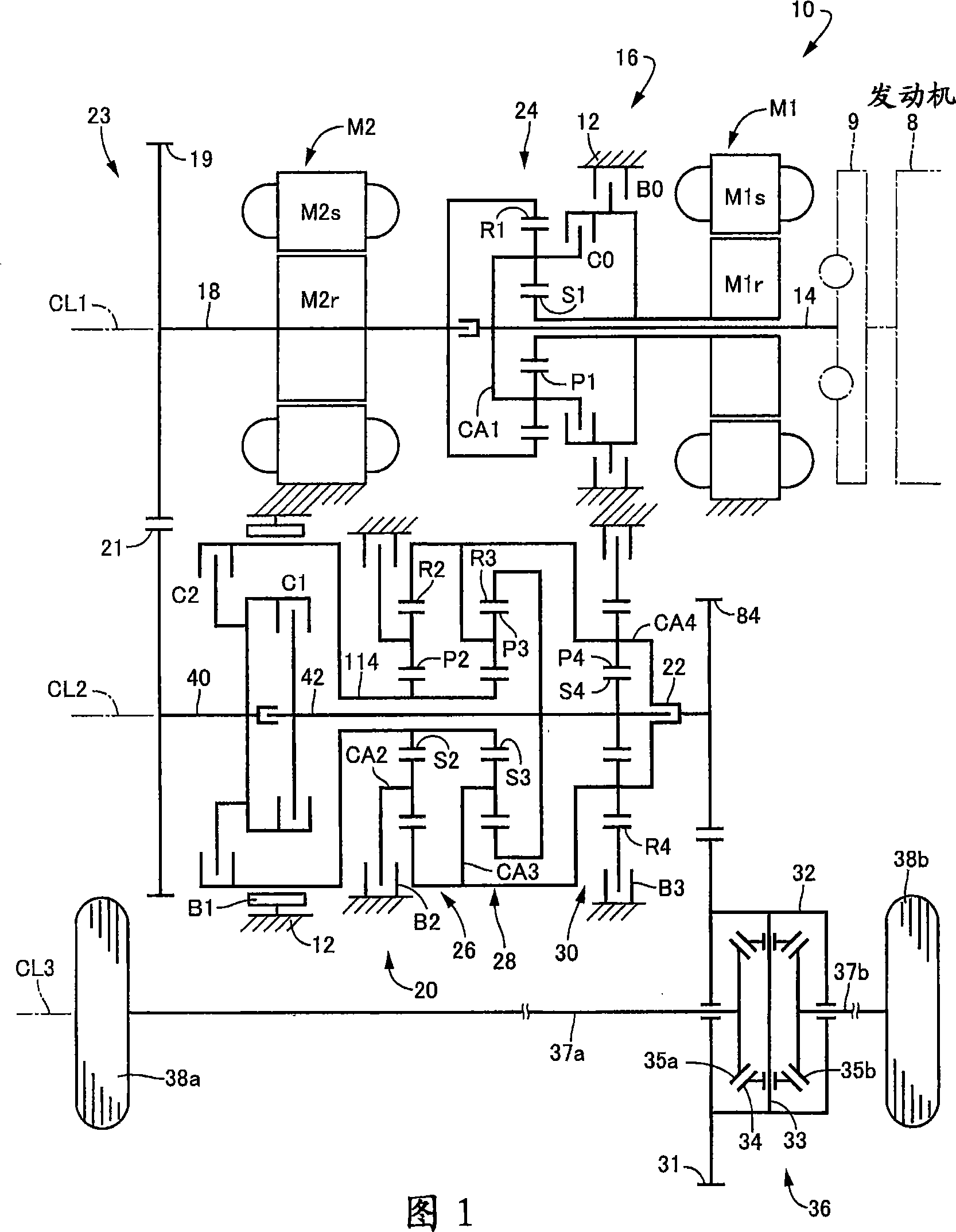

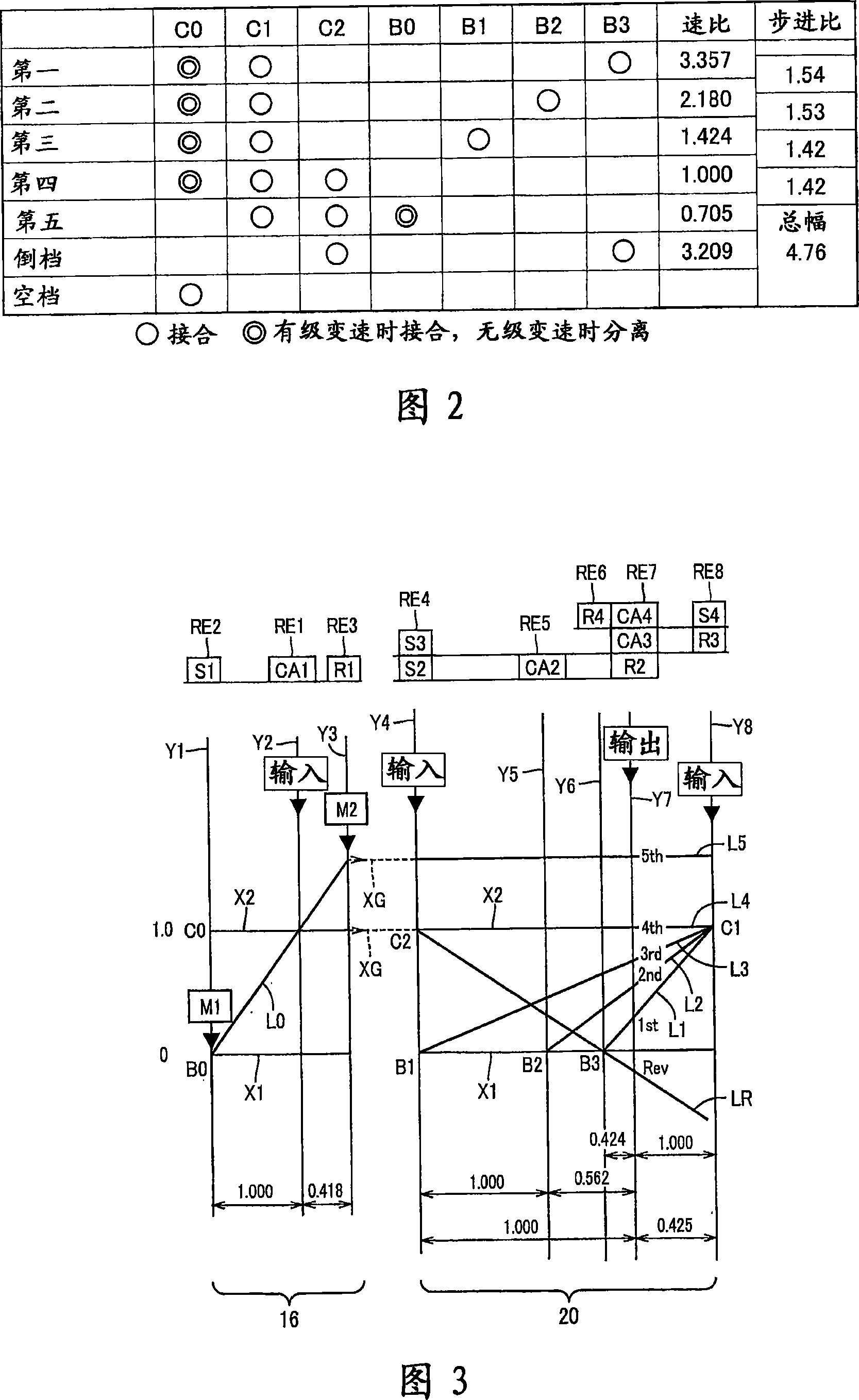

InactiveCN101247969AReduce axial sizeImprove cooling effectHybrid vehiclesGearboxesAutomatic transmissionMedial axis

Provides small vehicle drives with reduced axial dimensions without increasing the number of parallel shafts. The first electric motor (M1) and the power distributing mechanism (differential part) (16) are arranged on the first axis (CL1) which is the rotation center of the input rotating member (14) in order from the input rotating member (14), automatically The transmission (transmission unit) (20) is arranged on a second axis (CL2) parallel to the first axis (CL1). The transmission member (18), which is a rotating member located on the first axis (CL1) at the end opposite to the input rotating member (14), and arranged on the second axis at the end opposite to the input rotating member (14) Between the first intermediate shaft (rotating member) (40) on (CL2), a driving connection device (23) is provided to be able to transmit power. In this way, the power transmission path becomes a C-shape or a U-shape with reduced axial dimension, which can reduce the size and simplify the structure without increasing parallel shafts.

Owner:TOYOTA JIDOSHA KK

A kind of preparation method of porous cathode substrate

The invention provides a method for preparing a porous cathode substrate, which belongs to the field of powder metallurgy. The raw material powders used include various powders such as tungsten, iridium, rhenium, and scandium oxide. The various powders are mixed evenly according to a certain weight percentage, and the tungsten content is 40~100%. Mix and disperse the raw material powder particles and the binder evenly to make a granular feed, and the volume fraction of the powder in the feed is 40-75%. The feed material is formed into a green body of a certain shape on an injection molding machine, and the binder in the shaped green body is removed to obtain a porous cathode substrate. The invention has the advantages that the porous cathode substrate with special shape and size requirements can be directly prepared without mechanical processing, the material utilization rate is high, and the cost is low. It can effectively overcome the influence of harmful impurities brought by the traditional process, and improve the electron emission performance, service life and working reliability of the cathode. It can effectively control the pore size, pore distribution, porosity and pore connectivity of the material.

Owner:UNIV OF SCI & TECH BEIJING

Strip electrode electroslag surfacing process of nickel-based alloy of tube plate of nuclear power steam generator

InactiveCN101797660AImprove deposition efficiencyLow dilution rateArc welding apparatusNuclear powerAlloy

The invention discloses a strip electrode electroslag surfacing process of nickel-based alloy of a tube plate of a nuclear power steam generator, which comprises the following steps of: detecting the surface before surfacing; preheating; carrying out surfacing welding; carrying out post-heat treatment; polishing the surface of a surfacing layer; and detecting the surface after surfacing. When used for large-area surfacing of the tube plate, the strip electrode electroslag surfacing process can greatly improve the quality of the surfacing layer, reduce the surfacing time of the nickel-based alloy of the tube plate, quicken the proceeding of subsequent procedures, increase the production efficiency of the whole steam generator manufacturing, and shorten the manufacturing period.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

Casting process for crankshaft

InactiveCN104745917AOvercoming many processesIncrease productivityCrankshaftsFoundry mouldsComposite materialMolding sand

The invention discloses a casting process for a crankshaft. The casting process comprises a molding process and a smelting and casting process. The molding process comprises the following steps of: adopting resin sand for molding, wherein the resin sand comprises 1% of resin, 0.4% of a curing agent and the balance of molding sand; performing transverse molding during the molding, and after mould arrangement and mould assembly, lifting the whole mould vertically to form a resin sand mould. The smelting and casting process comprises the following steps of: preparing casting liquid by using C, Si, Mn, P, S, Mg, Re, Cu, Sn and Fe as raw materials according to a certain percentage; fully melting the raw materials to form molten iron; placing a spheroidizing agent and an inoculant into a ladle, pouring molten iron into the ladle for spheroidizing and inoculating to form the casting liquid; and pouring the casting liquid into the resin sand mold to form a crankshaft casting after solidification. Through the casting process provided by the invention, the defective rate of crankshaft products is low, the qualification ratio reaches 99% or above, and all properties can reach the standards.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

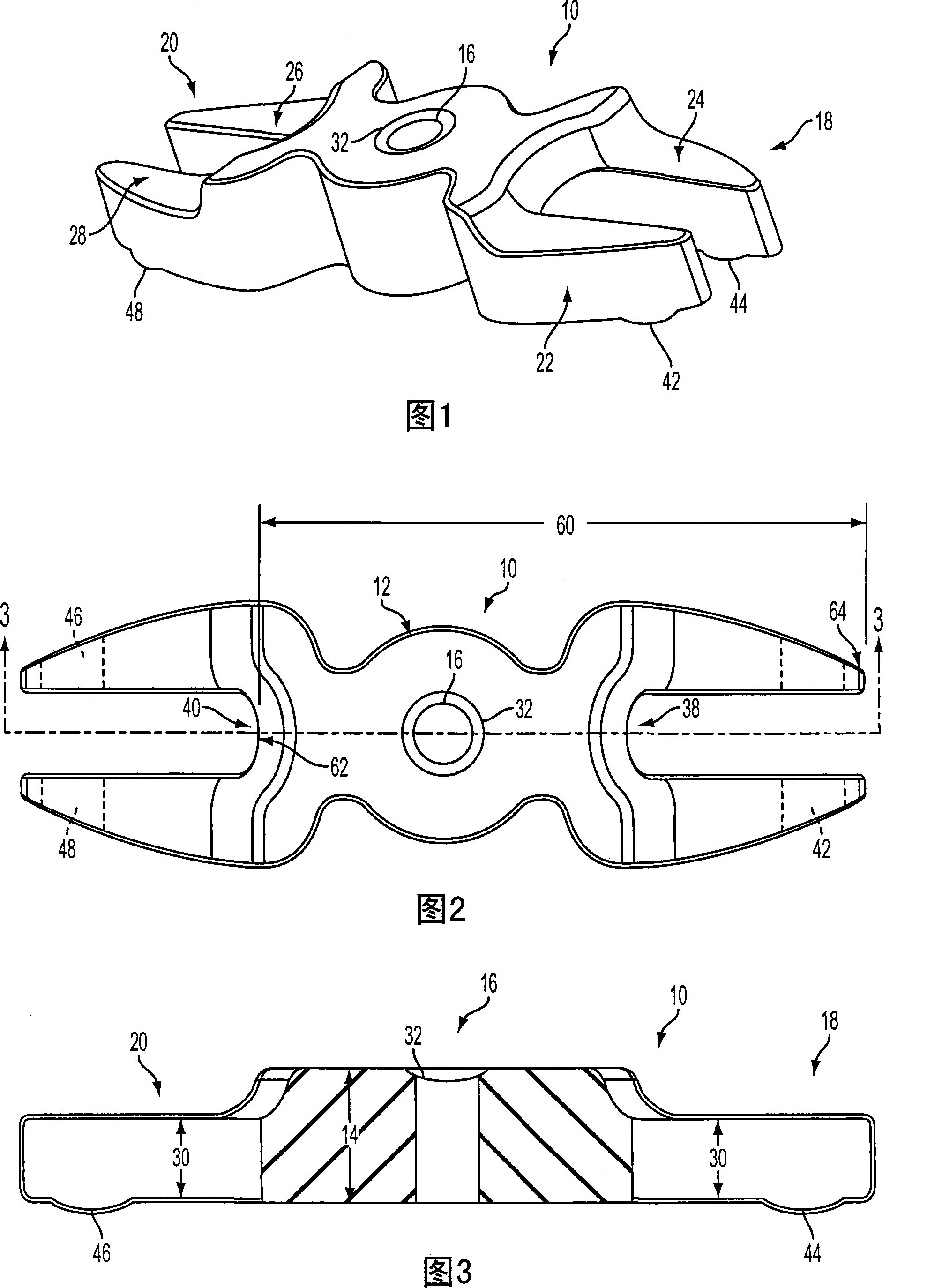

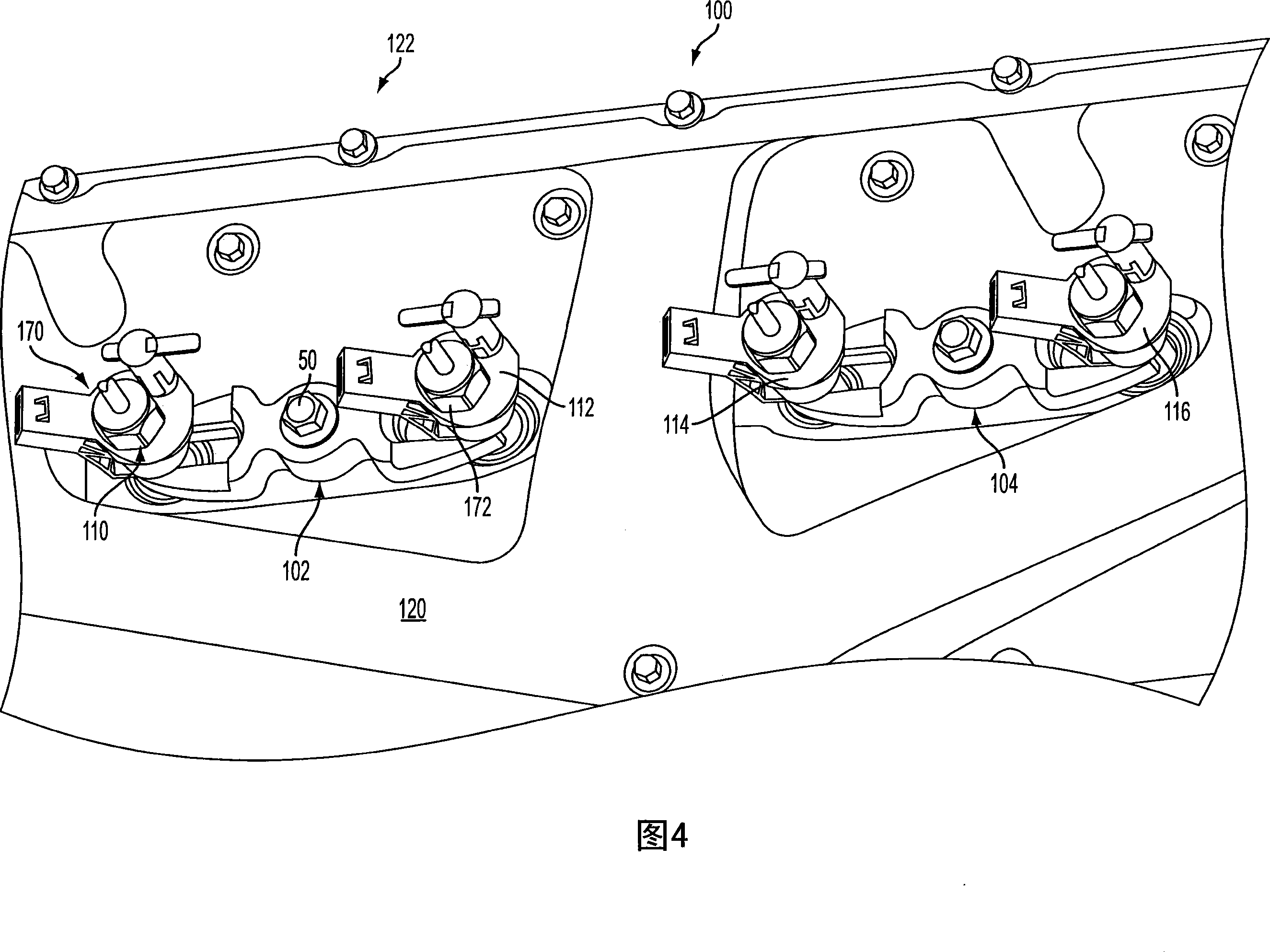

System and method for securing fuel injectors

InactiveCN101235779AReduce complexityReduce contact stressCasingsMachines/enginesCylinder headEngineering

A system and method for securing fuel injectors in an internal combustion engine includes a retainer for securing adjacent fuel injectors to a cylinder head. The retainer includes a central portion with a hole for receiving a fastener securing the retainer to the cylinder head, and a pair of symmetrical crescent-shaped forks forming a U-shaped opening with The retainer is facilitated in lateral sliding engagement with diametrically opposed flat portions on a corresponding fuel injector. Each clamping yoke includes an arcuate flange that engages a corresponding shoulder on the fuel injector to provide an axial clamping force to the fuel injector. The distance between the distal end of one prong and the semicircular base on the opposing prong is selected to allow the retainer to slide laterally out of one of the adjacent fuel injectors without rotating or removing the other fuel injector injectors to facilitate servicing of individual fuel injectors.

Owner:FORD GLOBAL TECH LLC

Precision casting method for graphite mould-ceramic core titanium alloy

InactiveCN104550755AOvercoming many processesIncrease productivityFoundry mouldsFoundry coresGraphiteProduction cycle

The invention discloses a precision casting method for a graphite mould-ceramic core titanium alloy. The precision casting method disclosed by the invention comprises the following steps: preparing a ceramic mould core and a graphite mould shell, then, degassing the graphite mould shell and the ceramic mould core, assembling the ceramic mould core and the graphite mould shell to form a casting mould according to a casting mould shell figure, smelting, and casting. The precision casting method disclosed by the invention has the advantages that aiming at a complex three-dimensional variable-curved surface titanium alloy precise casting, a titanium alloy casting is cast by utilizing the precision casting method disclosed by the invention; therefore, the dimensional accuracy, the internal quality and the surface quality of the casting are improved; the rejection rate of the casting is greatly reduced; the casting cost of the casting is reduced; and the production period of the casting is shortened.

Owner:青岛齐力铸钢有限公司

Casting method of pump body

InactiveCN107737871AIncrease profitOvercome the problems of many processes and heavy workloadFoundry mouldsFoundry coresChemical compositionAlloy

The invention discloses a casting method of a pump body. The casting method of the pump body comprises the steps that resin-bonded sand is taken as a raw material; the resin-bonded sand is adopted formanufacturing a sand mould, and a resin-bonded sand mould is manufactured after mould matching and mould assembling; then pouring liquid is prepared, wherein the pouring liquid comprises the following chemical components of 3.0-3.2% of C, 1.8-2.0% of Si, 0.4-0.5% of Mn, 0.08% of P, 0.01% of S, 0.03-0.04% of Mg, 0.01-0.02% of Re, 0.6-0.8% of Cu or 0.04-0.05% of Sn, and the balance Fe; the raw materials in the previous step are heated to a smelting temperature in an electric furnace, an alloy is fully molten into molten iron, and thus the pouring liquid is formed; the pouring liquid is poured into the resin-bonded sand mould, and a casting is formed after the pouring liquid is solidified; and after the casting is cooled wholly, the casting is subjected to sand removal and then heat treatment. With the adoption of the technical scheme, the production efficiency is improved, the production cost is lowered, and the casting quality is effectively ensured.

Owner:TAIHU AIJIE MACHINE CASTING

Vacuum-air pressure casting method of three-dimensional network ceramic-metal friction composite material

The invention discloses a vacuum-air pressure casting method of a three-dimensional network ceramic-metal friction composite material. The method comprises the process steps of pretreatment of a three-dimensional network ceramic skeleton, mold treatment and casting of metal. The three-dimensional network ceramic skeleton adopts SiC, B4C, Si3N4, Al2O3, ZrO2 or a mullite ceramic material; and the metal adopts aluminum or an aluminum alloy or a copper alloy or a titanium alloy or a steel and iron material. The pretreatment of the three-dimensional network ceramic skeleton can adopt the surface preoxidation treatment, the inorganic matter modification, the electroplating coating or the powder metallurgy method to diffuse and sinter a layer of high-melting point metal. The casting of the metal is performed in a vacuum-air pressure casting furnace. The method can prepare network ceramic-metal composite materials with different ceramic contents and different three-dimensional network apertures, can realize the compounding of low-melting point metal and three-dimensional network ceramic, and can prepare the three-dimensional network ceramic-metal friction composite material with a continuous bonding interface for the copper alloy or the steel and iron material with a higher melting point.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

Method for manufacturing iron-based alloy part

InactiveCN104972129AImprove performanceHigh dimensional accuracyTurbinesOther manufacturing equipments/toolsMachiningPowder injection

The invention relates to a method for manufacturing an iron-based alloy part and belongs to the technical field of iron-based alloy forming. According to the method for manufacturing the iron-based alloy part, a powder injection forming technology is adopted; firstly, metal and polymer binder powder are mixed into even injection forming feed with viscoplasticity; then, injection is conducted on an injection machine so that an injection blank can be formed; afterwards, the iron-based alloy part is manufactured through the steps of degreasing, sintering and the like. The finished iron-based alloy part product which is good in performance and high in size precision is obtained after heat treatment is conducted on the sintered product. The method for manufacturing the iron-based alloy part has the advantages that the product is formed with a net dimension, subsequent machining is not needed, the production cost is low, and iron-based alloy part products which are complex in shape and good in comprehensive performance can be produced in a batched mode; and the method is suitable for industrial production.

Owner:YUXI DAHONGSHAN MINING

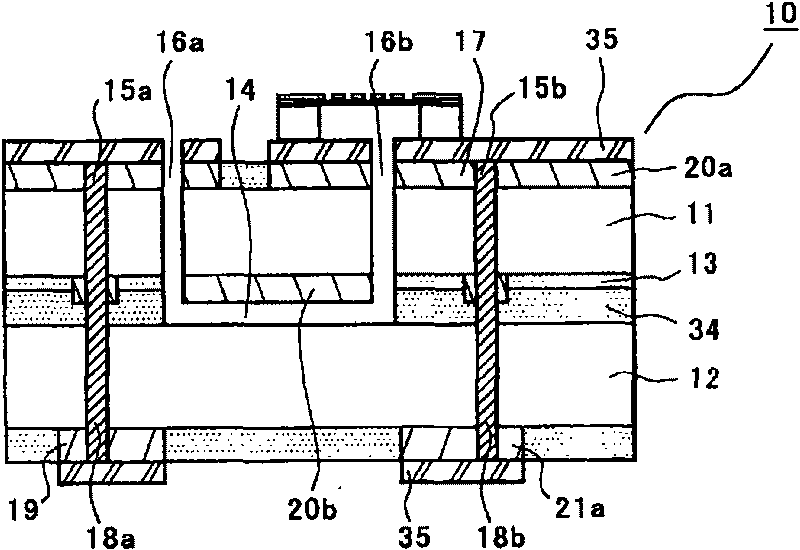

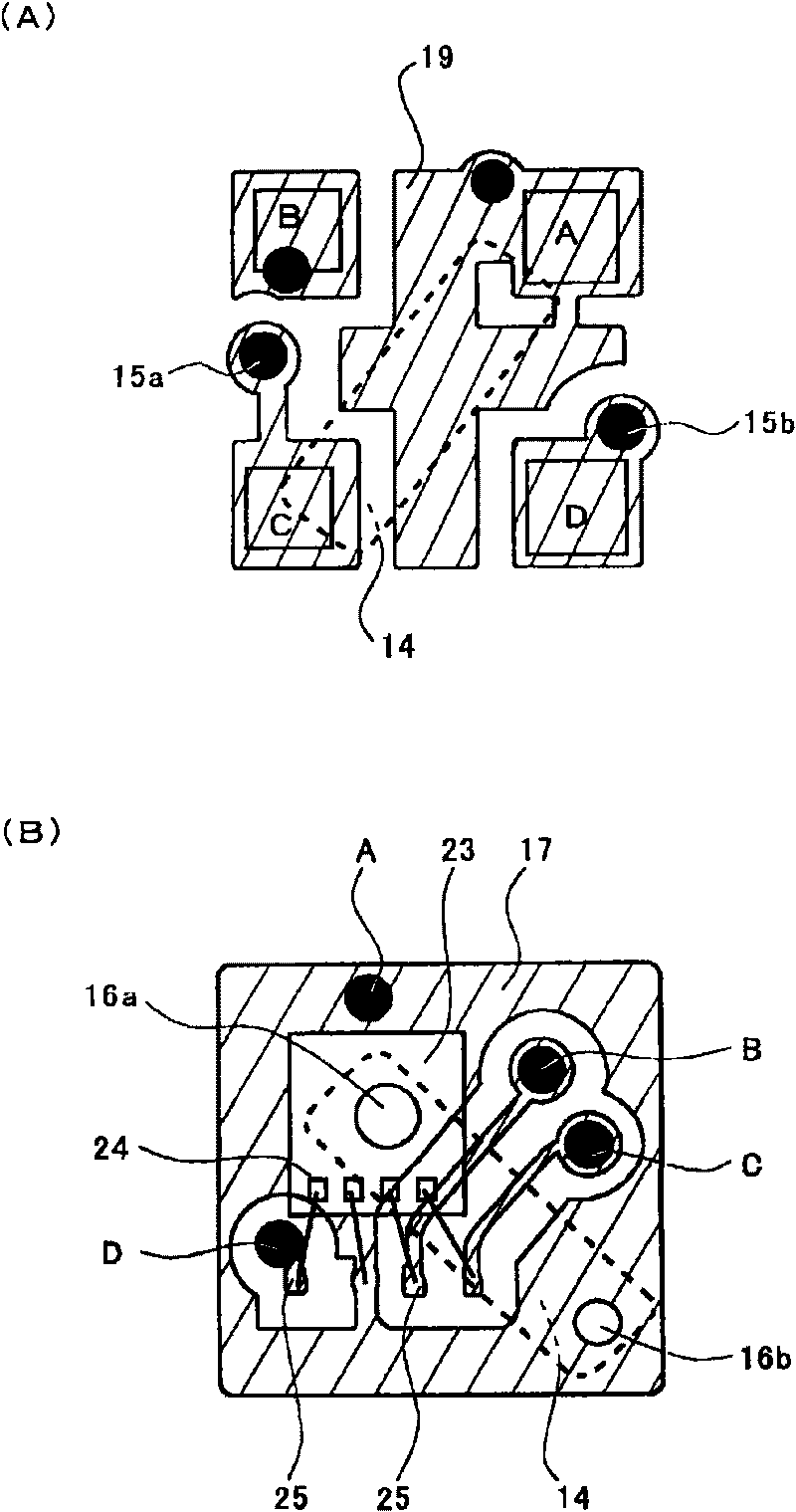

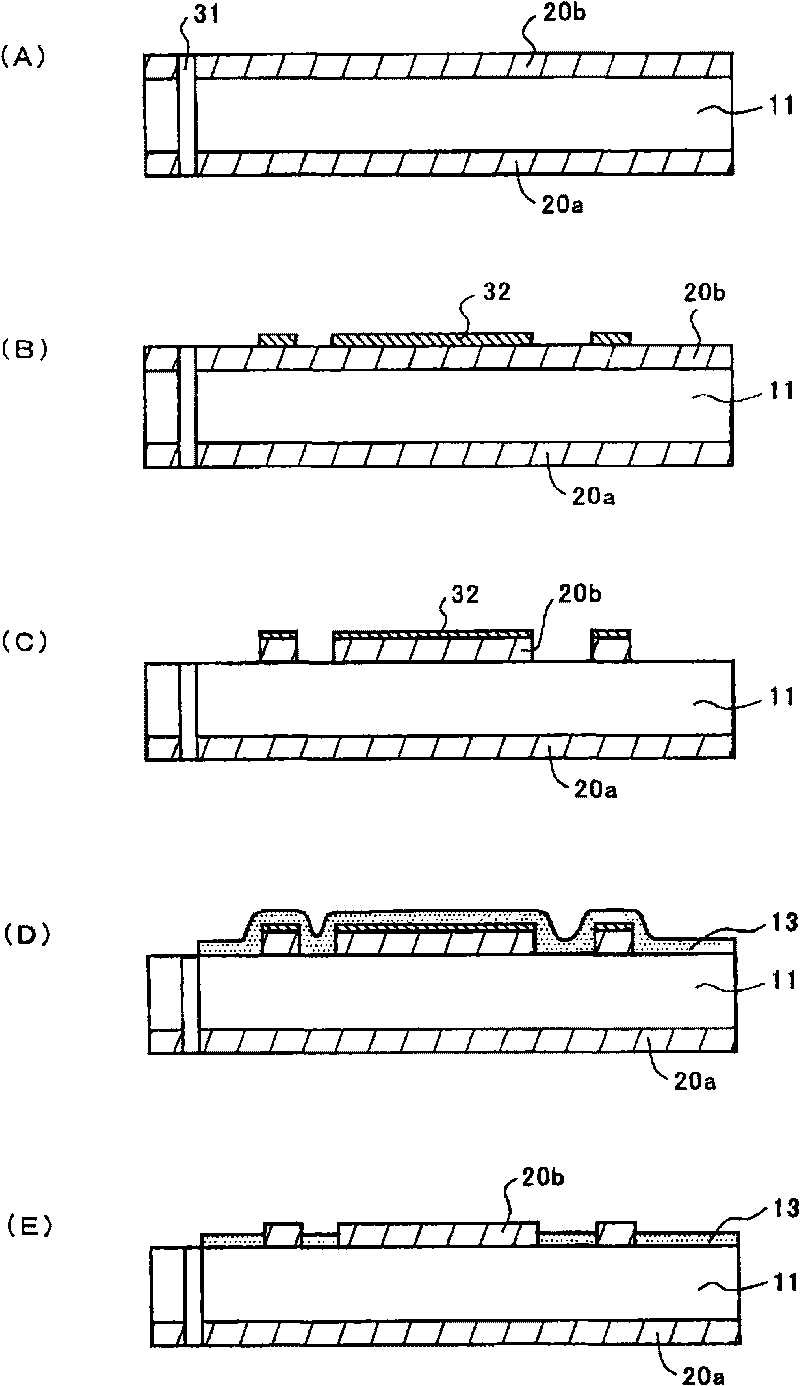

Circuit board with hollow space portion and method for manufacturing the same

InactiveCN101764105AImprove installation densityExclude intrusionSemiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

A circuit board with hollow space portion and method for manufacturing the same, uses two substrates to constitute a hollow space portion therein. The invention includes: a first circuit pattern 17 formed by the conductive foil 20a on the surface of an upper substrate 11, a bonding layer 13 formed on the back of the upper substrate 11, a second circuit pattern 19 formed by the conductive foil 21a on the surface of an lower substrate 12, a hollow space portion 14 formed by removing the conductive foil 21b on the back of the lower substrate 12, and an insulation layer 34 provided surrounding the hollow space portion 14, wherein the bonding layer 13 on the back of the upper substrate 11 is bonded with the insulation layer 34 on the back of the lower substrate 12, a hollow space portion 14 is surrounded by the upper substrate 11, the lower substrate 12 and the insulation layer 34 between the two substrates.

Owner:ELEMENT DENSHI

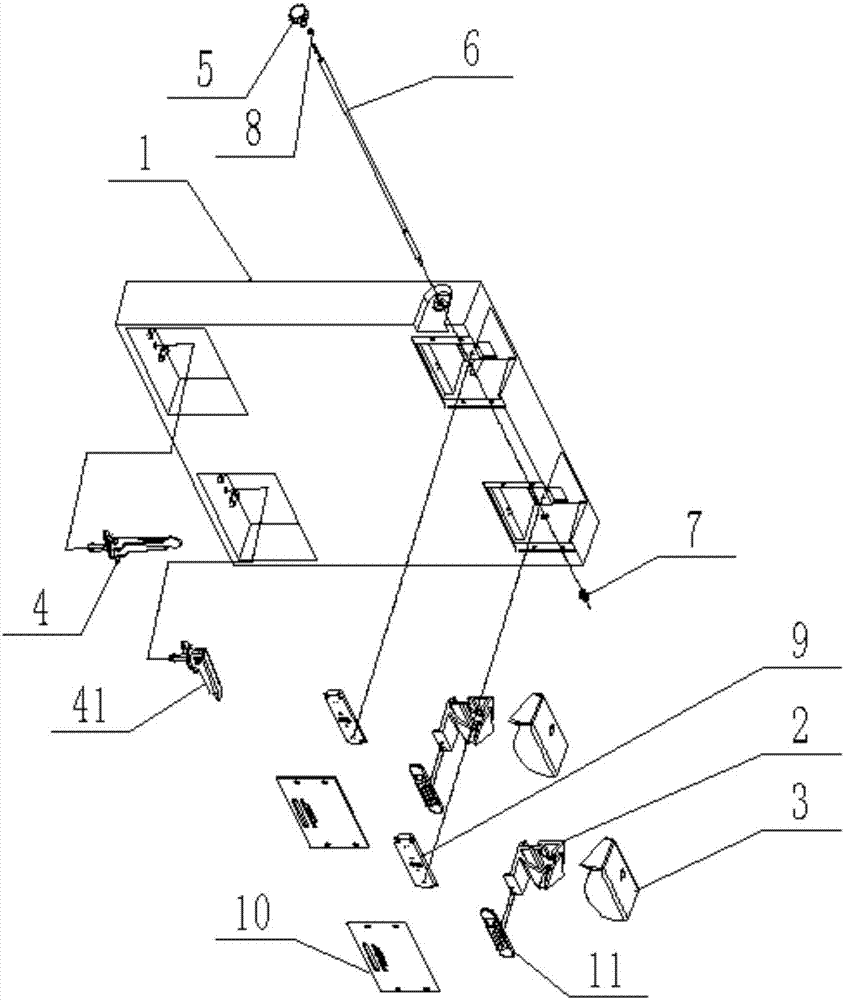

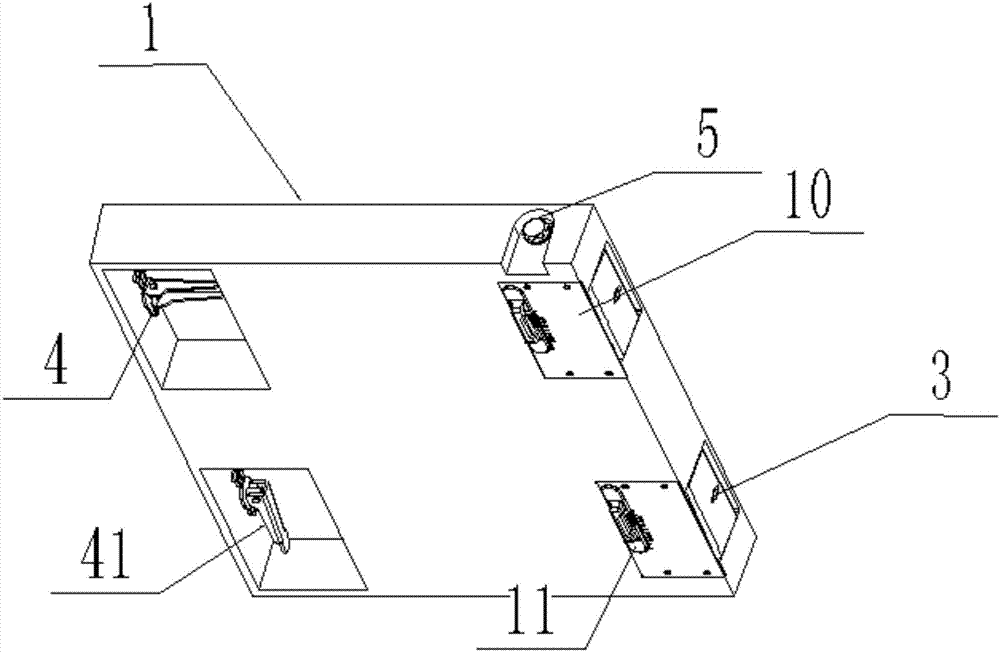

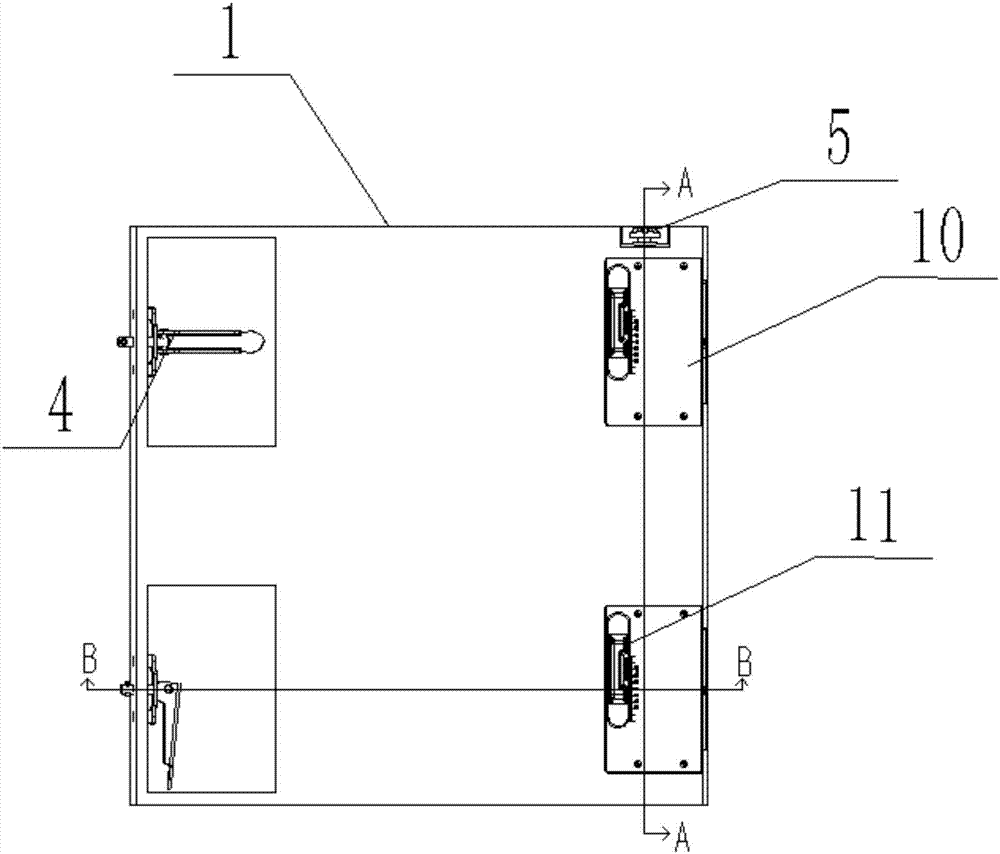

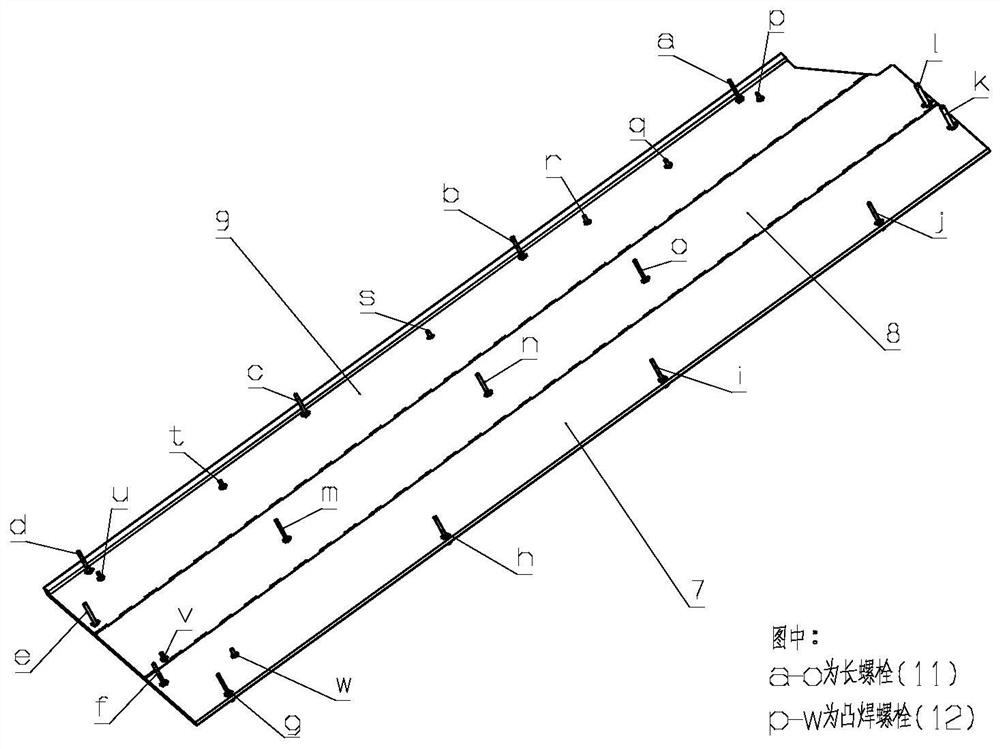

LED Display screen box lock structure

ActiveCN107452287AImprove Angular Stitching AccuracySimple structurePhotovoltaic energy generationIdentification meansLinear motionLED display

The invention belongs to the technical field of displays and discloses an LED display screen box lock structure, comprising adjusting blocks, angle blocks and curved guide rails; all the adjusting blocks, the angle blocks and the cured guide rails are arranged on a box body; the adjusting blocks are connected with the angle blocks through the curved guide rails; when the adjusting blocks are in linear motion, the angle blocks are driven to rotate through the curved guide rails; the box body is also provided with lock locking structures corresponding to the angle blocks; the angle blocks on one box body cooperate with lock locking structures of another box body to adjust the angle of the two box bodies; linear motion of the adjusting blocks is converted into rotational motion of the angle blocks through the curved guide rails so as to arrive at angle adjustment, and angle splicing precision is improved; the LED display screen box lock structure is simple in structure and convenient to operate, and has no need for machining so that the cost is greatly reduced.

Owner:UNILUMIN GRP

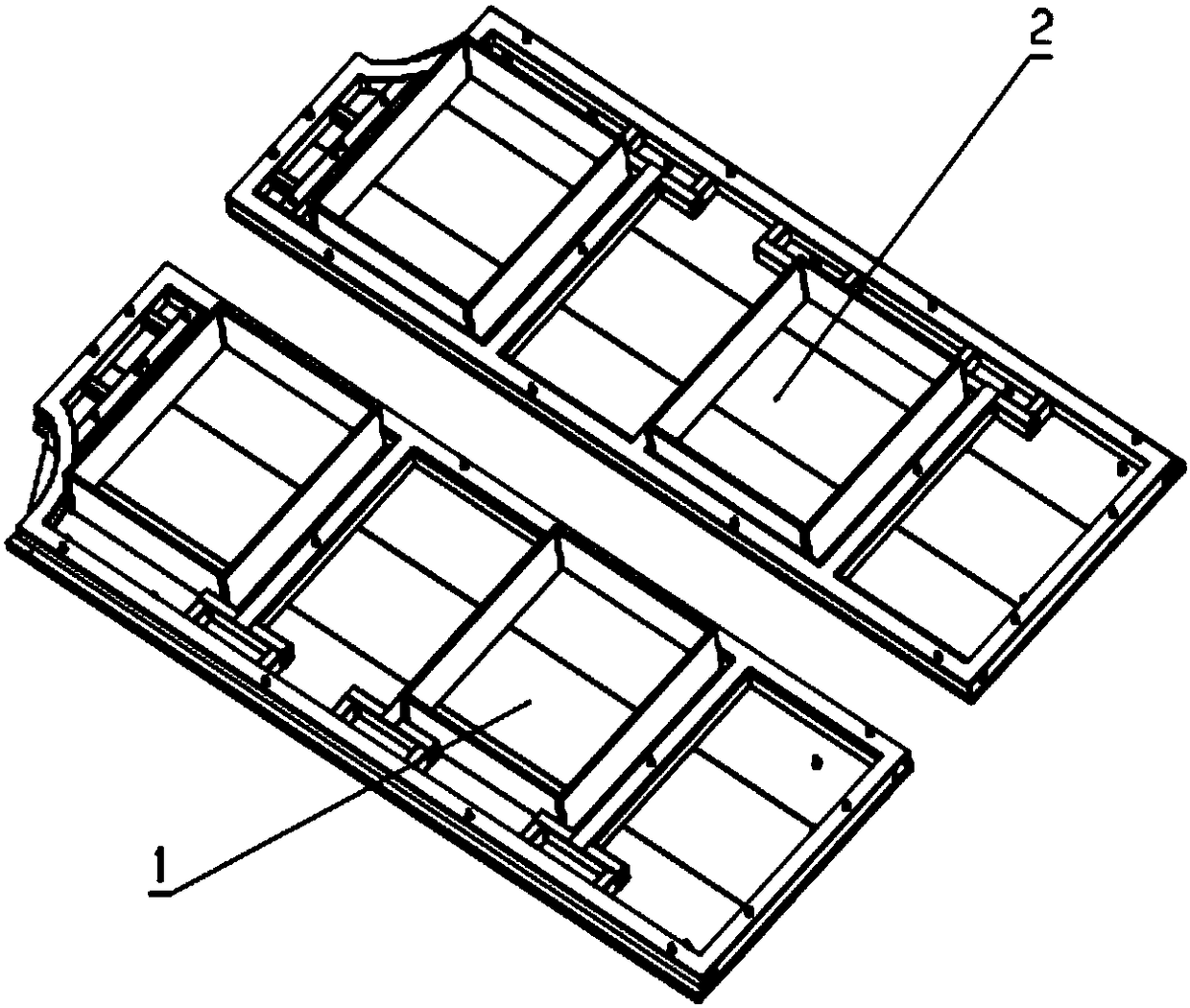

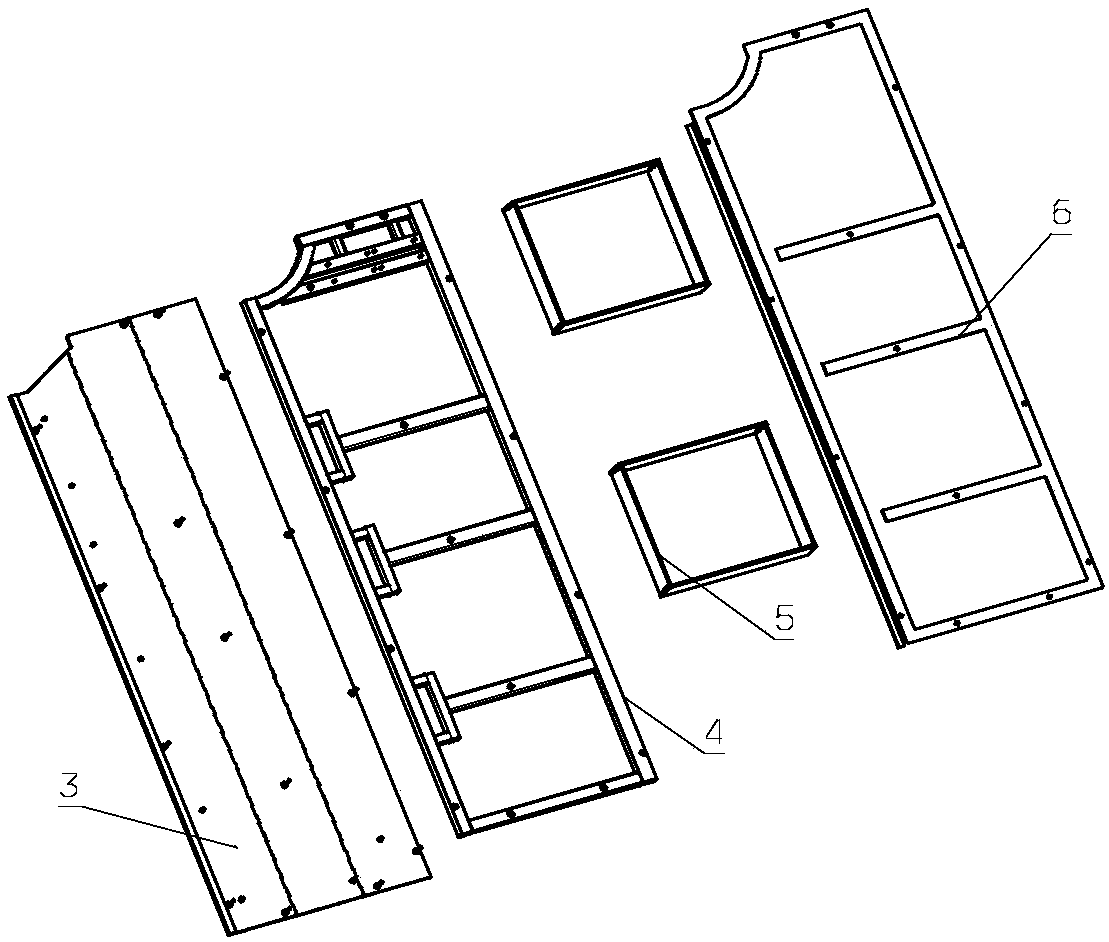

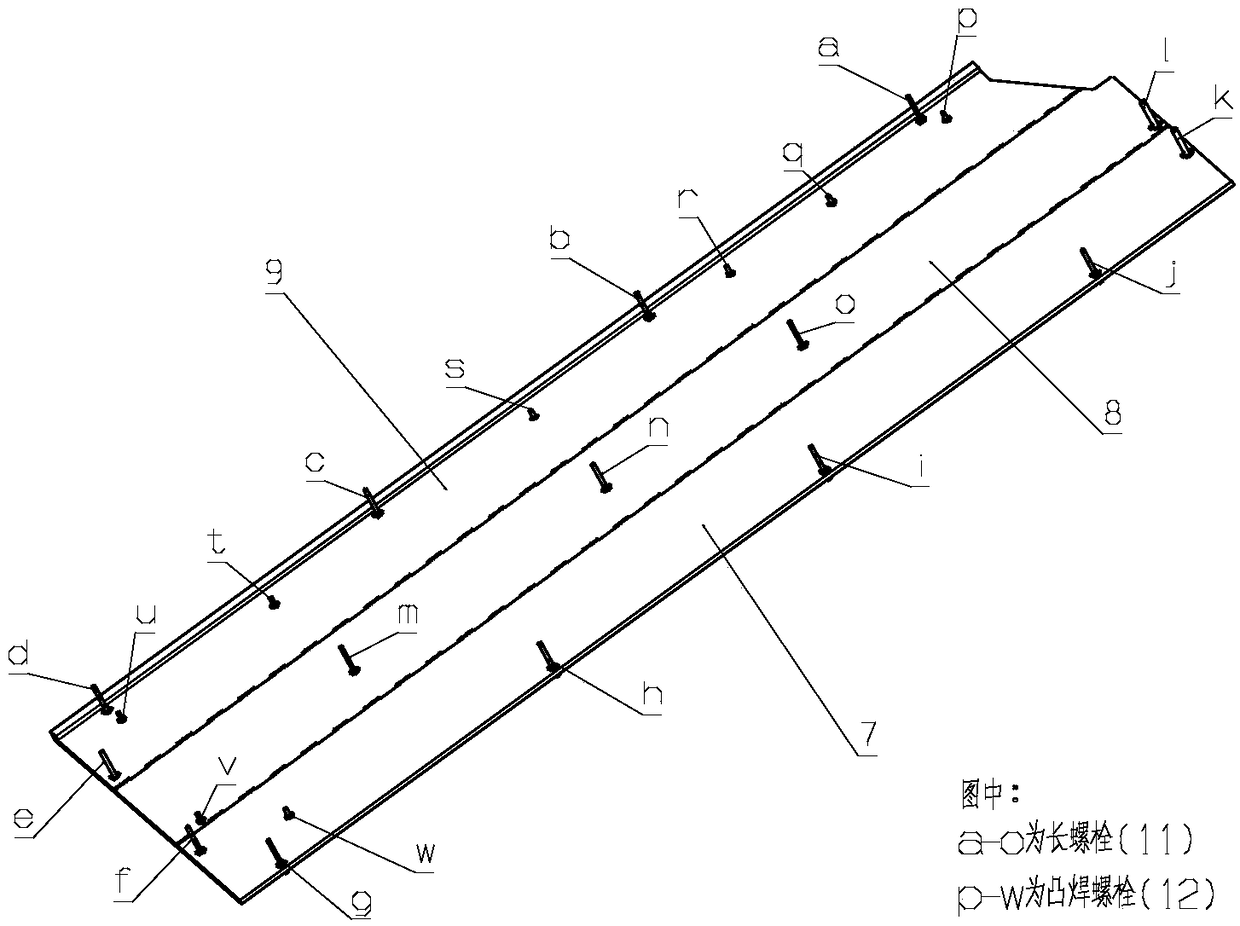

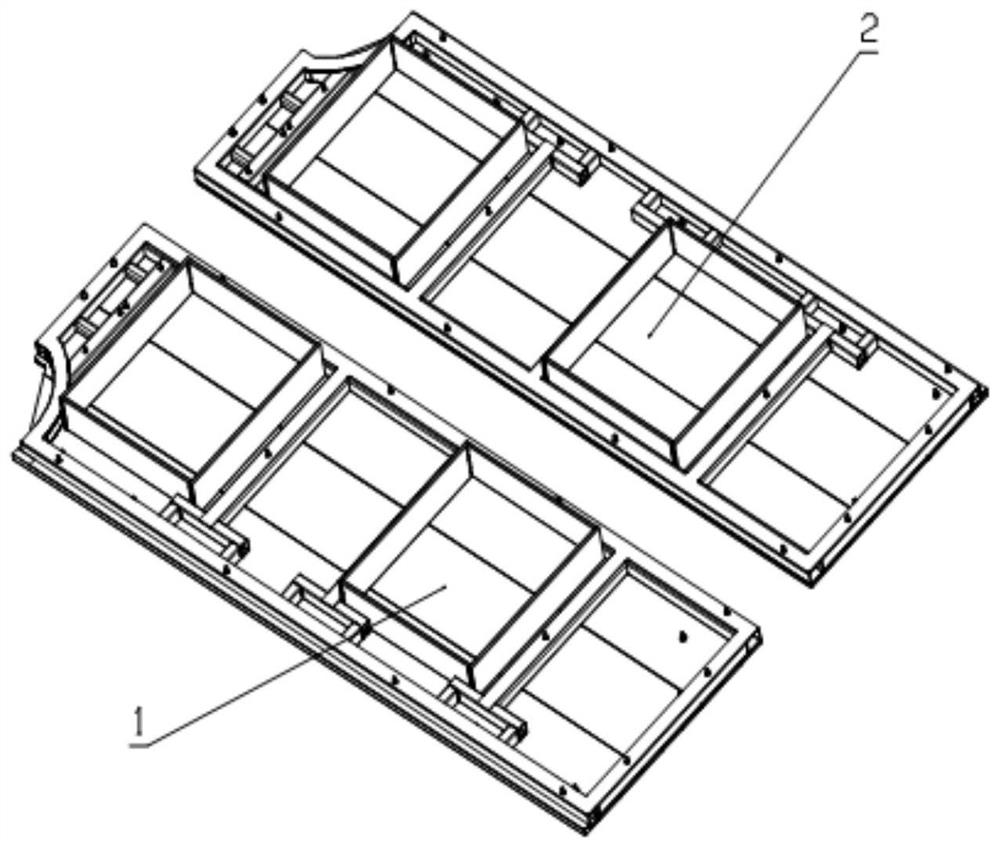

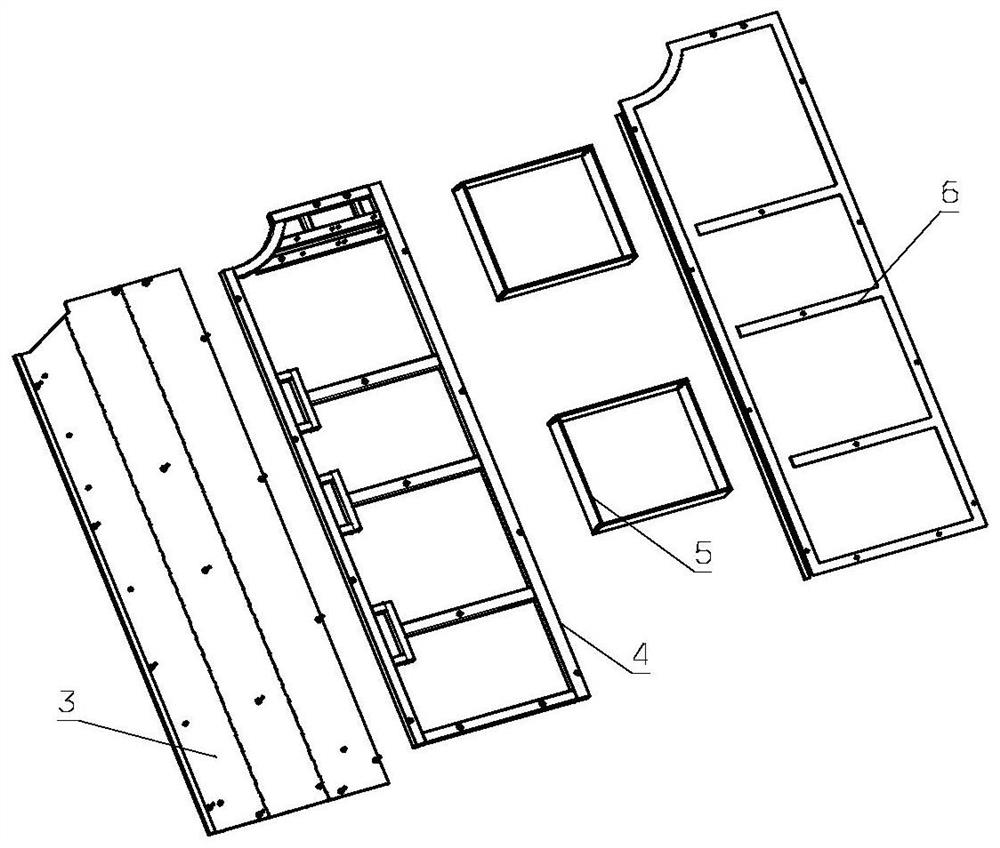

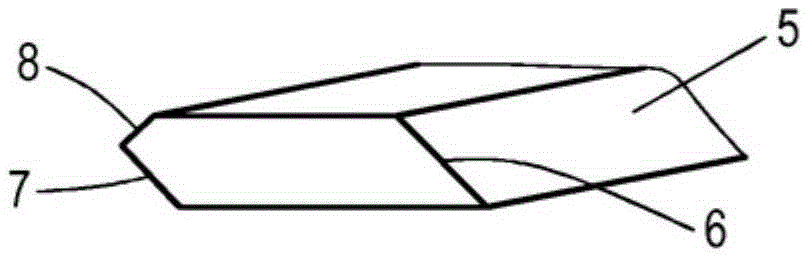

Automobile battery carrying board assembly structure

ActiveCN108237885AGood protectionCompact structureElectric propulsion mountingLap jointPower battery

The invention provides an automobile battery carrying board assembly structure. The structure comprises two parts of a left battery carrying board assembly (1) and a right battery carrying board assembly (2). The left battery carrying board assembly (1) and the right battery carrying board assembly (2) are symmetrically arranged. The left battery carrying board assembly (1) comprises a left battery carrying board subassembly (3), a left battery carrying board beam structure assembly (4), a battery installation beam assembly (5) and a left shock absorption sealing pad (6); and the left batterycarrying board subassembly (3), the left battery carrying board beam structure assembly (4), the battery installation beam assembly (5) and the left shock absorption sealing pad (6) are in lap joint sequentially. By the adoption of the provided automobile battery carrying board assembly structure, a power battery pack can be firmly fixed to a lower vehicle body of a vehicle body and can be well protected.

Owner:TJI INNOVA ENG & TECH

Preparation method of air-cooling lower bainite/martensite complex-phase wear resistant cast steel

The invention discloses a preparation method of air-cooling lower bainite / martensite complex-phase wear resistant cast steel. Mn is adopted as a main alloy element; small numbers of such alloy elements as Cr, B and rare earth elements (La, Ce, Nb and Pr) are added; and the balance is Fe. The alloy elements are smelted by a conventional steelmaking process, are cast and molded, are austenitized and air-cooled or forced-air-cooled, are heated and insulated, and are tempered with low temperature. The structure of the produced wear resistant cast steel after the air cooling consists of lower bainite / martensite and a small number of granular bainite. The hardness of the cast steel is higher than 50 (HRC); and the no-gap impact energy AK is higher than 50 J. The wear resistant cast steel has the advantages of low alloy element content, excellent toughness fit and wear resistance, simple process and low cost; the preparation method can be used for manufacturing various low-alloy wear resistant cast steel parts; and in particular, the preparation method has unique advantages for the wear resistant cast steel parts with complex shape structures, large sizes and easy rupture properties in quenching.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

Method of manufacturing small-sized and thin-wall Nb-W-Mo-Zr alloy parts

The invention belongs to the technical field of powder metallurgy and relates to a manufacturing method of niobium alloy parts, in particular to a manufacturing method of small-sized and thin-wall Nb-W-Mo-Zr alloy parts. The manufacturing method uses micro spherical Nb-W-Mo-Zr alloy powder which is treated through mechanical alloying and plasma spheroidizing as raw materials, and uses a method of injection molding to prepare a small-sized and thin-wall Nb-W-Mo-Zr alloy part, wherein the alloy part is characterized in that length is smaller than or equal to 30mm, width is smaller than or equal to 5mm, the thickness of thin wall is smaller than or equal to 1mm, dimensional tolerance is smaller than or equal to 0.09%, and a step structure and an arc structure are included in the alloy part. The method of manufacturing small-sized and thin-wall Nb-W-Mo-Zr alloy parts overcomes the defects of a traditional niobium alloy part manufacturing method, for example, stock utilization is low, pollution is serious, complicated shaped parts cannot be manufactured, and production efficiency is low. The method is suitable for manufacturing small-sized and complicated Nb-W-Mo-Zr alloy parts.

Owner:UNIV OF SCI & TECH BEIJING

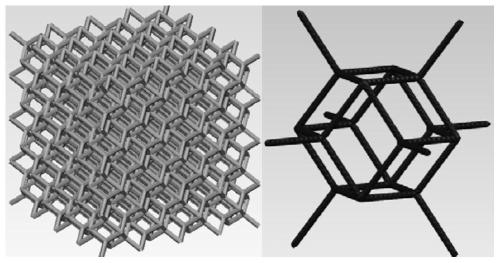

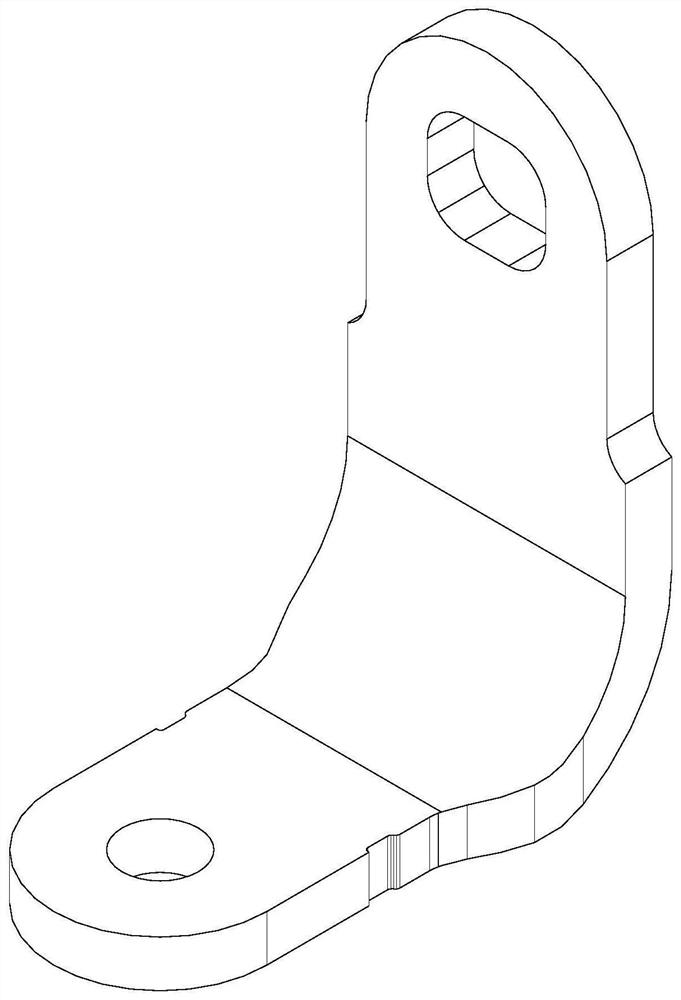

Gimbal ring structure lightweight design method suitable for additive manufacturing forming technology

ActiveCN111177861AReduce weightSmall deformation displacementGeometric CADIncreasing energy efficiencyStatic optimizationMaterial distribution

The invention discloses a gimbal ring structure lightweight design method suitable for an additive manufacturing forming technology. Structural characteristics, boundary conditions and stress workingconditions of a gimbal ring product are analyzed; an initial model suitable for gimbal topological optimization is established, and an optimization design area is determined; a gimbal optimal force transmission path and a material distribution initial model are obtained in combination with static optimization analysis, a design criterion considering a gimbal optimal topological structure and a good forming quality balance condition is provided, and a brand-new lightweight design model structure based on additive manufacturing is obtained.

Owner:XIAN SPACE ENGINE CO LTD

Carbon fiber epoxy resin matrix composite atr series chassis

ActiveCN110313240BHigh strengthIncrease profitDigital processing power distributionEpoxyCarbon fibers

The invention provides an ATR series chassis made of carbon fiber epoxy resin matrix composite material. The composite material ATR series case is prepared by laying up carbon fiber epoxy resin based composite material prepreg, heating, pressurizing and curing. The present invention uses the carbon fiber reinforced material of the new composite material and the resin-based composite material to prepare the ATR series chassis products, which are manufactured by one-time membrane pressing. The product has high processing precision and good consistency, no need for subsequent mechanical processing, high raw material utilization rate, no waste, and is suitable for mass production. Carbon fiber epoxy resin matrix composite material has high strength, flame retardancy and corrosion resistance. The product does not require surface protection treatment, and is suitable for harsh environments such as acid, alkali, and salt spray. Due to the low specific gravity of carbon fiber epoxy resin-based composite materials (aluminum alloy 1.4-1.6g / cm 3 ), the unit weight of the product parts is lighter.

Owner:NANJING RUNNINGTALE TECH CO LTD

Centrifugal casting process of high-performance engine alloy cylinder sleeve

The invention discloses a centrifugal casting process of a high-performance engine alloy cylinder sleeve; the radiating condition in the condensation of a casting melt is improved through optimizing the mold design; tin is added in a traditional cylinder jacket material for alloying; and meanwhile, the total inoculation quantity is reduced, and ladles are properly added for inoculating, so that graphite is more refined, the pearlite stability is improved, and the wear resistance of the cylinder jacket material is improved.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

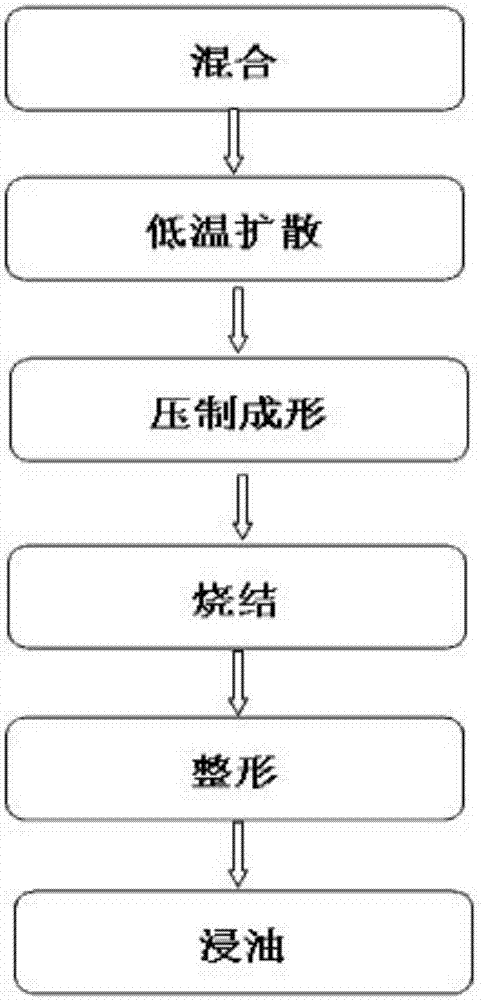

Manufacturing method of high-strength powder metallurgy brass base coupling

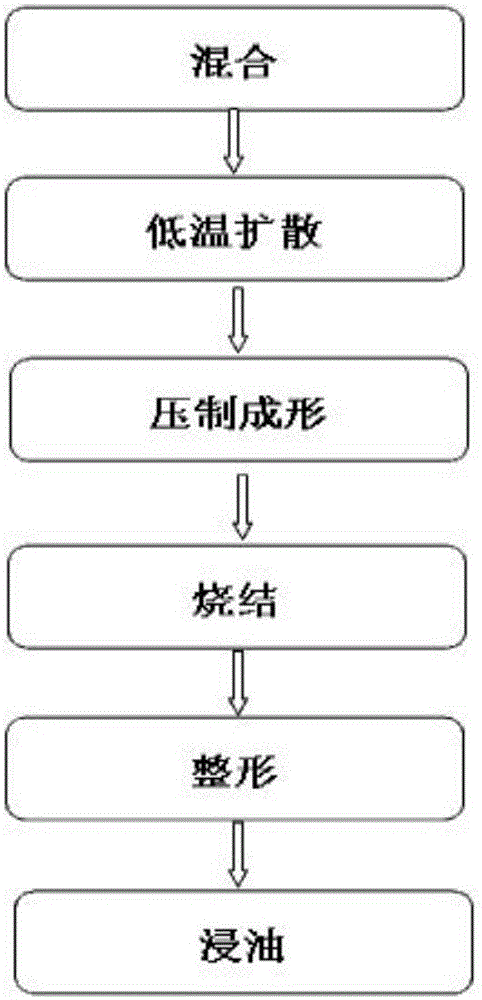

InactiveCN107175334AGuaranteed strength and toughnessEasy to manufactureRare-earth elementPowder metallurgy

The invention provides a preparation method of a high-strength powder metallurgy brass base coupling. The method comprises the following steps: powder mixing: the following raw material powder is put in a mixer for mixing to obtain mixed powder in percentage by weight: 28-32% of Zn element powder, 0.5-0.7% of rare earth element powder, and the balance of copper powder and inevitable impurities; low-temperature dispersion: the uniformly mixed mixture is dispersed at low temperature in a dispersion furnace through protection under N gas protective atmosphere, so that part of metal is prealloyed; and the high-strength powder metallurgy brass base coupling is obtained through pressing formation, sintering treatment, finishing and oil leaching treatment. The method solves the technical problem of difficult guarantee of the size consistency due to more variables in traditional machining.

Owner:HAIAN YINGQIU POWDER METALLURGY CO LTD

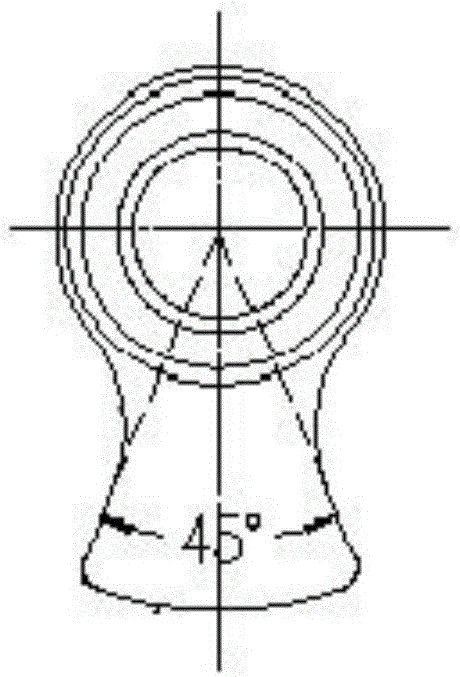

High-strength powder metallurgy brass-based coupler

InactiveCN107119206AGuaranteed StrengthGuaranteed toughnessTransportation and packagingMetal-working apparatusRare-earth elementHigh intensity

The invention aims to provide a high-strength powder metallurgy brass-based coupler. The high-strength powder metallurgy brass-based coupler comprises the following components by mass percent: 28-32% of Zn element powder, 0.5-0.7% of rare earth element powder and the balance of copper powder and inevitable impurities. The technical problem that the dimensional consistency is difficult to guarantee because many variables exist during traditional machining is solved.

Owner:HAIAN YINGQIU POWDER METALLURGY CO LTD

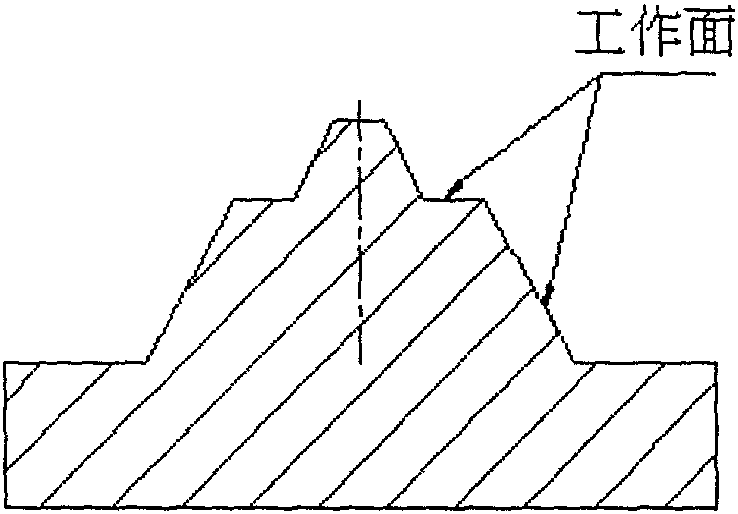

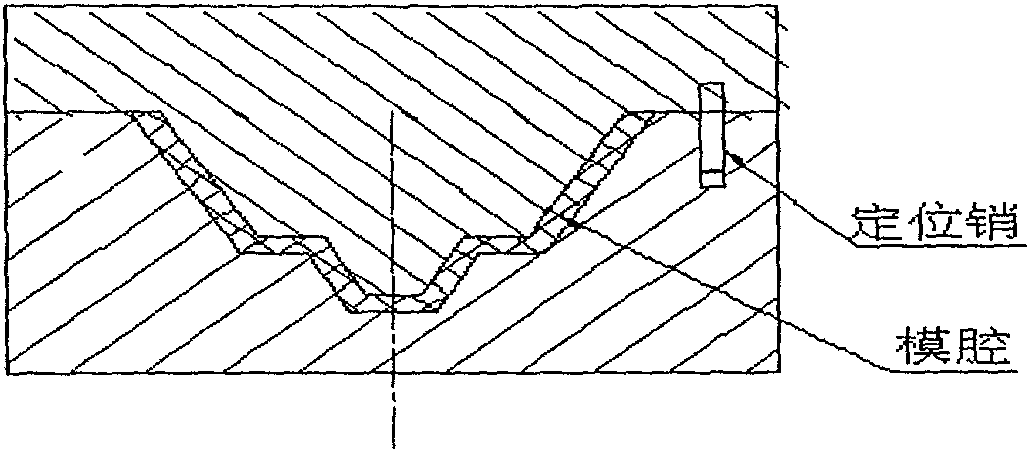

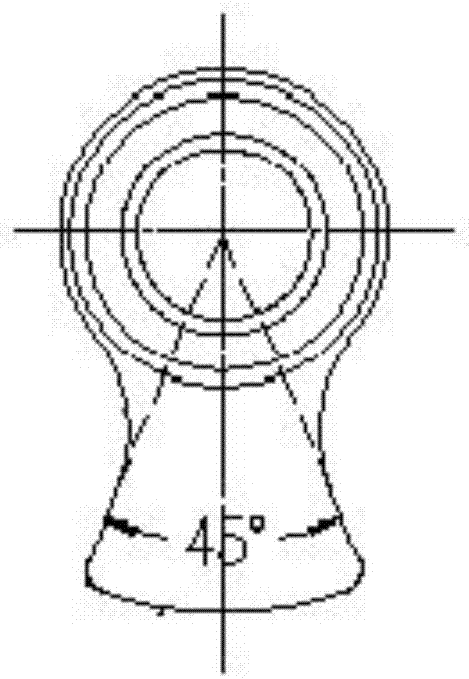

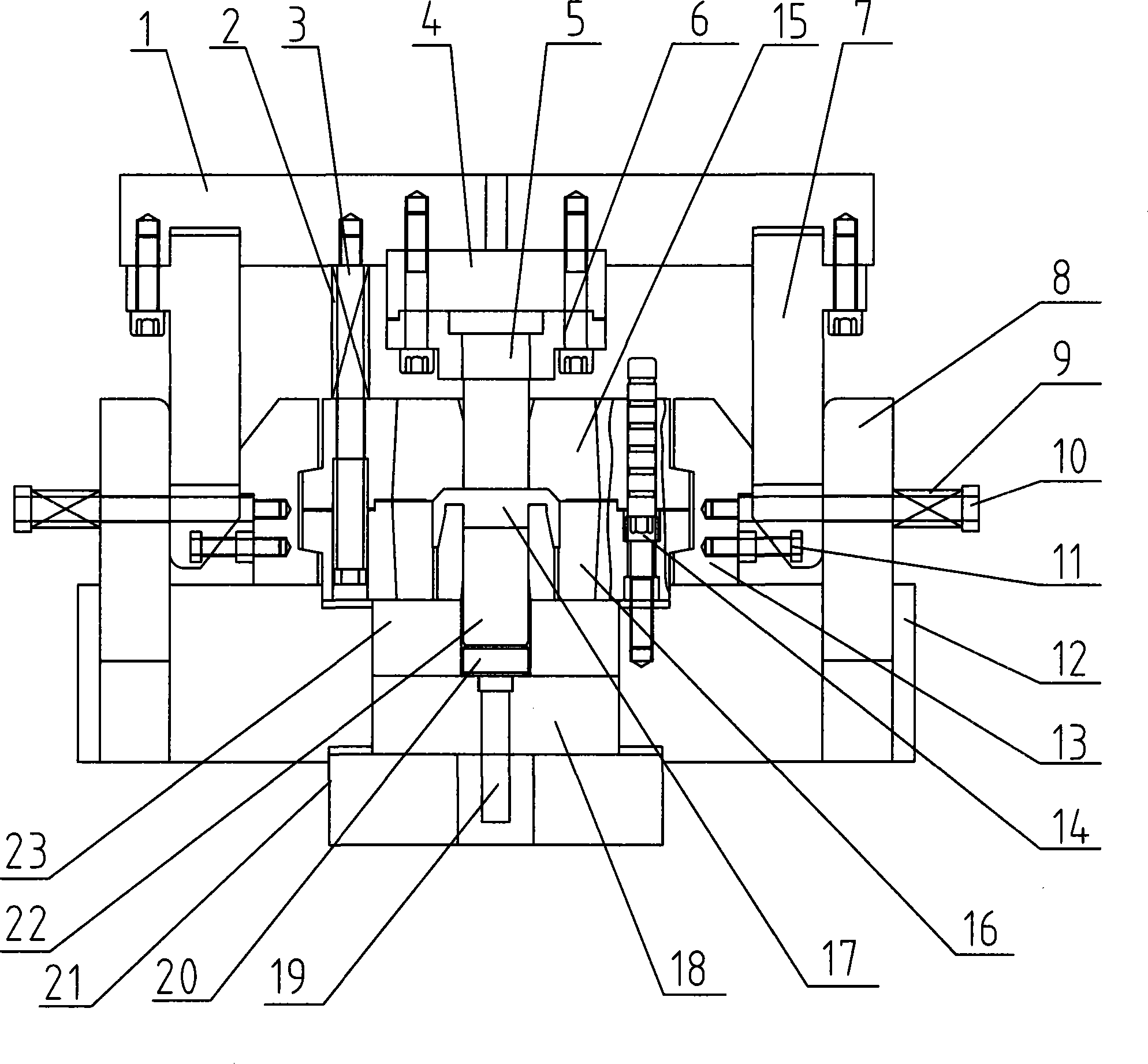

Mold device for producing alternator claw pole

The invention discloses a mold device for producing an alternator claw pole. The mold device comprises an upper mold fixing plate and a lower mold fixing plate. An upper punch, a mold separating pull rod and an annular wedge are mounted on the upper mold fixing plate. An upper semi die and a die resetting spring are mounted outside the mold separating pull rod. A lower semi die and a stopping block are mounted on the lower mold fixing plate. A guide column is mounted in the lower semi die, guide positioning between the lower semi die and the upper semi die is realized through the guide column. A lower punch is mounted in the lower semi die. A lower punch pad is mounted under the lower punch. An upper die pad and a lower die pad are mounted in the middle of the lower mold fixing plate. A pressing rod is mounted in the lower die pad. A locked module resetting pull rod is mounted on the stopping block. The stopping block is connected with a locked module through the locked module resetting pull rod. A locked module resetting spring is mounted outside the locked module resetting pull rod. Material utilization rate is high, and producing efficiency is high.

Owner:慈溪市丰盈电声配件有限公司

Casting production process for belt wheel casting

The invention discloses a casting production process for a belt wheel casting; the casting production process disclosed by the invention comprises the steps of manufacturing a mould, manufacturing a sand mould, setting a core, pouring and carrying out subsequent operation in sequence; the casting production process disclosed by the invention is characterized in that the step of manufacturing the sand mould comprises filling the mould by moulding sand, compacting the moulding sand to complete a mould, and simultaneously, setting an air inflation hole in the completed mould; a step of smelting is set between the step of setting the core and the step of pouring; the step of smelting comprises selecting materials according to the casting at first, adding alloy elements into molten iron, inoculating after discharging molten iron, and then, pouring; and the step of pouring comprises injecting molten iron into a cavity and pouring to obtain the belt wheel casting. By means of the casting production process disclosed by the invention, the problems of being more in process and high in workload in processing of the belt wheel casting in the prior art are solved; the production efficiency is increased; the quality defect due to the fact that the belt wheel is processed unqualifiedly is avoided; the utilization rate of raw materials is high; the production cost is reduced; the cast belt wheel is precise in size and unnecessary to machine; and thus, the quality of the casting is effectively ensured.

Owner:QINGDAO HEDELONG MACHINERY

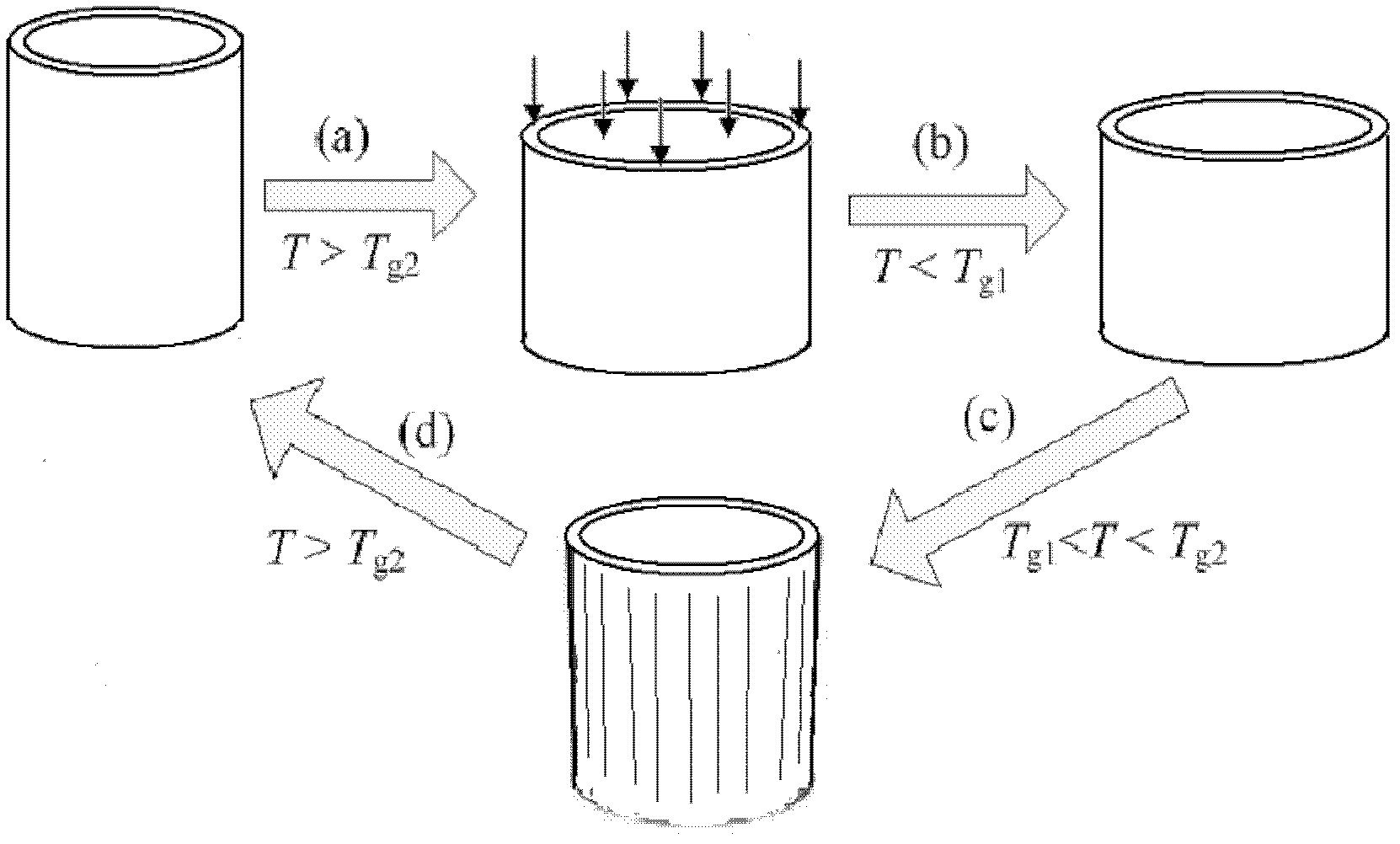

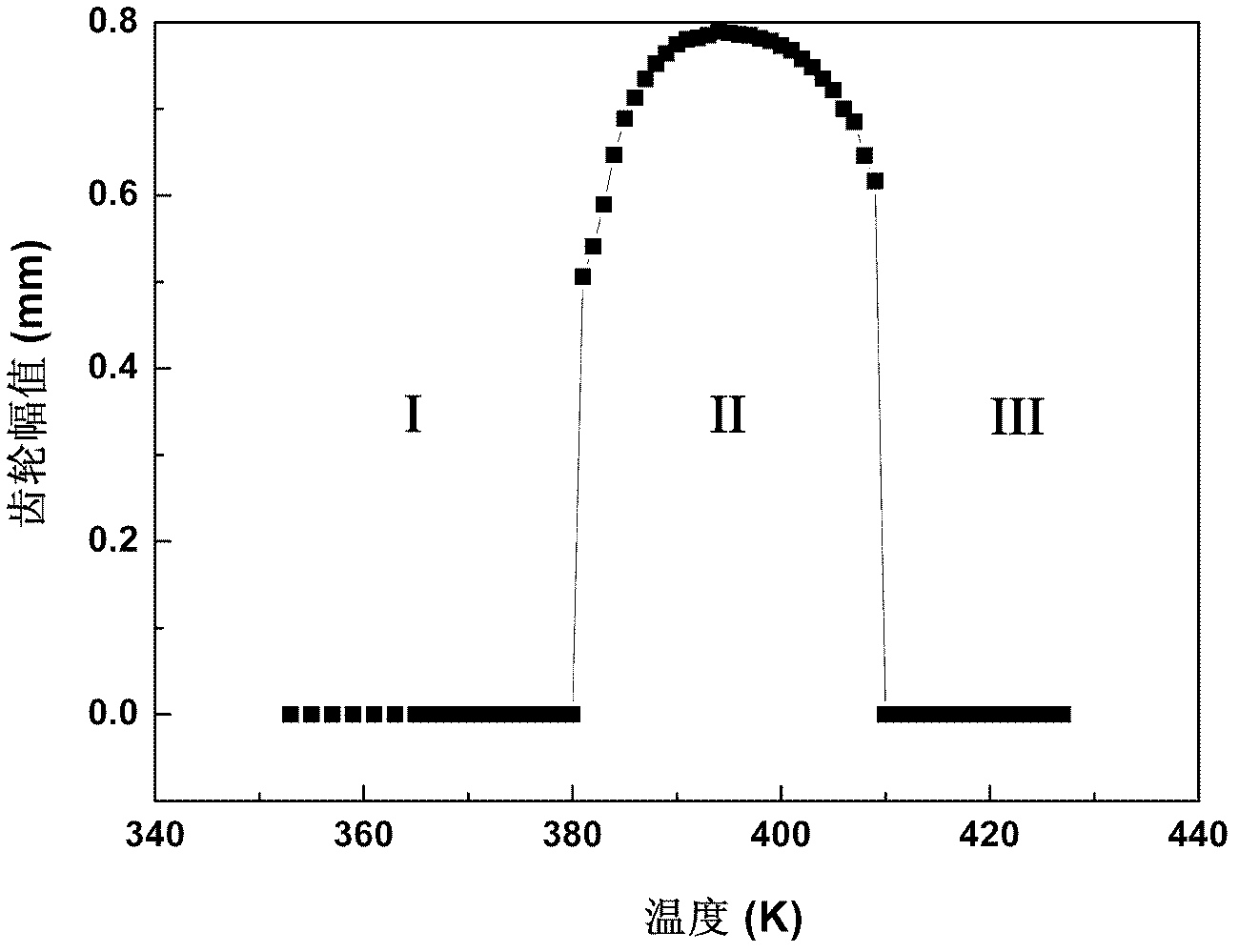

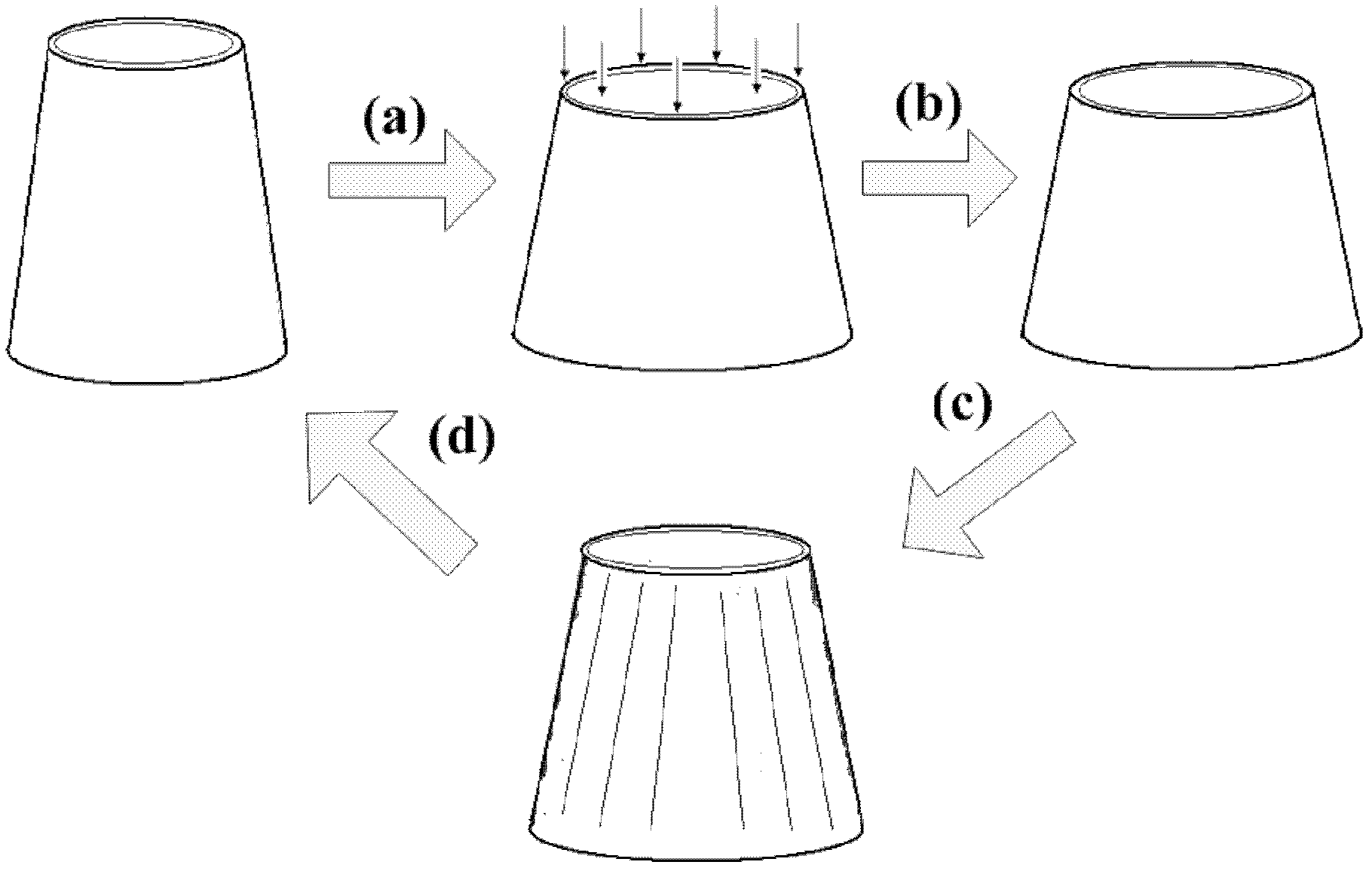

Composite structure of round-trip shape memory self-assembly gear and achieving method thereof

InactiveCN102555388BNo machining requiredAchieving two-way shape memory functionSynthetic resin layered productsShape changeEngineering

The invention discloses a method for achieving a round-trip shape memory self-assembly gear in the field of micro mechanical manufacturing, which achieves two-way reversible self-assembly shape change of a smooth structure and a gear structure. A composite structure is formed by an inner layer shape memory polymer cylinder core of low transition temperature and an outer layer shape memory polymer thin film of high transition temperature. By means of different transition temperatures of the shape memory polymer cylinder core and the outer layer thin film (namely, shape memory transition points are different), two-way reversible shape change of the composite structure of the smooth structure- the gear structure- the smooth structure in the heating process is achieved. Gear parameters are adjusted by changing parameter ratio of the cylinder core and the outer layer thin film, and the cylinder core structure is utilized to achieve profiled gear self-assembly. The method is capable of achieving automatic generation of small complex gears and free of machining, has important application prospects in the micro mechanical field, and further achieves the two-way shape memory function which traditional single shape memory polymer doesn't have.

Owner:BEIJING JIAOTONG UNIV

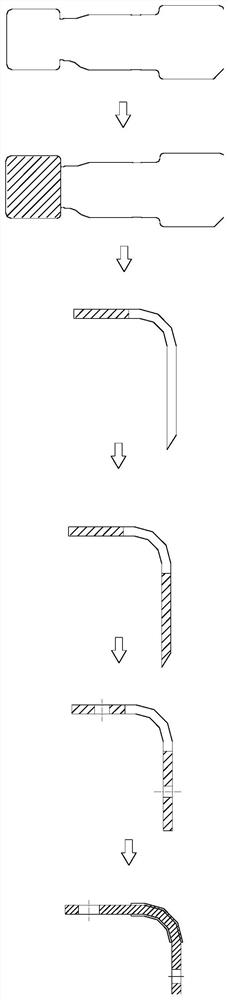

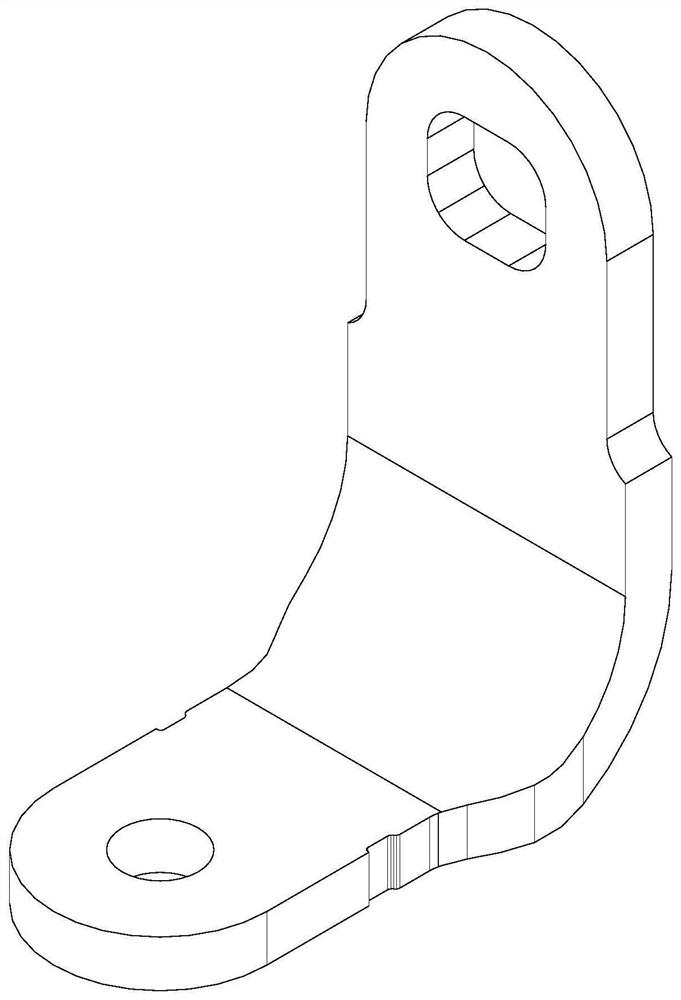

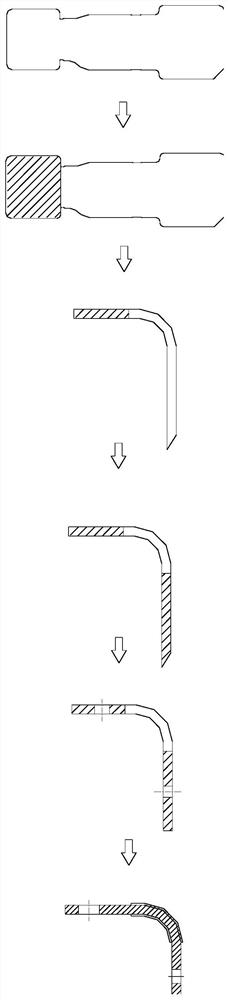

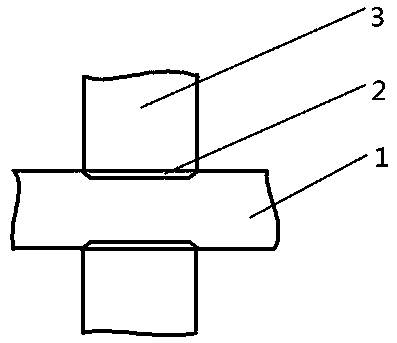

Production process of 90-degree soft copper bar free of NC machining

The invention provides a production process of a 90-degree soft copper bar free of NC machining. The production process comprises the following steps that a, discharging is conducted, copper foils arestacked in order, and thus a first semi-finished product is obtained; 2, one end of the first semi-finished product is aligned and then subjected to diffusion welding, and a second semi-finished product is obtained; 3, the middle of the second semi-finished product is bent by 90 degrees, and a third semi-finished product is obtained; 4, the other end of the third semi-finished product is alignedand then subjected to diffusion welding, and a fourth semi-finished product is obtained; 5, one end of the fourth semi-finished product is punched into a round connector with a square hole, the otherend of the fourth semi-finished product is punched into a round connector with a round hole, and a fifth semi-finished product is obtained; and 6, the middle of the semi-finished product is sleeved with a heat shrink tube to obtain a finished product. Compared with a traditional process that edging clamping and NC machining after diffusion welding are needed in the 90-degree bending process, copper foil stacks can be discharged through a punching die in an equal-length mode, two-step diffusion welding and two-step punching are conducted, operation is easy, efficiency is high, the yield is increased, copper foil loss is small, and cost is relatively reduced.

Owner:昆山维肯恩电子科技有限公司

An automobile battery pallet assembly structure

ActiveCN108237885BImprove protectionCompact structureElectric propulsion mountingPower batteryAutomotive battery

The invention provides an automobile battery supporting plate assembly structure, which comprises two parts, a left battery supporting plate assembly (1) and a right battery supporting plate assembly (2), the left battery supporting plate assembly (1) and the right The battery supporting plate assembly (2) is symmetrically arranged; the left battery supporting plate assembly (1) includes the left battery supporting plate subassembly (3), the left battery supporting plate beam structure assembly (4), the battery mounting beam assembly (5) and the left shock-absorbing gasket (6); the left battery support plate subassembly (3), the left battery support plate beam structure assembly (4), the battery installation beam assembly (5) and the left Shock gaskets (6) are overlapped successively. The automobile battery pallet assembly structure provided by the invention can securely fix the power battery group on the vehicle body under the vehicle body, and can better protect the battery group.

Owner:TJI INNOVA ENG & TECH

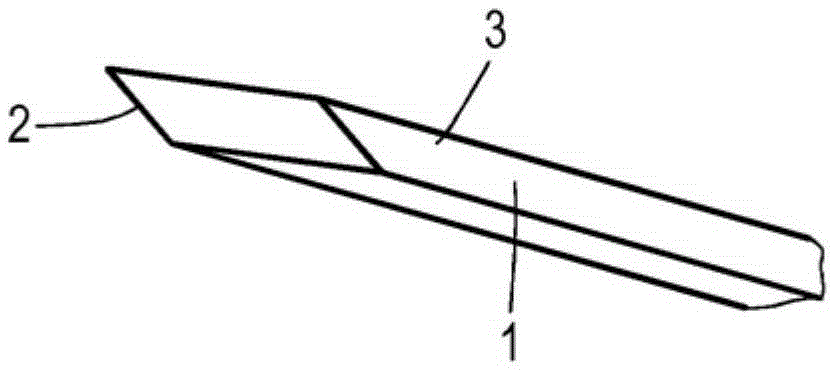

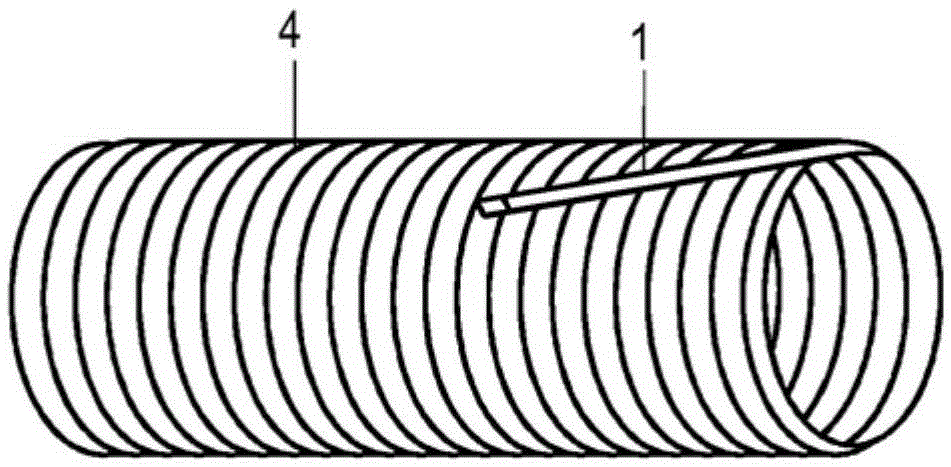

Outer ring and roller bearing comprising type of outer ring

InactiveCN105378312ATake advantage ofNo machining requiredBearing componentsMetal stripsRolling-element bearing

The invention relates to an outer ring (16) for a roller bearing comprising a raceway produced from a ball-and-roller bearing steel. According to the invention, said outer ring (16) is made of a metal strip (1, 5) wound to form a raceway tube (4, 12, 14) 5) and a cladding tube (9, 13, 15, 17) which is connected thereto and which surrounds the raceway tube (4, 12, 14) on the outer side.

Owner:SCHAEFFLER TECH AG & CO KG

A production process of 90° soft copper bar without NC processing

Owner:昆山维肯恩电子科技有限公司

Powder metallurgy component and production method of powder metallurgy component with mounting through hole

PendingCN112570712AHigh strengthImprove performanceEdge grinding machinesPolishing machinesIron sulfideAlloy

The invention discloses a powder metallurgy component. The powder metallurgy component comprises, by weight, 100 parts of steel powder, 4-5 parts of copper powder, 1-2 parts of iron sulfide, 1-2 partsof rare earth powder, 1-2 parts of nickel powder, 3-5 parts of calcium fluoride, 0.1-0.3 part of micronized wax, 1.2-1.5 parts of molybdenum powder, 2-4 parts of a forming agent and 0.5-0.9 part of alubricating agent. According to the powder metallurgy component, alloy iron-based powder obtained by fully mixing the steel powder, the copper powder, the iron sulfide, the rare earth powder, the nickel powder, the calcium fluoride, the micronized wax, the molybdenum powder, the forming agent and the lubricating agent is subjected to pressing, sintering, machining, heat treatment and surface vibration grinding treatment, and then a finished product is obtained. Due to the fact that a powder metallurgy machining technology is adopted, the integrated degree is high, large-scale repeated production is facilitated, the surface smoothness is good, cutting machining is not needed, and the advantages of material saving, time saving and the like are achieved.

Owner:HEZE SHUANGLONG METALLURGICAL MASCH CO LTD

A composite manufacturing method for shaft parts based on powder sintering

According to a shaft part composite manufacturing method based on powder sintering, a seamless pipe with the diameter being the same as that of a needed finished shaft product serves as a core shaft material, and after the core shaft material is marked, the marked portion which needs to be provided with a cam and / or other convex parts is machined into a slightly sunken part; the sunken part of thecore shaft material is wrapped with a copper alloy sheet, and prefabricated powder metallurgical presintering billets of the cam and / or the other convex parts are assembled with a core shaft, so thatthe powder metallurgical presintering billets of the cam and / or the other convex parts are mounted on the sunken part wrapped with the copper alloy sheet; and an assembled piece is put into a sintering furnace to be sintered and then subjected to finish machining, and the finished product is obtained. On the basis, powder metallurgical presintering billet components of the cam and / or the other convex parts are reasonably designed.

Owner:CIXI YONGLI ELECTRIC TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com