A composite manufacturing method for shaft parts based on powder sintering

A technology of shaft parts and manufacturing method, applied in the field of powder metallurgy, can solve the problems of high cost, complex process, more effective suggestions in sintering process, etc., achieve high precision, reasonable component selection, and save cleaning and grinding steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A composite manufacturing method for a shaft part based on powder sintering, the shaft part is a camshaft, comprising the steps of:

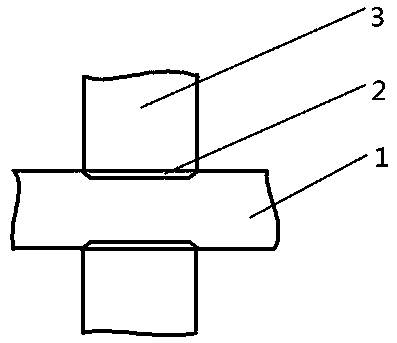

[0030] Step 1, select a seamless tube with the same diameter as the required camshaft as the material of the mandrel 1, cut it into the required length, clean or polish the cut, and the cutting method is dicing saw cutting, plasma cutting or laser cutting, The material of the seamless pipe is carbon steel;

[0031] Step 2, marking the mandrel material obtained in step 1 to mark the position where the cam and / or other protrusions need to be installed, the other protrusions are ends, journals, retaining rings, or induction rings one or more of

[0032] Step 3, performing mechanical processing or chemical etching on the mandrel material obtained in step 2, processing the marked parts where cams and / or other protrusions need to be installed into slight depressions, and the slight depressions Part means a recessed part with a depth dimension...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is:

[0043] For the cam powder metallurgy pre-sintered compact, it includes the following components by weight (the matrix is Fe): Cr content is 3.9%, C content is 2.0%, Si content is 1.1%, Zr content is 0.7%, W content is 0.1% , Cu content is 0.01%, Mn content is 0.01%;

[0044] For the powder metallurgy pre-sintered compact of the journal, it includes the following components by weight percentage (the matrix is Fe): Cr content is 3.0%, C content is 1.3%, Si content is 0.4%, Zr content is 0.7%, and W content is 0.1%, the Cu content is 0.02%, and the Mn content is 0.02%.

[0045] In the composite manufacturing method of shaft parts based on powder sintering, the composition of the copper alloy flake 2 includes 2.0% Mn, 2.0% Zn, 2.0% Sn, 1.0% Si, and the rest is Cu and unavoidable impurities.

Embodiment 3

[0047] The difference between this embodiment and embodiment 1 is:

[0048] For the cam powder metallurgy pre-sintered compact, it includes the following components by weight percentage (the matrix is Fe): Cr content is 3.2%, C content is 2.8%, Si content is 0.9%, Zr content is 0.4%, W content is 0.3% , Cu content is 0.01%, Mn content is 0.01%;

[0049] For the powder metallurgy pre-sintered compact of the journal, it includes the following components by weight percentage (the matrix is Fe): Cr content is 2.3%, C content is 1.8%, Si content is 0.6%, Zr content is 0.4%, W content is 0.4%, the Cu content is 0.02%, and the Mn content is 0.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com