Outer ring and roller bearing comprising type of outer ring

A technology of roller bearings and rolling bearings, applied in shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of cleaning, waste recovery, cutting waste waste generation, etc., and achieve the effect of saving resources and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

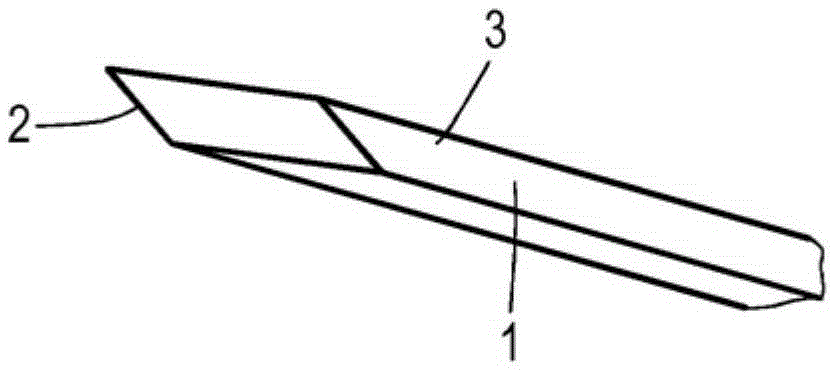

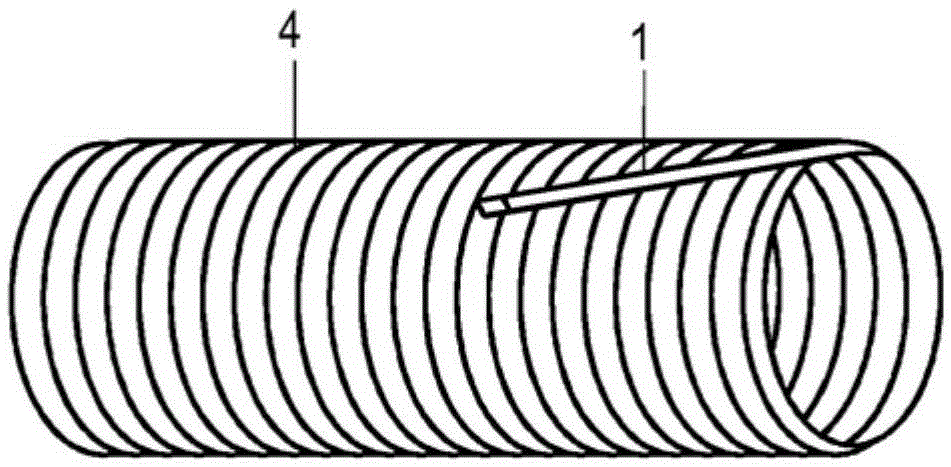

[0027] figure 1 A perspective view of a sheet metal strip 1 is shown, which is used for producing raceway tubes. In the exemplary embodiment shown, the metal strip 1 is made of a hardenable rolling bearing steel of the C80M type. The thickness of the metal strip 1 is approximately 1 mm, however, the thickness can be selected differently depending on the size of the outer ring to be produced. exist figure 1 Middle identification: The metal strip has the shape of a parallelogram in cross section, that is to say it has an underside parallel to the upper side and two oblique sides 2 , 3 parallel to one another. In the wound state, the inclined sides 2 , 3 rest against each other, thereby preventing movement. The inclination of the inclined sides 2 , 3 and the width of the sheet metal strip 1 are selected such that in the wound state approximately two helical groove turns are produced per raceway width, thereby having a favorable influence on the running noise. In other embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com