Drive device for vehicle

A vehicle driving device and driving wheel technology, which is applied in the transmission device, power device, gear transmission device, etc., and can solve the problems of difficult lubricating oil passage, complicated connection structure of the first shaft, and complicated structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

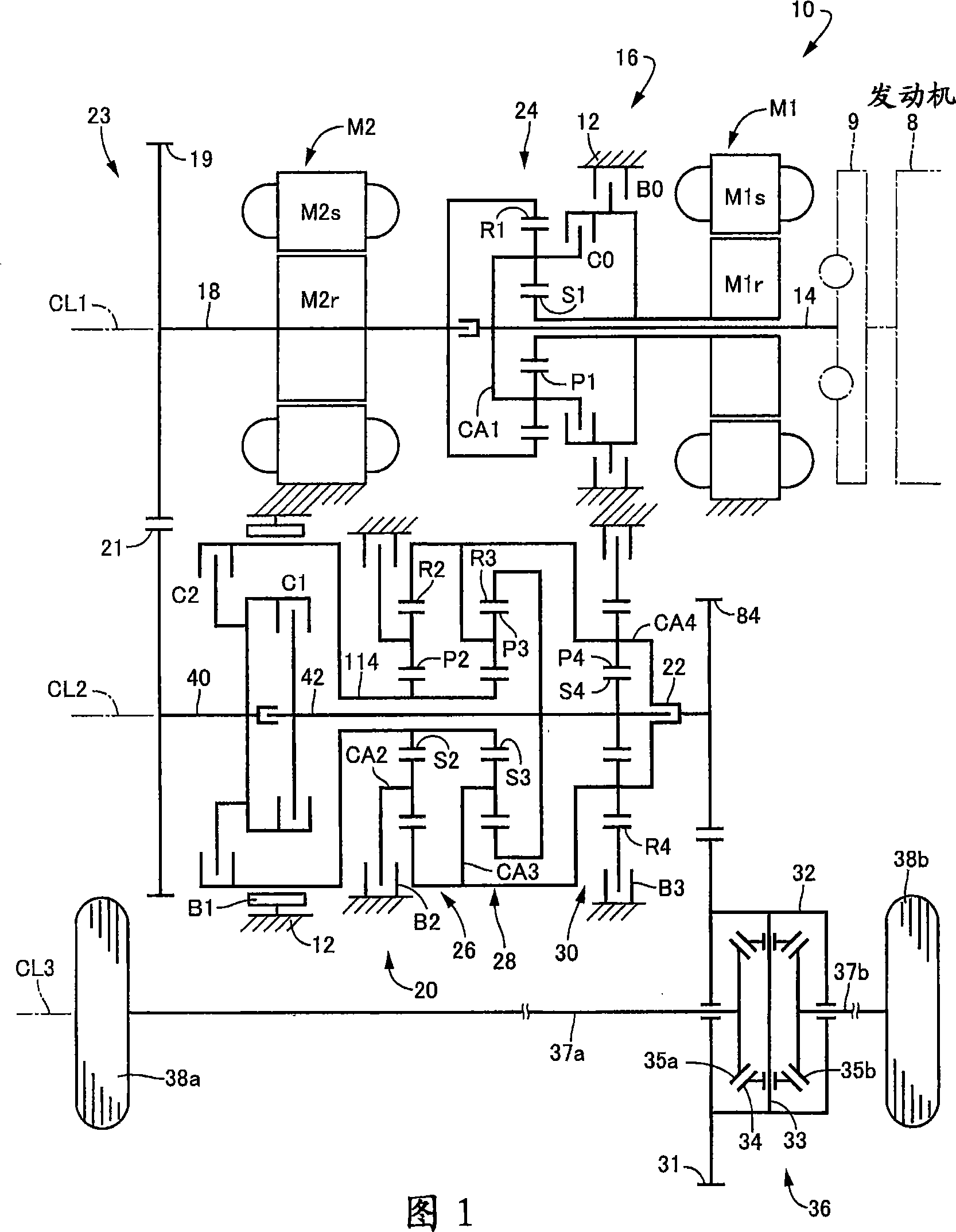

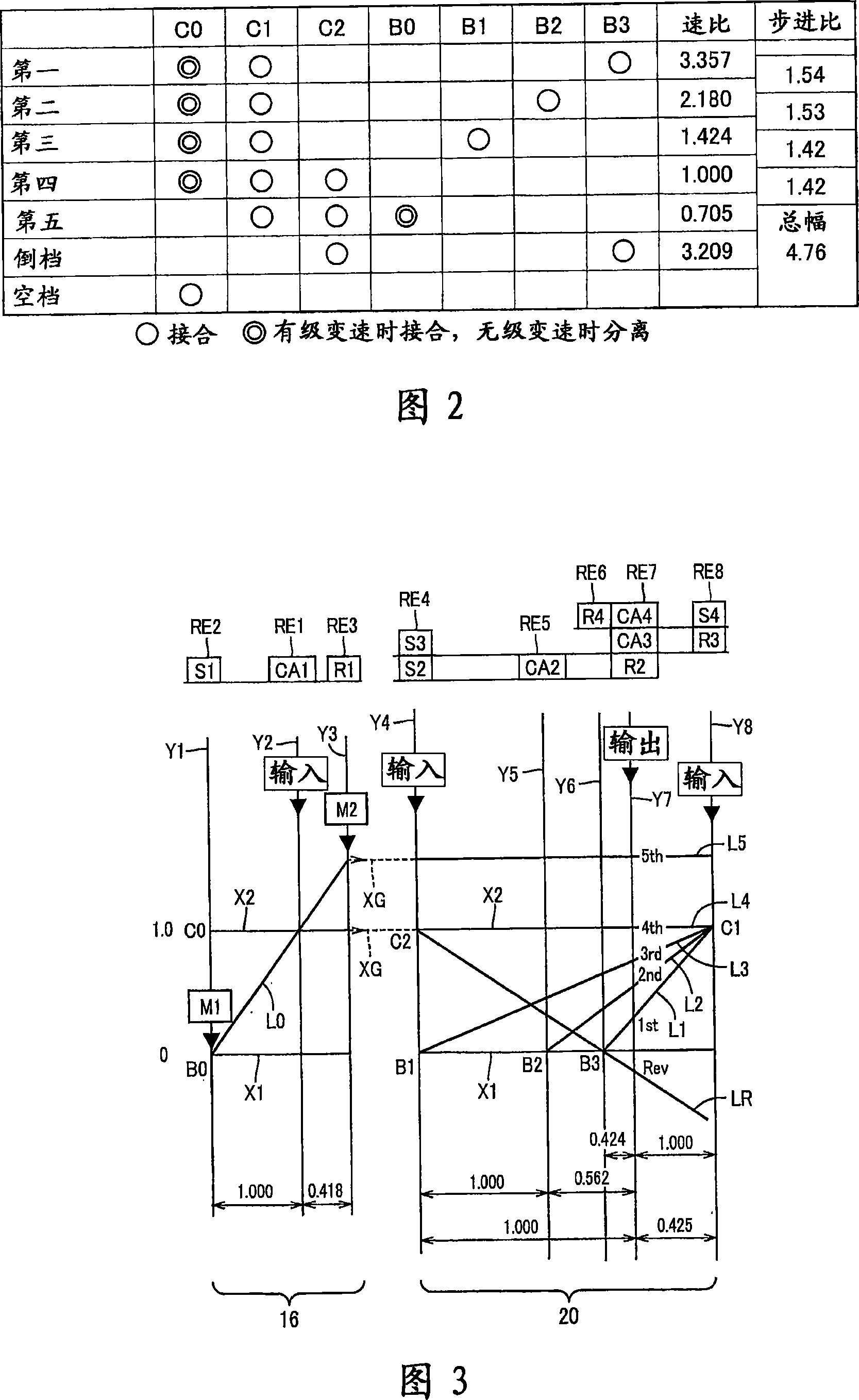

[0153] First, refer to the schematic diagram of FIG. 1, which shows a driving device 10 for a hybrid vehicle constructed according to an embodiment of the present invention. The driving device 10 shown in FIG. 1 includes: an engine 8; a transaxle housing 12 (hereinafter referred to as "housing 12"), which is a fixed member installed on the vehicle body; a pulsation absorbing damper (vibration damping device) 9; The first input shaft, which is in the form of an input rotating member 14 connected to the engine 8 via a pulsation absorbing damper 9 and receiving the output of the engine 8 via a pulsation absorbing damper 9 (vibration damping device); a first electric motor M1; a hydraulic operation type Differential limiting device, which is in the form of switching clutch C0 and switching brake B0; differential gear mechanism or differential part, which is in the form of power distribution mechanism 16 connected to input rotating member 14; power transmission member 18, its configura...

no. 1 example

[0245]According to the first embodiment, the driving device 10 includes a power distribution mechanism (differential portion) 16 and a second electric motor M2, and the driving force applied to the input rotating member 14 is distributed to the first electric motor M1 and the power transmission member via the power distribution mechanism 16 18. The second electric motor M2 is arranged in the power transmission path between the power transmission member 18 and the drive wheels 38a, 38b. In addition, the drive device 10 includes an automatic transmission portion (transmission portion) 20 arranged between the power transmission member 18 and the drive wheels 38a, 38b. The first electric motor M1 and the power distribution mechanism (differential portion) 16 are sequentially arranged from the input rotation member 14 side on the first axis CL1 forming the rotation axis of the input rotation member 14, and the automatic transmission portion (transmission portion) 20 is arranged on On t...

Embodiment 2

[0275] Other embodiments of the present invention will be described below. In the following description of the other embodiments, the same reference numerals as in the first embodiment are used to denote elements with the same functions, and redundant descriptions thereof will be omitted.

[0276] Refer to the partial cross-sectional view of FIG. 19, which shows a part of the vehicle drive device 186 according to the second embodiment of the present invention. The driving device 186 is different from the driving device 10 of the first embodiment only in that a driving connection device 188 is provided instead of the driving connection device 23. As shown in FIG. 19, the driving connection device 188 includes a driving sprocket 190, a driven sprocket 192 and a transmission belt 194. The transmission belt 194 is made of metal or resin and connects the driving sprocket 190 and the driven sprocket 192. The driving sprocket 190 is mounted on the axial end of the power transmission memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com