Method for preparing high-density pure tungsten product through low-temperature sintering

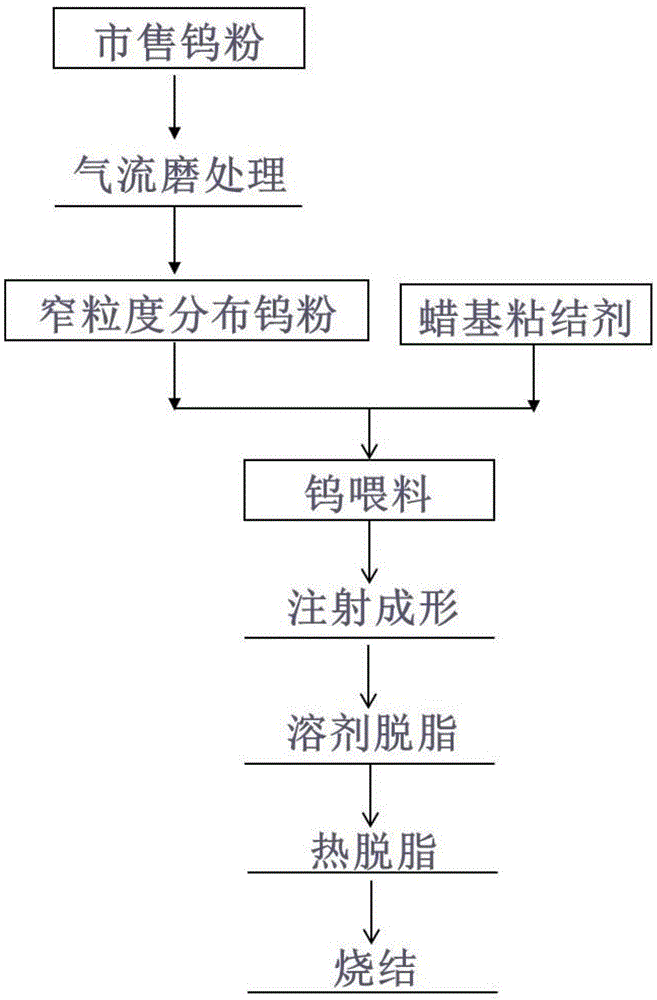

A low-temperature sintering and densification technology, which is applied in the field of powder injection molding, can solve the problems of difficult powder agglomeration, higher than 2100 ° C, and easy introduction of impurities by ball milling, so as to achieve fine grain size, reduce shrinkage and deformation, and improve dimensional accuracy and surface quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

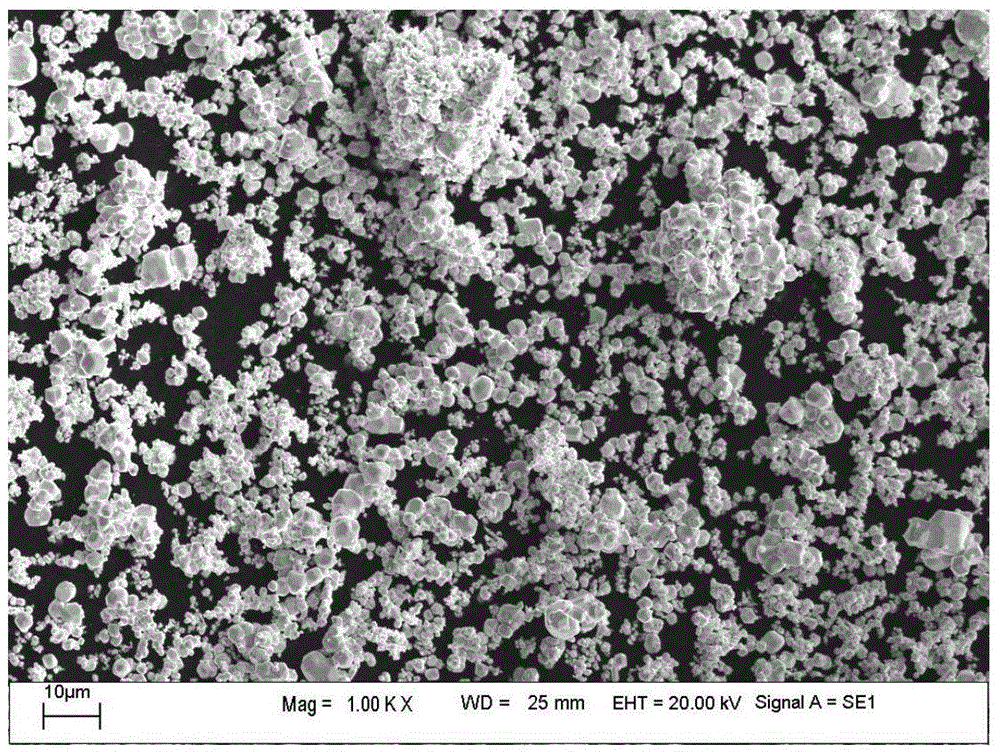

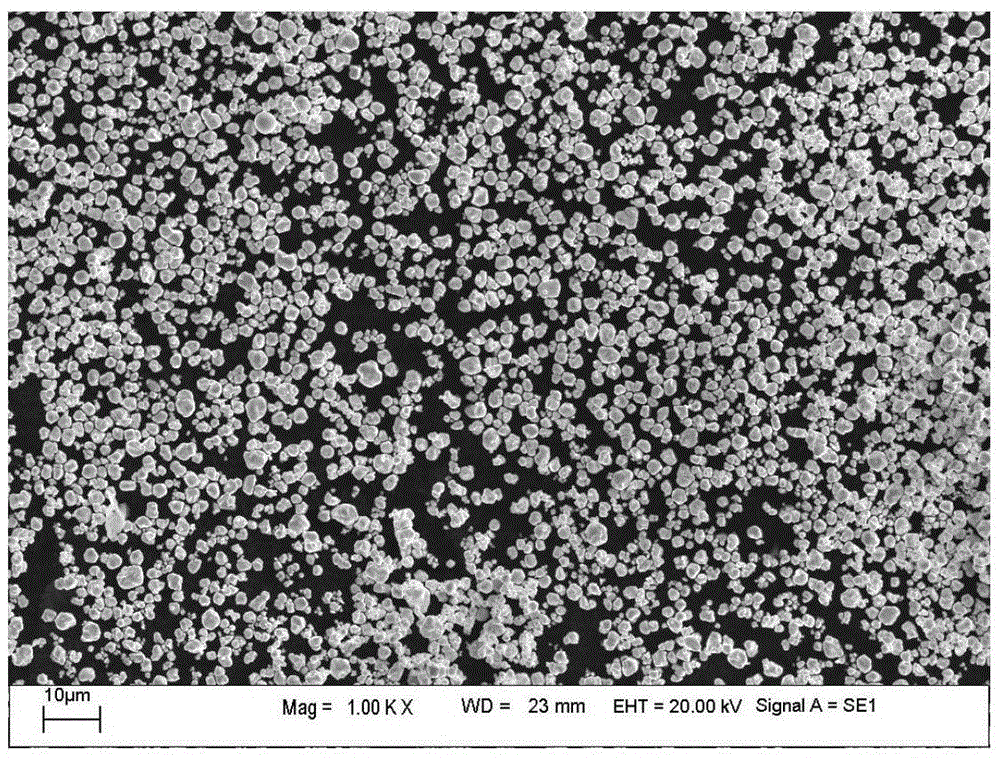

[0025] 1. Clean the jet mill equipment and fill it with high-purity nitrogen with a purity of more than 99.9% as the working atmosphere, reduce the oxygen content to 0.1%, and add commercially available tungsten powder with a purity of more than 99.9% and a particle size of 3um to the feeding chamber;

[0026] 2. Open the grinding valve, adjust the grinding gas pressure to 0.80Mpa, and send powder for grinding;

[0027] 3. Turn on the sorting wheel, adjust the rotating speed of the sorting wheel to 7500rpm, and collect the powder;

[0028] 4. Mix the treated tungsten powder and binder evenly to make granular feed, the mixing temperature is 160 degrees, the mixing time is 2 hours, and the volume fraction of tungsten powder in the feed after mixing is 65%;

[0029] 5. The feed material is formed into a green body of a certain shape on the injection molding machine, and the injection parameters are: the injection speed is 90%, the injection temperature is 165°C, and the injection...

Embodiment 2

[0038] 1. Clean the jet mill equipment and fill it with high-purity nitrogen with a purity of more than 99.9% as the working atmosphere, reduce the oxygen content to 0.1%, and add commercially available tungsten powder with a purity of more than 99.9% and a particle size of 1um to the feeding chamber;

[0039] 2. Open the grinding valve, adjust the grinding gas pressure to 1Mpa, and send powder for grinding;

[0040] 3. Turn on the sorting wheel, adjust the rotating speed of the sorting wheel to 8000rpm, and collect the powder;

[0041] 4. Collect the powder in step 3 for secondary treatment, the grinding pressure is 1Mpa, adjust the frequency of the sorting wheel to 9000rpm, and collect the powder;

[0042] 5. Mix the treated tungsten powder and binder evenly to make granular feed, the mixing temperature is 170 degrees, the mixing time is 3 hours, and the volume fraction of tungsten powder in the feed after mixing is 55%;

[0043]6. The feed material is formed into a green b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com