Special die for long bar ceramic blank bottom-pouring liquid lifting gel casting and preparation method for producing long bar ceramic by using same

A ceramic green body and long rod technology, which is applied in the field of special molds for inorganic non-metallic materials and their preparation, can solve problems such as pore defects, scrapping, and gas cannot be discharged, and achieve high production efficiency, high quality, and simplified processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Preparation of 99% alumina ceramic square billet

[0031] Assembly mold

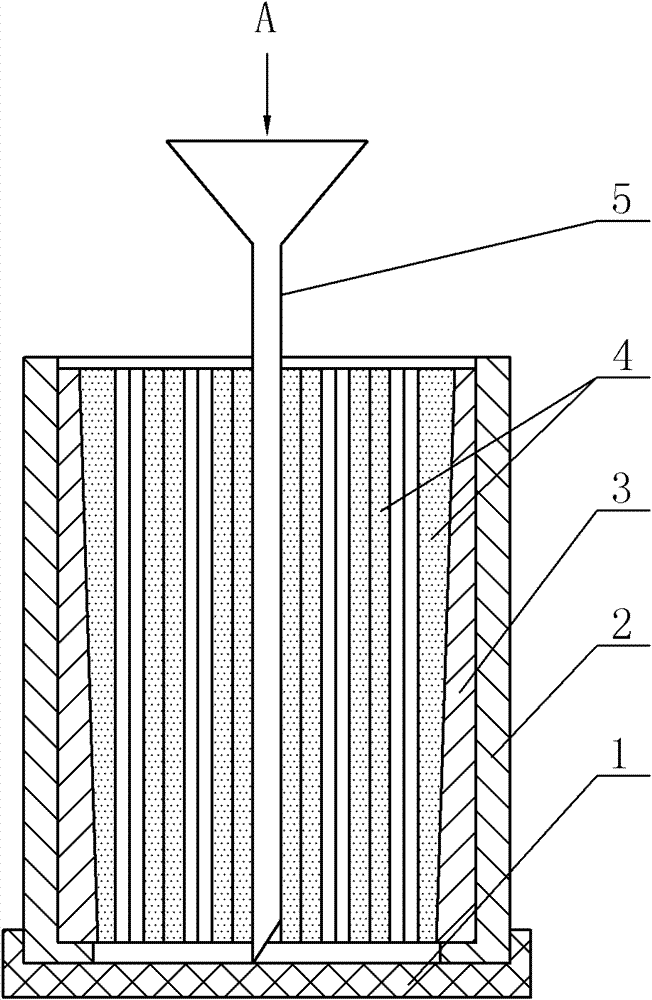

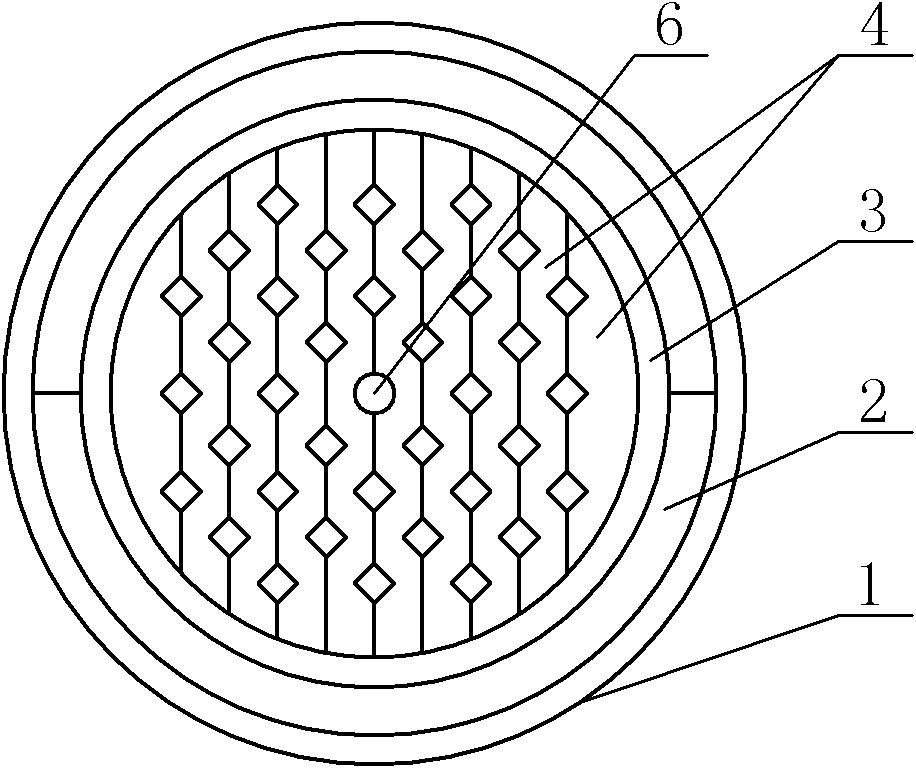

[0032] Such as figure 1 , figure 2 As shown: First, the slurry cylinder 2 is inserted into the base 1 through the groove to form a female mold for the slurry with a lower seal, and then the 12-layer half-hole template 4 is combined and inserted into the fastening ring 3 to become a fixed There are 47 male molds with 10mm×10mm×420mm square holes, put the male mold into the female mold, and install the lower end on the support step of the slurry cylinder 2, insert the long-handled funnel 5 in the pouring hole 6; The internal taper of the fastening ring 3 is 5°, and the external conicity of the composite formed by the template 4 with 12 layers of half holes is the same as the internal taper of the fastening ring 3 .

[0033] Production Method

[0034] Weigh 2200ml of the prepared gelatable 99% alumina ceramic slurry, slowly pour the slurry into the long-handled funnel 5, the slurry...

Embodiment 2

[0035] Example 2: Preparation of silicon carbide ceramic slender rod green body

[0036] Assembly mold

[0037] Formwork 4 with half-holes is 20 layers. After combination, there are 128 round holes of Φ3mm×230mm. The taper of fastening ring 3 is 10°. The internal taper is identical, and others are with embodiment 1.

[0038] Production Method

[0039] Weigh 230ml of gelatable SiC ceramic slurry, slowly pour the slurry into the long-handled funnel 5, the slurry flows into the bottom of the mold along the pouring hole, and then the rising liquid fills each round hole in the mold, then pull out the long-handled funnel 5, Insert in the casting hole 6 with a metal round rod. After the slurry gel is solidified, first withdraw from the base 1, then open the slurry cylinder 2, cut off the bottom 3mm thick gel body with a blade, and eject the 20-layer formwork 4 with half holes from the fastening ring 3 as a whole. Then peel off the templates of each layer one by one to obtain 128 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com