A kind of ceramic raw tape and its preparation process

A green tape and ceramic technology, applied in the field of ceramic green tape and its preparation, can solve the problem of low thermal conductivity of the substrate, achieve good thermal conductivity, low sintering densification temperature, and reduce pore defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

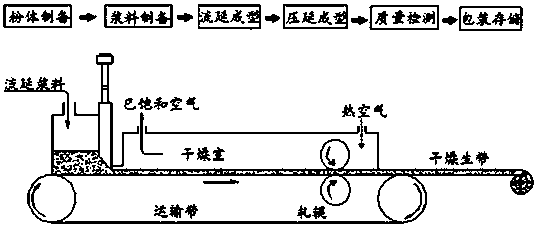

[0022] A kind of preparation technology of ceramic raw tape, such as figure 1 As shown, it mainly includes the following steps:

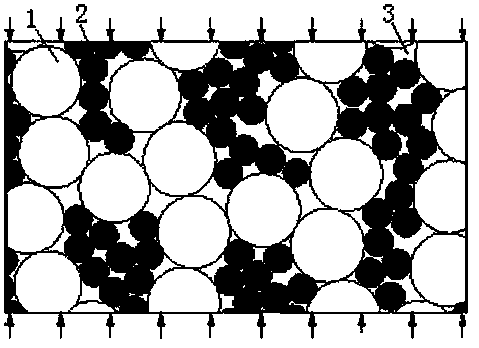

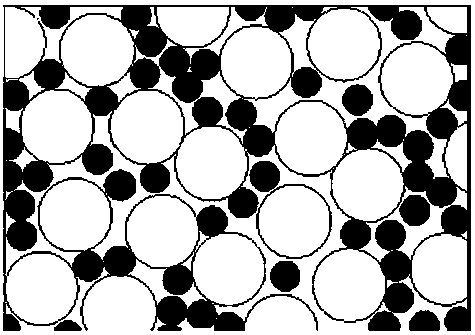

[0023] According to the total amount of 65g of ceramic material, calculate the amount of alumina powder with a median particle size of 2 μm and alumina powder with a median particle size of 50nm in a volume ratio of 90:10, and weigh them respectively; Ammonium polyacrylate was added to 12.9g of water for initial stirring, and an appropriate amount of ammonia water was added until the pH value was 10; 12g of styrene-acrylic emulsion with a concentration of 48% and 4g of polyvinyl alcohol aqueous solution with a concentration of 20% were stirred and mixed for 2 hours to prepare a mixed Adhesive, then add the prepared adhesive and 5g glycerol into the flask containing the solvent and heat and stir; then add it to the slurry that has been stirred for the first time for secondary stirring; The ratio was added to the slurry prepared above, and ball mille...

Embodiment 2

[0026] A kind of preparation technology of ceramic raw tape, such as figure 1 As shown, it mainly includes the following steps:

[0027] According to the total amount of ceramic material 68g, calculate the consumption of aluminum nitride powder with a median particle diameter of 1 μm and the alumina powder with a median particle diameter of 40nm with a volume ratio of 80:20, and weigh them respectively; Nano-alumina powder and Add 1g of ammonium polyacrylate to 12.7g of water for initial stirring, and add an appropriate amount of ammonia water until the pH value is 10; stir and mix 10g of 48% styrene-acrylic emulsion and 3.5g of 20% polyvinyl alcohol aqueous solution for 2 hours to prepare into a mixed binder, then add the prepared binder and 4.5g glycerol into a flask containing a solvent and heat and stir; then add it to the slurry that has been stirred for the first time for secondary stirring; micron nitrogen Add aluminum powder in proportion to the slurry prepared above,...

Embodiment 3

[0030] A kind of preparation technology of ceramic raw tape, such as figure 1 As shown, it mainly includes the following steps:

[0031] According to the total amount of ceramic material 70g, the amount of alumina powder with a median particle size of 3 μm and glass powder with a median particle size of 40nm is calculated with a volume ratio of 70:30, and weighed respectively; the nano glass powder and 0.9g polymer Ammonium acrylate was added to 12.5g of water for initial stirring, and an appropriate amount of ammonia water was added until the pH value was 10; 9g of styrene-acrylic emulsion with a concentration of 48% and 3.2g of polyvinyl alcohol aqueous solution with a concentration of 20% were stirred and mixed for 2 hours to prepare a mixed Adhesive, then add the prepared adhesive and 4 g glycerol into the flask containing the solvent and heat and stir; then add it to the slurry that has been stirred for the first time for secondary stirring; put micron-sized alumina powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com