A method for preparing high-density pure tungsten products by low-temperature sintering

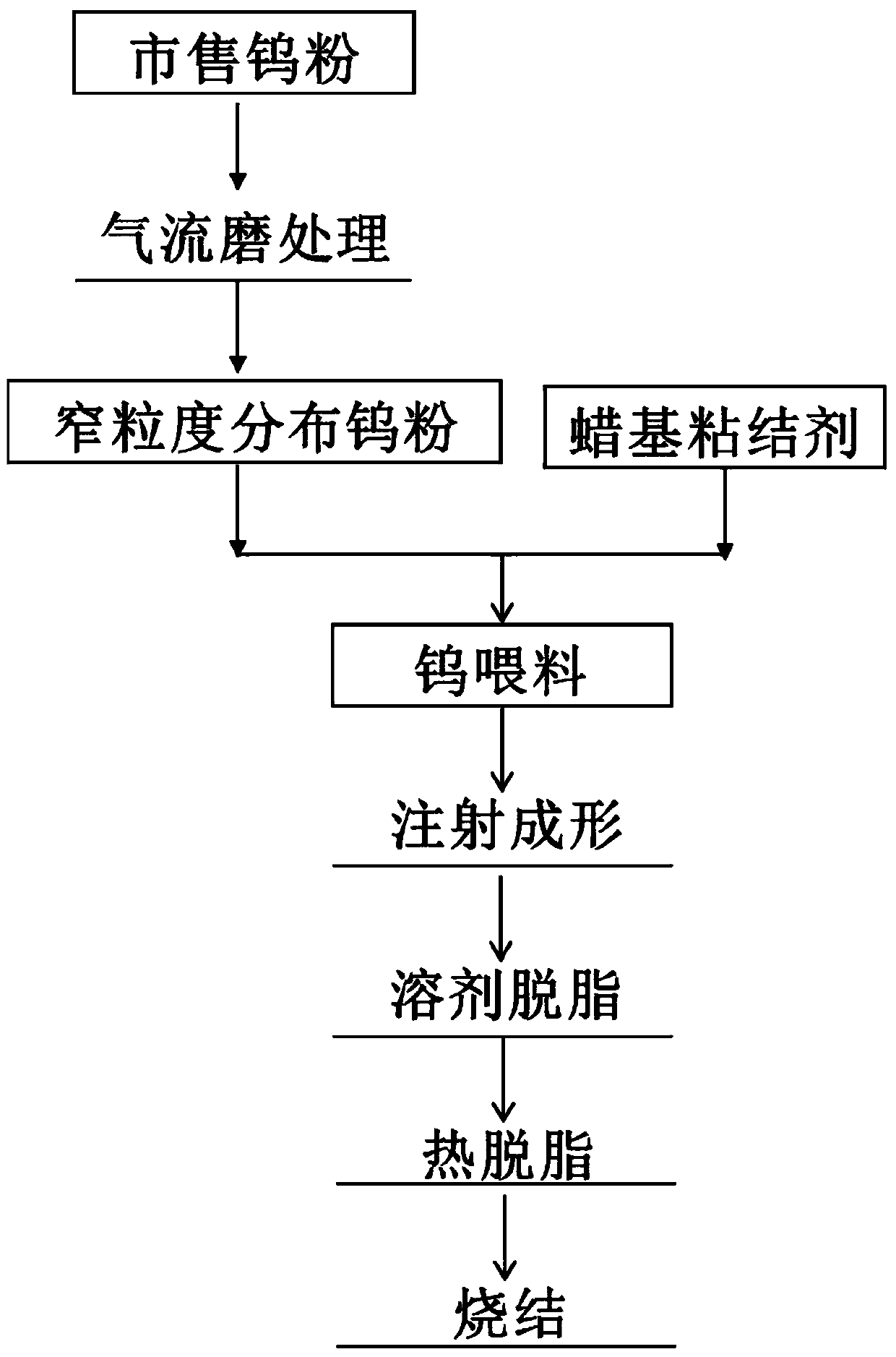

A low-temperature sintering and densification technology, which is applied in the field of powder injection molding, can solve problems such as difficult to remove powder agglomeration, easy introduction of impurities by ball milling, and higher than 2100 °C, so as to achieve fine grain size, improve dimensional accuracy and surface quality, and reduce The effect of shrinkage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Clean the jet mill equipment and fill it with high-purity nitrogen with a purity of more than 99.9% as the working atmosphere, reduce the oxygen content to 0.1%, and add commercially available tungsten powder with a purity of more than 99.9% and a particle size of 3 µm into the feeding chamber;

[0026] 2. Open the grinding valve, adjust the grinding gas pressure to 0.80Mpa, and send powder for grinding;

[0027] 3. Turn on the sorting wheel, adjust the rotating speed of the sorting wheel to 7500rpm, and collect the powder;

[0028] 4. Mix the treated tungsten powder and binder evenly to make granular feed, the mixing temperature is 160 degrees, the mixing time is 2 hours, and the volume fraction of tungsten powder in the feed after mixing is 65%;

[0029] 5. The feed material is formed into a green body of a certain shape on the injection molding machine, and the injection parameters are: the injection speed is 90%, the injection temperature is 165°C, and the inject...

Embodiment 2

[0038] 1. Clean the jet mill equipment and fill it with high-purity nitrogen with a purity of more than 99.9% as the working atmosphere, reduce the oxygen content to 0.1%, and add commercially available tungsten powder with a purity of more than 99.9% and a particle size of 1 µm into the feeding chamber;

[0039] 2. Open the grinding valve, adjust the grinding gas pressure to 1Mpa, and send powder for grinding;

[0040] 3. Turn on the sorting wheel, adjust the rotating speed of the sorting wheel to 8000rpm, and collect the powder;

[0041] 4. Collect the powder in step 3 for secondary treatment, the grinding pressure is 1Mpa, adjust the frequency of the sorting wheel to 9000rpm, and collect the powder;

[0042] 5. Mix the treated tungsten powder and binder evenly to make granular feed, the mixing temperature is 170 degrees, the mixing time is 3 hours, and the volume fraction of tungsten powder in the feeding material after mixing is 55%;

[0043]6. The feed material is formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com