Preparation method for ultrafine powder body of SiO2-based composite oxide system glass

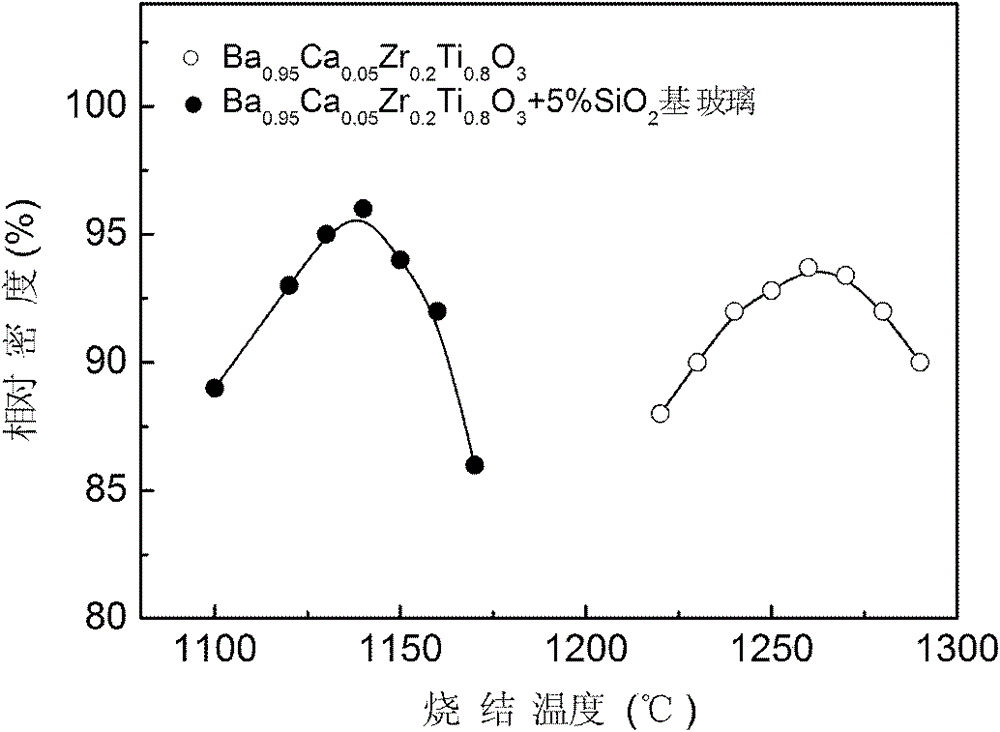

A composite oxide and ultra-fine powder technology, which is applied in the field of functional ceramic materials, can solve the problems of dielectric ceramic capacitor preparation process, difficulty in structure and dielectric properties, difficulty in uniform mixing, etc., and achieve good application prospects, good repeatability, The effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

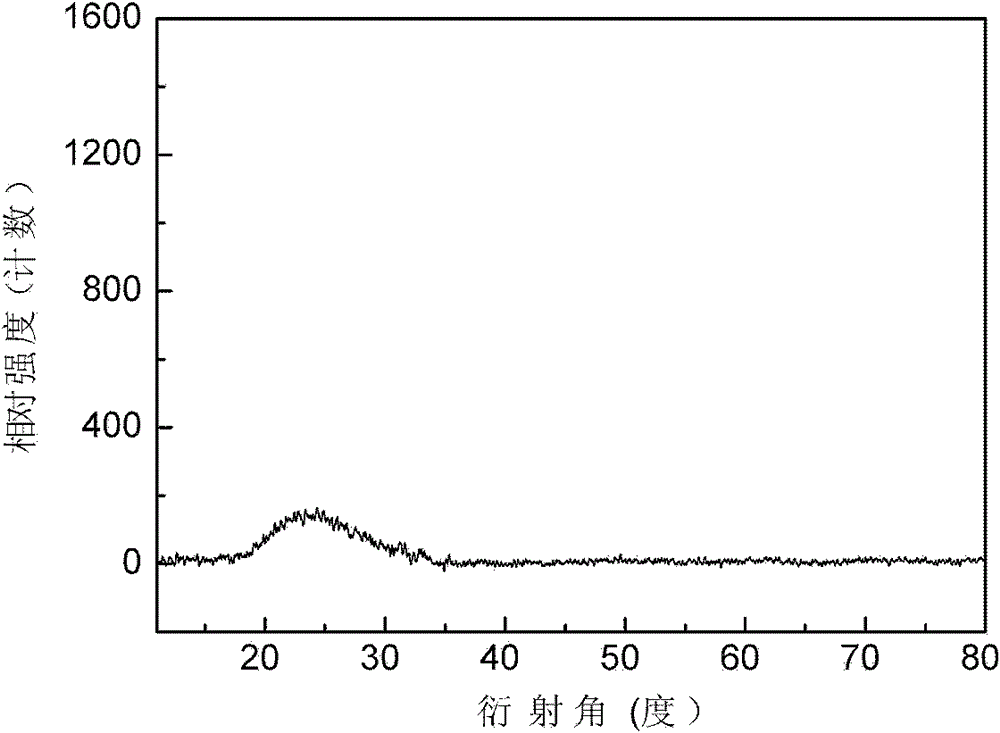

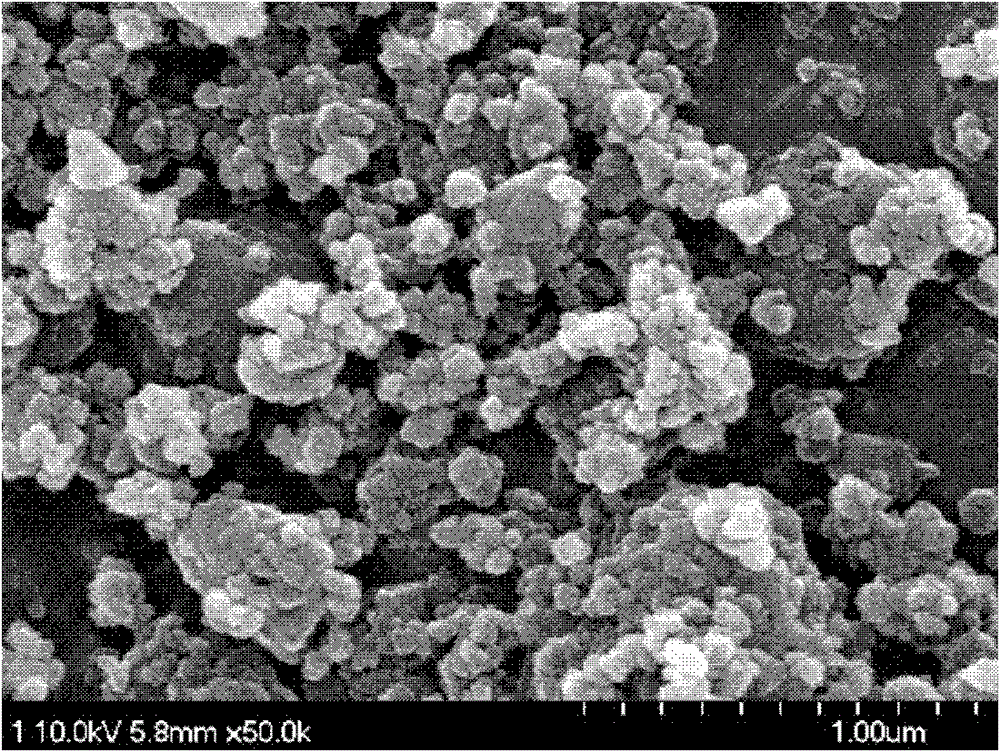

[0027] (1) Preparation of precursor solution: according to the mass ratio of glass composition 61% SiO 2 , 25% Al 2 o 3 , 7%CaO, 5%MgO, 1%BaO, 1%ZnO, weigh tetraethylorthosilicate, aluminum nitrate, calcium nitrate, magnesium nitrate, barium nitrate and zinc nitrate, and tetraethylorthosilicate Dissolve in absolute ethanol and add an appropriate amount of deionized water. The volume ratio of absolute ethanol to ionized water is 5:1. Add acetic acid dropwise to adjust the pH value of the solution to 1 to obtain a clear and transparent solution A. Add aluminum nitrate and calcium nitrate , magnesium nitrate, barium nitrate, zinc nitrate and citric acid were dissolved in absolute ethanol to obtain a clear and transparent solution B, and then the two solutions A and B were mixed, and a clear and transparent precursor was obtained after thermal stirring at 60 °C Solution, in the precursor solution, the molar ratio of citric acid and the total amount of reactant cations is 2: 1, a...

Embodiment 2

[0034] (1) Preparation of precursor solution: according to the mass ratio of glass composition 53% SiO 2 , 35%Al 2 o3 , 3%CaO, 4%MgO, 1%BaO, 4%ZnO ratio, weigh tetraethyl orthosilicate, aluminum nitrate, calcium nitrate, magnesium nitrate, barium nitrate and zinc nitrate, and tetraethyl orthosilicate Dissolve in absolute ethanol and add an appropriate amount of deionized water. The volume ratio of absolute ethanol to deionized water is 7:1. Add acetic acid dropwise to adjust the pH of the solution to 1 to obtain a clear and transparent solution A. Aluminum nitrate, Dissolve calcium nitrate, magnesium nitrate, barium nitrate, zinc nitrate and citric acid in absolute ethanol to obtain a clear and transparent solution B, then mix the two solutions A and B, and heat and stir at 60°C to obtain a clear and transparent solution The precursor solution, the molar ratio of citric acid and reactant cation total amount in the precursor solution is 1: 1, and the reactant cation in the pre...

Embodiment 3

[0038] (1) Preparation of precursor solution: according to the mass ratio of glass composition 68% SiO 2 , 18%Al 2 o 3 , 7%CaO, 2%MgO, 4%BaO, 1%ZnO ratio, weigh tetraethyl orthosilicate, aluminum nitrate, calcium nitrate, magnesium nitrate, barium nitrate and zinc nitrate, tetraethyl orthosilicate Dissolve in absolute ethanol and add an appropriate amount of deionized water. The volume ratio of absolute ethanol to deionized water is 6:1. Add acetic acid dropwise to adjust the pH of the solution to 1 to obtain a clear and transparent solution A. Aluminum nitrate, Dissolve calcium nitrate, magnesium nitrate, barium nitrate, zinc nitrate and citric acid in absolute ethanol to obtain a clear and transparent solution B, then mix the two solutions A and B, and heat and stir at 60°C to obtain a clear and transparent solution The precursor solution, the molar ratio of citric acid and reactant cation total amount in the precursor solution is 3: 1, and the reactant cation in the precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com