Special die for long bar ceramic blank bottom-pressing liquid lifting casting formation and preparation method for producing long bar ceramic by using same

A technology for ceramic blanks and long rods, which is applied in the field of special molds for inorganic non-metallic materials and their preparation, can solve the problems of scrapping, gas can not be discharged, pore defects, etc., and achieves the effects of high quality, good practical value and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below by taking the production of Y-TZP ceramic circular shaft blank as an example.

[0031] The production steps are as follows:

[0032] 1) Preparation of slurry

[0033] Prepare gelatable Y-TZP ceramic slurry according to process requirements;

[0034] 2.) Mold closing

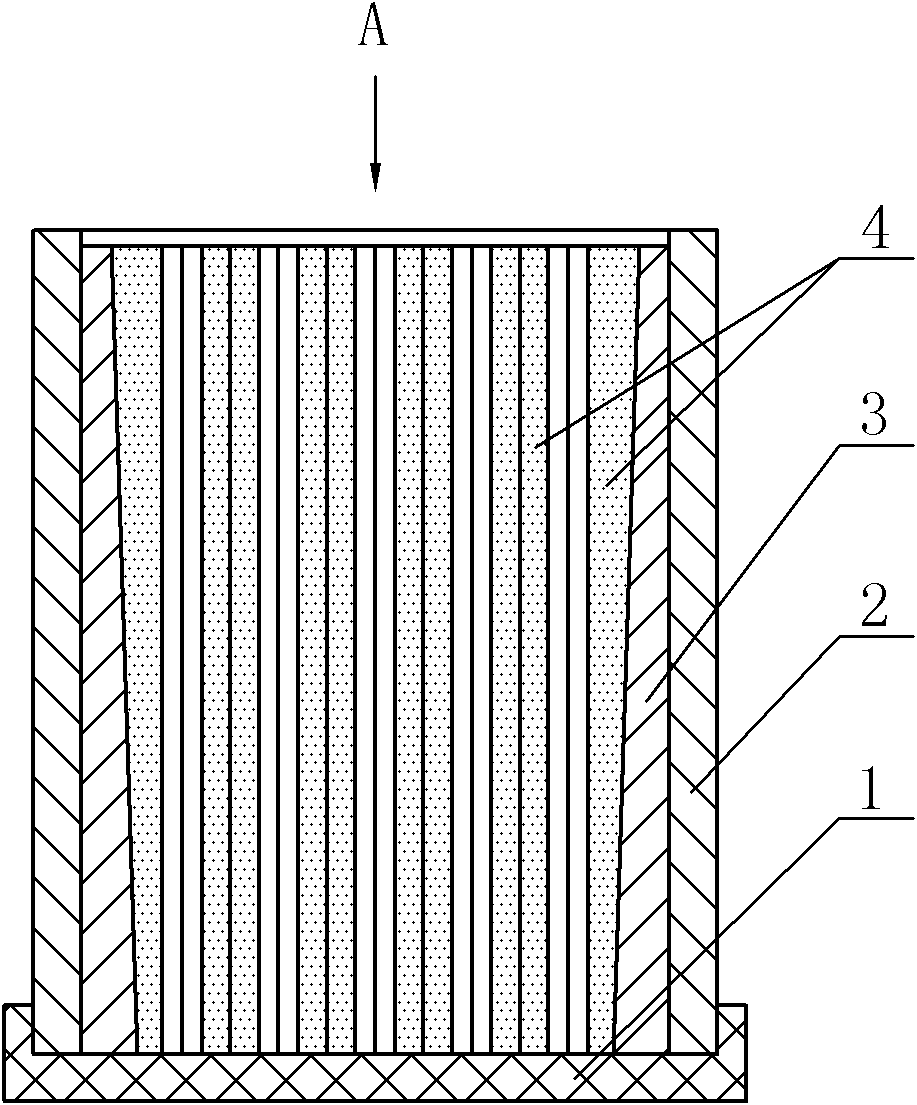

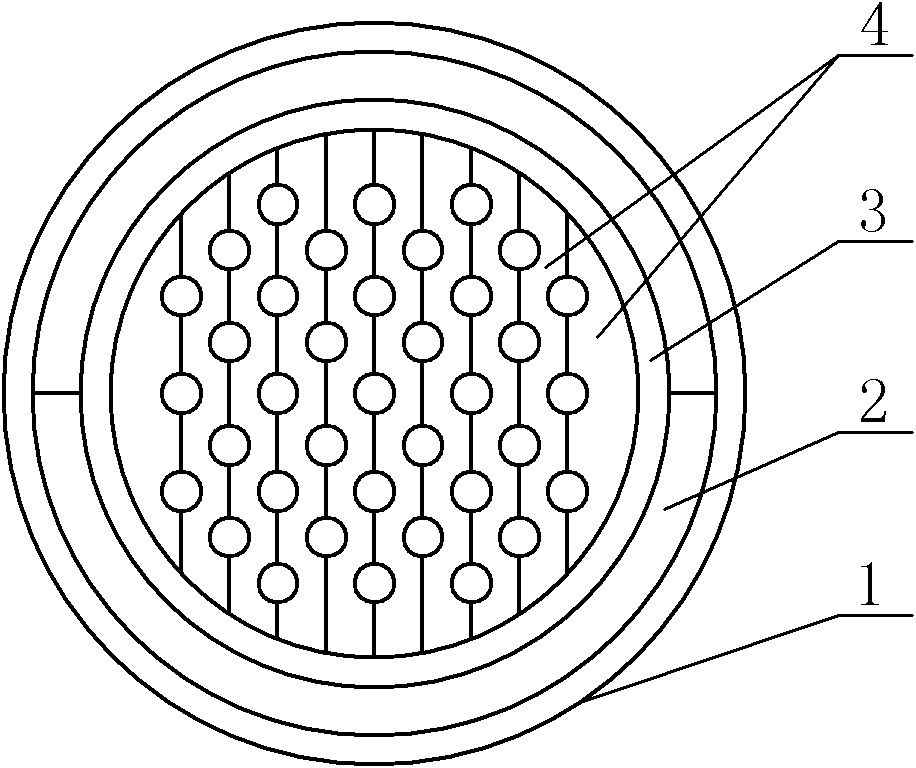

[0035] First, insert the slurry cylinder 2 into the base 1 through the groove to form a female mold for the slurry with a lower seal, and then combine the 10-layer template 4 with half holes and insert it into the fastening ring 3 to become a fixed belt 37. A male mold with a Φ6mm×110mm round through hole; the taper of the fastening ring 3 is 5°.

[0036] 3) Down-pressing liquid raising method pouring

[0037] Pour the slurry into the assembled female mold along the inner wall, then pull the male mold and slowly sink into the slurry of the female mold, pause for about 5 seconds when it reaches the bottom of about 5mm and then sink to the bottom, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com