Gimbal ring structure lightweight design method suitable for additive manufacturing forming technology

A lightweight design and additive manufacturing technology, applied in instrumentation, geometric CAD, electrical digital data processing, etc., can solve the problems of long production cycle, many processing steps, welding deformation affecting product qualification rate and reliability, etc. Lowering, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

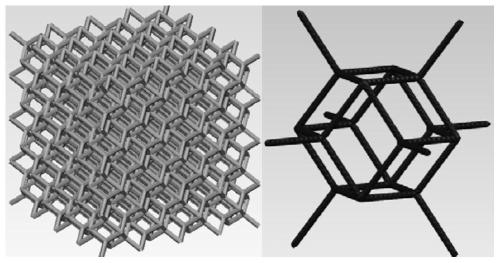

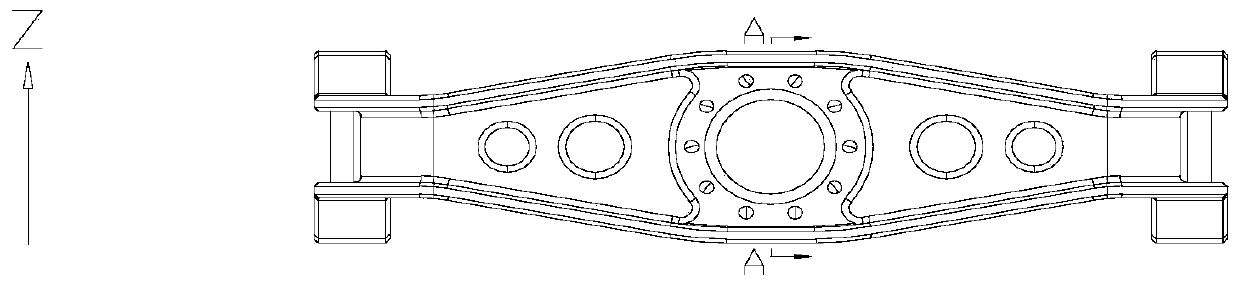

[0027] A lightweight design method for gimbal ring structures suitable for additive manufacturing forming technology, including establishing an initial model suitable for gimbal ring topology optimization and determining the optimal The design area, combined with the statics optimization, obtains the optimal force transmission path of the gimbal ring and the initial model of material distribution, and proposes a design criterion under the condition of taking into account the optimal topology of the gimbal ring and good forming mass balance, and obtains a new additive manufacturing-based Lightweight design model structure. Specific steps are as follows:

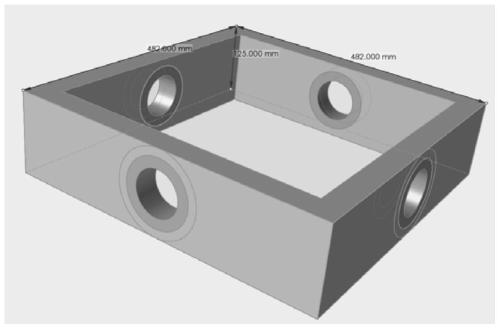

[0028] (1) The initial model of the constant level ring topology optimization and the design of the optimized area;

[0029] (2) The physical parameters of the gimbal ring material, the establishment of boundary constraints and the application of force conditions;

[0030] (3) Carry out grid division on the initial model of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com