Composite structure of round-trip shape memory self-assembly gear and achieving method thereof

A technology of composite structure and realization method, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as inability to realize reversible transformation, and achieve the effect of promoting wider application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

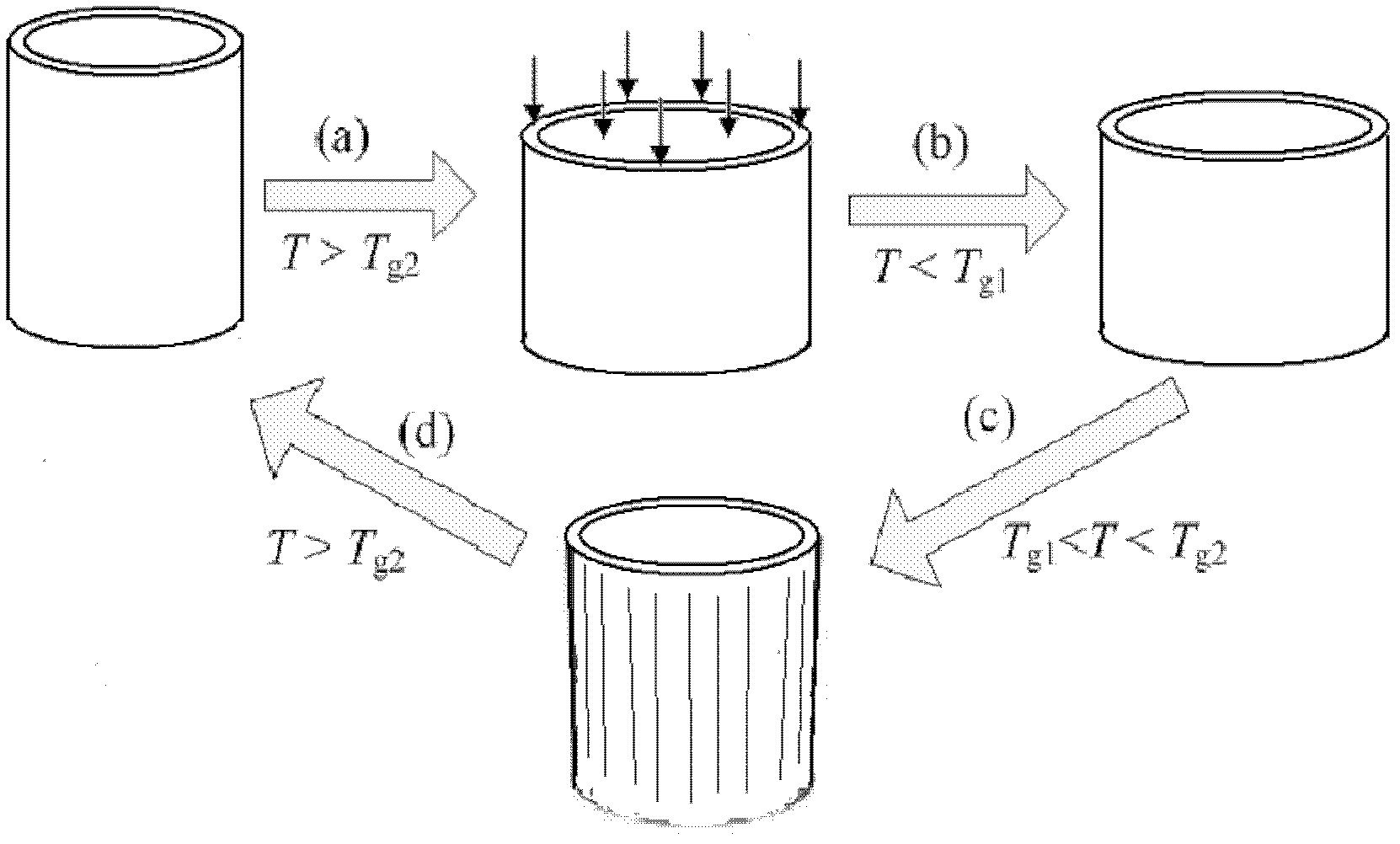

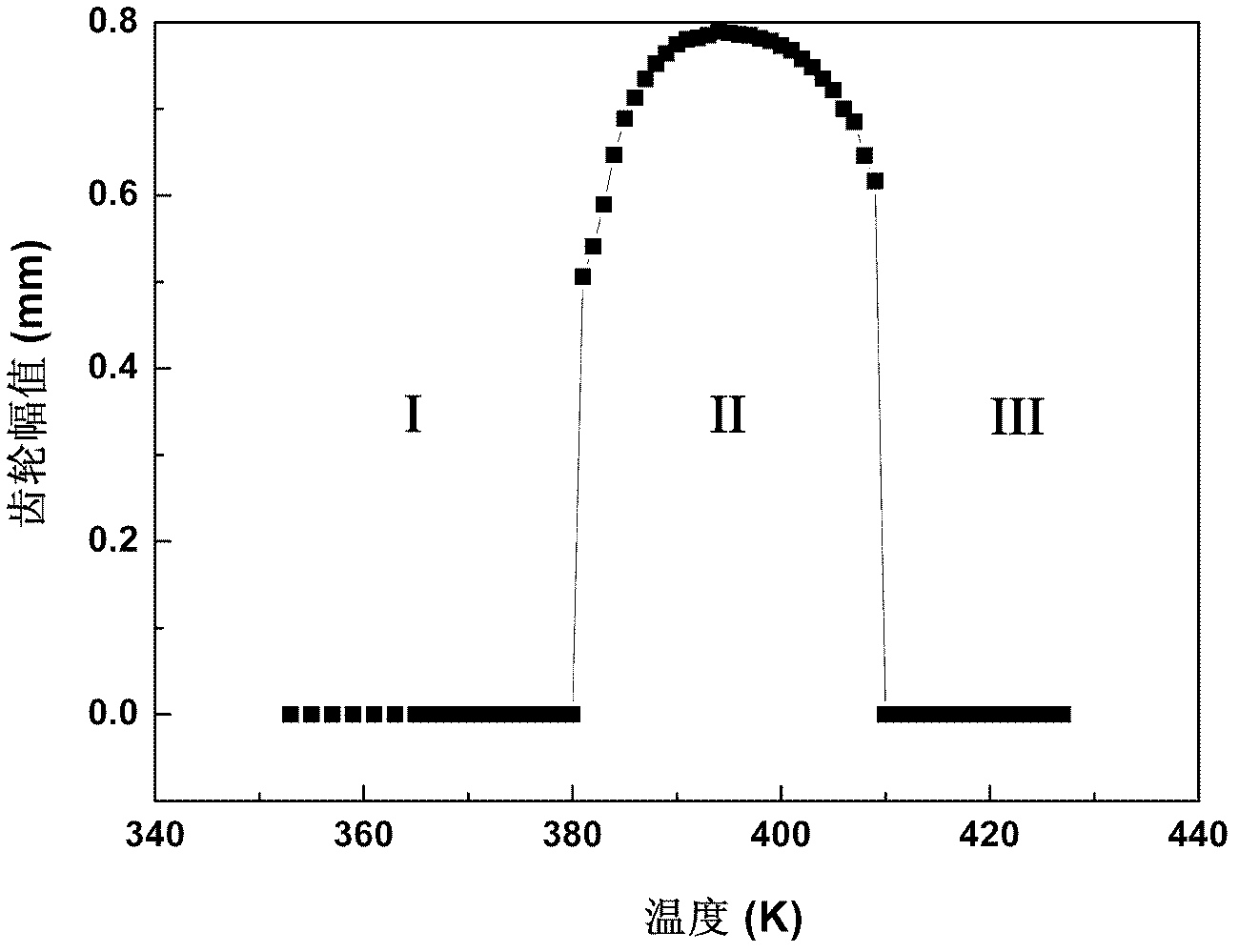

[0021] Attached figure 1 A schematic diagram of the deformation process of a two-way shape memory self-assembly spur gear. The composite structure is composed of the inner low transition temperature (T g1 ) Shape memory polymer cylinder core and outer layer with high transition temperature (T g2 ) Is composed of a shape memory polymer film, the cross-sectional radius of the shape memory polymer cylindrical core is 10mm, the height is 20mm, and the thickness of the shape memory polymer film is 0.5mm. As shown in the figure, the composite structure realizes a two-way shape The thermodynamic process of memory self-assembled spur gear includes the following 4 steps: (a) When T>T g2 The composite cylinder is subjected to axial compression loading at high temperature. Because the ambient temperature is higher than the material shape memory transition temperature at this time, the structure is in a rubber state, and a large compression deformation can be achieved; (b) Maintain the defor...

Embodiment 2

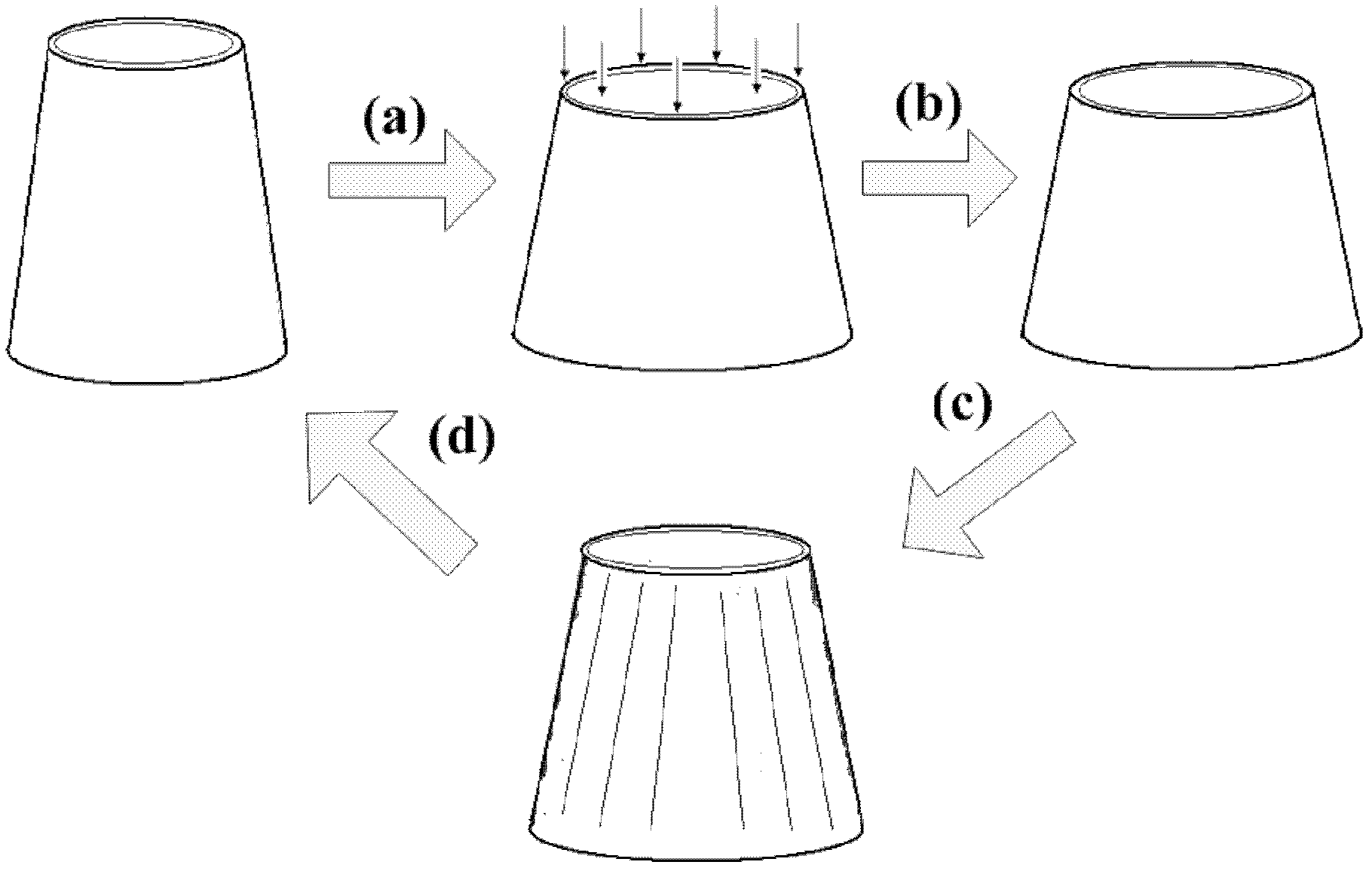

[0024] Attached image 3 Schematic diagram of the deformation process of the two-way shape memory self-assembled helical gear. The thermodynamic process is similar to that of Example 1, the only difference is that the inner core is a truncated cone structure. With this composite structure, a two-way shape memory self-assembled helical gear with continuously changing tooth pitch can be realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com