High-strength powder metallurgy brass-based coupler

A powder metallurgy, based coupling technology, applied in the field of bearing manufacturing, can solve problems such as difficulty in ensuring dimensional consistency, and achieve the effects of good consistency, easy manufacturing, and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A high-strength powder metallurgy brass-based coupling of the present invention, the coupling includes the following components in mass fraction: Zn element powder: 28%, rare earth element powder: 0.6%, the balance is copper powder and The impurity to be avoided, the weight of the impurity is less than 0.1% of the weight of the positioning sleeve.

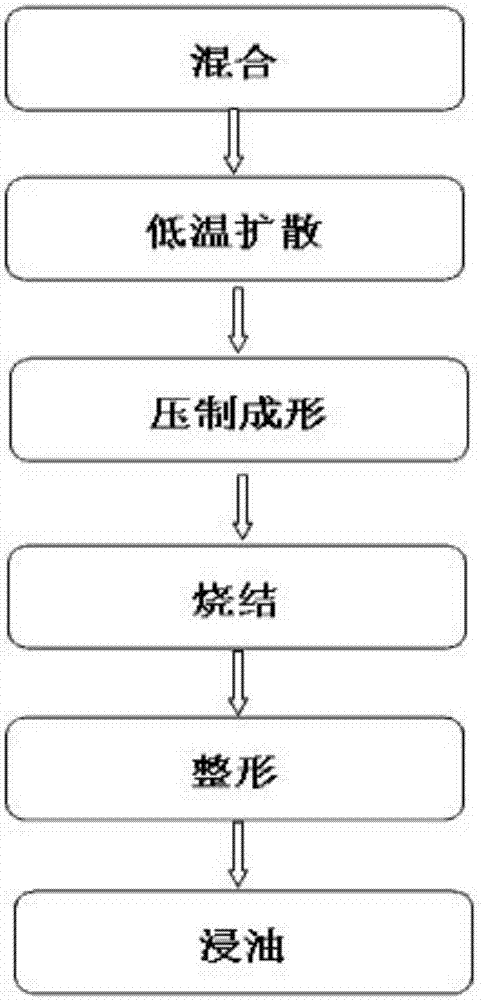

[0026] Such as figure 1 As shown, it is a flow chart of a preparation method of a high-strength powder metallurgy brass-based coupling of the present invention, and the manufacturing method of the coupling includes the following steps:

[0027] S101: Powder mixing: first select the base powder with a purity of 99.99% or more for proportioning and fully mix it with a V-shaped mixer, put the following raw material powders in the mixer for mixing, and obtain the mixed powder, Zn Element powder: 28%, rare earth element powder: 0.6%, the balance is copper powder and unavoidable impurities;

[0028] S102: Low-temperature diffusi...

Embodiment 2

[0034] A high-strength powder metallurgy brass-based coupling of the present invention, the coupling includes the following components in mass fraction: Zn element powder: 30%, rare earth element powder: 0.6%, the balance is copper powder and Avoid impurities.

[0035] Production method is the same as embodiment 1

Embodiment 3

[0037] A high-strength powder metallurgy brass-based coupling of the present invention, the coupling includes the following components in mass fraction: Zn element powder: 32%, rare earth element powder: 0.6%, the balance is copper powder and Avoid impurities.

[0038] Production method is the same as embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com