Strip electrode electroslag surfacing process of nickel-based alloy of tube plate of nuclear power steam generator

A technology of steam generators and nickel-based alloys, applied in arc welding equipment, metal processing equipment, manufacturing tools, etc., which can solve the problems of low plasticity and toughness of the surfacing layer, uneven depth of fusion, and high dilution rate of the base metal. Achieve the effects of improving quality, high deposition efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

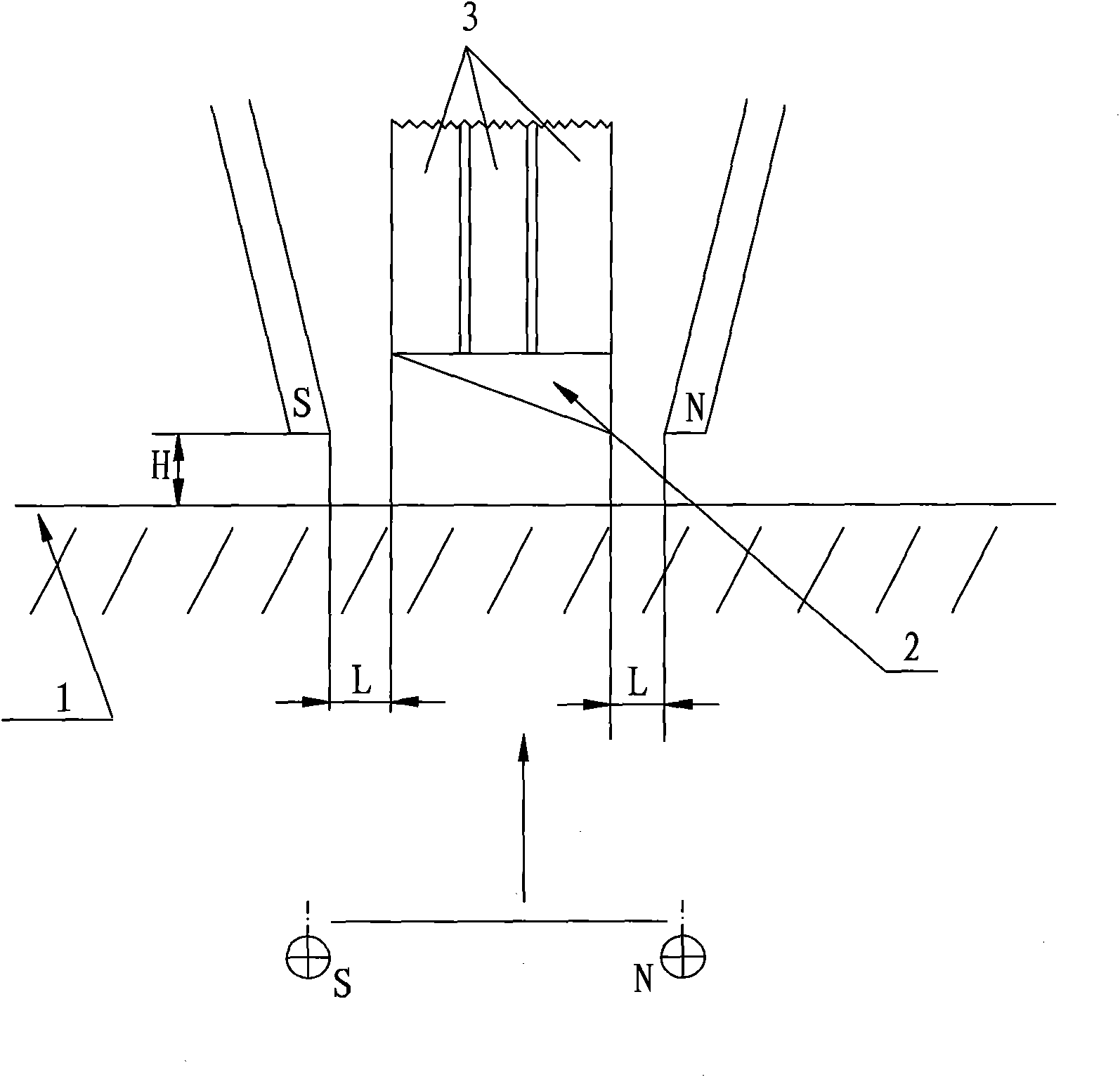

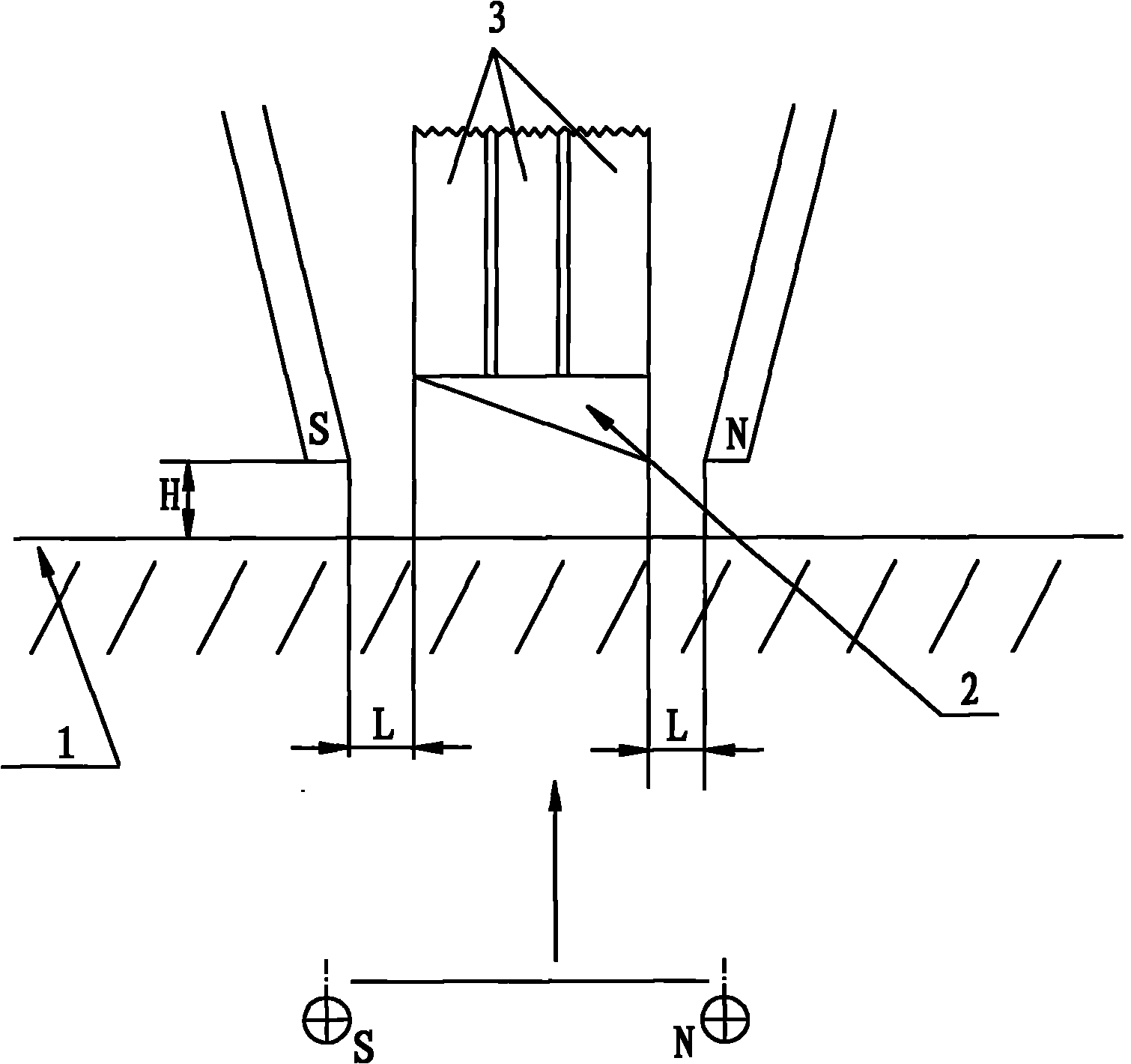

[0023] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

[0024] The electroslag surfacing process of the nickel-based alloy strip electrode of the nuclear steam generator tube plate of the present invention comprises the following steps:

[0025] 100% magnetic particle inspection is used for the surface inspection before surfacing;

[0026] In the preheating step, the preheating temperature is ≥121°C and is maintained until the post-heat treatment;

[0027] For surfacing welding steps, the welding material (strip and flux) is EQNiCrFe-7A welding strip / flux from SMC Company of the United States, the welding strip is INCONEL WELDSTRIP 52M, the flux is INCOFLUX ESS2, and the size is 60×0.5mm; welding current 1150±100A, voltage 24~26V, welding speed 200~220mm / min, current polarity reversed, welding bead overlap 7~8mm, interlayer temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com