Method of manufacturing small-sized and thin-wall Nb-W-Mo-Zr alloy parts

An nb-w-mo-zr, small-scale technology, applied in the field of powder metallurgy, can solve the problems of difficult preparation, high pollution, difficult to prepare parts with complex shapes and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

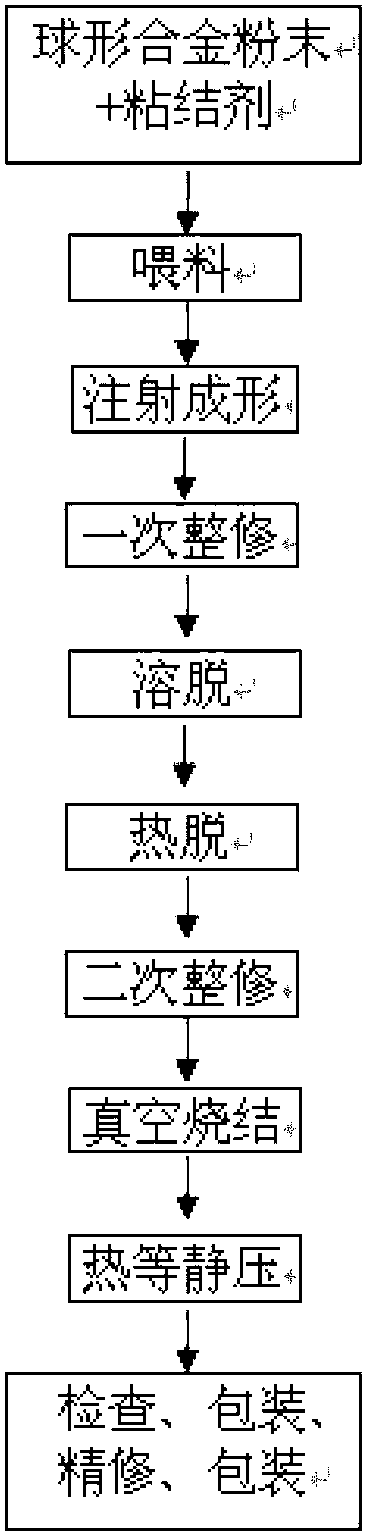

Method used

Image

Examples

Embodiment Construction

[0023] In the first step, the spherical Nb-5wt%W-2wt%Mo-1wt%Zr alloy powder with an average particle size of 15 μm prepared by mechanical alloying and plasma spheroidization is used as a raw material;

[0024] In the second step, the alloy powder and the binder (65wt% paraffin, 13wt% high-density polyethylene, 16wt% polypropylene, 6wt% stearic acid) were prepared into a feed with a loading of 58vol%. material;

[0025] The third step is to fill the feed into the mold through the injection molding machine to obtain the injection blank. The injection temperature is 155-165°C, the injection pressure is 65-70MPa, the holding pressure is 75-80MPa, and the injection speed is 55-60mm / s;

[0026] The fourth step is to conduct preliminary inspection on the injection blank and remove the flash;

[0027] The fifth step is to put the qualified injection billet after repairing the flash into the trichlorethylene solution for 8 hours of stripping to obtain the stripped billet;

[0028] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com