Carbon fiber epoxy resin matrix composite atr series chassis

A technology of composite materials and epoxy resin, which is applied in the field of composite materials, can solve the problems of processing accuracy and difficult guarantee of products, low utilization rate of metal materials, large processing and cutting volume, etc., and achieve high utilization rate of raw materials, light weight of a single piece, The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

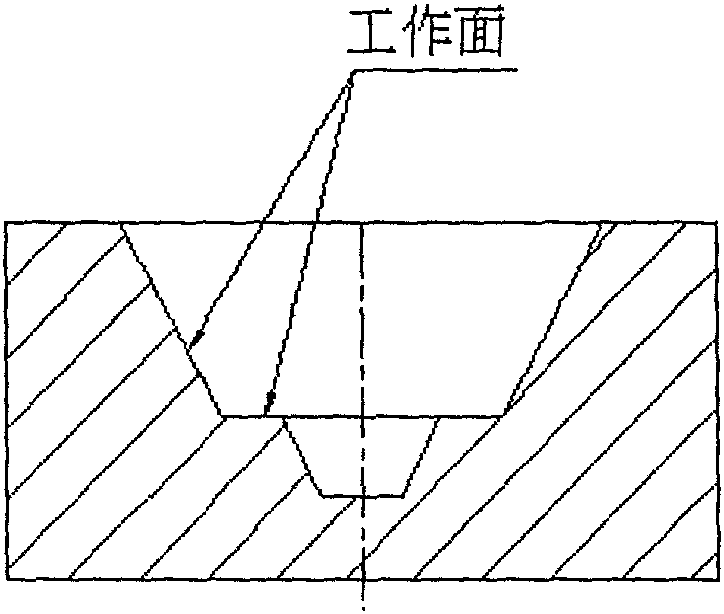

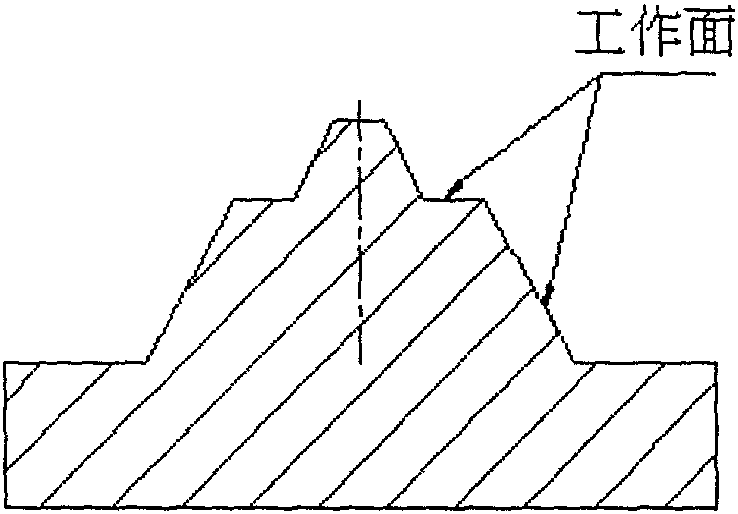

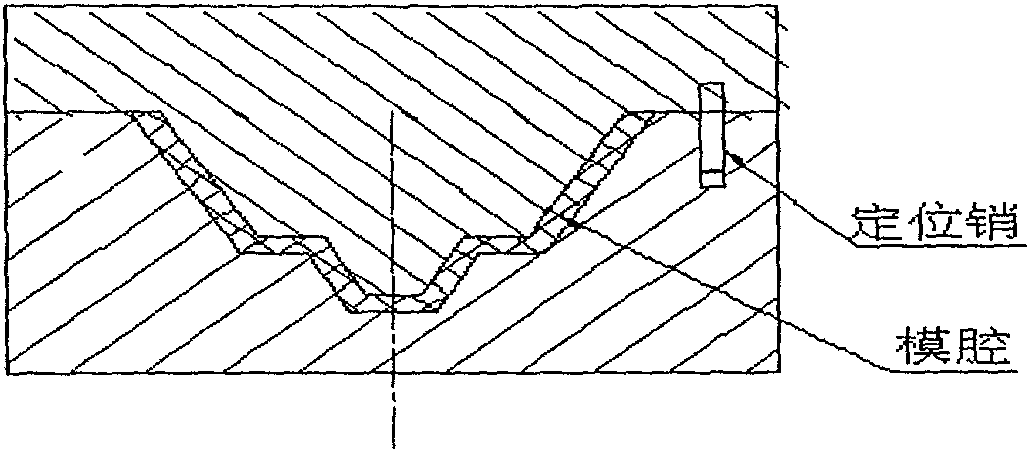

[0026] A carbon fiber epoxy resin-based composite material ATR series chassis, the composite material ATR series chassis is prepared from carbon fiber epoxy resin-based composite material prepreg through laying, heating, pressurizing, and curing molding. The specific steps as follows:

[0027] The first step is material preparation, carbon fiber epoxy resin matrix composite material prepreg cutting;

[0028] Carbon fiber epoxy resin-based composite material prepreg is an intermediate material that is dipped into a resin matrix by directional arrayed fiber bundles or fabrics, and is stored for use after certain treatments. The purpose of cutting prepreg is to control the composite structure shape, thickness and meet the resin / fiber distribution specified by the design. The designability of the composite material is achieved by adjusting the thickness of the prepreg, the orientation of the fibers and its lay-up sequence, and then closed curing to make a high-quality finished pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com