Method for preparing specially-shaped porous tungsten product with uniform pores

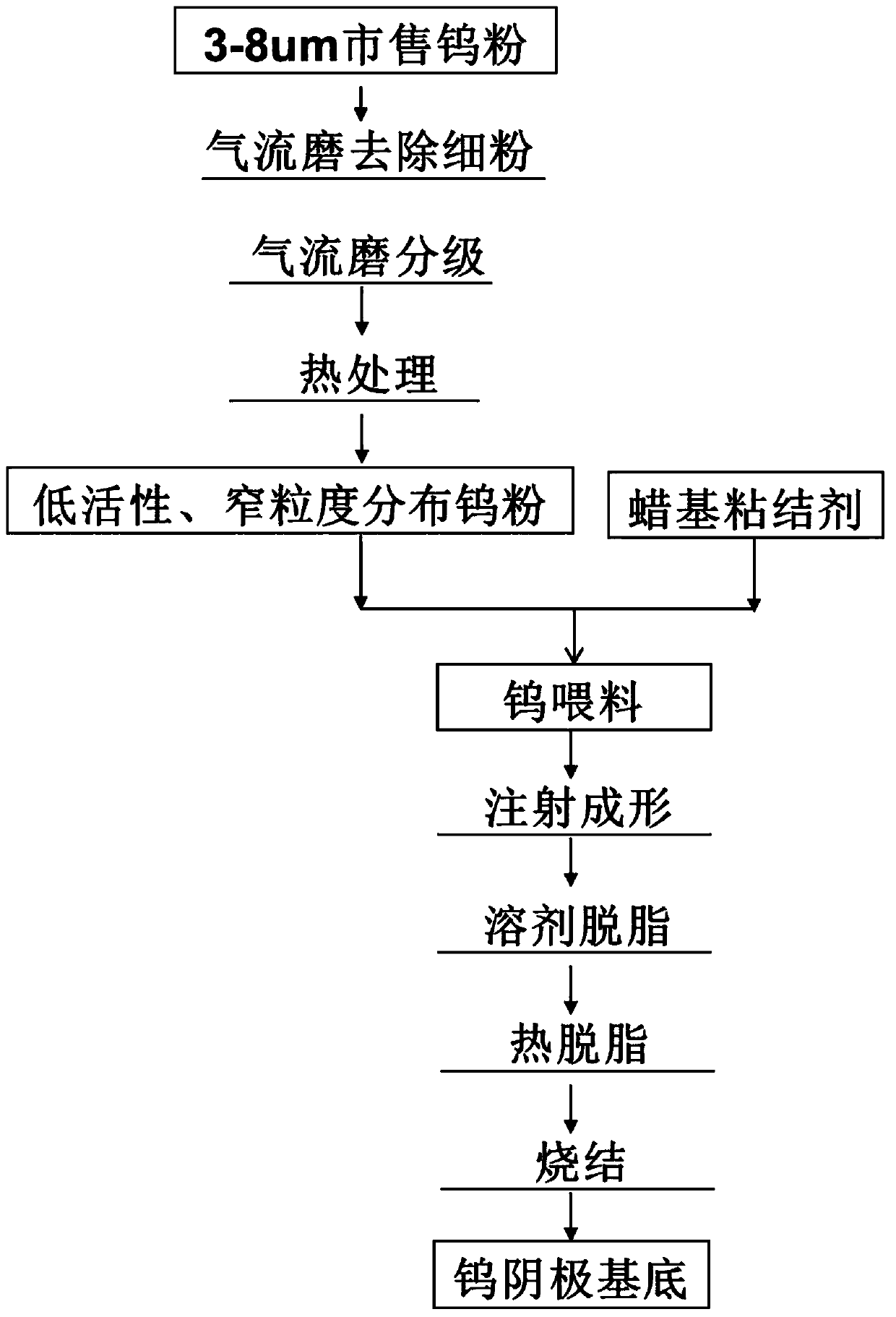

A technology of porous tungsten products, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as loose packing and low tap density, easy deformation and cracking, and large sintering shrinkage of the formed green body, so as to improve loose packing and vibration Density, avoiding uneven distribution of pores, and improving the effect of product dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Raw material powder: the raw material powder is commercially available tungsten powder, the purity is greater than 99.9%, and the Fischer particle size is 3um;

[0033]2. Feed preparation: Mix and disperse the tungsten powder particles obtained by the first heat treatment with the organic binder evenly, and make granular feed. The volume fraction of powder particles in the feed is 54%;

[0034] 3. Injection molding: The feed material is formed into a tungsten body of the required shape and size on the injection molding machine. The injection parameters are: injection speed is 90%, injection pressure is 100Mpa, and injection temperature is 165°C;

[0035] 4. Degreasing: Remove the binder in the tungsten body by proper process. The degreasing process is: immerse in trichlorethylene for 12 hours. The thermal degreasing process system is to raise the temperature to 300°C at 1°C / min and keep it warm for 60min. , then raise the temperature to 420°C at 2°C / min, hold for 30 ...

Embodiment 2

[0038] 1. Raw material powder: the raw material powder is commercially available tungsten powder, the purity is greater than 99.9%, and the Fischer particle size is 3um;

[0039] 2. Jet mill disperses and removes fine powder: Clean the jet mill equipment, turn on the main control to preheat, fill in high-purity nitrogen with a purity higher than 99.9% as the working gas, reduce the oxygen content to 0.1%, open the grinding valve, and adjust the grinding The pressure is 0.70Mpa, add high-purity tungsten powder into the grinding chamber for grinding, so that the agglomerates are opened, start the sorting wheel, adjust the speed of the sorting wheel to 6000rpm, and collect the sorted ultrafine particle tungsten powder (<2um);

[0040] 3. Jet mill classification treatment: reduce the rotation speed of the sorting wheel to 6000rpm to 3000rpm four times, and collect tungsten powder in batches;

[0041] 4. Powder heat treatment: under the protection of high-purity hydrogen atmosphere...

Embodiment 3

[0047] 1. Raw material powder: The raw material powder is commercially available tungsten powder with a purity greater than 99.9% and a Fischer particle size of 5um;

[0048] 2. Feed preparation: Mix and disperse the tungsten powder particles obtained by the first heat treatment with the organic binder evenly, and make granular feed. The volume fraction of powder particles in the feed is 54%;

[0049] 3. Injection molding: The feed material is formed into a tungsten body of the required shape and size on the injection molding machine. The injection parameters are: injection speed is 90%, injection pressure is 100Mpa, and injection temperature is 165°C;

[0050] 4. Degreasing: Remove the binder in the tungsten body by proper process. The degreasing process is: immerse in trichlorethylene for 12 hours. The thermal degreasing process system is to raise the temperature to 300°C at 1°C / min and keep it warm for 60min. , then raise the temperature to 420°C at 2°C / min, hold for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com